Industrial Jib Cranes: Efficient Solutions for Tight Spaces

Industrial jib cranes provide compact, cost-effective lifting solutions for small-scale production and maintenance, enhancing safety and space efficiency.

Category: Featured

Your Trusted Industrial Jib Crane Manufacturer & Supplier

How Jib Cranes Boost Efficiency in Small-Scale Production

The Role of Jib Cranes in Small-Scale Production

Industrial Jib Cranes: Compact Lifting Solutions for Maintenance and Small-Scale Production”:

Industrial Jib Cranes: Efficient Solutions for Tight Spaces

Industrial jib cranes provide compact, cost-effective lifting solutions for small-scale production and maintenance, enhancing safety and space efficiency.

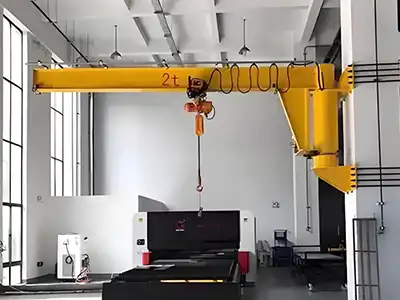

Industrial jib cranes are efficient, compact lifting solutions that play a vital role in material handling across various industries. Designed to lift and move heavy loads within a defined area, these cranes offer exceptional flexibility and ease of use. The key components of a jib crane include a boom (the horizontal arm), a hoist or winch, and a supporting pillar or wall mount. With their simple yet effective design, jib cranes are becoming increasingly popular in environments where space is limited, and precise lifting is required. If you need industrial cranes, please feel free to contact us to get your customized design.

Jib Cranes in Confined Spaces and Maintenance Workshops

Jib cranes are particularly valuable in confined spaces where other lifting equipment may struggle to operate effectively. They are designed to work in tight spaces, offering a solution for tasks that would otherwise require larger, more cumbersome equipment. In maintenance workshops, this compact design allows jib cranes to lift heavy machinery parts, engines, or equipment that require regular servicing or repairs.

- Space-Efficient Design: Jib cranes can be installed in corners, along walls, or in areas where floor space is at a premium. This flexibility ensures that every inch of space is utilized efficiently.

- Versatile in Tight Areas: Whether it's a corner of a workshop or a small maintenance bay, jib cranes can rotate, lift, and move loads in areas where larger cranes cannot operate.

- Improved Accessibility: Jib cranes are easy to move or adjust, providing excellent access to various parts of the workspace for maintenance tasks.

Industrial Jib Cranes

Industrial jib cranes are essential lifting solutions used in a variety of industries for efficient material handling in confined spaces. Their compact design and versatility make them ideal for tasks that require precise lifting and maneuverability within restricted areas. Let’s dive into the key components and types of industrial jib cranes, and why their compact design is crucial.

Key Parts of Industrial Jib Cranes

- Boom/Jib Arm: The horizontal arm of an industrial jib crane, also known as the jib arm, extends outward to provide the reach necessary for lifting and positioning loads. This part is essential for determining the crane’s lifting capacity and range of motion.

- Hoist: The hoist system is used to raise and lower the load. It includes a motorized winch or chain, a rope or chain, and lifting attachments like hooks or slings. The hoist provides the power needed for vertical lifting operations.

- Pillar/Base: The pillar or base is the support structure that anchors the crane. It is typically mounted to the floor in floor-mounted industrial jib cranes or attached to a wall in wall-mounted models. This component ensures stability during operation and determines the crane's range of motion.

Types of Industrial Jib Cranes

Several types of industrial jib cranes are available, each suited to specific tasks and operational environments:

- Floor-Mounted Industrial Jib Cranes: These are mounted directly to the floor and are capable of rotating up to 360 degrees, offering maximum flexibility for lifting and moving materials within the operational area. They are well-suited for workshops and factories where ample floor space is available.

- Wall-Mounted Industrial Jib Cranes: These cranes are mounted on a wall or structural support, allowing for lifting tasks in areas where floor space is limited. Wall-mounted jib cranes are ideal for industrial environments where floor space is scarce but overhead space can be utilized.

- Portable Jib Cranes: Also known as portable or mobile jib cranes, these cranes feature movable jib crane base on rollers that provides flexible design. The design allows for light and flexible material handling from place to place.

Each type of industrial jib crane is designed for specific applications, offering a balance of load capacity, flexibility, and space optimization.

Why Compact Design Matters in Industrial Jib Cranes

The compact design of industrial jib cranes offers significant advantages in terms of space efficiency and versatility, making them perfect for working in confined or restricted spaces. Here’s why this design is essential:

- Space Efficiency: Industrial jib cranes are designed to take up minimal floor space. This makes them ideal for small workshops, maintenance bays, or production lines where space is limited. Their compact structure allows them to be installed in tight corners, against walls, or in narrow aisles, without occupying valuable workspace.

- Ease of Installation: Compared to larger lifting systems like overhead cranes or gantry cranes, industrial jib cranes are much easier and quicker to install. Floor-mounted models can be set up in a short time, while wall-mounted models require less space and can be installed without major modifications to the workspace.

- Adaptability in Confined Spaces: The ability of industrial jib cranes to rotate and extend in tight spaces is a key benefit. Whether in a maintenance workshop with limited overhead clearance or a small-scale production environment, these cranes can efficiently handle materials in areas where larger lifting equipment would be impractical. Their ability to work in narrow or restricted areas without sacrificing performance makes them a preferred solution for many industries.

In conclusion, the compact design of industrial jib cranes allows them to operate efficiently in confined or restricted spaces, offering space savings, ease of installation, and versatility in various industrial applications. Whether used in small-scale production or maintenance workshops, industrial jib cranes are a powerful, cost-effective solution for lifting and material handling needs.

Role of Industrial Jib Cranes in Small-Scale Production

Industrial jib cranes are vital tools in small-scale production environments, offering several advantages in handling materials, improving workflow, and ensuring safety. Their compact design and versatile functionality make them ideal for lifting small, lightweight loads and supporting various tasks across production lines.

Handling Small, Lightweight Loads

One of the primary benefits of industrial jib cranes in small-scale production is their ability to handle small, lightweight loads with precision and ease. Typically, these cranes are designed to lift and move loads ranging from 500 kg to 5 tons, making them ideal for many production tasks where precision and accuracy are key.

- Ideal Load Capacities for Small-Scale Production: Jib cranes are well-suited for small-scale operations that require lifting components such as parts, tools, raw materials, and semi-finished products. Their load capacity of up to 5 tons makes them perfect for industries such as electronics manufacturing, automotive assembly, and precision machining, where the weight of the materials handled is often below 5 tons.

- Precision in Lifting and Placing Materials: The ability of industrial jib cranes to move loads with high precision ensures that materials are placed exactly where needed. This level of control is essential in production processes that require careful alignment or placement of parts. Whether it's positioning a heavy part onto a workbench or placing materials into specific machines, jib cranes help ensure accuracy without the risk of damage to sensitive components.

Flexibility in Production Environments

Industrial jib cranes are incredibly flexible and can be quickly adapted to various tasks in a small-scale production environment. Their versatility makes them invaluable when production lines need to be set up or changed frequently.

- Quick Setup for Temporary Production Lines: In small-scale or project-based production environments, operations can often shift, requiring the quick installation of new production lines or workflows. Jib cranes can be set up quickly, offering flexibility when new tasks or equipment need to be integrated into a workspace. This adaptability helps businesses maintain efficiency without long delays in production.

- Ability to Serve Various Production Tasks: Industrial jib cranes are used in many different production processes. Whether it’s assembly, welding, machining, or material handling, jib cranes can easily be adjusted to suit the specific needs of each task. For example, in automotive assembly, jib cranes are often used to lift parts like engines or doors into position, while in metalworking, they may be used to position raw materials for cutting or welding.

Enhanced Productivity and Safety

In small-scale production environments, enhancing productivity and maintaining a safe work environment are top priorities. Industrial jib cranes contribute significantly to both of these factors.

- Minimizing Human Effort and Enhancing Workplace Safety: By automating the lifting and movement of heavy or awkward loads, jib cranes reduce the physical strain on workers. This helps minimize fatigue and increases the overall speed of production, as workers can focus on more complex tasks without needing to worry about physically handling heavy materials.

- Reducing the Risk of Workplace Injuries: One of the most important benefits of industrial jib cranes is their ability to reduce workplace injuries related to manual lifting. Lifting heavy components by hand can lead to strain injuries, falls, and accidents. By using jib cranes to handle lifting tasks, the risk of these injuries is significantly lowered, creating a safer, healthier working environment for employees. Additionally, jib cranes often come with built-in safety features such as overload protection, limit switches, and ergonomic designs, all of which contribute to overall safety.

In conclusion, industrial jib cranes play a critical role in small-scale production environments by handling lightweight loads with precision, offering flexibility in production setups, and enhancing overall productivity and safety. These cranes are ideal for industries that require quick adaptations and high precision, all while reducing human effort and the risk of injuries.

Benefits of Jib Cranes in Maintenance Workshops

In maintenance workshops, where the handling of heavy equipment and machinery is a regular task, industrial jib cranes provide numerous advantages. They offer the ability to lift and position large components with ease, improve workspace accessibility, and enhance worker safety and comfort. Below are the key benefits of using jib cranes in maintenance settings.

Efficient for Heavy Maintenance Tasks

Maintenance workshops often require lifting and positioning heavy components such as motors, pumps, engines, and other industrial machinery parts. Jib cranes are designed to handle these tasks efficiently, reducing the manual effort needed for moving large, cumbersome loads.

- Lifting and Positioning Heavy Components for Repairs: Jib cranes are highly effective at lifting heavy items like motors, pumps, or engines, which are commonly found in maintenance operations. Their ability to move these parts into precise positions helps ensure that repairs are performed accurately and safely.

- Reducing the Need for Forklifts or Overhead Cranes in Tight Spaces: In maintenance workshops, space is often limited, and traditional lifting equipment like forklifts or overhead cranes may be impractical. Jib cranes, with their compact design and flexibility, can perform the same lifting tasks in confined areas. Unlike forklifts, which require open spaces to maneuver, jib cranes can operate in tight corners or against walls, saving valuable workshop space while improving efficiency.

Increased Mobility and Accessibility

In workshops with limited space, the ability to move lifting equipment easily and efficiently is crucial. Jib cranes offer exceptional mobility, making them well-suited for various workshop configurations.

- Mobile Jib Cranes for Workshops with Limited Space: Mobile jib cranes provide the flexibility to move between workstations and equipment within a workshop. This is particularly useful in smaller maintenance facilities where floor space is constrained. Operators can move the crane to different locations, allowing for efficient handling of heavy components without needing additional equipment or rearranging the entire workshop.

- Wall-Mounted Cranes for Unobstructed Floor Space: Wall-mounted jib cranes are another ideal solution for maintenance workshops with limited floor space. Mounted on the wall or a support column, these cranes free up the floor area, leaving more room for workers and equipment. Wall-mounted designs allow for easy access to various parts of the workshop without the need to navigate around bulky equipment.

Improved Worker Ergonomics

Lifting heavy components manually in a maintenance environment can place significant strain on workers, leading to fatigue, injuries, and decreased productivity. Jib cranes significantly improve ergonomics by providing mechanical lifting support.

- Reducing Strain on Workers: Jib cranes reduce the physical strain on workers by taking over the heavy lifting. With a jib crane, operators can lift, move, and position large parts without needing to rely on physical strength, which helps prevent musculoskeletal injuries commonly caused by manual lifting. This reduction in strain leads to increased worker satisfaction and decreased downtime due to injury.

- Ease of Use for Operators in Confined or Awkward Positions: In maintenance workshops, operators often have to work in confined or awkward positions, such as beneath equipment or in cramped spaces. Jib cranes provide an easy-to-use lifting solution that allows workers to position components accurately, even in hard-to-reach areas. The crane’s adjustable arm and rotational capabilities make it easier to handle loads in challenging spaces, improving overall accessibility and efficiency.

In summary, industrial jib cranes offer significant benefits in maintenance workshops by enabling the efficient handling of heavy components, improving space accessibility, and enhancing worker ergonomics. They reduce the reliance on larger equipment, offer mobility in confined spaces, and provide a safer, more comfortable working environment for maintenance personnel. Whether mobile or wall-mounted, jib cranes are an invaluable asset to any maintenance workshop.

Key Advantages of Jib Cranes in Confined Spaces

In environments where space is limited, such as small workshops or maintenance bays, jib cranes offer significant benefits. Their compact design, versatility, and ease of operation make them the ideal solution for material handling in confined spaces. Below are the key advantages of using jib cranes in such environments.

Space Efficiency

Jib cranes are renowned for their ability to maximize space in small or crowded environments. In confined spaces where every inch counts, their compact design makes them an invaluable tool for efficient material handling.

- Perfect for Small, Crowded Workshops or Maintenance Bays: Whether it’s a small workshop, a maintenance bay, or a production line with limited space, jib cranes are designed to fit seamlessly into tight environments. Unlike larger cranes or forklifts that require considerable floor area to operate, jib cranes can be mounted on the floor, ceiling, or walls, making them ideal for areas with limited room for maneuvering. This space-saving design allows workers to operate freely without the clutter or obstacles typically found in congested environments.

- Reaching Overhead Spaces or Tight Corners: Jib cranes can extend their boom to reach overhead spaces or maneuver into tight corners where other equipment cannot fit. This makes them particularly useful in spaces with high ceilings, narrow aisles, or in areas where accessibility is limited. The flexibility to reach overhead or around obstacles is key for maximizing the use of available space in production or maintenance areas.

Versatility and Customization

One of the most attractive features of jib cranes is their versatility and customization options. These cranes can be tailored to meet the specific needs of a workspace, ensuring maximum efficiency and functionality.

- Options for Customization to Fit Specific Space and Lifting Requirements: Jib cranes are highly customizable to fit the precise lifting needs of a space. Depending on the workshop's layout, weight capacities, and the types of materials handled, the crane’s design can be modified. For example, jib cranes can be adjusted in terms of arm length, hoist capacity, and rotation angles to ensure they meet the specific demands of a given application. This level of customization allows businesses to optimize their workflow and increase operational efficiency in limited spaces.

- Rotating Boom for Better Maneuverability in Narrow Aisles or Corners: Many jib cranes come with a rotating boom, which allows them to move loads in various directions. This feature is especially valuable in narrow aisles or tight corners where traditional lifting equipment might struggle. The ability to rotate the boom 180° or even 360° provides excellent maneuverability, allowing the crane to lift and place materials in hard-to-reach areas with ease. This enhances flexibility in confined workspaces and improves operational efficiency.

Ease of Operation

Jib cranes are designed to be user-friendly, requiring minimal training for operators. Their simplicity and versatility make them easy to integrate into production or maintenance workflows without causing disruptions.

- Simple Controls for Operators with Minimal Training: One of the key benefits of jib cranes in confined spaces is their ease of operation. These cranes typically feature simple, intuitive controls that require minimal operator training. Whether controlling the hoist or adjusting the crane's boom, operators can quickly learn how to safely and efficiently operate the crane. This ease of use makes jib cranes suitable for a variety of workers, improving workflow without the need for specialized training.

- Manual, Electric, and Pneumatic Options for Tailored Needs: Jib cranes come in different configurations to meet specific operational needs. Manual jib cranes are perfect for lighter loads and smaller spaces, requiring little to no power source. For heavier lifting, electric or pneumatic-powered jib cranes provide enhanced lifting capabilities with greater speed and control. Depending on the workshop's requirements, businesses can choose the right type of crane, ensuring that they meet both operational and space constraints effectively.

In summary, the key advantages of jib cranes in confined spaces include their exceptional space efficiency, versatile customization options, and ease of operation. These cranes are perfectly suited for small, crowded environments where maximizing space and handling materials efficiently is critical. Their ability to maneuver in tight spaces, combined with simple control systems and various power options, makes jib cranes an invaluable asset in any confined workspace.

Cost-Effectiveness of Jib Cranes for Small-Scale Operations

Industrial jib cranes offer significant cost advantages for small-scale operations. Their affordability, low maintenance needs, and energy-efficient design make them an ideal investment for businesses looking to improve material handling without breaking the budget.

Low Initial Investment

When compared to larger, more complex lifting systems such as overhead cranes or gantry cranes, jib cranes are highly cost-effective in terms of initial investment. Their relatively simple design and compact size make them a budget-friendly option for small-scale operations.

- Affordable Compared to Large-Scale Lifting Systems: Jib cranes are much more affordable upfront, especially for businesses with limited budgets or those that don’t require the heavy-duty capabilities of large-scale lifting systems. Their lower initial cost makes them an attractive option for small workshops, maintenance facilities, and production environments where cost constraints are a consideration. The lower investment in equipment allows businesses to allocate resources to other essential areas, such as staff training or production materials.

Low Maintenance and Operating Costs

In addition to their low purchase price, jib cranes also come with reduced ongoing maintenance and operational costs. Their durable construction and simple design contribute to lower upkeep and longer service life.

- Durable Construction and Low-Maintenance Design: Jib cranes are built with sturdy materials designed to withstand the rigors of everyday use. Unlike more complex systems, jib cranes have fewer moving parts, which means there are fewer components that require regular maintenance or replacement. This durability reduces the frequency and cost of repairs, helping businesses keep operational costs low over time.

- Energy-Efficient Operation: Jib cranes, especially manual or electric models, are designed to be energy-efficient. Manual jib cranes require no power, while electric models consume minimal energy compared to larger cranes. This lower energy usage directly translates into lower operating costs, making them a cost-effective choice for small-scale operations focused on reducing overhead.

Reduced Repair Costs

Another key cost advantage of jib cranes is their robust materials and simple mechanical design, which lead to fewer breakdowns and lower repair expenses.

- Robust Materials and Fewer Mechanical Complexities: Jib cranes are typically constructed with high-quality, durable materials that are built to last. Their simpler mechanical systems mean there are fewer parts to wear out, reducing the likelihood of expensive repairs. In comparison, larger, more complex lifting systems have intricate components that are more prone to malfunction or require costly repairs when they break down.

- Longer Lifespan and Fewer Issues: Because of their simplified design and solid construction, jib cranes generally have a longer operational lifespan with fewer issues. This reliability further drives down costs, as businesses don’t have to worry about frequent downtime or major repairs. The longevity of jib cranes makes them a wise investment for small operations looking to maximize their return on investment.

In conclusion, jib cranes offer a highly cost-effective solution for small-scale operations. Their low initial investment, coupled with low maintenance and operating costs, ensures that businesses can enhance their material handling capabilities without significant financial strain. With their durable construction and energy-efficient operation, jib cranes provide excellent value for businesses looking to optimize efficiency and reduce long-term costs.

Safety Features and Compliance

Safety is a critical consideration in any industrial setting, and jib cranes are equipped with various safety features to ensure secure and efficient operation. These features not only protect workers but also help businesses meet regulatory requirements, ensuring compliance with industrial safety standards.

Built-in Safety Mechanisms

Jib cranes are designed with a variety of built-in safety mechanisms that help prevent accidents and ensure safe operation in busy, high-risk environments.

- Overload Protection: One of the primary safety features of industrial jib cranes is overload protection. This mechanism prevents the crane from lifting loads beyond its rated capacity, reducing the risk of crane failure, load drops, or equipment damage. Overload protection ensures that the crane operates within safe limits, reducing the likelihood of accidents and maintaining the integrity of both the crane and the load being lifted.

- Limit Switches: Limit switches are installed on jib cranes to stop the movement of the crane once it reaches a preset limit. This helps prevent over-travel, avoiding damage to the crane or nearby equipment. Limit switches also provide a safeguard against excessive movement, ensuring that loads are lifted and placed accurately and safely.

- Additional Safety Features: Many jib cranes are equipped with other safety features, such as emergency stop buttons, anti-sway devices, and safety locks on hoists. These additional safety measures help reduce the risk of accidents by providing immediate control over crane movements in the event of an emergency or malfunction.

Ergonomics and Compliance with Safety Standards

In addition to built-in safety mechanisms, jib cranes are designed with operator safety and comfort in mind, enhancing both productivity and overall well-being.

- Enhancing Operator Safety and Comfort: Jib cranes are ergonomically designed to minimize strain on operators during operation. The crane’s intuitive controls and user-friendly design reduce the physical effort required to move loads, promoting worker comfort and reducing the risk of injuries related to lifting or strain. Furthermore, the ability to operate the crane with minimal effort and in confined spaces ensures that operators can work in a safe and comfortable environment, even in challenging positions or awkward spaces.

- Compliance with Industrial Safety Standards and Regulations: Jib cranes are built to comply with a variety of industry-specific safety standards and regulations, such as those set by the Occupational Safety and Health Administration (OSHA), the American National Standards Institute (ANSI), or the European Union’s Machinery Directive. These standards ensure that the crane meets minimum safety requirements regarding design, operation, and maintenance. Compliance with these standards is essential not only for protecting workers but also for avoiding fines, legal issues, and potential work stoppages.

- Ensuring Safe Workplace Practices: Compliance with safety regulations also includes routine inspections, training for operators, and proper maintenance. Many jib cranes include features that simplify maintenance tasks and ensure that the crane remains in good working condition, reducing the risk of mechanical failure or accidents caused by poor upkeep.

In summary, jib cranes are equipped with critical safety features like overload protection, limit switches, and ergonomic designs to enhance worker safety and comfort. Their compliance with industrial safety standards ensures that they meet or exceed regulatory requirements, protecting both the operators and the business. With built-in safety mechanisms and a focus on ergonomic operation, jib cranes provide a secure and efficient lifting solution for various industrial applications.

Conclusion

In conclusion, industrial jib cranes offer numerous advantages for small-scale production and maintenance environments, making them an essential tool for businesses seeking to improve operational efficiency, safety, and space utilization. Their compact design, versatility, and cost-effectiveness make them ideal for confined spaces where larger equipment might not be practical. Additionally, jib cranes are equipped with safety features and ergonomic designs that enhance worker comfort and reduce the risk of injuries.

- Space Efficiency: Jib cranes excel in small or crowded workspaces, offering maximum utilization of available space.

- Versatility and Customization: Their ability to be tailored to specific lifting needs and workspace constraints provides businesses with a flexible solution for a variety of tasks.

- Improved Safety: Built-in safety features like overload protection, limit switches, and ergonomic design ensure a safer working environment for operators.

- Cost-Effectiveness: Jib cranes are affordable to purchase, maintain, and operate, making them a great investment for small-scale operations looking to optimize material handling.

Investing in a compact jib crane offers businesses a reliable and cost-effective way to improve their material handling capabilities in confined spaces. With their space-saving design, flexibility, and safety features, jib cranes help streamline workflows, enhance productivity, and ensure that workers can operate safely and comfortably even in restricted environments. Their ability to lift heavy loads in tight spaces with minimal physical effort makes them invaluable assets for maintenance workshops, small production lines, and other environments where space and safety are top priorities.

If you’re looking to enhance efficiency, safety, and space utilization in your small-scale production or maintenance operations, consider exploring the best jib crane solutions tailored to your needs. Whether you require a mobile, wall-mounted, or customized design, there’s a jib crane that can meet your specific lifting and space requirements. Reach out to a reputable crane supplier today to find the ideal solution for your business and elevate your material handling capabilities.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch