Rubber-Tyred Gantry Cranes (RTG) for Efficient Container Handling

Flexible and mobile, RTG cranes offer exceptional performance, streamlining container stacking and transferring in busy terminals and ports.

Category: Container Crane

Your Trusted Container Crane Manufacturer & Supplier

Rubber-Tyred Wheels Gantry Cranes for Container Handling

Overview of Rubber-Tyred Gantry Cranes (RTGs)

A Rubber-Tyred Gantry Crane (RTG) is a type of mobile container crane designed specifically for handling and stacking containers in areas such as port terminals, container yards, and logistics hubs. Unlike traditional cranes that are mounted on fixed tracks, RTGs run on rubber tyres, which gives them the ability to move freely across the ground. This mobility makes them ideal for container handling where space is limited, and flexible movement is required.

The main purpose of an RTG is to efficiently lift, move, and stack containers in areas with high container traffic. These cranes can handle containers of various sizes (like 20-foot, 40-foot, and 45-foot containers) and have adjustable lifting heights to fit the needs of the terminal or yard. RTGs are used for unloading containers from ships, moving them to storage, stacking them, and then later loading them onto trucks or trains for further transport.

RTGs play an important role in optimizing container flow, reducing the need for manual labor, and improving the speed and safety of container handling. They are flexible, efficient, and cost-effective, making them indispensable in modern container terminals and yards.

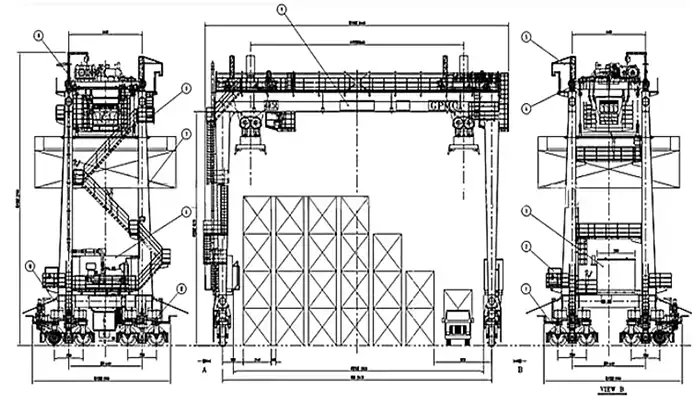

Rubber typed gantry crane for container handling

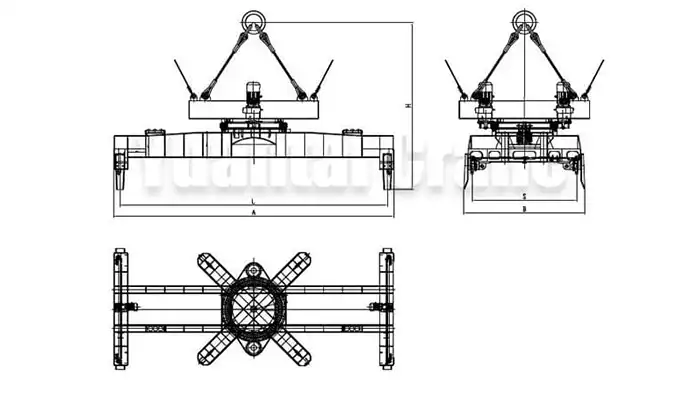

Drawing of RTG container cranes

Importance in Container Handling at Ports, Yards, and Logistics Hubs

In ports, container yards, and logistics hubs, RTGs are crucial to the smooth flow of containerized goods. These cranes are an integral part of the loading, unloading, and stacking process, helping terminals move large volumes of containers with minimal delay. Here's why they are so important:

- Efficient Container Handling: RTGs improve the efficiency of container movements within a terminal. They can quickly load and unload containers from ships, move them to storage areas, and stack them in an organized manner. This reduces bottlenecks and helps maintain a steady flow of containers in busy terminals.

- Space Optimization: One of the biggest challenges in container yards is maximizing storage space. RTGs can stack containers in multiple layers, often up to 4-5 layers high, which helps optimize limited yard space and makes better use of the available area. This is crucial in busy ports with limited room for expansion.

- Handling Different Container Sizes: RTGs are versatile, capable of handling containers of varying sizes, such as 20', 40', and 45' containers. This flexibility allows terminals to cater to different types of cargo and container requirements without needing multiple types of cranes.

- Seamless Integration in Terminal Operations: RTGs provide reliable and flexible handling of containers at key points in the supply chain. They can move containers between ships, trucks, trains, and storage areas, helping maintain a continuous workflow and reducing turnaround times.

The Role of RTGs in Modern Port Operations

Efficiency in Container Loading, Unloading, and Stacking

In modern ports and logistics hubs, efficiency is key to maintaining high productivity and meeting the increasing demands of global trade. RTGs enhance the speed and precision of container handling, which is crucial for several reasons:

- Fast Hoisting and Movement: RTGs are equipped with powerful hoisting systems that can lift containers quickly. For example, depending on the model, the hoisting speed can reach up to 50 meters per minute (for empty containers). This ensures that containers are moved swiftly, reducing the time spent on loading and unloading operations.

- Precise Stacking and Organization: The high lifting capacity and advanced control systems allow RTGs to stack containers in a precise and organized manner. Containers can be stacked up to 5 layers high, helping to make efficient use of vertical space and enabling the terminal to store more containers in less space.

- Optimized Container Handling Process: The speed of RTGs, combined with their ability to precisely position containers, ensures that operations run smoothly. This reduces waiting times for trucks and ships, leading to faster turnover and improved port productivity.

By speeding up the loading, unloading, and stacking processes, RTGs help terminals meet tight deadlines and increase their throughput, which is essential for maintaining efficient operations in busy ports.

Flexibility in Terminal Operations Due to Mobility

One of the main advantages of RTGs over traditional rail-mounted cranes is their mobility. RTGs are not tied to a fixed track system, meaning they can move freely within the terminal or yard. This gives them a level of flexibility that is crucial in dynamic, high-volume environments.

- Adaptability to Terminal Layouts: RTGs can move across the yard to handle containers wherever they are needed, making them highly adaptable to changing terminal layouts. This flexibility allows them to serve multiple roles, such as loading and unloading containers from ships, moving containers between different transport modes, or stacking containers for storage.

- Turning and Maneuvering in Tight Spaces: RTGs are equipped with the ability to turn 90 degrees, move laterally, and travel straight ahead. This allows them to navigate narrow aisles and work efficiently in tight spaces, which is often the case in container yards with limited room for large equipment.

- Movement on Uneven Ground: Unlike fixed cranes that require a perfectly smooth and level foundation, RTGs are designed to work on uneven or rough ground, which is common in busy port environments. The use of rubber tyres provides better maneuverability and ensures smooth operation even in challenging conditions.

- Mobility Across Different Areas: Because RTGs can move across the entire terminal or yard, they offer a level of flexibility that enables efficient operations at all stages of container handling. They can move containers from one area to another, helping optimize the flow of goods and reducing delays.

- Operational Flexibility: RTGs are available in various operation modes, including manual, semi-automatic, and fully automated systems. This versatility allows operators to adjust the crane's level of automation depending on the needs of the terminal, offering both human control and automation for a balanced approach.

In busy and evolving port environments, RTGs provide the flexibility needed to handle unpredictable conditions and shifting workloads. Their ability to move quickly and adapt to different operational needs is one of the reasons they have become a central component of modern port infrastructure.

Specifications of Rubber-Tired Gantry (RTG) Crane

The specifications of an RTG crane may vary depending on the manufacturer and the customer's requirements. However, some common parameters are:

- Lifting capacity: how much weight the crane can lift under the spreader. It usually ranges from 30 to 65 tons.

- Span length: how wide the crane can span over the container rows. It usually ranges from 22 to 28 meters.

- Hoisting height: how high the crane can lift the containers. It usually ranges from 1 over 3 to 1 over 6 containers high.

- Lifting speed: how fast the crane can lift or lower the containers. It usually ranges from 12 to 46 meters per minute.

- Crane speed: how fast the crane can move along the yard. It usually ranges from 45 to 90 meters per minute.

- Operating temperature: what range of temperature the crane can work in. It usually ranges from -20°C to 40°C.

Main Technical Parameters of Rubber Tyred Gantry Crane for Container Handling | ||||

| 35 | 41 | 70 | |

Base Distance (m) | 7 | 7 | 7.5 | |

| 23.47/26 | 23.47/26 | 23.47/26 | |

| 15.5/18.5 | 15.5/18.5 | 15.5/18.5 | |

| 4/5 | 4/5 | 4/5 | |

| 20', 40' ,45' | 20', 40', 45' | 20', 40' ,45' | |

|

| 20/40 | 25/50 | 25/50 |

| 30/130 | 30/130 | 30/130 | |

| 70 | 70 | 70 | |

| 8 | 8/16 | 16 | |

| 300 | 320/180 | 200 | |

|

| |||

Technical Specifications of Rubber-Tyred Gantry Cranes (RTGs)

Lifting Speed

The lifting speed of RTGs is a critical factor in determining the overall efficiency of container handling operations. RTGs are designed to handle both full load and empty load conditions, with speeds tailored to maximize productivity while ensuring safety.

- For full load lifting, RTGs typically operate at speeds of 20 meters per minute (m/min), enabling them to lift heavy containers steadily and safely.

- When lifting empty containers, the cranes can operate at higher speeds, such as 40 m/min, which helps reduce cycle times and improve throughput in less demanding lifting conditions.

- Some models feature even higher lifting speeds, such as 25 m/min for full loads and 50 m/min for empty loads, making them suitable for high-throughput operations where fast container handling is essential.

These speeds are adjustable, ensuring that operators can adapt the crane's operation to specific container types and terminal needs, while also minimizing the risk of container damage due to excessive speed or sudden movements.

Gantry and Trolley Traveling Speeds

The gantry travel speed and trolley travel speed determine how quickly RTGs can reposition themselves within the terminal, influencing overall productivity.

- The gantry traveling speed is typically around 30 m/min for full load conditions, allowing the crane to move containers from one stacking position to another quickly and efficiently. When operating with an empty load, the speed increases, often reaching up to 130 m/min. This allows the crane to reposition itself across large terminal areas in a short time, improving operational flexibility.

- The trolley travel speed is generally 70 m/min, which provides the necessary speed to position the spreader correctly over the container for loading or unloading. This speed allows for efficient movements within the gantry structure, enabling the crane to swiftly align the spreader to containers, thereby reducing handling time.

These travel speeds are optimized to provide the right balance between efficiency and safety, ensuring that the RTG can handle containers quickly while maintaining precise control over their movement.

Wheel Configuration and Load Capacity

The wheel configuration and load capacity are crucial for determining the stability, performance, and operational efficiency of the RTG under different working conditions. The number of wheels and their distribution are designed to ensure optimal weight distribution and maneuverability.

Wheel Number and Distribution: Depending on the model, RTGs can be equipped with 8 to 16 wheels, ensuring proper weight distribution across the crane. The configuration allows for efficient movement and stability, particularly in high-load applications. Cranes with more wheels (e.g., 16 wheels) are generally designed for heavier-duty applications, providing greater stability when handling larger containers or operating in less stable environments.

Maximum Wheel Load: The maximum wheel load varies based on the model and the weight-bearing capabilities of the wheels. Typical maximum loads for RTGs include:

- 300 kN per wheel (for lighter-duty models),

- 320 kN per wheel (for mid-range models),

- 180 kN per wheel (for smaller models).

These load capacities ensure that the crane can handle heavy containers with stability, preventing any undue stress on the wheels, which could affect the crane's performance or lead to damage.

Power Supply Options

RTGs can be powered through different energy sources, allowing them to be adapted to a variety of operational environments. The choice of power supply can impact both operational costs and environmental sustainability.

- Diesel Engine: Many RTGs are powered by diesel engines, which provide robust, reliable power in environments without access to city electricity or where mobility is crucial. Diesel-powered RTGs are particularly useful in remote locations or terminals with limited power infrastructure, ensuring continued operations even in challenging conditions.

- Electric Power (AC380V 50Hz): For environmentally-conscious operations or facilities connected to the grid, RTGs can be powered using three-phase AC electricity (380V, 50Hz). This energy source offers a cleaner, more cost-effective solution compared to diesel, reducing emissions and operational costs. Electric-powered RTGs are well-suited for high-throughput terminals with established power infrastructure.

Some models also offer a hybrid power system, combining both diesel and electric power sources, allowing terminals to benefit from both the flexibility of diesel engines and the environmental benefits of electric systems.

The technical specifications of Rubber-Tyred Gantry Cranes (RTGs) ensure that these cranes are well-suited to meet the demands of modern container handling. With high lifting speeds, variable gantry and trolley travel speeds, and optimized wheel configurations, RTGs are designed for efficiency, stability, and flexibility. Their power supply options further allow terminal operators to choose between diesel and electric systems based on their operational needs, optimizing both cost-efficiency and environmental sustainability. These features make RTGs essential for improving throughput and productivity in container terminals and logistics hubs worldwide.

Key Features of Rubber-Tyred Gantry Cranes (RTGs)

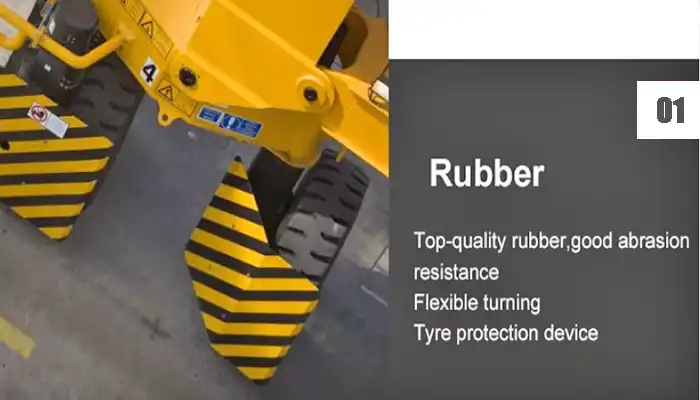

rubber tyred container crane travelling wheels

open winch trolley customized for meet various industrial use

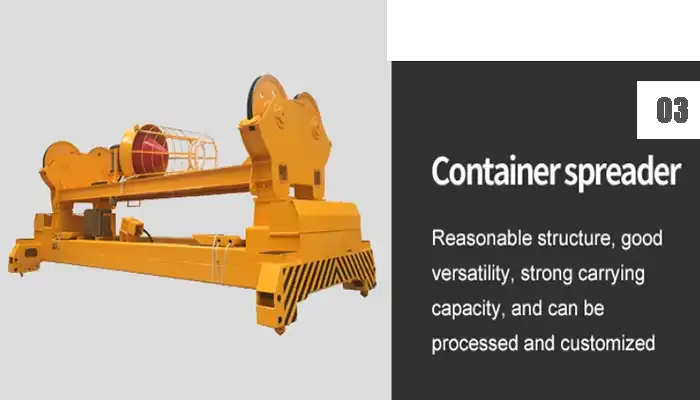

container spreader , various types are available for your selection

Crane cabin for rubber tyred container gantry crane operation

Mobility and Flexibility

One of the standout features of Rubber-Tyred Gantry Cranes (RTGs) is their mobility, which provides the flexibility needed to handle containers in dynamic, high-traffic environments such as ports and container yards. Unlike fixed-track cranes, RTGs are powered by various sources, including diesel engines, city electricity, or lithium batteries, offering flexibility depending on the operational needs of the terminal.

- Diesel engines provide a robust power source for RTGs that operate in areas without direct access to grid power, making them a great choice for port terminals with high mobility demands and where frequent repositioning of containers is required.

- City electricity is ideal for more stationary or environmentally-conscious operations, as it provides a consistent and clean energy source, reducing emissions and offering lower operational costs.

- Lithium battery power is increasingly popular due to its eco-friendly and cost-efficient nature. It offers the advantage of quieter operations and lower maintenance requirements, while also being compatible with the latest technological advancements in automation.

The pneumatic rubber tyres that RTGs use allow them to move independently on the yard or terminal surface. This ability to travel freely across the ground gives RTGs the versatility to handle containers at different locations within the terminal without being limited to a fixed track system. The tyres also provide a smooth ride, allowing for better maneuverability even on slightly uneven surfaces. This feature makes them ideal for locations with frequent shifts in layout or for areas where space constraints require adaptability.

High Lifting Capacity

RTGs are designed to handle heavy-duty container handling tasks with their impressive lifting capacities. Depending on the model, they can handle lifting capacities ranging from 35 tons to 70 tons. This wide range allows RTGs to manage both lighter loads and heavy containers with ease.

- The 35-ton models are ideal for smaller container operations or for handling lighter cargo in regions with lower throughput demands.

- The 41-ton models are well-suited for standard container handling in mid-sized ports or yards.

- The 70-ton models are designed to handle larger, heavier containers, often required for big port terminals or operations that need to manage heavy industrial goods.

Their ability to lift and move heavy containers makes RTGs particularly valuable for ports handling large volumes of goods or those that manage containers with high-density cargo, such as refrigerated or over-sized containers. The high lifting capacity ensures that RTGs can handle containers of different sizes, from 20-foot to 45-foot containers, with ease and precision.

Stacking Capabilities

One of the most important features of RTGs is their ability to maximize yard space through efficient stacking technology. RTGs are capable of stacking containers up to 4-5 layers high, enabling terminals to make the most out of their limited space.

- Stacking containers in multiple layers is especially useful in busy terminals where space is at a premium. This feature allows RTGs to store containers compactly and organize them efficiently, which improves the overall container flow within the yard.

- The advanced control systems in RTGs ensure that containers are stacked accurately and safely, minimizing the risk of container damage during stacking or retrieval. Additionally, modern RTGs are equipped with anti-sway and anti-swing systems, ensuring that containers remain stable during movement and placement.

Efficient stacking also helps reduce container retrieval times, as the RTGs can place containers in a manner that allows quick access to the most frequently moved containers. By improving stacking efficiency, RTGs enable terminals to optimize storage capacity and improve the turnaround time for container handling.

The key features of Rubber-Tyred Gantry Cranes (RTGs), such as their mobility, high lifting capacity, adjustable span and lifting heights, and stacking capabilities, make them indispensable for modern container handling. Their flexibility and adaptability allow them to meet the ever-changing needs of busy terminals, ports, and logistics hubs. Whether it's high-capacity lifting or efficient use of space, RTGs are designed to improve operational productivity, increase storage capacity, and enhance the overall efficiency of container handling processes.

Container Spreaders for RMG and RTG Cranes

Rotary Container Spreader

rotary container spreader for rtg gantry crane for your selection

drawing of rotatry container speader

| Rotary Container Spreader Specifications | 20' Container | 40' Container | |

| Lifting capacity | 32 ton | 40.5 ton | |

| Rotation speed | 0-1.5 r/min | 0-1.5 r/min | |

| Power supply | AC 380/3/50 | AC 380/3/50 | |

| Size(mm) | L | 5853 | 11985 |

| S | 2260 | 2260 | |

| A | 6056 | 12188 | |

| B | 2436 | 2436 | |

| H | 3620 | 3887 | |

Telescopic Rotary Container Spreader

Telescopic container spreader

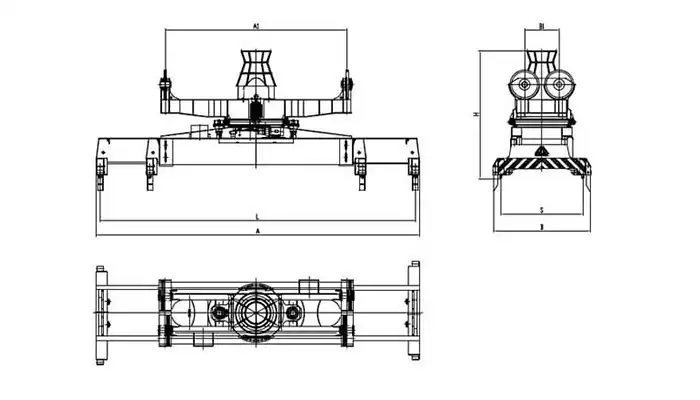

drawing of telescopic container spreader

| Telescoping Rotary ContainerSpreader | 20' 40' 45' Container | |

| Lifting capacity | 40.5 ton (under spreader) | |

| Rotation speed | 0-1.5 r/min | |

| Rotation time | 1.5S | |

| Telescopic action time | 40S | |

| Hydraulic system | 10MPa | |

| Power supply | AC 380/3/50 | |

| Self-weight | 12 ton | |

| Size(mm) | L | 5853-11985-13510 |

| S | 2260 | |

| A | 6053-12185-13710 | |

| B | 2436 | |

| A1 | 5000 | |

| B1 | 1200 | |

| H | 3620 | |

Advantages of Rubber-Tyred Gantry Cranes (RTGs)

Energy Efficiency

One of the primary benefits of Rubber-Tyred Gantry Cranes (RTGs) is their energy efficiency, which helps reduce operational costs while also being environmentally friendly.

- Multiple Power Supply Options: RTGs offer a range of power supply options, including diesel engines, city power, and lithium batteries, providing flexibility depending on the operational environment. Diesel engines are ideal for remote areas without electricity, while electric-powered systems offer a cleaner and more cost-effective solution for terminals with grid access. Lithium battery-powered RTGs provide additional environmental benefits, reducing emissions and fuel consumption.

- Energy-Saving Features: Modern RTGs are equipped with electric energy feedback systems, which allow energy generated during certain operations (like lowering the load) to be returned to the power grid or stored for later use. This regenerative braking system helps lower energy consumption and improve overall efficiency. By recapturing energy that would otherwise be wasted, RTGs reduce their overall energy costs and contribute to a greener operation.

The combination of these energy-efficient features ensures that RTGs are not only cost-effective but also play a role in reducing the environmental impact of container handling.

Stability and Precision

The stability and precision of RTGs are key factors in ensuring safe and efficient container handling, especially in busy terminal environments.

- Anti-Sway Technologies: One of the significant challenges in container handling is preventing the sway of the load as it is being moved. RTGs are equipped with anti-sway systems that reduce the swinging of containers, resulting in smoother and safer operations. These systems use sensors and advanced control algorithms to detect and counteract unwanted movements of the crane's load, preventing damage to the container and ensuring that the crane operates safely.

- Advanced Control Systems: RTGs feature advanced control systems with real-time monitoring, allowing operators to keep track of the crane's position, speed, and load at all times. These systems improve operational precision and safety by providing operators with instant feedback on the crane's performance, enabling them to make adjustments as needed. The use of PLC (Programmable Logic Controllers) and variable frequency drives (VFDs) allows for more precise control of the crane's movements, ensuring that containers are handled with accuracy and reducing the potential for human error.

These features make RTGs highly reliable and capable of maintaining high operational standards even in challenging conditions, ensuring safety, efficiency, and precision throughout the lifting and moving process.

Cost-Effectiveness

RTGs offer a strong return on investment (ROI) by keeping operational costs low and providing high productivity with minimal overhead.

- Low Operational and Maintenance Costs: The combination of energy-efficient systems, advanced technologies, and robust design makes RTGs cost-effective to operate and maintain. Their modular design allows for easier maintenance, reducing downtime and increasing the crane's lifespan. Regular maintenance is simplified with diagnostic systems that alert operators to potential issues before they become critical. This helps extend the life of the crane, ensuring a good return on investment over time.

- Flexibility in Container Handling: RTGs are highly flexible and adaptable, able to handle various container types, such as standard and high-cube containers, with ease. They can be easily adjusted for different container sizes, stacking heights, and operational configurations, without the need for major infrastructure changes. This flexibility makes them ideal for growing ports and logistics hubs, where container handling needs can change frequently.

- Reduced Need for Infrastructure: Unlike fixed cranes or those requiring rail systems, RTGs move on pneumatic rubber tyres and do not require complex infrastructure like fixed tracks or railways. This reduced need for infrastructure not only lowers initial investment costs but also minimizes maintenance and operational disruptions, making RTGs a cost-effective solution for ports with limited space or flexible operational needs.

The advantages of Rubber-Tyred Gantry Cranes (RTGs) are numerous and significant, particularly in terms of energy efficiency, stability, and cost-effectiveness. The ability to choose from multiple power supply options and integrate energy-saving technologies helps RTGs operate with lower energy costs and a smaller environmental footprint. Their anti-sway systems and advanced control mechanisms ensure stable, precise handling of containers, making operations safer and more efficient. Furthermore, RTGs offer excellent cost savings due to low operational and maintenance costs, as well as their flexibility in handling various container types and configurations without the need for significant infrastructure investments. These advantages make RTGs an essential tool for improving productivity, safety, and cost-efficiency in container handling at ports and logistics hubs.

Key Technologies in RTG Cranes

Anti-Swing Systems

The movement of containers during lifting and lowering is one of the primary challenges in crane operations. To ensure smooth, stable, and safe handling, RTG cranes are equipped with advanced anti-swing systems designed to minimize load sway and prevent accidents.

- Standard Two-Way Flexible Resistance Anti-Swing: The standard anti-swing system uses a two-way flexible resistance mechanism to reduce swinging movements during container handling. This system is designed to respond to and counteract unwanted motion, ensuring that the crane can handle loads efficiently without the risk of containers colliding or tipping. The result is smoother, safer, and more controlled crane movements, reducing the likelihood of accidents and improving overall operational stability.

- Optional Multi-Function Frequency Control and Electronic Anti-Swing Systems: For more demanding operational environments, RTGs can be equipped with multi-function frequency control systems that adjust the crane's movements in real-time. This advanced system uses electronic sensors and control algorithms to calculate the ideal response for preventing sway, based on the load's weight and position. These systems can be further enhanced with electronic anti-swing technology, which fine-tunes the crane's response, minimizing any residual sway for high-precision handling. With these upgrades, the crane operates with greater stability, reducing load damage and improving the safety and efficiency of terminal operations.

Intelligent Control Systems

RTGs are equipped with cutting-edge intelligent control systems that allow for real-time monitoring, precise adjustments, and automated safety checks, significantly improving the efficiency, reliability, and safety of crane operations.

- CMS (Condition Monitoring System): The Condition Monitoring System (CMS) is an integral part of modern RTGs, providing operators with real-time data on the crane's health and performance. CMS monitors critical components such as motors, hydraulics, and electrical systems, offering insights into potential issues before they become serious problems. This proactive monitoring helps ensure maximum uptime and reduces the risk of unplanned downtime, which can disrupt port operations. The system also provides predictive maintenance recommendations, allowing operators to schedule maintenance only when necessary, thus reducing costs and avoiding unnecessary service calls.

- Automatic Fault Detection and Data Display: Advanced fault detection systems are embedded within the RTG's control infrastructure, allowing for immediate identification of any issues during operation. These systems continuously assess the crane's performance and automatically display real-time data, alerting operators to any irregularities, such as overloading, electrical faults, or mechanical malfunctions. This technology ensures safer operations by preventing accidents caused by undetected faults, enhancing the overall safety of the crane and the terminal.

Load and Movement Control

Efficient and precise control over the crane's movements is essential for high-performance container handling. RTGs are equipped with advanced load and movement control technologies to enhance the accuracy and efficiency of operations.

- Vector Frequency Control: Vector frequency control technology is used to optimize the crane's lifting, traveling, and hoisting operations. By adjusting the crane's motor speed and torque in real-time, vector frequency control ensures that the crane's movements are both smooth and efficient, particularly during high-load handling. This system also improves energy efficiency, as it allows for the crane to adjust its power usage based on the operational demands of each task. It ensures that the crane operates at peak performance, even under challenging conditions, resulting in improved cycle times and reduced energy consumption.

- Smart Systems for Precise Positioning and Container Landing: RTGs use smart control systems that enable precise positioning and container landing. These systems utilize sensors and advanced algorithms to calculate the exact position of the crane, ensuring that containers are safely and accurately placed on stacking frames. The crane's movements are automatically adjusted based on the container's size, weight, and stacking location, ensuring that containers are landed precisely where they need to go. These technologies not only improve the speed of operations but also reduce the risk of container damage due to inaccurate placement.

Safety Features

Safety is a top priority in container handling operations, and RTG cranes come equipped with a wide range of safety technologies to protect both operators and equipment.

- Wind Alarms: RTGs are often used in open yard areas, where weather conditions, such as high winds, can impact operations. To mitigate the risks of operating under unsafe conditions, RTGs are equipped with wind alarms that automatically detect when wind speeds exceed safe operating thresholds. These alarms provide audible and visual warnings to operators, who can then take necessary actions, such as halting operations or securing the load, to prevent accidents.

- Safety Dynamic Scanning: RTGs are equipped with dynamic scanning technology that continuously monitors the environment around the crane during operation. This system scans for obstacles or people in the crane's path, alerting the operator if a potential collision is detected. The dynamic scanning system helps prevent accidents by ensuring that the crane only moves when the area is clear, protecting both personnel and equipment from accidental impacts.

- Intelligent Safety Protection: In addition to wind alarms and dynamic scanning, RTGs also feature intelligent safety protection systems that adjust crane behavior to prevent accidents. These systems include features like overload protection, which ensures that the crane does not exceed its weight limits, and emergency stop functions that can instantly halt operations if a critical fault or safety risk is detected. Intelligent safety systems monitor the crane's status and operational environment in real time, ensuring that the crane operates within safe parameters and reducing the risk of injury to personnel.

The advanced technologies integrated into Rubber-Tyred Gantry Cranes (RTGs) significantly enhance their performance, safety, and reliability in container handling operations. Anti-sway systems ensure smooth, stable lifting, while intelligent control systems like CMS provide real-time data and fault detection to maintain high operational standards. With vector frequency control and smart positioning systems, RTGs can handle containers with precision and efficiency. Furthermore, safety features such as wind alarms, dynamic scanning, and intelligent safety protection ensure that RTGs operate in a safe environment, protecting both operators and equipment. These advanced technologies make RTGs a critical asset for modern container terminals, enhancing operational efficiency and safety.

Applications of Rubber-Tyred Gantry Cranes

Rubber-Tyred Gantry (RTG) cranes are essential pieces of equipment in various logistics and transport operations, particularly in environments where container handling, storage, and transfer are key to efficient operations. Their mobility, versatility, and high lifting capacities make them ideal for applications in port terminals, container yards, logistics centers, and transfer stations. Here's a closer look at how RTGs are utilized in these critical environments.

Port Terminals

Port terminals are busy hubs where goods are transported across international borders, and the ability to quickly and efficiently load, unload, and store containers is essential to the overall performance of the port. RTG cranes play a central role in maintaining the efficiency and speed of these operations.

- Loading and Unloading Containers from Ships: One of the primary uses of RTGs in port terminals is the loading and unloading of containers from ships. RTGs operate in the container yard, working in conjunction with ship-to-shore cranes to transfer containers from ships to the yard and vice versa. Their ability to handle heavy loads and their adjustable lifting heights make them ideal for reaching containers on large vessels. The mobility of RTGs also allows them to work at different locations along the quay, providing flexibility in managing multiple ships at once.

- Stacking Containers in Busy Terminal Yards: Once containers have been unloaded, RTGs are used to stack containers in the terminal yard. These cranes are highly efficient in arranging containers in multi-level stacks, ensuring that yard space is maximized and containers are stored in an organized and accessible manner. With the ability to stack containers up to 5 layers high, RTGs significantly increase the storage capacity of the terminal yard, enabling operators to handle a larger number of containers within the same area. This efficient stacking and storage system helps ports meet the growing demand for container storage in increasingly crowded environments.

Container Yards and Logistics Centers

Container yards and logistics centers are vital links in the supply chain, facilitating the smooth movement of goods between different transport modes. RTGs are used in these settings to improve operational efficiency and ensure quick turnover of containers.

- Efficient Stacking and Storage of Containers: In container yards, RTGs are used to stack containers and organize them for easy retrieval. The ability to stack containers in multiple layers means that yards can store a higher volume of containers in a compact space, increasing overall yard capacity. RTGs with adjustable spans and lifting heights can accommodate containers of different sizes, from standard 20-foot and 40-foot containers to larger 45-foot units, making them versatile for different container types. Their smooth travel capabilities ensure that containers are stacked safely and securely, reducing the risk of damage.

- Transporting Containers Between Different Transport Modes (Rail, Truck, Sea): In logistics centers, containers need to be seamlessly transferred between different transport modes. RTGs are integral to these operations, as they can efficiently move containers between trucks, rail cars, and ships. For instance, an RTG may be used to load containers onto rail cars or unload them from trucks before transferring them to the next step in the transport process. RTGs can move containers quickly and with high precision, minimizing delays and ensuring that goods are transferred efficiently between transport modes. This flexibility is essential for modern logistics centers that manage complex multi-modal transport operations.

Transfer Stations

Transfer stations are critical points in the transportation network where containers are transferred from one transport mode to another, such as from rail to truck or vice versa. RTGs play a key role in ensuring that these transfers happen smoothly and efficiently.

- Seamless Transfer of Containers Between Transport Networks: RTGs are particularly valuable in transfer stations where containers need to be moved quickly from one mode of transport to another. They are designed for high maneuverability, allowing them to position containers with precision at transfer points. Whether moving containers between rail and road transport or unloading containers from barges at an inland terminal, RTGs enable smooth transitions between different transport systems. This seamless transfer process reduces bottlenecks and keeps goods flowing through the network, which is crucial in high-volume operations.

RTG cranes are indispensable in a wide range of applications, from port terminals and container yards to logistics centers and transfer stations. Their mobility, high lifting capacities, and flexibility in container stacking and transport make them ideal for handling containers in fast-paced, high-volume environments. Whether it's unloading containers from ships, stacking containers in a terminal yard, or facilitating smooth transfers between different transport modes, RTGs contribute significantly to the efficiency and success of container handling operations. These cranes are at the heart of modern logistics and transportation networks, improving productivity, safety, and operational efficiency across the supply chain.

Customization and Configurations

Rubber-Tyred Gantry (RTG) cranes are designed to offer flexibility and customization to meet the specific needs of various operational environments. From power supply options to safety features and performance enhancements, RTGs can be tailored to maximize efficiency, safety, and cost-effectiveness. Here's an overview of the key customization options available for RTG cranes.

Power Supply Options

RTGs can be powered using a variety of sources, providing flexibility depending on the location, environmental considerations, and customer requirements. The three main power supply options are:

- Diesel Engine: Diesel-powered RTGs are commonly used in locations where grid electricity is not available or for applications requiring high mobility. These cranes are equipped with diesel generator sets, which provide the necessary power for crane operations while offering independence from external power sources. Diesel-powered cranes are especially useful in remote areas or outdoor environments where mobility and flexibility are key.

- City Electricity: For operations in locations where reliable electricity infrastructure is available, RTGs can be powered by city electricity (AC380V 50Hz). This option is ideal for environmentally-conscious operations as it reduces emissions and fuel consumption. City-powered RTGs are typically used in more established terminal yards or port operations where stable electricity grids are available.

- Lithium Battery: As part of the growing trend for sustainability and energy efficiency, RTGs can be equipped with lithium battery systems. This option provides zero-emissions operations, making it an excellent choice for eco-friendly terminals or urban areas where reducing the environmental footprint is a priority. Lithium batteries also offer the advantage of being easily recharged, providing a more efficient and quieter alternative to traditional power sources.

These power options allow for energy-efficient operations, catering to different terminal needs while reducing operating costs and environmental impact.

Lifting Capacity and Span Adjustments

To meet the diverse operational requirements of container handling, RTG cranes offer customizable lifting capacities and span configurations. These adjustments ensure that the crane is well-suited for different terminal layouts, container sizes, and operational demands.

- Lifting Capacity: RTG cranes come with various lifting capacity options to suit the needs of different terminals. The typical lifting capacities range from 35 tons, 41 tons, to 70 tons, with options for even higher capacities in specialized models. The lifting capacity can be customized based on the weight and size of the containers being handled. Cranes with higher capacities are essential for terminals handling larger and heavier containers, while smaller models are suitable for lighter operations.

- Span Configurations: The span of the RTG crane is critical in determining its reach and the ability to access containers. RTG cranes typically come in 23.47-meter and 26-meter span configurations, with customizable options available to fit specific terminal layouts. The span configuration is important to ensure that the crane can effectively reach containers of varying sizes while maximizing yard space and operational efficiency.

- Lifting Height: RTG cranes also offer adjustable lifting heights, commonly ranging from 15.5 meters to 18.5 meters, ensuring that they can handle containers stacked at different heights. This customization option is particularly useful in terminals with high container stacks or where vertical space optimization is crucial.

By tailoring the lifting capacity, span, and height of the crane, RTGs can be perfectly matched to the operational needs of different terminals, enhancing their overall productivity and efficiency.

Safety and Performance Enhancements

Safety is paramount in port operations, and RTG cranes come with a range of optional safety features and performance upgrades to ensure smooth and secure operations. These enhancements can be customized based on the unique needs of the terminal and the type of goods being handled.

- Anti-Swing and Stability Systems: RTGs can be equipped with advanced anti-swing systems, including the standard two-way flexible resistance anti-swing system, and optional multi-function frequency control or electronic anti-swing systems. These systems help to minimize sway during container handling, improving the precision and safety of operations. The anti-swing system is particularly useful when handling high-stacked or oversized containers, reducing the risk of accidents or damage.

- Condition Monitoring Systems (CMS): RTG cranes can be fitted with Condition Monitoring Systems (CMS) for real-time monitoring of the crane's operational status. This system tracks parameters such as lifting speed, load weight, and overall crane performance. The system also enables automatic fault detection and data display, allowing operators to quickly address issues before they become critical, thus enhancing the crane's reliability and operational safety.

- Wind and Weather Safety: RTGs are designed with various weather safety measures to ensure safe operations even in challenging conditions. Wind alarms, safety dynamic scanning, and intelligent safety protection systems are available to alert operators when environmental conditions are unfavorable for crane operation. These systems help to prevent accidents and ensure that cranes are only operated in safe conditions.

- Performance Upgrades: Depending on the operational environment, RTG cranes can be upgraded with high-performance motors, advanced drive systems, and speed control technologies. These upgrades improve crane efficiency, reduce energy consumption, and enhance overall performance, especially in high-traffic or high-demand terminals.

By offering customizable safety systems and performance features, RTG cranes ensure that terminal operations run smoothly while keeping operators and equipment safe from potential hazards.

Customization is a key advantage of Rubber-Tyred Gantry (RTG) cranes, enabling them to meet the diverse needs of various operational environments. With options for different power supply sources, lifting capacities, span configurations, and a range of safety and performance enhancements, RTGs can be tailored to suit specific terminal requirements. These customization options ensure that RTG cranes operate at maximum efficiency, while also improving safety, flexibility, and environmental sustainability. Whether for high-volume port operations or environmentally-conscious logistics hubs, RTG cranes can be configured to meet the challenges of modern container handling and transport.

Conclusion

Why Choose Rubber-Tyred Gantry Cranes for Container Handling

Rubber-Tyred Gantry (RTG) cranes have become a vital asset in modern container handling operations, offering a range of benefits that make them ideal for port terminals, container yards, and logistics hubs.

- Flexibility: One of the standout advantages of RTGs is their mobility. Powered by diesel engines, city electricity, or lithium batteries, these cranes can operate independently and travel freely across container yards without the need for rail infrastructure. This flexibility makes RTGs suitable for a wide range of container handling tasks, from loading and unloading containers at the dockside to stacking and moving containers within yards. Their ability to move seamlessly across different areas maximizes operational efficiency and allows for quicker response times in busy environments.

- Energy Efficiency: RTGs offer various energy-efficient power supply options, including lithium batteries and electric power from the grid. These alternatives contribute to lowering fuel consumption and reducing the carbon footprint, making RTGs a more sustainable choice compared to traditional diesel-powered cranes. Additionally, features like electric energy feedback and vector frequency control further enhance their energy efficiency, ensuring optimal power use during operations.

- High Performance: RTGs are built to handle the heavy lifting required in port and terminal operations, with lifting capacities ranging from 35 to 70 tons or more. With adjustable spans and lifting heights, these cranes can handle containers of various sizes and stacking configurations, making them versatile and adaptable to different terminal requirements. Furthermore, advanced technologies such as anti-sway systems, real-time monitoring, and automatic fault detection ensure smooth and efficient operations, minimizing downtime and increasing productivity.

These key benefits—flexibility, energy efficiency, and high performance—make RTGs an essential tool for modern container handling and logistics operations, improving throughput and reducing operational costs.

Rubber-Tyred Gantry (RTG) cranes offer unmatched flexibility, energy efficiency, and high performance, making them a top choice for modern container handling operations. With options for different power supplies, lifting capacities, and spans, RTGs can be tailored to meet the diverse needs of terminal and yard operators. As technology advances, RTGs will continue to evolve with features such as automated operations, AI integration, and green technology, further enhancing their efficiency and sustainability. Choosing RTGs for container handling ensures that ports and logistics hubs are equipped with a reliable, efficient, and future-ready solution.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch