Magnetic Crane System for Bundles Rebars & Rebar Coils Lifting

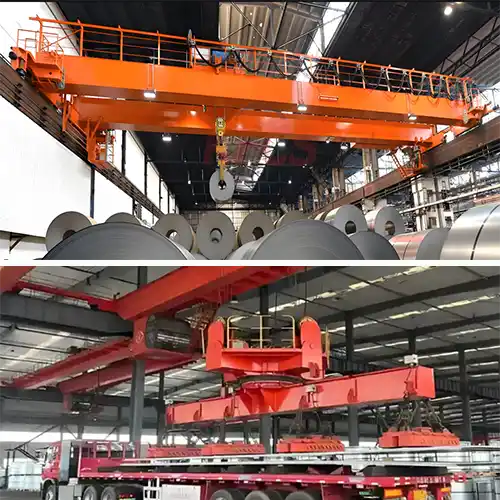

Magnetic overhead crane system for rebar handling. Custom overhead crane & gantry crane with electromagnet & magnet beam for rebar bundles & coils lifting.

Category: Magnetic Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Magnetic Crane System for Bundles Rebars & Rebar Coils Lifting

Rebar Handling Cranes with Magnetic Overhead Cranes & Gantry Crane

As for steel rebar handling, there are types of lifting hoist and crane equipments and rebar lifters available to improve efficiency and safety. Magnetic overhead crane system for rebar handling will improve your production efficiency and safety, save your labor costs and help to take advantages of your warehouse storage space, etc. Custom overhead crane & gantry crane with electromagnet & magnet beam for rebar bundles & coils lifting. Based crane structrues, the rebar handling cranes can be grouped into overhead cranes and gantry cranes, which can be further classified into the following types:

Types of overhead cranes for rebar handling

- Overhead crane with magnetic beam spreader

- Double trolley overhead cranes

- Electric hoist overhead crane

- Open winch overhead crane

- single girder overhead crane

- double girder overhead crane

Types of gantry cranes for steel rebar handling

- Gantry crane with magnetic beam spreader

- Double trolley gantry crane

- Box girder gantry crane

- Truss girder gantry cranes

- L leg gantry crane

top running single girder crane for rebar cage handling

Outdoor overhead crane with double girder design for scrap rebar handling

Outdoor gantry crane double girder designed for rebar storage yard

Indoor use single girder gantry crane for rebar bundles handling

Truss gantry cranes for rebar coils handling

Magnetic cranes for rebar handling

Overhead magnetic cranes are one of the most efficient long and large steel objects handling cranes, which are widley used to handling steel projects such as billets, pipes, profile beams, plates, sheet and rebars, etc. With advanced and efficient magentic lifters and beam spreader, the magnetic overhead crane systems can be used to handle all types of steel rebars of various lengthes. If you have any need of rebar handling cranes, please feel free to contact us.

Electromagnetic overhead cranes is usually an electric overhead crane,equipped with an electromagnet spreader, which is widley used for handling steel or metal products such as, steel plate, pipe, profile steel, steel bar, steel billets, steel coil, or large material in steel mill, shipyard, port yard, etc.

Magnetic gantry cranes & goliath crane for outdoor use such as storage yards, or ports, etc. . In many pipe steel plants or steel mill plants, the gantry cranes are used to handle the pipes, billets rebar from stacking yard to transportation truck.

For different applications, the gantry cranes can be equipped with different rebar lifters and most frequently, the magnet lifters and beam spreaders are used.

Magnetic beam spreader for efficient steel rebar handlings & storage

Electromagnet spreaders are classified into two types: lifting electromagnets and electromagnetic beams. Generally, the following two types of electromagnetic beams are used: non-rotating beams (vertical or parallel to the main girder) and spinning beams (Upper beam or hanging beam). Tailoring supplies you with attachments for any steel product as well as additional capacity based on your needs. Check more on types of magentic lifters for your selection.

magnetic beam overhead crane with upper rotating desgin for rebar handling

Rotatry beam magnetic spreader for long rebar bundles handling

Operation: The lifting electromagnet is integrated with the rebar handling crane after installation, and is controlled by a wireless controller, which is easy to operate;

Precautions

When the lifting electromagnet is used outdoors, some waterproof measures should be taken; when the product uses 380V voltage, it is converted to 220V, please slightly protect the 380V power supply, and do not magnetize for a long time when using it.

- 1. Determine or select the magnetic hanging beam and installation method according to specific requirements.

- 2. Check the output parameters of the supporting power control equipment and cable reel equipment, which should meet the requirements of the electromagnet.

- 3. Connect the cable connector connecting the cable reel and the electromagnet, turn on the power, and conduct a trial run for 0.5-1h on the electromagnet. If there is no abnormal phenomenon, it can be put into normal use.

- 4. When two sets of material handling cranes are used together, the distance between them is half of the length of the material.

- 5. When not in use, do not allow the electromagnet to stay, linger, or store in the high temperature area.

- 6. The allowable voltage error does not exceed ±10%.

- 7. Please do not power on the electromagnet before it is placed on the surface of the object to be sucked stably. It is strictly forbidden to use the electromagnet as a floating hammer.

Special Notes: Due to the different customized specifications of each product, the size and shape of the product are different, and the actual product shall prevail. Our company has many series of lifting electromagnets with different targets. Please refer to the selection guide for comparison and selection. First determine the use function and select different categories of products.

Advantages of magnetic crane for rebar handling

A one-man operation,reduce your labor costs .

Even the storage of exceptionally lengthy rebar bundles can be controlled by one person when using a rebar handling magnet system. You will profit from effective people deployment and a safe workplace if the rebar handling bridge crane and magnet system are set up properly.

Your advantages and benifits

No need to climb over rebar piles, and there is no requirement for employees in the material handling area. Zero risk of injury when handling products or objects with sharp edges. No need for aisles between the stacks. No need for wooden spacers to separate the bundles. Simple system control from the cabin or through remote. No operational helpers are required. Less accidents and higher levels of safety. More space-saving storage. More rapid handling speed. Lower labor costs; a more appealing work environment.

For efficient handling long rebar bundles

- The rebar handling overhead cranes can be designed and manufactured with specific magnet systems to handle all rebar bundles of standard length.

- The extremely narrow design of the spreader beam makes it simpler to pick up small bundles. This makes rebar handling and moving between high heaps of stuff easier.

- A low headroom design makes the building more lightweight, which lowers the dead weight of the spreader beams. The crane system's service life is significantly extended by lower dead weight.

- The magnet suspension incorporates a long travel path. This compensates for any irregularities in the rebar bundles or piles. The first contact magnets are retained in place until all of the magnets are resting on the load.

- The rebar magnet control system enables individual magnet activation. Magnets are positioned and activated one after the other in the instance of a bent rebar bundle. The load can then be placed parallel to the spreader beam and lifted by adjusting the rebar overhead crane.

Magnetic overhead crane system for single bundle of rebar handling

Magentic bridge crane system for 2 bundles of long rebar handling

3 bundels of rebar handling crane with magnetic beam

5 bundles of rebar handling overhead lifting equipment

Application areas of electromagnetic lifting cranes for rebar handling

- Manipulating single rebar bundles, moving layers of rebar bundles, manipulating rebar coils magnetically, e, tc.

- Useful for manufacturing and stock yards.

- Loading and unloading of rebar trucks.

- Rebar movement throughout the plant.

- It is compatible with all types of overhead travelling cranes.

- Magnets capable of handling hot materials up to 600°C are also available.

- Optional battery backup is available.

- Customers can also order spreader beams that are suited for 6/9 or 12 m billets/plates.

rebar bundles

steel rebar coils

Magnetic cranes for handling double and multiple bundles

Two rebar bundles may be handled in one lift thanks to specially formed pole shoes, considerably enhancing the efficiency of steel rebar handling operations. Magnets are positioned across to the spreader beam for even greater handling capability . The breadth of the magnets is determined by the size and quantity of rebar bundles (layer width). This highly effective material handling method is typically employed in steel mills and steel logistics service centers with high stock flow.

Material handling with magnet overhead crane systems broadens the possibilities in warehouse management. Contact us to get your custom design for the particular setting.

Magnetic overhead cranes and gantry cranes for safe transportation of rebar coils

A rebar handling magnet bridge crane system can transport not just long rebar bundles, but also rebar coils of various dimensions. Rebar coils can be stacked horizontally or vertically with a sound basis. However, the steel rebar coils must be rigid in shape, i.e. compactly coiled and tightly clamped. It is no longer required to restrict stack height to that of a man when using an electromagentic magnet overhead crane system.

Coiled rebar handling overhead electromagnetic crane system

Gantry crane system for outdoor rebar coils hanlding, 3 coils handling

4 rebar coil handling by magnetic lifting crane equipment

Vertical rebar coil handling crane

Electromagnetic crane system for steel mills & plants

Steel mill operators must complete significant amounts of material throughput. Multiple steel rebar coils can be transported in a single lift by arranging many magnets on a spreader beam according to individual customer specifications. The rebar coils can be carried parallel to or at right angles to the spreader beam. As a result, the magnet gripper can be optimized for the rebar production line and volume. Using hot rebar handling magnets allows rebar coils to be magnetically transferred from the production line to the warehouse at temperatures of up to 450°C.

Steel distributors / Steel service centers

Individual rebar coils can be handled using a magnetic crane system, which is very handy for steel distributors and steel service centers. Even at lower material throughput levels, the processed overhead cranes also can benefit your factory and workshop in the above mentioned aspects. The highly compact way in which magnet electric crane systems enable material be stored is a critical success factor.

Tips on all types of rebar handling and storage

In the following, the tips on rebar hanlding and storages are presented for your reference. If you need any rebar handling crane systems and lifting devices, please feel free to contact us.

How should black rebar be handled and stored?

- Handling of Rebar: Prevent handling Rebar roughly.Use slings and rigings, magnets, or other custom lifters, etc.

- Storage: If the rebars are maintained outside, they should be covered with polyethylene sheeting or another suitable material.Off the ground.

How should galvanized rebar be handled and stored?

- Rebar handling: The handling of steel rebar should be done gently.Use common handling equipment like slings and riggings, and magnetic spreader, etc.

- Storage : Avoid dealing with or touching uncoated rebars when storing.Stay off the ground and avoid spending a lot of time on surfaces made of wood, which are prone to surface discoloration.

How should epoxy-coated rebar be handled and stored?

- Rebar handling: To reduce sags, use spreader bars or robust backs with several pick-up points.To lessen harm to the coating, use synthetic slings or magnet spreader. Avoid utilizing cables and chains.Avoid being dragged and colliding.

- When shipping, all contact points must to be protected with wood or plastic.Foam should be placed between the bar and the strapping to protect the coating.

- Storage: Off the ground on suitable materials, such as wooden boards or timber cribbing, and it should be kept clear of mud, trash, and other harmful elements.

How should stainless steel rebar be handled and stored?

- Steel Rebar Handling: When strapping, use plastic, stainless steel wire, or synthetic straps or magentic beam spreader. For lifting, use synthetic straps.Avoid utilizing lifting equipment made of carbon steel.Avoid using exposed steel bands and chains; if you must, disconnect them from the rebars to avoid coming into direct touch with ferrous objects.

- Storage:Off the ground on appropriate surfaces. Avoid coming into contact with or underneath any ferrous elements, such as carbon steel rebar.If shipment will inevitably result in contact with ferrous material, it should be placed on top.When storing rebar outside, it should be covered with polyethylene sheeting or another suitable material.

Wrap it up, You can store a lot more material in the same space, which allows you to: Reduce the size of the storage facilities you need or put them to other uses . Save a lot of time thanks to compact storage and shorter overhead crane traveling distances. Material handling using magnetic overhead crane systems opens up new opportunities for you in warehouse management. Contact us today to check how the magnetic rebar handling cranes can make benefit for your business.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch