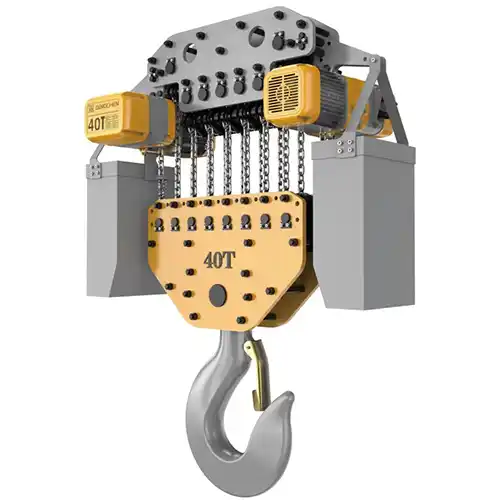

40 Ton Electric Chain Hoist Safety Factor, Testing, and ISO Certificates

Electric hoist for sale. Learn about the safety factors, testing procedures, and ISO certifications ensuring reliability and performance of 40-ton electric chain hoists.

Category: Featured

Your Trusted Electric Chain Hoist Manufacturer & Supplier

40 Ton Electric Chain Hoist Safety Factor, Testing, and ISO Certificates

Electric hoist for sale. Learn about the safety factors, testing procedures, and ISO certifications ensuring reliability and performance of 40-ton electric chain hoists.

Introduction: The Importance of Safety in Hoist Operations

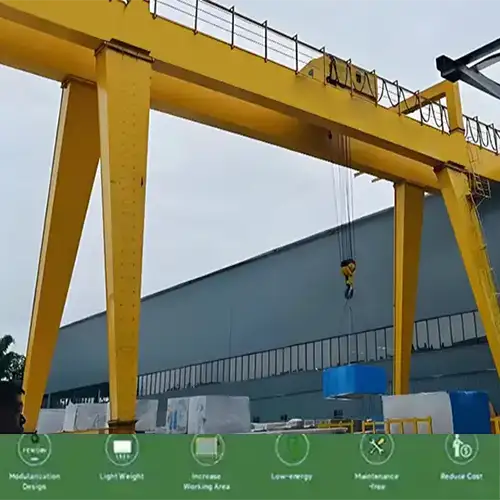

Safety is a top priority when working with heavy equipment like hoists. Chain hoists are essential tools in industries such as construction, manufacturing, and logistics. They help lift and move heavy loads, making tasks easier and safer. However, because these machines handle large weights, there are risks involved. That's why features like safety factors, testing, and certification are so important to ensure hoists work properly and safely.

The safety factor is a built-in margin of strength that protects against unexpected situations. For example, if a hoist has a safety factor of 4 times, it means the hoist is strong enough to lift four times its rated capacity under extreme conditions. This ensures that the hoist will still function safely, even in tough or unexpected situations.

For a 40-ton Electric Chain Hoist, safety is even more critical. These hoists lift very heavy loads, and a failure could lead to serious accidents, damage, or injury. Whether lifting equipment in factories or materials on construction sites, the safety of both the workers and the load depends on the hoist's ability to handle such large weights.

Testing and certification are crucial to make sure a hoist works safely. Testing checks if the hoist can handle its rated load and more. Certification, like the well-known ISO standards, ensures the hoist meets safety rules and quality expectations. This includes rigorous tests for both static loads (when the load is still) and dynamic loads (when the load is moving). Certification, such as ISO 9001 for quality and ISO 4301-1 for crane classification, guarantees the hoist meets safety and performance standards recognized worldwide.

In short, a 40-ton chain hoist needs to be built with a proper safety factor, thoroughly tested, and certified to ensure it performs safely and reliably. This helps reduce risks and keeps everyone safe while using the hoist.

Safety Factor of a 40-Ton Electric Chain Hoist

What is a Safety Factor?

A safety factor is a built-in strength margin that ensures equipment can handle more than its normal load capacity without breaking. It's the ratio between the maximum load a hoist can lift (before it fails) and the rated load (the weight it's designed to lift under regular conditions).

For example, if a hoist is rated to lift 40 tons and has a safety factor of 4:1, it means the hoist is built to safely lift up to 160 tons in extreme situations.

The safety factor ensures that the hoist can handle unexpected events like sudden impacts or overloads without failing, protecting both the equipment and the workers.

Why is a 4:1 Safety Factor Important for a 40-Ton Electric Chain Hoist?

A 40-ton Electric Chain Hoist is used in industries where heavy loads need to be lifted, such as construction and manufacturing. Because of the size of these loads, it's important that the hoist can handle more than just its rated weight.

With a 4:1 safety factor, the hoist can safely lift up to 160 tons — that's four times the rated capacity. This added strength is crucial in real-world conditions, where unexpected things can happen. The hoist could face sudden shocks, uneven loads, or harsh environmental conditions, all of which could put extra stress on the hoist.

The 4:1 safety factor provides extra protection against:

- Sudden Impacts: Sometimes the load may be dropped or moved too quickly. The safety factor ensures the hoist won't break under these shocks.

- Uneven Loads: Not all loads are the same. Sometimes a hoist may lift a load that's heavier or unbalanced. The safety factor ensures the hoist can safely handle these moments.

- Wear and Tear: Over time, equipment naturally wears out. The safety factor ensures the hoist will still be safe and reliable even as it ages.

Why Choose a 4:1 Safety Factor?

A 4:1 safety factor is standard for heavy-duty hoists because it provides a good balance between safety and practicality.

Here's why it works:

- Handling Shocks: Lifting heavy loads can cause sudden jerks or impacts. The safety factor makes sure the hoist can handle these without damage.

- Handling Unexpected Loads: When lifting or lowering, the hoist might sometimes face extra weight or force. The safety factor ensures the hoist stays safe in those situations.

- Tough Environments: Some hoists work in extreme temperatures or harsh conditions, like chemical exposure. The safety factor helps ensure the hoist performs well even in these tough environments.

The 4:1 safety factor ensures the hoist can handle surprises and still perform safely. This extra margin of safety keeps both workers and equipment safe, even in challenging situations.

How the Safety Factor is Calculated

The Calculation Method

The safety factor is determined by dividing the ultimate load capacity (the maximum weight the hoist can safely handle before failure) by the rated load capacity (the weight the hoist is designed to lift under normal operating conditions).

Formula: Safety Factor = Ultimate Load Capacity ÷ Rated Load Capacity

The ultimate load capacity is set higher than the rated load to ensure that the hoist can handle unexpected situations, such as sudden shocks, impacts, or extreme environmental conditions.

Example: Calculating the Safety Factor for a 40-Ton Hoist

Let's break down the calculation for a 40-ton hoist with a 4:1 safety factor.

- Rated Load Capacity: This is the weight the hoist is rated to lift under normal conditions. For this example, the hoist is rated for 40 tons.

- Ultimate Load Capacity: The hoist is designed to handle 4 times the rated load to ensure it can cope with extreme conditions. For a 40-ton hoist: Ultimate Load Capacity = 40 tons × 4 = 160 tons

- Safety Factor Calculation: Using the formula: Safety Factor = 160 tons /40 tons = 4 : 1

- Result: The safety factor for this hoist is 4:1, meaning the hoist can safely lift up to 160 tons under extreme conditions, which is four times its rated load.

Testing Methodology for the 40-Ton Electric Chain Hoist

Dynamic Load Testing

Dynamic load testing simulates real-world conditions where the hoist might experience varying loads during operation. It is crucial to ensure that the hoist can handle the stresses and forces that occur when lifting and moving loads, especially under changing or unpredictable conditions.

Importance: Dynamic load testing helps verify that the hoist can safely lift and move loads without failure, even when the load is not stationary. This type of testing accounts for factors like acceleration, deceleration, and the movement of the load during operation.

Testing Procedure: To test the hoist's ability to handle dynamic loads, we apply a load that is 1.1 times the rated load. For a 40-ton hoist, this means testing the hoist with a load of 44 tons to ensure it can perform safely under dynamic conditions.

Static Load Testing

Static load testing checks the hoist's ability to handle stationary loads. Unlike dynamic testing, static testing focuses on the hoist's strength and stability when the load is not in motion.

Importance: Static load testing is critical to ensure that the hoist can safely lift heavy loads without risk of failure when the load is stationary. This test ensures the hoist can withstand long periods of load-bearing without any movement, which is a common scenario in certain industrial applications.

Testing Procedure: For static load testing, we apply a load that is 1.25 times the rated load. For a 40-ton hoist, this means the hoist is tested with a load of 50 tons to verify its safety and performance under stationary conditions.

Proof Testing and Load Verification

What is Proof Testing?

Proof testing is a critical process used to verify the strength and reliability of lifting equipment, such as hoists, to ensure it can safely handle the loads it is rated for. The primary purpose of proof testing is to simulate conditions beyond normal operation to confirm that the hoist can withstand both typical and extreme working conditions without failure.

- Purpose: The goal of proof testing is to ensure the hoist performs reliably under stress, confirming that it meets or exceeds safety standards and can safely handle a higher load than it would in everyday use.

Load Limits for Proof Testing

During proof testing, the hoist is subjected to loads higher than its rated capacity to test its structural integrity and safety margin. For our 40-ton hoist, the following load limits are applied during proof testing:

Static Load Testing: The hoist is proof-tested with a load of 1.25 times the rated load, which for a 40-ton hoist means a test load of 50 tons. This ensures the hoist can handle heavy stationary loads without risk of failure.

Dynamic Load Testing: For dynamic testing, the hoist is proof-tested with a load of 1.1 times the rated load, equating to a load of 44 tons for a 40-ton hoist. This verifies that the hoist can handle varying loads during movement safely.

Importance of Proof Testing

Proof testing is essential in confirming the hoist's ability to handle both extreme and typical working conditions. By testing the hoist beyond its rated load, we can be confident that the hoist will perform reliably and safely even in challenging operating environments, providing peace of mind for operators and maintenance teams alike.

ISO Certification: Quality Assurance and Global Standards

The Certificate Of Occupational Health and Safety Management System

The Certificate Of Environmental Management System

The Certificate Of Quality Management System

What is ISO Certification?

ISO (International Organization for Standardization) certification ensures that products, services, and systems meet global standards for quality, safety, and efficiency. ISO certification is a mark of reliability and consistency, demonstrating that equipment, like hoists, is designed and manufactured to meet rigorous safety and performance criteria recognized worldwide.

- Purpose: ISO certification helps businesses maintain high standards, improve operational efficiency, and build trust with customers by ensuring that their products meet established quality benchmarks. For hoists, this means adherence to industry-specific safety protocols and performance guidelines.

ISO 9001: Quality Management System

ISO 9001 is a global standard for quality management systems (QMS) that ensures organizations maintain a focus on customer satisfaction, continuous improvement, and the consistent quality of their products and services.

- Relevance for Hoist Manufacturing: ISO 9001 certification demonstrates that the hoist manufacturer follows best practices in quality management, ensuring that every hoist, including the 40-ton electric chain hoist, is produced to the highest standards. It ensures that manufacturers implement rigorous processes for testing, quality control, and customer service.

ISO 4301-1: Classification of Cranes

ISO 4301-1 provides standards for the classification of cranes, including hoists, based on their design, capacity, and performance requirements. This standard ensures that all cranes and hoists are appropriately rated to handle the loads they are designed for, guaranteeing safe operation under various conditions.

- Importance: Compliance with ISO 4301-1 ensures that hoists meet global safety requirements and are built to handle the specific demands of various industries. This standard is critical in confirming that the hoist will operate safely, reliably, and efficiently in real-world working conditions.

Ensuring Compliance with International Standards

Purchasing a certified 40-ton electric chain hoist ensures that the hoist meets not only the manufacturer's design specifications but also international safety and performance standards.

Benefits:

- Reliability: Certified hoists are built to last and perform consistently over time, reducing the risk of failures.

- Safety: ISO certification guarantees that the hoist meets stringent safety criteria, minimizing the risk of accidents or injuries.

- Global Compliance: ISO certification ensures that the hoist complies with international regulations, making it suitable for use in diverse markets and industries.

By purchasing a certified hoist, customers can have confidence that the equipment will deliver dependable performance, support safety protocols, and adhere to global standards, providing peace of mind for operators and facility managers.

Conclusion: Why Proper Testing and Certification Matter

Recap of the Importance of Safety Factors, Testing Methods, and ISO Certification

The safety, reliability, and performance of a 40-ton electric chain hoist depend on several critical factors, including:

- Safety Factors: A safety factor of 4:1 ensures the hoist can handle extreme conditions without risk of failure, providing peace of mind for operators.

- Testing Methods: Dynamic and static load tests confirm the hoist's ability to operate safely under both moving and stationary loads, ensuring it can handle typical and extreme conditions.

- ISO Certification: Certifications like ISO 9001 and ISO 4301-1 guarantee that the hoist meets global safety standards, further validating its design, performance, and manufacturing processes.

These elements work together to ensure that the hoist performs reliably and safely over time, minimizing risks and ensuring operational efficiency.

Final Thoughts on Choosing a Hoist that Complies with Global Standards

When selecting a hoist, it's essential to prioritize equipment that adheres to recognized global standards and undergoes rigorous testing. A certified hoist that has been proof-tested and manufactured according to international guidelines ensures:

- Enhanced Safety: Adherence to global safety standards means fewer risks and a lower chance of equipment failure.

- Reliability and Durability: A well-tested hoist will last longer and perform consistently, reducing downtime and maintenance costs.

- Peace of Mind: With ISO certification, you can be confident that the hoist meets both your safety requirements and your operational needs.

Choosing a hoist with proper certification and proven reliability is an investment in your workplace safety and operational success.

If you have any further questions or would like more information about our 40-Ton Electric Chain Hoist, including detailed testing procedures, safety factors, or ISO certifications, feel free to reach out to us! Our team is ready to provide you with the information you need to make an informed decision.Contact us today to discuss your specific needs, request a quote, or learn more about how our certified hoists can enhance your operations with reliability and safety.We look forward to assisting you!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch