5 Ton -50 Ton Insulation Overhead Crane for Smelting Workshops

5 ton, 10 ton,16 ton, 32 ton, 50 ton insulation double girder overhead crane for smelting workshops of electrolytic aluminum, magnesium, lead & zinc,etc.

Category: Double Girder Overhead Crane

Your Trusted Double Girder Overhead Crane Manufacturer & Supplier

5 Ton -50 Ton Insulation Overhead Crane for Smelting Workshops

5 ton -10 ton,16 ton-32 ton, 32 ton -50 ton insulation type of double girder overhead cranes are designed for smelting workshops of electrolytic aluminum, magnesium, lead & zinc,etc., to secure crane during operation in the charged application. Isolation crane or insulated crane is with working class A6 and 1 year assurance and 20 + years' service life.

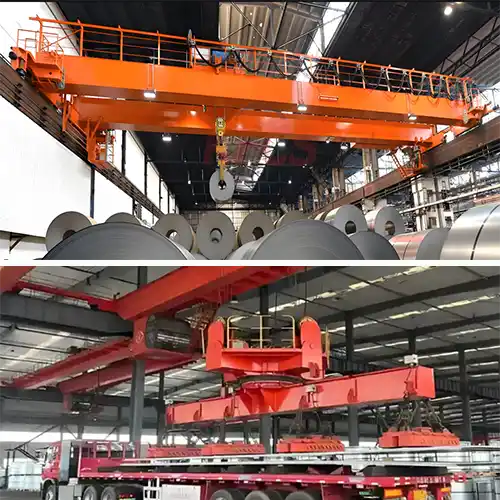

Insulation Double Girder Overhead Crane

QY type isolation or insulation designed double girder overhead crane is basically with same structure as QD type of double girder bridge crane with a hook. To avoid the charged equipment which may conduct electricity to the overhead crane by hoisted articles from endangering the driver's life, insulation equipment & devices are applied on the hook group, crab frame, crab wheel (or under the crab rails). The insulation material such as epoxy phenol aldehyde glass cloth laminated board are usually adopted. The insulation crane or isolation crane with double girder overhead crane design are widely used to aluminum and magnesium smelting factories.

Insulation overhead crane with double girder overhead crane design

Isolation overhead crane with double girder overhead crane design

Main Specifications of Insulation Double Girder Overhead Crane

Isolation crane and insulation crane is a double girder overhead crane with the insulation measures in every necessary parts of overhead crane to ensure it from electricity shock to ensure safety. The insulation type double girder overhead crane is the customized material handling crane to lift and transport loads in charged environment, such as the plants where electrolyse non-ferrous metals, such as magnesium, aluminum.

Isolation crane is a heavy duty double girder overhead with double brake in the hoisting for the sake of safety. The lifting capacity of the insulation double girder overhead crane is 5 to 50 tons and the working class is A6. The specific parameters of the double girder overhead crane is as follow:

- Product type of insulation overhead crane: QY Double girder overhead crane with insulation safety devices

- Lifting capacity of insulation overhead crane: 5~50t

- Span length of insulation overhead crane: 10.5~31.5m

- Working class of insulation overhead crane: A6

- Ambient temperature of insulation overhead crane: -25~50℃

Insulation Bridge Crane -Main Specifictions for Your Reference, Customized Designs are Provided

Lifting Weight (t) | 5 | 10 | 16 | 20 | 32 | 50 | |

Span (m) | 10.5~31.5 | ||||||

Max Lifting Height (m) | Main | 20 | 20 | 16 | 12 | 16 | 12 |

| Aux. | 22 | 22 | 18 | 14 | 18 | 16 | |

Speed (m/min) | Crab travelling | 37.2 | 43.8 | 44.6 | 44.6 | 42.4 | 38.5 |

Trolley travelling | 90.7-117 | 90.7-113 | 84.7-101.4 | 84.7-101.4 | 87.6-101.8 | 74.6-87.3 | |

Max. wheel pressure (KN) | 124 | 158 | 232 | 265 | 333 | 455 | |

Power source | 3-Phase A.C 50Hz 380v | ||||||

Components of Insulation Double Girder Overhead Crane

The insulated feeding crane is composed of a bridge frame, crane driver operating mechanism, crane trolley, aluminum tapping trolley, feeding trolley, electrical control system, air compressor, and gas circuit control system, hydraulic station and oil circuit control system, etc.

5 ton -10 ton isolation overhead crane double girder drawing

10 ton -20 ton insulation overhead crane with double girder overhead crane design

32 ton-50 ton insulation crane with double girder overhead crane design

Features of isolation overhead crane

1. Insulation measures of isolation overhead cranes

In order to prevent the double girder overhead crane and crane operator from danger of current shock to ensure their safety, there are three insulated devices equipped on the isolation crane, which are placed between:

- the hook and pulley,

- lifting mechanism and the trolley frame,

- trolley frame and crane.

2. Bridge frame of insulation overhead crane

As the main force component of isolation overhead crane , the bridge frame or main girder is mainly consisted of double beam, double track, end beams or end carriages, trolley tracks, walkways, railings, ladders, and other metal structures.

- The main beam girders and end carriages are structured with the box-shape, made of Q235 or Q345 steel, with the minimum thickness no less than 6 mm.

- Main beam camber of overhead crane girder is (1 ~ 1.4) S / 1000, and the maximum camber position controlled within tenth of central span.

The insulating devices are placed between the trolley tracks and trolley wheels to ensure the isolation crane's insulating features. Trolley tracks that lay on the the top of bridge are girder is a set of railway to ensure the smooth moving of the crane trolley, and the insulating devices are placed between the trolley tracks and trolley wheels to ensure the insulating features of the isolation double girder overhead crane.

3. Driver's cabin

- The driver's cabin of insulation overhead crane is a closed cabin with tempered glass that serves as the crane operator's workspace. As such, the driver's cabin must be robust, safe, and dependable, while also providing the driver with adequate visibility and comfort. The following are the features of the driver's cabin:

- Good vision with 270 ° viewing angle at the front. .

- Reliable quality and easy cleaning and maintenance.

- High safety, cabin alarms, unobstructed walking and activity space, etc.

4. Crane traveling mechanism

The traveling mechanism of isolation overhead crane is reliable with all the necessary safety devices to ensure smooth travelling to avoid slip and to ensure steady and reliable braking.

5. Trolley parts

Insulation overhead cranes have distinct drive systems for the main and auxiliary hoisting mechanisms, which may lift and handle loads independently and coordinate to finish the operation of turning loads over. The hoisting mechanism employs dual brakes.

6. Isolation overhead crane safety protection device

- On the main crane hook, an overload limiter is placed with the function of weight display, overload alerting, and automated power off devices,etc.

- Each mechanism has a closed electro-hydraulic brake, while the primary lifting mechanism has dual brakes.

- Lifting limit switch, over-current protection, no-voltage protection, phase protection, zero protection, emergency switch, main isolating switch, hatch door interlock switch, bells prompt, and other safety devices are used to assure crane operation and crew safety.

Depending on your needs, a few shock-proof bulbs can be put beneath the bridge structure.

Application of Insulation Overhead Crane

The insulation overhead crane is suitable for non-ferrous metal electrolytic aluminum, magnesium, lead, zinc and other smelting workshops.

The insulation overhead crane is widely used in the environment of high-temperature molten salt, high current, strong magnetic field, dust and hydrogen fluoride atmosphere in the electrolysis workshops.

If you need a customized insulation overhead crane, please feel free to contact us. A insulation double girder overhead crane will be designed based on your specific application.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch