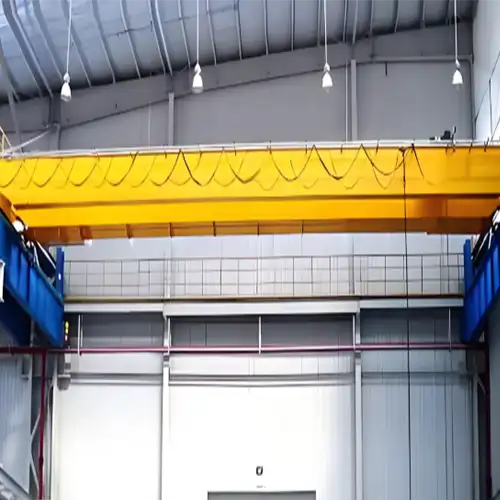

Gantry Cranes 10 Ton for Prefabricated Cable Trench Mold Handling

Double girder gantry crane 10 ton for prefabricated cable trench mold & prefabricated cable trench concrete handling. Get your custom 10 ton gantry crane.

Category: Construction

Your Trusted Gantry Crane Manufacturer & Supplier

Double Girder Gantry Cranes 10 Ton for Prefabricated Cable Trench Mold and Concrete Handling

Overview of Double Girder Gantry Cranes and Their Importance in Industrial Applications

A double girder gantry crane is a highly reliable lifting system used in various industrial sectors. It consists of two parallel girders that support a horizontal bridge, with a hoist and trolley mounted on it. This design provides exceptional stability and strength, making it ideal for handling heavy loads. Double girder gantry cranes are used in applications where high lifting capacities and precision are required, such as construction, manufacturing, and heavy-duty material handling.

The main benefits of double girder gantry cranes include:

- Higher lifting capacities compared to single girder cranes.

- Increased lifting height to accommodate larger or taller objects.

- Durability and stability, particularly in harsh or outdoor environments.

- Flexibility, allowing these cranes to be used in both indoor and outdoor settings.

In industrial operations, the ability to lift and move large, heavy components with precision is critical, and double girder gantry cranes provide the necessary power and control.

The Role of 10 Ton Gantry Cranes in Handling Heavy Prefabricated Molds and Concrete Sections

In the context of prefabricated cable trench molds and concrete sections, a 10 Ton double girder gantry crane becomes a critical asset for ensuring efficiency and safety. These prefabricated materials, often weighing several tons, need a powerful crane capable of precise lifting and transport to prevent damage and minimize safety risks.

A 10 Ton gantry crane is particularly suited for this task because:

- High capacity (10 tons): It can easily handle the heavy weight of prefabricated concrete and trench molds.

- Precision in movement: The crane’s hoisting and movement systems allow for careful positioning of these large components, crucial for ensuring their accuracy during installation.

- Safety: With built-in safety features like overload protection, the crane ensures safe operation while lifting and moving heavy materials.

Having the right lifting equipment ensures smooth, reliable operations during construction projects, especially when dealing with large, pre-built sections that must be moved into precise locations.

Significance of Cable Trench Mold and Concrete Handling in Construction and Infrastructure Projects

Handling cable trench molds and concrete sections is a critical aspect of construction, particularly in projects involving utilities, infrastructure, and foundation work. These components are foundational to the success of the project, ensuring proper cable management and structural stability for the rest of the system.

The importance of effective handling includes:

- Accurate positioning: Ensuring that molds and concrete sections are placed exactly where needed to prevent issues later in the construction process.

- Reducing project delays: Efficient handling speeds up the workflow, minimizing downtime that can occur from improper handling or transportation delays.

- Minimizing risks: Heavy lifting involves a certain level of risk, and proper crane handling helps ensure the safety of workers and the integrity of the materials being moved.

- Maintaining quality standards: By ensuring the precise movement of materials, the quality and integrity of the prefabricated components are preserved, preventing costly mistakes.

A 10 Ton double girder gantry crane provides the necessary power, safety, and precision to handle these materials effectively, ensuring that construction and infrastructure projects progress smoothly and stay on track. The crane not only improves efficiency but also enhances the overall safety and quality of the project.

Double Girder Gantry Cranes

Definition and Design Overview

A double girder gantry crane is a powerful material handling system primarily used for lifting heavy loads in industrial settings. The structure consists of two parallel girders that form the bridge, supported by vertical legs. These cranes are mounted on rails or tracks, allowing them to move along a defined path while lifting and transporting large, heavy components.

Key Components:

- Girders: Two large horizontal beams that provide the main structural support for the crane. Made of durable materials like steel, they help distribute weight and stabilize the load.

- Hoists: The hoisting mechanism, responsible for lifting and lowering objects. Hoists are typically electric but can also be manual or hydraulic depending on the application.

- Trolleys: Mounted on the girders, the trolley moves horizontally and carries the hoist to the required location along the crane's span.

- Support Legs: The vertical structures that support the crane and allow it to move along tracks or rails. These legs provide stability and ensure the crane operates securely over its working area.

How Double Girder Gantry Cranes Work

Double girder gantry cranes are designed to perform two main functions: horizontal movement (across the rails) and vertical lifting (up and down). These mechanisms work together to enable the crane to transport heavy loads with precision.

- Horizontal Movement: The crane is mounted on wheels or tracks, which allow it to travel back and forth over a large area. This feature is particularly useful for moving materials or equipment across long distances in industrial yards or warehouses.

- Vertical Lifting: The hoist moves up and down along the girders to lift or lower the load. This function is driven by a motorized winch or pulley system, which can adjust the height based on the requirements of the job.

Key Benefits:

- Stability: The double girder structure offers increased stability, making the crane ideal for lifting and moving heavy, oversized objects.

- Capacity: These cranes are built to handle higher lifting capacities, making them suitable for industrial environments where heavy-duty material handling is required.

- Lifting Height: The design allows for greater lifting heights, offering versatility in tasks that require raising and lowering large objects to considerable heights.

Together, these mechanisms allow double girder gantry cranes to handle heavy loads safely and efficiently, making them essential for various industrial operations.

Applications in Various Industries

Double girder gantry cranes are used across a broad range of industries where heavy lifting, precision, and mobility are critical. Their versatility and strength make them indispensable in sectors such as:

- Construction: In construction, these cranes are used for lifting heavy materials like steel beams, precast concrete panels, and large machinery. They are essential in building infrastructure such as bridges, tunnels, and skyscrapers, where large, heavy components need to be lifted and positioned accurately.

- Manufacturing: Within manufacturing plants, double girder gantry cranes are used to handle raw materials, parts, and finished products. Examples include moving car parts in automotive plants or lifting steel sheets in metal fabrication workshops.

- Heavy Industry: In heavy-duty industries like shipbuilding, steel production, or power generation, double girder gantry cranes are used to move heavy machinery, raw materials like steel coils, or large equipment that requires high lifting capacity and stability.

- Ports and Shipping: These cranes are commonly used in shipping yards for container handling or loading/unloading cargo from ships. Their ability to move across large areas and lift massive containers makes them vital in logistics and maritime operations.

In conclusion, double girder gantry cranes are essential tools in industries that require lifting large, heavy, and sometimes oversized materials. Their strength, flexibility, and high capacity make them indispensable for a wide range of applications, ensuring efficiency and safety in heavy lifting and material handling.

Importance of Double Girder Gantry Cranes in Prefabricated Cable Trench Mold and Concrete Handling

Challenges in Handling Cable Trench Molds and Concrete

Handling cable trench molds and concrete sections presents several challenges due to their weight, size, and the precision required for their placement. These materials are typically bulky, heavy, and have complex shapes, demanding specialized lifting equipment to move them safely and efficiently.

- Weight and Size of Prefabricated Molds and Concrete Sections:

Prefabricated cable trench molds and concrete sections can weigh several tons, making them difficult to lift with manual labor or standard equipment. Their large size and complex shapes further complicate the handling process, as precise positioning is crucial to avoid material damage or delays. Ensuring that these heavy components are moved and placed correctly is essential for the smooth progression of construction or installation. - Need for Precise, Safe, and Efficient Handling:

Improper handling can lead to significant delays, material damage, or safety hazards. With prefabricated molds, which need to be placed in specific locations to create accurate cable pathways, precision is critical. Moreover, handling large and heavy components in confined spaces or on outdoor sites increases the complexity of the task. Cranes used in these settings must be able to maneuver in tight spaces and adapt to various environmental factors, such as changing weather conditions, without compromising on safety or operational efficiency.

These challenges demonstrate the need for a reliable and robust lifting solution capable of handling heavy, delicate materials with precision. A 10-ton double girder gantry crane offers the ideal solution for safely and efficiently managing the heavy lifting and precise placement of cable trench molds and concrete sections.

Why Choose a Double Girder Gantry Crane for This Task?

A 10 Ton double girder gantry crane is an ideal solution for handling heavy cable trench molds and concrete sections. The crane's advanced features ensure that these materials are moved safely, efficiently, and with the required level of precision.

- 10 Ton Capacity: The 10 Ton lifting capacity ensures that the crane can handle the heavy weight of prefabricated concrete and trench molds. Whether it’s lifting large concrete sections or moving bulky molds, this crane’s capacity ensures that materials are lifted securely without the risk of overloading or damaging the components. The 10 Ton capacity also means that it can manage the combined weight of several heavy items, improving workflow and reducing the number of lifts required for the task.

- Efficient Load Distribution and Lifting Power: The double girder design allows for optimal load distribution across the crane’s structure, ensuring that even the heaviest loads are lifted safely. The lifting power of a double girder gantry crane is far superior to single girder models, as the two girders share the load, preventing stress or bending that could damage the crane or the materials being lifted. This robust power makes it possible to lift oversized concrete sections and molds without strain.

- Durability and Reliability in Harsh Construction Environments: Construction sites, especially those dealing with outdoor or heavy-duty materials, can be tough environments for cranes. A double girder gantry crane is designed to operate reliably in challenging conditions, such as extreme temperatures, heavy wind, or rain. Its durability and robust construction allow it to function efficiently in harsh construction environments where other cranes might struggle. This means fewer maintenance issues and more consistent performance, keeping projects on track and minimizing delays caused by equipment breakdowns.

In conclusion, double girder gantry cranes with a 10 Ton capacity are an essential tool in handling prefabricated cable trench molds and concrete sections. Their capacity, efficient load distribution, and reliability in demanding environments ensure that these heavy, oversized materials are moved safely and efficiently, enhancing the overall effectiveness and safety of construction projects.

Section 3: Key Features of 10 Ton Double Girder Gantry Cranes for Cable Trench Applications

Load Capacity and Safety Features

Handling Heavy Prefabricated Molds

The 10 Ton capacity of a double girder gantry crane is essential when lifting and moving prefabricated molds and concrete sections used in cable trench applications. These components typically range from 1 to 10 tons, requiring a crane with the lifting power to handle such weights safely and efficiently.

- Handling Heavy Molds: The crane's robust design allows it to lift large and heavy molds without strain, ensuring smooth, controlled movements. These molds, often used to form cable trenches, come in various sizes and shapes. The crane’s lifting capacity allows it to manage a wide range of weights and sizes of prefabricated molds, from smaller components (around 1-2 tons) to larger sections (up to 10 tons).

Safety Features

Safety is paramount when handling heavy materials like cable trench molds and concrete. A 10 Ton double girder gantry crane is equipped with several safety features designed to prevent accidents and ensure safe operations in challenging environments.

- Overload Protection: The crane is equipped with overload protection systems that prevent it from lifting loads exceeding its safe working capacity. This feature ensures that the crane does not become damaged and prevents accidents from occurring due to overloading.

- Emergency Stops: The crane has emergency stop buttons located in key positions to allow operators to immediately halt operations in case of a malfunction or dangerous situation. This quick response feature is critical for maintaining safety on busy construction sites.

- Limit Switches: Limit switches are installed to prevent the hoist from moving beyond its designated travel path, thereby protecting both the crane and the load from potential damage. These switches help maintain precise control during lifting and positioning tasks.

Together, these safety features ensure that the crane operates within its safe limits and provides a secure environment for workers.

Design Considerations for Cable Trench Mold Handling

When designing a 10 Ton double girder gantry crane for cable trench mold handling, several key factors are taken into account to ensure the crane can efficiently handle large molds and concrete sections in various construction settings.

Crane Height, Span, and Clearance

To effectively handle large prefabricated molds, the crane must be designed with the right height, span, and clearance to accommodate oversized materials and ensure smooth operation.

- Crane Height: The height of the crane is critical for lifting large molds and concrete sections to the necessary clearance, especially when these materials need to be placed at significant heights or stacked. A higher lifting range increases the crane's versatility, making it suitable for a wide range of lifting tasks.

- Crane Span: The span of the crane determines how far the lifting mechanism can reach horizontally. A wider span is needed to cover a larger operational area and reach multiple points along a construction site or workshop, ensuring the crane can handle molds and concrete sections at various locations.

- Clearance: Adequate clearance ensures that the crane can lift materials without obstruction from other structures or equipment. It also provides enough space to maneuver the molds and concrete sections into place without interference, particularly in tight spaces.

Special Lifting Tools and Attachments

To further enhance its ability to handle cable trench molds and concrete sections, a 10 Ton gantry crane can be equipped with specialized lifting tools and attachments:

- Spreader Beams: Spreader beams are often used when lifting large or bulky molds to help evenly distribute the load across the crane’s hoist. This prevents the load from shifting or becoming unbalanced during the lift. The spreader beam increases the crane’s lifting capability and ensures that heavy, irregularly shaped molds are lifted safely.

- Custom Slings and Hooks: Custom lifting slings or hooks may be used to securely attach to different types of molds, ensuring that materials are lifted without slipping or damage.

These design considerations ensure that the crane is optimized for lifting heavy, oversized molds and concrete sections while providing the flexibility to adapt to various lifting conditions.

Durability and Material Considerations

Steel Construction for Maximum Strength and Longevity

A 10 Ton double girder gantry crane is constructed from high-strength steel to provide superior durability, strength, and longevity. Steel is an ideal material for cranes due to its ability to withstand heavy lifting loads without deformation or failure. The robust construction ensures that the crane can endure the stresses of daily operations in demanding environments.

- Maximum Strength: Steel’s tensile strength allows the crane to handle high-capacity loads without compromising structural integrity. This is particularly important when lifting heavy concrete sections and molds, which put significant strain on the crane’s components.

Anti-Corrosion Coatings for Outdoor or Harsh Environments

Crane systems used in outdoor or harsh environments—such as construction sites, coastal areas, or regions with extreme weather conditions—must be resistant to corrosion. Anti-corrosion coatings are applied to protect the crane’s steel parts from rust and deterioration caused by moisture, chemicals, or salt.

- Durability in Harsh Conditions: The anti-corrosion coating helps extend the lifespan of the crane by preventing damage from environmental factors such as rain, snow, or exposure to seawater. This is especially crucial for cranes operating in coastal areas or places with high humidity, where rust and corrosion can quickly weaken unprotected steel structures.

- Reduced Maintenance Costs: Anti-corrosion treatments reduce the frequency of repairs and maintenance, lowering the long-term operational costs of the crane. This makes the crane more reliable and cost-effective, even in challenging working conditions.

With steel construction and protective coatings, a 10 Ton double girder gantry crane is built for maximum durability and longevity, making it a dependable solution for heavy-duty material handling in cable trench mold and concrete applications.

In conclusion, the key features of a 10 Ton double girder gantry crane, such as its load capacity, safety systems, design considerations, and material durability, make it an excellent choice for handling heavy prefabricated molds and concrete sections. These features ensure that the crane performs efficiently, safely, and reliably, even in demanding construction environments.

Case Studies and Real-World Applications

Handling Prefabricated Cable Trench Molds in Large Construction Projects

Project Overview:

In a large-scale construction project involving the development of an underground cable trench system for a new city infrastructure, a 10 Ton double girder gantry crane was employed to handle heavy prefabricated cable trench molds. The molds were designed to form the walls and base of the trench, and each section weighed between 5 to 10 tons. The project required precision and efficiency in the handling of these heavy and bulky components across a confined construction site.

Challenges Faced:

- Limited Space: The construction site was located in a densely packed urban area with limited room for crane operation, which required a crane with high maneuverability and precise movement.

- Heavy Lifting: The prefabricated cable trench molds, while robust, were large and difficult to handle manually, with significant risks involved in moving and placing them incorrectly.

- Safety Concerns: The complexity of handling heavy loads in a crowded environment posed serious safety risks to workers, especially when lifting and placing the molds in confined spaces.

Outcomes:

- Improved Efficiency: The use of the double girder gantry crane allowed for faster handling and placement of the molds. With its 10 Ton capacity and precise lifting mechanisms, the crane significantly reduced the time required to move each mold, increasing overall project efficiency.

- Enhanced Safety: The crane's advanced safety features, such as overload protection, emergency stops, and limit switches, minimized the risk of accidents. Workers were able to operate the crane remotely, maintaining a safe distance from heavy lifting operations.

- Cost-Effectiveness: By reducing the need for manual labor and minimizing the risk of damage to molds, the crane helped reduce both labor and material costs. Fewer delays and less damage translated into cost savings for the project.

Handling Prefabricated Concrete Sections in Infrastructure Development

Project Overview:

A major infrastructure project required the installation of large, prefabricated concrete sections for the construction of a highway overpass. Each concrete section weighed between 7 to 10 tons and was delivered in modular units that needed to be lifted and placed with precision. A 10 Ton double girder gantry crane was used to manage the heavy lifting and placement of these concrete sections, which needed to be stacked and aligned perfectly to meet engineering specifications.

Challenges Faced:

- Heavy Load Handling: The prefabricated concrete sections were massive, requiring the crane to have sufficient capacity to lift and move them without exceeding safety limits.

- Tight Timelines: The highway overpass was a critical part of the project, and any delays could result in a cascade of delays for other parts of the construction.

- Logistical Coordination: The coordination of lifting and placing the concrete sections across multiple locations added to the complexity of the project, demanding precise timing and handling.

Outcomes:

- Positive Impact on Project Timelines: The crane’s high lifting capacity and ability to handle multiple sections quickly ensured that the overpass was completed on time. The ability to lift multiple concrete sections at once also helped streamline operations and save valuable project time.

- Improved Material Handling: The crane’s precise control allowed for efficient handling of large, heavy concrete sections. It ensured that the components were placed exactly where needed, reducing rework and the risk of costly mistakes.

- Enhanced Safety and Worker Productivity: By automating the lifting and placement of heavy concrete sections, workers were kept at a safe distance from the lifting zones. This improved the overall safety of the operation, reducing workplace injuries and enhancing worker productivity.

Both of these case studies highlight the significant benefits of using a 10 Ton double girder gantry crane in large-scale construction and infrastructure projects. The crane’s combination of heavy lifting capacity, precision control, and advanced safety features not only improves project timelines but also enhances safety, reduces costs, and optimizes material handling. These real-world applications demonstrate the crane’s effectiveness in tackling complex, demanding tasks, making it an invaluable asset for any large construction or infrastructure development project.

Conclusion

Recap of the Benefits of Using a 10 Ton Double Girder Gantry Crane for Prefabricated Cable Trench Mold and Concrete Handling

The 10 Ton double girder gantry crane proves to be an invaluable tool in the handling of heavy prefabricated cable trench molds and concrete sections. Its key benefits include:

- High Lifting Capacity: With the ability to safely handle loads of up to 10 tons, it is perfectly suited for moving large, heavy molds and concrete sections, minimizing the need for manual labor and enhancing overall project efficiency.

- Precision and Control: The crane's ability to operate with precise control, especially when maneuvering heavy and bulky materials, ensures that molds and concrete sections are placed exactly where they are needed without risk of damage.

- Enhanced Safety: Equipped with advanced safety features like overload protection, emergency stops, and limit switches, the crane reduces the risk of accidents, ensuring that workers are protected during operation.

- Durability: Built for tough construction environments, the crane's steel construction and anti-corrosion coatings ensure it remains functional in outdoor or harsh working conditions, providing long-term reliability.

These benefits make the 10 Ton double girder gantry crane an essential piece of equipment for handling prefabricated molds and concrete, improving the overall workflow and safety on construction sites.

Final Thoughts on How Choosing the Right Crane Enhances Project Efficiency and Safety

Selecting the right crane, such as a 10 Ton double girder gantry crane, is crucial for the successful execution of complex construction and infrastructure projects. The right crane not only ensures the safe handling of heavy materials but also optimizes project timelines, reduces labor costs, and improves overall worksite safety. By providing reliable, precise, and efficient lifting capabilities, it enhances the overall workflow, preventing delays and ensuring that materials are handled securely and with minimal risk.

As construction projects grow in scale and complexity, the demand for advanced, safe, and efficient lifting solutions will continue to rise. By choosing the right crane, companies can ensure the smooth execution of projects, ultimately leading to better results, higher productivity, and a safer working environment.

In conclusion, a 10 Ton double girder gantry crane is not just a piece of equipment—it's a critical investment in the future success and safety of construction and infrastructure projects.

FAQs

Q1: What is the maximum weight a 10 Ton gantry crane can handle?

A 10 Ton gantry crane is designed to lift a maximum load of 10 tons (10,000 kg). This weight limit refers to the total load that can be safely lifted by the crane, including the weight of the mold or concrete section and any lifting equipment attached to it.

Q2: Can a double girder gantry crane be used outdoors for heavy concrete lifting?

Yes, a double girder gantry crane is well-suited for outdoor use, especially in construction environments. These cranes are designed to handle heavy lifting tasks in various weather conditions, making them ideal for lifting heavy concrete sections. The crane's steel construction and anti-corrosion coatings ensure durability even in harsh, outdoor environments.

Q3: What are the key safety measures when operating a double girder gantry crane for handling molds?

When operating a double girder gantry crane for handling heavy molds, several safety measures should be followed:

- Overload Protection: Ensures the crane doesn't exceed its lifting capacity.

- Emergency Stops: Allows for immediate halting of crane operations in case of emergency.

- Limit Switches: Prevents the crane from moving beyond its designated path.

- Regular Inspections: Ensures that all safety components, like hooks, slings, and hoists, are functioning properly.

Additionally, operators should be properly trained and should always use personal protective equipment (PPE) while working.

Q4: How often should a 10 Ton gantry crane be maintained?

A 10 Ton gantry crane should undergo regular maintenance checks to ensure optimal performance and safety. Typically, daily checks on operational functions (e.g., hoist, trolley, and controls) should be performed before use. A more thorough inspection, including lubrication, structural checks, and safety feature tests, should be conducted annually or as specified by the manufacturer. Regular maintenance helps prevent breakdowns, prolongs crane lifespan, and ensures safe operations.

Q5: Are there any alternative cranes for handling prefabricated cable trench molds?

Yes, while the double girder gantry crane is a popular choice, alternative cranes can also be used depending on the project requirements:

- Single Girder Gantry Crane: Suitable for lighter loads and smaller project spaces.

- Bridge Cranes: Can be effective for indoor mold handling and if the space allows for overhead travel.

- Jib Cranes: Ideal for more localized lifting tasks in confined spaces. Each crane type has its specific advantages, but for heavy-duty mold handling, a double girder gantry crane remains the most reliable choice.

10 Ton Gantry Crane Options

When selecting a gantry crane for your project, understanding the various 10 Ton gantry crane options available is essential for choosing the most suitable one for your specific needs. Below are three popular types of 10 Ton gantry cranes, each with unique advantages depending on the application:

Overview:

A single girder gantry crane is a more lightweight and cost-effective option compared to a double girder gantry crane. It uses a single beam (girder) to support the load and is commonly used for lighter loads or in smaller spaces.

Key Features:

- Lifting Capacity: Typically up to 10 tons, depending on the specific design.

- Design: One girder and hoisting system, making it simpler and more affordable than double girder cranes.

- Applications: Ideal for light-to-medium duty tasks, such as handling smaller prefabricated molds, concrete sections, or warehouse operations.

Advantages:

- Cost-Effective: More affordable than double girder cranes.

- Compact Design: Suitable for smaller areas with limited headroom.

- Ease of Installation: Faster and less complex to install compared to double girder cranes.

Limitations:

- Lower Lifting Height: The design often results in limited lifting height compared to double girder options.

- Less Stability: Not as stable as double girder gantries for handling larger, heavier loads or in windy conditions.

Rubber-Tyred Gantry Crane (RTG)

A rubber-tyred gantry crane (RTG) is a mobile crane that features rubber tyres instead of fixed rails, allowing it to move freely on concrete surfaces. RTGs are highly suitable for outdoor use in ports, container yards, or sites with large open spaces.

Key Features:

- Lifting Capacity: 10 Ton capacity is typical, but can vary depending on the crane model.

- Mobility: The RTG can travel freely within the designated area, making it ideal for large yards or warehouses where flexibility is required.

- Design: It features a wheeled design, allowing for movement along pre-designated paths without the need for fixed rails.

- Applications: Commonly used in container yards, large construction projects, and places where multiple lifting and transportation tasks need to be handled in an open area.

Advantages:

- High Mobility: The ability to move to different locations within a site without rail installations.

- Flexible for Large Sites: Works well in large, open areas where a fixed crane might be impractical.

- Easily Maneuverable: Excellent for handling a variety of loads over long distances on flat surfaces.

Limitations:

- Limited to Flat Terrain: Rubber-tyred cranes are best used on smooth, flat surfaces. They can struggle in uneven or rough terrain.

- Higher Maintenance Costs: More moving parts mean potentially higher maintenance requirements over time.

U-Frame Rail-Mounted Gantry Crane (RMG)

Overview:

The U-frame rail-mounted gantry crane is a stationary, high-capacity crane that moves along fixed rails. The "U-frame" refers to the crane's unique structure that provides enhanced stability and can support large, heavy loads like prefabricated molds and concrete sections.

Key Features:

- Lifting Capacity: 10 Ton capacity or more, depending on design specifications.

- Design: The U-frame structure provides excellent stability for lifting heavy or bulky loads. It is rail-mounted and typically used in large construction yards or factories.

- Applications: This crane is ideal for outdoor handling of heavy materials, including large prefabricated concrete sections, molds, and other bulky equipment.

Advantages:

- Stability and Safety: The U-frame design ensures superior stability, especially when lifting heavy loads.

- Efficiency in Large Sites: Great for use in industrial settings with large space requirements where the crane can move along fixed tracks.

- Increased Lifting Height and Capacity: Due to its design, it can handle higher lifting heights and larger load capacities compared to some mobile cranes.

Limitations:

- Limited Mobility: Unlike the rubber-tyred gantry crane, it is confined to rail tracks, reducing its mobility in large, dynamic spaces.

- Higher Initial Cost: The installation of fixed tracks can add to the initial investment costs compared to more mobile crane options.

Choosing the Right 10 Ton Gantry Crane for Your Application

Selecting the ideal 10 Ton gantry crane depends on several factors, including the work environment, the nature of the load being handled, space constraints, and budget. Here’s a quick guide to help you decide:

- For Smaller, Indoor Applications: The single girder gantry crane may be the best option if you're operating in a confined space or need a cost-effective solution for light-to-medium lifting tasks.

- For Large Outdoor Spaces: The rubber-tyred gantry crane (RTG) is ideal if you need high mobility across a large, flat surface with flexible maneuvering.

- For Heavy Duty, Rail-Mounted Operations: The U-frame rail-mounted gantry crane (RMG) is perfect for sites with fixed tracks and requires high lifting capacities and stability.

Each type of crane offers unique advantages depending on the specific needs of your project, making it important to consider the work environment and material handling requirements before making a decision.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch