Your Trusted Overhead Travelling Crane Manufacturer & Supplier

EOT Crane UAE: Single & Double Girder, Top & Underhung Crane

Types of Electric Travelling Eot Cranes for Sale UAE, Dubai, Good Price

The three motion electric travelling EOT crane is without any doubt the most adaptable and frequently used type of electric travelling crane for indoor material handing service. Compared to other permanent types of hoisting equipment , it serves a larger area of floor space within its own travelling crane limitations.

The eot bridge cranes raise and lower the loads using a trolley-mounted hoist. The trolley moves back and forth along a bridge. The bridge is moving along an runway. Besides, the overhead gantry cranes and overhead slewing jib cranes are also available for indoor material handling, which are selected based on your lifting requirements and application conditions.

Types of eot cranes for sale UAE markets

An EOT crane is an electric overhead travelling crane, which is composed of at least one primarily horizontal main girder, bolted with end carriages,which are driven by electric power to travel along the runway beams, supported by the internal facility structure or by freestanding steel structures. Top-running, under-running, single and double-girder electric travelling eot cranes are the four major types. The overhead bridge EOT crane, as the name suggests, can move above the floor level. As a result, it takes up no floor space and can never interfere with any movement of the work being done on the building's floor.

Top Running eot crane

Motorized Single Girder Eot Crane

Featuring a reduced-torque start and electronic dual-speed operation, these eot cranes offer superior headroom with spans that can exceed 85 feet, they're available in one- to 20-ton capacities.

Top running single-girder overhead eot cranes with spans in excess of 65 ft. frequently utilize a box girder construction. Featuring a light weight-to-span ratio, box girder eot cranes – often referred to as mono box eot cranes – can oftentimes reduce the size requirement for the structure supporting them.

Single-girder motorized overhead eot cranes utilize underhung hoists, such as electric chain, wire rope, and air. Unless otherwise specified, these motorized eot cranes include air or electric festoon systems.

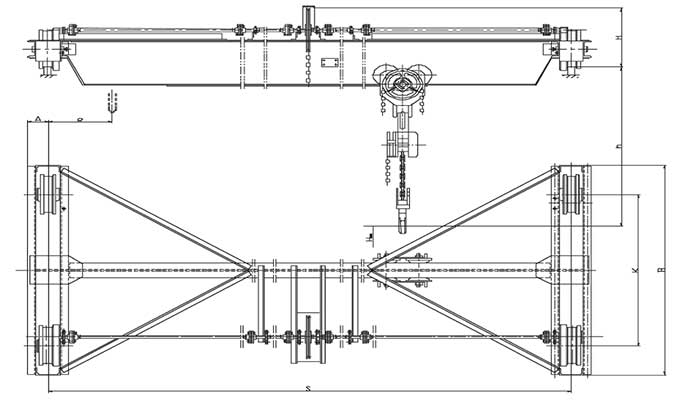

Electric Travelling Double-Girder Eot Crane

With near-limitless capabilities, the double-girder top running bridge crane can feature two hoists on one trolley. This is the most heavy-duty model available, and can handle wider spans and heavier loads that the smaller cranes cannot. Double girder overhead eot cranes can be constructed with either structural steel beams (W flange beams) or welded steel plates, commonly known as box girders. Box girder cranes have a very light weight-to-span ratio and in many cases can reduce the size of the structure required to support them as well as the cost of the crane itself. The our engineering team can help determine which design is right for your application.

- Available in almost unlimited capacities

- Commonly built with either four or eight wheels (called a double-bogie type)

- Can have two hoists on a single trolley or two separate hoists

- Generally move at higher speeds than underhung cranes, Free-traveling pendants and radio controls available

- All our powered cranes are shipped fully assembled and tested*

Overhead eot cranes with an end truck length of over eight ft. must be disassembled for shipping

Manual eot crane

Single Girder Manual Travelling Eot Crane

One of the most economical ways to move light loads, these top running eot cranes are pushed/pulled by the operator, who controls the speed. This allows them to adjust to changing production demands. Top running cranes offer the advantage of a higher hoist elevation than underhung cranes. The extra hook height allows the crane to lift equipment and products higher.

- Inexpensively manipulates loads up to five tons.

- However, because push/pull overhead traveling cranes become harder to use as the physical size of the product increases, it is generally not recommended for capacities over two tons.

- Because it's important for the operator to have good footing at all times, they are not recommended where floors are slick or regularly covered with debris.

Hand Chain Drive Single Girder Eot Crane

Hand chain driven manual eot cranes are operated by pulling a chain that is looped over a chain wheel to turn the drive shaft and the drive gears on the bridges wheels. Due to the relatively slow nature of a manual chain hoist, they are recommended for use in applications that require precision spotting. As loads increase in size and weight, hand chain eot cranes become preferable to manual push/pull cranes.

- Higher capacities are available with a double-girder setup

- Works well with chain fall hoists, electric hoists, air hoists and air balancers.

- Great for maintenance, die handling, and fabrication assembly applications

Underhung eot crane

Underhung motorized travelling eot bridge crane

These eot cranes are available in one- to 20-ton capacities and have a reduced-torque start and electronic dual-speed operation. They provide superior headroom and have spans of 7.5m-28.5m

With long span design, the top running single-girder overhead eot cranes frequently use a box girder construction. Box girder eot cranes, also known as single girder box eot cranes, have a low weight-to-span ratio and can frequently reduce the size of the structure needed to support them.

- Underhung hoists like electric chain, wire rope, and air are used by single-girder motorized overhead eot cranes. These motorized eot cranes come with air or electric festoon systems unless otherwise stated.

- All eot cranes are available with radio controls and independent traveling pendants, and they have capacities ranging from one to 20 tons. To facilitate quick delivery, many eot cranes are pre-engineered.

Push/Pull travelling eot crane

Push/pull cranes have excellent speed control and accelerate and decelerate at the operator's speed. When compared to using powered (motorized) cranes with preset speed points, this method may be more effective for handling similar loads. Underhung push/pull manual cranes are the most affordable eot cranes available, and they have a standard I-beam construction. If high and repetitive use is required, however, patented rail and enclosed rail cranes are also an option.

- Light loads are easily operated.

- Because of the applied manual force required to move the bridge eot crane, some conditions, such as slick floors and areas with many floor obstructions, may not be suitable for this type of crane system.

- Excellent speed control.

Hand Chain Drive

The hand chain that propels the geared wheels along the railway is pulled to operate chain-driven eot cranes. Compared to a push/pull system, this gearing makes it simpler to move loads, but it also makes the process relatively slow, facilitating simpler, more accurate load positioning.

- Underhung manual overhead eot cranes are typically less expensive and easier to use than top running eot cranes of the same capacity.

- With an electrical festoon wire or air hoist to supply power to the lifting equipment, manual travelling overhead travelling bridges work well with manual chain hoists, air hoists, electric hoists, and air balancers.

- Moves loads up to 15 tons for a reasonable price.

- Allows for precision position, which is ideal for pumping stations, assembly applications, and maintenance bays.

Rigid Work Station Cranes

The use of rigid work station cranes has been proven to boost production, improve quality, and produce a safer working environment. Our workstation crane systems use enclosed track that is strong and light, allowing for simple movement and a long lifespan, in both aluminum and steel construction.

Our line of ergonomic workstaion eot crane products, which have lift capacities between 500kg -3 ton, and cusotmized design can be used to handle loads with capacity up to 5 ton to ensure increased productivity. Our the workstation cranes that can be customized based on your project lifting requirement and needs.

Free standing eot workstation cranes

- The enclosed track. The work station eot crane can be set up anywhere on the facility floor. It makes it possible for the heavy load to be moved along the moving surface with ease.

- ·Ease of crane movement.With this structure, moving the bridge and the trolleys is made simpler, and the track is kept free of debris. Trolley wheels last a long time if they move easily and consistently, which will reduce the need for maintenance, potential repairs, and downtime.

- Excellent load positioning. The enclosed track prevents any unforeseen shifting, such as swaying, shimmying, or crabwalking, as the bridge moves along it. Because every component of the frame is assembled to ensure superior load distribution, the load is transported efficiently from point to point.

- Flexible precision.

Workers can rely on the precise location of the load when performing their duties thanks to a sturdy design. The work station eot crane can be moved to accommodate the needs of your employees on the assembly line as your product requirements change.

- Made to order. To fit their constantly changing facility and work flow, a production manager can easily change the workstation crane's design and location. Your Rigid workstation crane can help ensure production efficiency where it is most needed, whether it be by adjusting the runway length or adding more bridges.

- Flexible layout.With this system, the production manager can quickly add or remove extra sections from the runway's track to adapt material handling tasks or the transportation of large loads.

- Safe material handling operation. Each track profile is predesigned to accommodate hoist weight and has an impact safety factor built in. At any point along the track, a trolley operator can make sure that the load or parts assembly is moved in a safe and comfortable manner (vertically or horizontally).

- Reliable and accurate positioning.Accident risks are higher in any production or distribution facility where employees are handling heavy loads. Workers can confidently perform assembly or hoisting tasks because the entire mechanism will remain rigid (allowing for zero movement of the load).

What are the applications of electric travelling eot crane UAE?

For UAE market, our factory can provide vairious types of eot cranes and electric travelling eot cranes for different applications and working sites, such as machinery assemble and maintenance manufacturing plant, mines, chemical plant, steel mill, and explosion proof environments,etc. Our customers usually can choose suitable electric travelling eot cranes in our company.

Construction and civil engineering

Electric eot cranes used in construction and civil engineering projects need to be safe, reliable, and optimized for the workplace. Consider the following as an illustration: When tunnels are being built in urban areas or beneath rivers using the shield construction method, the circular segments are put together immediately following excavation in very small working spaces. Specialized lifting equipment is required for materials handling, equipment transportation, etc. when building high-rise structures and bridges.

Low-headroom electric hoists are employed when building tunnels to ensure effective lifting even in confined spaces. Our crane factory has a special team and team for research and development, which it employs to produce products that are tailored to the customer's needs and offer specialized services.

Explosion proof crane for UAE Oil and gas industry

There are various types of overhead travelling cranes and hoists that are designed with advanced technology, allowing us to provide hoisting equipment that is exceptionally compact, lightweight, safe, and operable. Our electric hoists and eot cranes are widely used in gas and petroleum facilities because they are simple to install and simple to maintain thanks to careful design.

The eot cranes used in the gas and petroleum sites serve two functions: machinery maintenance and material handling transportation. While a variety of electric equipment is used to lift, lower, and transport loads, our manual chain hoists and other equipment are used for routine facility maintenance. For locations or sites that are exposed to flammable gases, explosion proof hoists are especially produced.

Automotive industrial use overhead crane & eot crane uae market

Electric hoists and eot cranes are used for car handling in the automotive industries. For handling cars, a lot of people use our electric hoist and eot crane.

Electric hoists and eot cranes are used in the auto manufacturing sector to increase overall productivity by enhancing the stability and efficiency of production lines. Large-scale production lines typically push auto factories to their maximum capacity; as a result, equipment failure in the auto industry can result in serious production downtime and reduce profits. For maximum productivity, the production machinery must be simple to operate for long periods of time while also providing high levels of safety and reliability.

Electric hoists, small-capacity light overhead cranes, and slinging tools are available from our electric hoist and eot crane to locations and factories that manufacture engines, transmissions, vehicle bodies, etc.

The majority of the automotive industry is a pipeline, so in order to handle the materials and maintain internal logistics, various industrial lifting tools, industrial cranes, and electric hoists were needed. Our eot crane is typically used for lifting and transportation during the manufacturing and product assembly processes of automobile manufacturers and their suppliers all over the world!

Customized industrial overhead crane for manufacturing plant in UAE

You can use our electric travelling eot cranes in the UAE in a variety of manufacturing facilities. The general use eot crane , low headroom, explosion proof overhead cranes, and other processed industrial cranes are available for general manufacturing plants.

Mines use explosion proof overhead travelling crane for sale UAE

To lift mineral powder and other materials from mines, we can manufacture grab eot cranes. The needs of the customer and the working environment can determine the size of the grab. In addition, the waste treatment industry can use the grab electric travelling eot crane to lift trash.

Steel mill cranes for metallurgical industry for steel processing & handling in UAE

For handling and moving molten metal, we have a specialized metallurgical overhead eot crane, which can make the lifting process safer. Additionally, this type of crane's beams have high-temperature heat insulation plates, making them more appropriate for steel mills.

Explosion Proof Plant: An electric travelling eot crane for the UAE can be produced with an explosion-proof design, and it will function with an explosion-proof hoist in explosive environments like the chemical industry.

How to get your custom designed EOT Cranes?

The key operating guidelines for EOT cranes, such as the crane's structure's type of motion, the weight and nature of the load, the crane's location, geometric features, operating procedures, and the environment in which it operates, determine how the bridge cranes are designed in a variety of ways. In order to streamline operations and boost output, it is crucial to select the right kind of EOT crane. There are many factors considered, including the following:

- What is the eot crane's required capacity?

- How frequently will the bridge crane be used?

- What is the span's length?

- How much time does it take to travel from one runway end to the other?

- How high must the overheac travelling crane hoist lift?

- Will the bridge eot crane be self-supporting? Will it be supported by the structure, or will it be both?

- Do you want to install the bridge overhead crane indoors or outside?

- Where does the electric bridge crane get its power from? Is there a mix of manually geared and motorized push-pull?

- If it is motorized, how quickly will it go? Which is preferable, one speed or two speeds? What do variable frequency drives do exactly?

- How much voltage is required for this application?

- What sort of control do you desire? Which is preferable: a remote control, a separate track, or a pendant from the hoist?

- Do you have any distinguishing qualities? To name a few, there are cabs, pathways, horns, and lights.

- Exist any applicable standards, codes, or local laws?

We strive to provide the most suitable solution for the customer's industry and application from our wide range of overhead eot crane equipment, which includes single girder& double girder eot crane, European standard crane , underslung crane, grab cranes, explosion proof bridge cranes, electromagnetic cranes, metallurgical use overhead cranes, and so on.

For all types of industrial applications, our EOT crane is dedicated to offering UAE customers the most effective and affordable lifting solutions.

FAQ on eot crane delivery and installation in UAE

- How long does it take for delivery services? Electric traveling eot crane deliveries typically take 20 to 40 days. Delivery times may be prolonged if special customization is needed.

- Can your eot crane delivery to UAE ? Yes, we do deliver to UAE, including Abu Dhabi, Ajman, Dubai, Fujairah, Ras Al Khaimah, Sharjah, and Umm Al Quwain. Abu Dhabi is the capital while Dubai is the most populous Emirate.

- What packaging do your products use? The main girder and large steel parts and components are typically wrapped in plastic film. Smaller components such as electrical and other parts are packed in plywood or standard export-use non-fumigation wooden boxes that are reinforced with steel plates to prevent damage.

- Are you able to handle shipping? No problem. We have a powerful shipping department that can handle your shipping-related issues.

- Are you able to offer crane installation in UAE? Yes, if the customer requests it, we can dispatch 1-2 engineers to the installation site to provide assistance in UAE. Customers need to pay for round-trip airfare, visa fees, local lodging and transportation, and so on.

Eot crane services for UAE crane markets

- How much time is left on your warranty? The warranty is valid for a year. Within a year, if there is a failure or component damage brought on by a quality issue, our business is liable for providing free replacement parts.

- Can you supply wear parts? Yes, we will give you wear parts for a year.

- How do You offer after sale support? Engineers can provide remote guidance, and we can offer online services seven days a week, twenty-four hours a day. We can dispatch an engineer if the issue cannot be fixed.