Orange Peel Grab Gantry Cranes 10 Ton to 40 Ton to Scrap Yards

Orange peel grab gantry cranes, ranging from 10 to 40 tons, efficiently handle various scrap materials in recycling yards.

Category: Steel

url:scrap-handling-grab-gantry-crane

Your Trusted Outdoor Gantry Crane Manufacturer & Supplier

Orange Peel Grab Gantry Cranes 10 Ton to 40 Ton to Scrap Yards

Overview of Scrap Yard Operations

Scrap yards handle a variety of materials, from old vehicles to metal scraps, and the sheer volume can be overwhelming. Gantry cranes are like the unsung heroes of scrap yards. They're versatile and incredibly useful for lifting and moving heavy scrap materials. Imagine having a powerful tool that can navigate around piles of scrap with ease, lifting and placing materials exactly where you need them.

Gantry cranes offer specific benefits that are a game-changer for scrap handling. They improve efficiency by making it quicker to move materials, which can significantly boost your overall productivity. Plus, their ability to handle large and heavy loads reduces manual labor, making your operations safer and more streamlined.

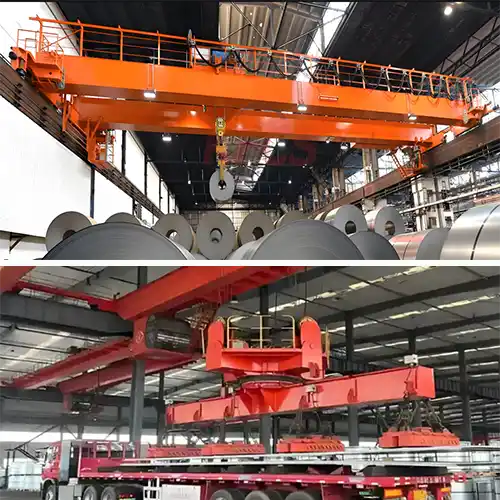

Orange Peel Grab Gantry Cranes

What is an Orange Peel Grab Gantry Crane?An Orange Peel Grab Gantry Crane is an essential tool in scrap yards, specifically designed for the efficient handling of various scrap materials. The name "orange peel" derives from the crane's distinctive grab, which mimics the shape of an orange peel with its multiple, claw-like jaws. This design is highly effective for gripping and moving bulk materials such as metal, plastic, and industrial waste.

Components of an Orange Peel Grab Gantry Crane include:

- Gantry Structure: This is the main framework of the crane, consisting of vertical legs and horizontal beams that support the entire system. It provides stability and allows the crane to traverse along a rail system.

- Crane Trolley: Mounted on the gantry structure, the trolley allows for horizontal movement of the grab. It ensures smooth and controlled motion across the length of the crane.

- Orange Peel Grab: The grabbing mechanism itself, which features multiple jaws or "claws" that can open and close. This grab is designed to efficiently pick up, hold, and release scrap materials. The shape and number of jaws can be customized depending on the type and size of materials being handled.

- Hoisting System: This system is responsible for lifting and lowering the grab. It typically includes a motor, cables or chains, and pulleys, all of which work together to control the vertical movement of the grab.

Mechanism and Operation

The operation of an Orange Peel Grab Gantry Crane is designed to be both efficient and effective. Here's a breakdown of how it works:

- Positioning: The crane's hoist lowers the orange peel grab towards a pile of scrap. The crane trolley allows the grab to be positioned precisely over the desired area.

- Gripping: Once the grab is in the correct position, its jaws close around the scrap material. The design of the grab ensures a firm grip, securing the load effectively.

- Lifting and Moving: After gripping the material, the hoisting system lifts the grab and its load. The crane trolley then moves horizontally to transport the scrap to the designated location.

- Releasing: Once the crane reaches the target area, the grab's jaws open, releasing the material. The crane can then retract, reposition, and repeat the process as needed.

This straightforward mechanism allows for quick and precise handling of scrap, making Orange Peel Grab Gantry Cranes an invaluable asset in managing and processing materials efficiently.

Orange Peel Grab Gantry Cranes for Scrap Yard Handling

Standard Light Duty Orange Peel Grab Gantry Cranes

- Overview: Equipped with a basic orange peel grab for general scrap handling.

- Capacity: 10 to 20 tons.

- Applications: Ideal for mixed scrap, including metal fragments and light machinery parts.

- Use Case: Suited for yards needing versatility without extreme load requirements.

Heavy-Duty Orange Peel Grab Gantry Cranes, Custom Double Girder Gantry Crane

- Overview: Features reinforced structures and high-capacity grabs for heavy or bulky materials.

- Capacity: 20 to 40 tons.

- Applications: Best for large vehicle parts and heavy metal plates.

- Use Case: Designed for demanding environments with significant weight and size challenges.

Compact Gantry Cranes with Orange Peel Grab

- Overview: Tailored for smaller scrap yards, balancing compact design with powerful grabs.

- Capacity: 5 to 10 tons.

- Applications: Effective for small to medium-sized scrap materials.

- Use Case: Ideal for yards with limited space, maximizing efficiency in tight layouts.

Specialized Orange Peel Grab Portable Gantry Cranes

- Overview: Custom-designed for specific scrap types or unique environmental conditions.

- Capacity: Varies, typically 10 to 30 tons based on customization.

- Applications: Handles electronic waste and materials in extreme environments.

- Use Case: Perfect for specialized facilities requiring tailored adaptations.

Choosing the right type of Orange Peel Grab Gantry Crane ensures efficient and safe scrap handling tailored to your yard's operational needs and environmental conditions. Each design offers specific advantages to optimize performance in various settings.

Typical Scrap Yards Requiring Orange Peel Grab Gantry Cranes

Automotive Scrap Yards

Automotive scrap yards specialize in the disposal and recycling of old or damaged vehicles. These yards deal with a range of large and heavy vehicle parts, including engines, transmissions, and body panels. Due to the size and weight of these components, handling and sorting them efficiently is crucial.

Need for Orange Peel Grab Gantry Cranes:

Typical Capacity: 10 to 30 tons.The heavy lifting of large automotive parts like engines and transmissions necessitates robust cranes. High capacity grabs are crucial for efficiently handling bulky, irregular shapes.

Heavy Lifting

Robust Lifting Capabilities:

- High Capacity Grabs: Automotive parts like engines and transmissions are substantial and heavy. Therefore, cranes must be equipped with grabs that can handle these large loads efficiently. The crane should have a high lifting capacity to manage these weights safely and effectively.

- Structural Strength: The gantry crane itself needs to be built with a robust frame and hoisting system to support the heavy loads without risk of failure. This includes using high-strength materials and ensuring proper engineering to handle the stress of lifting and moving bulky components.

Efficiency in Sorting

Effective Handling and Sorting:

- Specialized Grabs: The grabs on these cranes must be designed to handle large, irregularly shaped automotive parts. This involves customizing the grab size and jaw configuration to ensure secure gripping and precise placement of parts.

- Fast Processing: Efficiency is key in automotive scrap yards where quick turnaround times are essential. The crane should be able to swiftly pick up, move, and sort large parts to maintain productivity and reduce operational delays.

Durability

Anti-Corrosion Features:

- Resistant to Harsh Conditions: Automotive scrap yards often deal with exposure to oils, rust, and other automotive fluids that can accelerate corrosion. Therefore, cranes need to be equipped with strong anti-corrosion treatments and coatings to withstand these conditions.

- Maintenance-Friendly Design: Choose cranes designed for easy maintenance and repair, especially in environments where exposure to corrosive substances is common. This can include features that allow for easy cleaning and maintenance of critical components.

Additional Considerations:

Custom Features for Automotive Scrap Yards

Customized Grab Design:

- Adjustable Grabs: Incorporate adjustable grabs that can handle various sizes of automotive parts, from small components to large engine blocks. This flexibility helps in managing diverse types of scrap efficiently.

- Enhanced Maneuverability: Given the cluttered nature of automotive scrap yards, the crane should offer excellent maneuverability to access tight spaces and navigate around other equipment and materials.

Operational Efficiency

Optimized Workflow:

- Integrated Systems: Consider integrating the crane with other systems in the yard, such as sorting lines or conveyor belts, to streamline operations and improve overall efficiency.

- Operator Training: Ensure that crane operators are well-trained in handling automotive parts to maximize safety and efficiency. Proper training helps in operating the crane effectively and minimizing the risk of accidents or damage.

By equipping automotive scrap yards with Orange Peel Grab Gantry Cranes tailored for heavy lifting, efficient sorting, and durability, you can significantly enhance the efficiency and safety of handling large automotive components. These specialized cranes help manage the demanding tasks associated with automotive recycling and disposal, making them an invaluable asset in the industry.

Metal Recycling Facilities

These facilities focus on recycling scrap metal, such as steel and aluminum. Metal recycling involves managing large volumes of scrap, which can vary in size and type, from industrial metal sheets to smaller metal fragments.

Need for Orange Peel Grab Gantry Cranes:

Typical Capacity: 15 to 40 tons.These facilities manage high volumes of scrap metal, requiring cranes capable of quick, efficient handling of various metal sizes. Large capacity grabs facilitate fast processing and sorting.

High Throughput

Efficient Handling:

- Large Capacity Grabs: To keep up with the high volume of scrap metal, the cranes need to be capable of handling large quantities quickly. Grabs should be designed to lift and move multiple loads in a short period, contributing to faster processing and increased throughput.

- High-Speed Operation: The crane's hoisting system should allow for rapid lifting and moving, minimizing downtime and ensuring that the facility can process as much scrap as possible within operational hours.

Versatility

Adaptability to Different Materials:

- Adjustable Grab Configuration: Since metal recycling facilities handle a diverse range of scrap types and sizes, the cranes should have grabs that can be easily adjusted or customized. This versatility allows the crane to handle everything from large metal sheets to small metal fragments efficiently.

- Multi-Material Handling: The crane must be capable of dealing with various types of metals without causing contamination or damage. This means having features that accommodate different metal properties and sizes while maintaining operational efficiency.

Precision Handling

Accurate Sorting:

- Precision Grabs: For effective sorting, the grabs need to be designed for precise handling. This includes the ability to gently pick up and place metal pieces without causing damage, which is vital for maintaining the quality and value of the recycled material.

- Careful Management: Precision in handling also helps in separating different types of metals correctly. This ensures that the recycling process can sort metals into the right categories for further processing or resale, avoiding cross-contamination and improving the overall quality of the recycled product.

Additional Considerations:

Custom Features for Metal Recycling Facilities

Customized Grab Design:

- Multi-Size Grabs: Implement grabs with adjustable or interchangeable jaws to handle varying sizes of metal scrap, from large industrial sheets to small fragments. This flexibility is crucial for adapting to the wide range of materials processed in metal recycling.

- Enhanced Reach and Height: Ensure that the crane offers adjustable reach and height to access all areas of the facility and handle different stack heights or pile sizes effectively.

Operational Efficiency

Streamlined Processes:

- Integration with Sorting Systems: Consider integrating the crane with existing sorting and conveyor systems to create a seamless workflow. This integration can enhance overall efficiency and reduce manual handling.

- Operator Training and Safety: Train operators thoroughly to handle various types of metal scrap and ensure that safety protocols are followed to minimize risks associated with handling heavy and potentially hazardous materials.

By incorporating these features into Orange Peel Grab Gantry Cranes for metal recycling facilities, you can improve efficiency, versatility, and precision in scrap metal handling. This results in a more effective recycling process and a higher quality end product, benefiting both the facility's operations and environmental impact.

Industrial Waste Yards

Description: Industrial waste yards are tasked with managing a wide array of materials, including mixed metals, old machinery parts, and other forms of industrial debris. This type of waste is often irregular in shape and varied in size, presenting unique challenges for handling and processing. Effective management in these environments requires equipment that can adapt to diverse waste types and conditions.

Need for Orange Peel Grab Gantry Cranes:

Typical Capacity: 10 to 25 tons.With diverse and often irregular materials, these cranes need to adapt to different waste types while maintaining structural strength and durability to withstand harsh conditions.

Adaptability

Versatile Grabs:

- Handling Diverse Materials: The crane's grab must be designed to handle a wide variety of scrap types, from small metal fragments to large, bulky components. This adaptability ensures that the crane can efficiently pick up and move different types of industrial waste, regardless of size or shape.

- Customizable Jaws: Grabs with adjustable or interchangeable jaws offer flexibility in managing different materials. This feature allows the crane to handle everything from small, loose scraps to large, heavy machinery parts without requiring multiple types of equipment.

Durability

Robust Construction:

- High-Grade Materials: Given the abrasive nature of industrial waste, the crane must be constructed from high-grade materials that can withstand wear and tear. Steel with enhanced toughness and resistance to abrasion is commonly used.

- Anti-Corrosion Coatings: Protective coatings are essential to combat corrosion caused by exposure to various chemicals, oils, and other harsh substances. These coatings extend the life of the crane and reduce maintenance needs.

Flexibility

Mobility and Maneuverability:

- Easy Movement: The crane should be designed to move smoothly across the yard, which is often cluttered with obstacles and varying waste piles. This requires a gantry system that offers good maneuverability and can navigate tight spaces effectively.

- Adjustable Reach: Features that allow the crane to extend its reach and adjust its height are crucial for accessing different areas of the yard and managing various stack heights. This flexibility helps in efficiently sorting and processing waste materials.

Additional Considerations:

Operational Efficiency

Integration with Waste Management Systems:

- Seamless Workflow: Integrate the crane with existing waste management and sorting systems to create a streamlined workflow. This integration enhances efficiency by minimizing manual handling and ensuring that waste is processed quickly and accurately.

- Efficient Sorting: The crane's grab should be capable of sorting different types of industrial waste effectively. Proper sorting ensures that materials are separated correctly, facilitating easier recycling or disposal and improving overall waste management.

Safety and Maintenance

Safety Features:

- Operator Safety: Incorporate safety features such as sensors and alarms to alert operators of potential hazards. Ensure that operators are trained in safe handling practices and understand the specific challenges associated with industrial waste.

- Regular Maintenance: Develop a maintenance schedule to address wear and tear on the crane. Regular inspections and timely repairs will help maintain the crane's performance and extend its operational life.

By equipping Orange Peel Grab Gantry Cranes with these features, industrial waste yards can effectively manage a diverse range of materials while ensuring durability and operational efficiency. This tailored approach improves the overall waste handling process, contributing to a more efficient and productive yard.

Typical Objects or Loads Handled by Orange Peel Grab Gantry Cranes

Heavy Metal Sheets and Plates

Description: Large, flat metal sheets and plates are prevalent in scrap yards, particularly those focusing on construction, manufacturing, or industrial scrap. These materials, often sourced from decommissioned machinery, construction debris, or manufacturing overruns, are typically made from steel, aluminum, or other heavy metals. Due to their size and weight, they present specific challenges for handling and require specialized equipment to manage efficiently.

Gantry Crane Sheets and Plates Scrap Handling

Typical Weight Range: 10 tons to 40 tons

This specialized gantry crane is designed to efficiently handle heavy metal sheets and plates in scrap yards. Its robust construction and advanced features ensure safe and effective operations, maximizing productivity.

Key Features

- High Load Capacity: Designed to lift loads between 10 tons and 40 tons, accommodating various sheet sizes and weights.

- Customized Orange Peel Grab: Features wide jaws made of high-strength materials for secure gripping of large, flat metal sheets. Reinforced jaws prevent deformation during lifting.

Handling Efficiency

- Gentle Lifting Mechanism: Ensures minimal surface damage to metal sheets during handling.

- Adjustable Jaws: Offers flexibility to accommodate different sizes and thicknesses, enhancing versatility in operations.

Safety Considerations

- Load Monitoring Systems: Keeps track of weight to prevent overload and ensure safe operation.

- Regular Maintenance Checks: Essential for maintaining crane performance and prolonging equipment lifespan.

The customized Orange Peel Grab Gantry Goliath Crane is an ultimate solution for heavy metal sheet handling in scrap yards, combining high load capacity with advanced safety and operational features. This design optimizes efficiency and safety, ensuring effective scrap processing.

Handling Requirements:

Robust Grabs

Strength and Durability:

- Material Strength: The grab used for handling metal sheets and plates needs to be constructed from high-strength, durable materials, such as hardened steel or heavy-duty alloys. This ensures it can support the substantial weight of the metal without deformation or failure.

- Reinforced Jaws: The jaws of the grab should be reinforced to handle the stress of lifting large and heavy sheets. They should be designed to distribute the load evenly to prevent any bending or breaking under the weight.

Design Considerations:

- Wide Jaws: Grabs with wide jaws or multiple tines are beneficial for securely holding large, flat sheets. This design helps in gripping the full surface area and distributing the weight evenly.

- Adjustable Jaws: For added flexibility, consider grabs with adjustable jaws that can accommodate different sizes and thicknesses of metal plates.

Careful Handling

Minimizing Damage:

- Gentle Lifting: When handling metal sheets and plates, it's crucial to lift them gently to avoid damaging their surfaces. Sudden movements or jerks can cause dents, scratches, or other forms of damage, which can affect their recycling value and usability.

- Proper Placement: Ensure that metal sheets are placed carefully on the ground or into storage areas to prevent them from bending or warping. Proper placement also aids in efficient stacking and sorting.

Handling Techniques:

- Balanced Load: Maintain a balanced load during lifting to prevent the sheets from tilting or shifting, which could lead to accidents or damage.

- Use of Slings: In some cases, using lifting slings or pads can help in distributing the load more evenly and reducing the risk of damage.

Operational Considerations

Crane Specifications:

- High Load Capacity: The crane's hoisting system should have a high load capacity to handle the weight of heavy metal sheets and plates safely.

- Precision Control: Equip the crane with precise control mechanisms to ensure accurate placement and handling, reducing the risk of errors and damage.

Safety Features:

- Load Monitoring: Implement load monitoring systems to keep track of the weight being lifted and ensure the crane operates within its rated capacity.

- Inspection and Maintenance: Regularly inspect and maintain the grab and crane to ensure they are in good working condition and capable of handling heavy metal sheets efficiently.

By addressing these handling requirements, you can ensure that your crane and grab system are well-equipped to manage heavy metal sheets and plates effectively. This not only improves operational efficiency but also helps in maintaining the quality and value of the scrap materials.

Bulky Material Handling in Automotive Scrape Yards

Description: In automotive scrap yards, bulky vehicle parts such as car engines, axles, and large castings are common. These components are typically heavy and irregularly shaped, which makes them challenging to handle with standard equipment. The variety in sizes and shapes adds complexity to the sorting and processing tasks, requiring specialized equipment to manage these parts effectively.

Gantry Goliath Crane for Automotive Scrap Yards

The Gantry Goliath Crane is specifically engineered for automotive scrap yards, focusing on the efficient handling of bulky vehicle parts. This crane offers the robust design and operational capabilities necessary for managing heavy loads.

Typical Weight Range: 10 tons to 40 tons

Key Features

- Heavy-Duty Construction: Built to withstand the demands of handling large and irregularly shaped vehicle parts, such as engines, axles, and castings.

- Orange Peel Grab Design: Features multiple claws for a secure grip on bulky components, ensuring safe transport and preventing slippage.

Handling Efficiency

- High Capacity: Supports loads between 10 tons and 40 tons, making it suitable for various automotive scrap materials.

- Precise Control Mechanisms: Enables accurate placement and sorting of vehicle parts, minimizing the risk of damage.

Safety Considerations

- Load Monitoring Systems: Integrated sensors ensure the crane operates within its rated capacity, enhancing safety during operations.

- Regular Maintenance Protocols: Essential for keeping the crane and grab in optimal condition, reducing the risk of breakdowns.

The Gantry Goliath Crane equipped with an Orange Peel Grab is the ideal solution for automotive scrap yards, providing high load capacity and advanced handling capabilities for bulky vehicle parts. Its design promotes operational efficiency and safety, streamlining the scrap processing workflow.

Handling Requirements:

High Capacity Grabs

Strength and Size:

- Heavy-Duty Construction: The grab used for handling bulky vehicle parts must be constructed from robust materials, such as reinforced steel or high-strength alloys, to support the substantial weight of these components. The design should include strong hydraulic or mechanical systems to ensure reliable lifting and maneuvering.

- Large Grabbing Area: Grabs should have a substantial surface area or multiple claws to handle large, irregular shapes securely. This ensures a firm grip on components like engines or castings, preventing slippage and ensuring safe transport.

Design Considerations:

- Reinforced Jaws: The jaws should be reinforced to manage the stress and weight of large vehicle parts without deformation. They should also be equipped with high-friction surfaces or pads to enhance grip and prevent damage.

- Adjustable Claws: To accommodate various shapes and sizes, consider grabs with adjustable claws or multiple gripping points. This flexibility helps in securely handling diverse types of bulky vehicle parts.

Effective Sorting

Precision and Maneuverability:

- High Precision Control: The crane should offer precise control over the grab's movements to accurately place and sort large vehicle parts. This helps in avoiding accidental damage to the parts and ensures efficient sorting.

- Flexible Movement: The crane should have the capability to maneuver in tight or cluttered spaces, as automotive scrap yards often have limited space. Features such as articulated booms or extended reach can help in accessing different areas and managing large parts efficiently.

Operational Techniques:

- Balanced Handling: Ensure that the crane maintains a balanced load during lifting to prevent tipping or swinging, which could cause accidents or damage. This is especially important for handling large, heavy parts.

- Careful Placement: When placing bulky vehicle parts, handle them with care to avoid damage to the components or the surrounding area. Proper placement also aids in effective sorting and processing.

Safety Features

Load Monitoring:

- Weight Sensors: Implement weight sensors and monitoring systems to ensure that the crane operates within its rated capacity and to avoid overloading. This helps in maintaining safety and prolonging the lifespan of the equipment.

- Regular Maintenance: Conduct regular inspections and maintenance of both the crane and the grab to ensure they remain in good working condition. Check for signs of wear or damage that could affect performance and safety.

Custom Adaptations

Tailored Design:

- Custom Grabs: Depending on the specific types of vehicle parts handled, customize the grab design to include features such as larger claws or specialized gripping mechanisms for enhanced handling.

- Enhanced Reach: If the yard layout includes high stacks or tight corners, consider cranes with extended reach or adjustable height capabilities to ensure all areas are accessible.

By addressing these handling requirements, you can ensure that your crane and grab system are well-suited for managing bulky vehicle parts. This optimization enhances operational efficiency, improves safety, and facilitates effective sorting and processing in automotive scrap yards.

Mixed Scrap Yards

Mixed scrap consists of a diverse array of materials including small metal fragments, electronic waste, and other assorted items. This type of scrap is characterized by its variability in size, shape, and composition, which presents unique challenges in handling and processing. The diversity of materials means that the equipment used must be highly adaptable to effectively manage and sort these mixed loads.

Outdoor Gantry Crane with Truss Girder Design for Mixed Scrap Yard

Outdoor Gantry Cranes are essential for handling mixed scrap materials, offering versatility and strength for various load types.

Typical Loads and Weights

- Mixed Scrap: Includes small metal fragments, electronic waste, and assorted items, with weights typically ranging from 1 ton to 20 tons.

- Heavy Items: Larger components may weigh up to 40 tons, depending on the specific scrap materials handled.

Handling Features

- Versatile Grabs: Equipped with adjustable claws or multi-functional grabs to accommodate diverse materials.

- Robust Design: Built to endure outdoor conditions while efficiently managing variable weights and sizes.

The Outdoor Gantry Crane is optimized for mixed scrap yards, effectively handling a range of weights from 1 ton to 40 tons, ensuring efficient and safe operations.

Handling Requirements:

Versatile Grabs

Adaptability and Flexibility:

- Multi-Function Grabs: The grab used for handling mixed scrap must be versatile enough to handle a wide range of materials. This often means incorporating features such as adjustable jaws or multi-claw designs that can adapt to different sizes and shapes of scrap.

- Fine and Coarse Handling: The grab should be capable of picking up both small fragments and larger, irregular pieces. This can be achieved with a design that includes variable jaw widths or interchangeable grabbing tools to accommodate various scrap types.

Design Considerations:

- Adjustable Claws: Grabs with adjustable claws or fingers allow for handling of both small and large items, ensuring a secure grip on diverse materials.

- Enhanced Control: Incorporate precise control mechanisms to enable accurate handling and placement of different scrap types, reducing the risk of damage and improving sorting efficiency.

Efficient Sorting

Effective Processing:

- Sorting Mechanisms: To manage mixed scrap efficiently, the crane should be equipped with sorting mechanisms that can categorize materials as they are handled. This might include features such as multiple compartments or automated sorting systems.

- Operational Efficiency: The crane must operate with speed and precision to minimize downtime and enhance overall productivity. Efficient handling and sorting processes are crucial for maintaining a smooth workflow and maximizing throughput.

Operational Techniques:

- Regular Maintenance: Mixed scrap handling can be abrasive and demanding on equipment. Regular maintenance and inspections are essential to ensure that the grab and crane remain in optimal working condition.

- Effective Placement: Proper placement of materials into designated areas or containers is crucial for efficient recycling and processing. The crane should be able to handle and place mixed scrap accurately to facilitate effective sorting and reduce manual labor.

Safety Features

Load Monitoring:

- Safety Sensors: Implement safety sensors to monitor the weight and type of scrap being handled, helping to avoid overloading and ensuring safe operation. This is particularly important when dealing with mixed scrap, which can vary greatly in weight and density.

- Protective Measures: Equip the crane with protective measures to safeguard against accidental damage to both the equipment and the surrounding environment. This includes features such as collision detection and impact-absorbing components.

Custom Adaptations

Tailored Design:

- Custom Grabs: Depending on the specific types of mixed scrap handled, customize the grab design to include features that enhance versatility. This may involve adding specialized tools or adjusting the grab's configuration to better accommodate the varied materials.

- Flexible Reach and Maneuverability: Ensure the crane has flexible reach and maneuverability to handle mixed scrap in complex or cluttered environments. This helps in accessing different areas and managing materials efficiently.

By understanding the specific requirements for handling mixed scrap, you can customize your Orange Peel Grab Gantry Crane to optimize its performance. Adapting the crane's design and features to meet the diverse needs of mixed scrap processing ensures efficient, effective, and safe material handling in your scrap yard.

Customizing Gantry Cranes for Different Scrap Yard Environments

Material Type Adaptation

Grab Size and Configuration:

- Bulk Metal Parts: For large, heavy metal components, opt for bigger, more robust grabs. These should have reinforced jaws and a wider opening to handle the substantial weight and size.

- Mixed or Smaller Scrap: Use more versatile grabs with adjustable jaws or segmented designs to manage varying scrap types and sizes. These grabs should be capable of efficiently sorting and handling irregular materials.

Customization Tips:

- Modular Grabs: Consider modular grabs that can be adjusted or swapped out based on the scrap being processed. This flexibility can enhance efficiency and adaptability.

- Load Capacity: Ensure that the grab's load capacity aligns with the maximum weight of the materials you handle to prevent operational strain and potential damage.

Environmental Considerations

Anti-Corrosion Measures:

- Coastal Areas: For scrap yards located in coastal regions with high humidity, apply anti-corrosion coatings to protect against rust and degradation. Use materials such as galvanized steel or stainless steel for added durability.

- Extreme Conditions: In environments with extreme temperatures, whether hot or cold, ensure that the crane is equipped with temperature-resistant components. This includes heat-resistant paints and cooling systems to prevent overheating.

Operational Efficiency:

- Temperature Control: Implement features like cooling fans or heat shields to maintain optimal operating conditions. This will help ensure the crane performs reliably even in harsh climates.

Space and Layout Adjustments

Crane Dimensions and Maneuverability:

- Tight Spaces: In yards with limited space, customize the crane to have a compact design with reduced dimensions. This can include a shorter span or a more compact gantry structure to navigate narrow aisles and congested areas.

- Enhanced Mobility: For yards with complex layouts, consider adding features such as improved steering mechanisms or more flexible hoisting systems to increase the crane's maneuverability.

Design Considerations:

- Foldable or Extendable Arms: Use cranes with foldable or extendable arms to adapt to different operational areas. This allows for easy adjustment in tight or cluttered spaces.

- Space-Saving Features: Incorporate design elements like telescoping masts or retractable legs to optimize space usage and enhance operational flexibility.

By tailoring your gantry crane to accommodate these specific environmental and operational factors, you can significantly enhance its efficiency, durability, and effectiveness in handling various types of scrap in different yard settings.

Typical Features for Scrap Yard Gantry Cranes

High Load Capacity

- Hoisting Systems: A high load capacity is essential for handling the large and heavy materials typical in scrap yards. This includes using powerful hoisting systems that can lift substantial weights with ease.

- Durable Grabs: The grabs should be constructed from high-strength materials, designed to withstand the stresses of lifting and moving heavy loads without bending or breaking.

Why It Matters:

- Handling Large Loads: Scrap yards often deal with heavy items like engines, metal sheets, and large machinery parts. A crane with a high load capacity ensures these materials can be moved safely and efficiently.

- Operational Efficiency: Adequate load capacity reduces the number of lifts required and minimizes operational downtime, leading to smoother and faster processing of scrap.

Adjustable Reach and Height

- Extendable Reach: The crane should have the ability to extend its reach to access materials in different areas of the scrap yard. This feature is especially important in yards with large or irregularly shaped layouts.

- Height Adjustments: The ability to adjust the crane's height is crucial for handling materials at various elevations, from ground level to elevated stacks.

Why It Matters:

- Versatility: Adjustable reach and height make the crane more versatile, allowing it to handle a variety of tasks and materials that may be at different heights or distances.

- Access to Hard-to-Reach Areas: These features help the crane navigate tight spaces and reach materials that might otherwise be difficult to access, improving overall efficiency.

Anti-Corrosion Coatings

- Protective Coatings: Anti-corrosion coatings are applied to the crane to prevent rust and deterioration caused by exposure to moisture, chemicals, or harsh weather conditions. Common coatings include galvanization, epoxy paints, and rust-resistant alloys.

- Material Selection: Use of corrosion-resistant materials such as stainless steel or aluminum in the crane's construction further protects against rust and extends the equipment's lifespan.

Why It Matters:

- Longevity: Anti-corrosion treatments significantly extend the life of the crane by protecting it from environmental damage, reducing the frequency of repairs and replacements.

- Reduced Maintenance: Regular maintenance can be minimized with effective coatings, leading to lower operational costs and less downtime.

Why These Features Matter

Efficiency and Productivity

Customized Functionality: Tailoring these features to the specific needs of a scrap yard ensures that the crane operates at peak efficiency. This customization helps to streamline operations, reduce handling time, and increase overall productivity.

Durability and Longevity

Enhanced Resilience: Proper material selection and environmental adaptations make the crane more resilient to the harsh conditions of a scrap yard. This durability translates to a longer service life and reduced maintenance requirements, providing better value over time.

Adaptability

Versatility in Operation: Custom features allow the crane to adapt to various scrap types and conditions. Whether handling large vehicle parts, mixed metal scrap, or different environmental challenges, a well-customized crane remains a versatile tool, enhancing its effectiveness in diverse scenarios.

Incorporating these tailored features into your Orange Peel Grab Gantry Crane ensures optimal performance, making it a critical asset for managing and processing scrap materials efficiently.

Advantages of Orange Peel Grabs

Orange Peel Grabs are renowned for their ability to handle scrap materials with remarkable efficiency. Here's a closer look at the key advantages they offer:

Efficiency in Handling Scrap

One of the standout features of Orange Peel Grabs is their exceptional efficiency. Designed to handle large volumes of material in a single operation, these grabs significantly reduce the time needed to move scrap. The multi-jaw design allows them to grasp substantial quantities of material, which means fewer trips and faster processing times. This improved efficiency directly translates to higher productivity and throughput within a scrap yard.

Versatility and Durability

Orange Peel Grabs are incredibly versatile, capable of managing a wide range of scrap materials—from heavy metals and automotive parts to industrial waste. This versatility makes them a go-to solution for various types of scrap yards.

Moreover, these grabs are built to endure the tough conditions typical of scrap yards. They are constructed from robust materials and designed to withstand significant wear and tear. This durability ensures consistent performance even in demanding environments, where other equipment might falter.

Robust Tools for Streamlined Operations

In summary, Orange Peel Grab Gantry Cranes are more than just heavy-duty equipment; they are key to streamlining scrap handling processes. Their design not only facilitates quick and efficient material movement but also ensures long-term reliability and adaptability. For any scrap yard operation aiming to boost efficiency and handle diverse materials effectively, investing in an Orange Peel Grab Gantry Crane proves to be a valuable decision.

Customizing Gantry Cranes for Your Particular Scrap Yards

Assessing Your Scrap Yard Needs

To ensure your gantry crane delivers optimal performance, start by evaluating the specific needs of your scrap yard. Here's a breakdown of what to consider:

Types of Scrap Materials:

- Identify Your Materials: Determine the types of scrap you handle. Are you dealing with heavy metal sheets, large vehicle parts, or various kinds of industrial waste?

- Handling Requirements: Different materials have different handling requirements. For instance, if you're working with heavy metals, you'll need a crane equipped with a robust grab to handle the weight and size effectively. On the other hand, if your focus is on lighter or mixed waste, a crane with a more versatile grab that can handle a range of material types might be more suitable.

The specific types of scrap materials you manage will guide you in selecting a crane with the right features and capacity to efficiently handle your operational demands.

Size and Volume of Scrap

- Assess the Scrap Size: Evaluate the dimensions and weight of the scrap materials you handle. If your yard deals with massive piles, you'll require a gantry crane with a high lifting capacity and a larger grab to manage these substantial loads efficiently.

- Consider Load Volume: For scrap yards with smaller, more manageable loads, focus on a crane that emphasizes precision and maneuverability. This might involve a crane with a smaller grab and finer control mechanisms to handle the material accurately without overcompensating for unnecessary capacity.

By matching the crane's specifications to the size and volume of your scrap, you ensure that the equipment will operate effectively and efficiently, minimizing downtime and optimizing productivity.

Environmental Conditions and Site Layout

- Environmental Conditions: Assess whether your scrap yard is exposed to harsh weather, such as extreme temperatures or high moisture levels. If so, opt for a crane with enhanced features like anti-corrosion coatings to withstand these conditions and ensure long-term durability.

- Site Layout: Examine the layout of your yard. If it's cluttered with tight spaces and obstacles, choose a crane that offers greater maneuverability and flexibility. A crane with a compact design and precise control can navigate through narrow or congested areas more effectively, improving overall efficiency in your operations.

Tailoring your crane to these environmental and spatial factors will help maintain performance and extend the equipment's lifespan.

By thoroughly assessing these aspects, you can customize your gantry crane to better fit your scrap yard's operational requirements, ensuring optimal performance and longevity.

Custom Design Features

Customizing your gantry crane is about ensuring it fits seamlessly with your specific operational needs. Here's how to approach it:

Crane Capacity and Dimensions

- Crane Capacity: The crane's lifting capacity must align with the maximum load you expect to handle. If you deal with particularly heavy or bulky scrap, opt for a crane with a higher load rating to ensure it can lift and move materials safely and efficiently.

- Crane Dimensions: The dimensions of the crane should be compatible with your site's layout. Measure the available space to ensure the crane fits within the confines of your scrap yard while allowing for necessary movement and operations. This includes accounting for the crane's height, width, and length, ensuring it integrates smoothly with your existing setup.

Grab Size and Configuration

- Grab Size: The grab's dimensions need to match the typical scrap sizes you handle. A larger grab can handle bigger loads, reducing the number of trips required and increasing efficiency. However, it should also be balanced with the crane's capacity to avoid overloading.

- Grab Configuration: Different scrap types may require different grab configurations. For instance, grabs with multiple claws are ideal for bulky and irregular materials, while those with fewer, larger claws might be better for handling uniform or compact scrap. Customize the grab to suit the specific materials and handling requirements of your operation.

Reach and Height Adjustments

- Reach: Ensure that the crane's reach is sufficient to cover all areas of your scrap yard. This includes the ability to extend to all parts of the yard where scrap is stored or needs to be moved. An adjustable reach allows for flexible handling and access to different zones within the site.

- Height Adjustments: The crane should have adjustable height capabilities to accommodate various lifting tasks. This feature is particularly important if you handle materials of different sizes or need to position loads at varying heights. Ensure the crane can adjust its height to reach overhead storage or drop materials into containers or specific areas.

By focusing on these custom design features, you can tailor your gantry crane to enhance efficiency and effectiveness in your scrap yard operations, ensuring it meets all your specific handling needs.

Material and Build Considerations

When customizing your gantry crane, focusing on the materials and build quality is crucial for ensuring durability and longevity. Here's what to consider:

Durability and Material Selection

- Material Choice: Opt for high-grade steel or other robust materials known for their strength and resistance to wear and tear. Scrap yard operations can be harsh, with cranes often exposed to heavy loads and rough handling. Using high-quality materials will help the crane withstand these stresses and extend its service life.

- Structural Integrity: Ensure that all structural components, such as beams, supports, and joints, are designed to handle the maximum load and environmental conditions. Reinforced structures and quality welding will contribute to the crane's overall durability and reliability.

Anti-Corrosion Treatments and Coatings

- Corrosion Protection: Scrap yards often deal with materials that can contribute to rust and corrosion. To combat this, apply anti-corrosion treatments and coatings to the crane. These coatings protect metal surfaces from moisture, chemicals, and other corrosive elements.

- Maintenance: Regularly inspect and maintain the coating to ensure it remains effective. Over time, coatings can wear off or become damaged, so proactive maintenance helps prevent rust and prolongs the crane's lifespan.

By prioritizing these material and build considerations, you ensure that your customized gantry crane not only meets your operational needs but also stands up to the tough conditions of a scrap yard environment. This focus on durability and protection will enhance the crane's efficiency and reduce long-term maintenance costs.

Case Studies and Examples

Successful Customizations

Case Study 1: Large-Scale Scrap Yard Operation

In a bustling large-scale scrap yard, customization was key to managing a high volume of diverse materials. This facility required a gantry crane capable of handling massive loads, including bulky metal sheets and heavy industrial components. The solution was a custom-built gantry crane with an extended reach and enhanced lifting capacity.

The crane featured a robust orange peel grab with extra-large jaws to accommodate the large scrap piles. Additionally, the crane's dimensions were tailored to fit the expansive layout of the yard, ensuring efficient operation across the entire site. The customization included advanced anti-corrosion treatments to withstand the harsh, outdoor environment.

Case Study 2: Compact and Specialized Scrap Handling

In contrast, a smaller scrap yard specializing in electronic waste needed a crane that fit within tighter spaces but was still highly efficient. Here, the customization focused on a compact gantry crane with a smaller, precision-engineered grab. The crane's design was optimized for maneuverability in a confined area, with adjustable reach and height to handle various types of electronic scrap.

The smaller grab was designed with fine-tuned control for delicate handling of sensitive materials. The crane was also fitted with a specialized coating to protect against the chemical residues often found in electronic waste, ensuring both durability and performance in this unique environment.

Lessons Learned and Best Practices

Key Takeaways from Real-World Applications

- Understand Your Unique Needs: Whether you're handling massive metal piles or delicate electronic waste, knowing your specific requirements is crucial. Each scrap yard's needs are different, so customization should be tailored accordingly.

- Prioritize Durability: For large-scale operations, durability and strength are paramount. High-quality materials and anti-corrosion treatments are essential for long-term performance, especially in harsh environments.

- Optimize for Space: In compact or specialized settings, design for space efficiency and maneuverability. Custom dimensions and adjustable features can make a significant difference in operational efficiency.

Tips for Effective Customization

- Consult with Experts: Work closely with crane manufacturers to ensure all your specific needs are met. Their expertise can help you choose the right features and design elements for your operation.

- Consider Future Growth: When customizing, think about potential future needs. Opt for adjustable features and robust designs that can adapt to changing requirements over time.

- Test and Validate: Before finalizing your customization, ensure thorough testing of the crane's features and performance. This helps to identify any issues and ensures that the crane meets all your operational requirements.

By learning from these case studies and applying best practices, you can achieve a customized gantry crane that enhances efficiency, safety, and overall performance in your scrap yard.

Installation and Maintenance

Installation Process

Site Preparation and Crane Assembly

Before installing your gantry crane, proper site preparation is crucial. Start by ensuring the area where the crane will be installed is level and free of obstructions. This includes clearing any debris and checking that the ground can support the crane's weight. Accurate measurements are essential to ensure the crane will fit within your operational space and meet all safety standards.

Once the site is ready, proceed with crane assembly. This typically involves assembling the gantry structure, installing the hoisting system, and attaching the orange peel grab. Make sure each component is correctly aligned and securely fastened. It's often beneficial to have experienced technicians handle the assembly to ensure everything is set up correctly.

Safety Protocols and Inspections

Safety is paramount during installation. Follow all manufacturer guidelines and industry standards to avoid accidents. This includes using appropriate lifting equipment and ensuring that all team members are trained in safety procedures. Perform a thorough inspection of all components before the crane becomes operational. Check for any signs of damage or misalignment, and confirm that all safety features are functioning properly.

Ongoing Maintenance

Regular Maintenance Tasks

Regular maintenance is key to keeping your gantry crane running smoothly. Routine tasks include lubricating moving parts, checking for wear and tear, and inspecting the hoisting system. Regularly clean the crane to remove any debris or contaminants that could affect performance. Scheduled maintenance should follow the manufacturer's recommendations and be conducted by qualified personnel to ensure all parts are in good working order.

Troubleshooting Common Issues

Even with regular maintenance, issues can arise. Common problems might include irregular movements, unusual noises, or operational failures. If you notice any of these issues, start by checking the crane's basic functions, such as power supply and control settings. Look for any signs of damage or malfunction in the grab or hoisting system. Sometimes, issues can be traced back to simple problems like loose bolts or inadequate lubrication.

For more complex issues, consult the crane's service manual or contact a professional technician. Regular troubleshooting and prompt repairs can prevent minor problems from escalating into major failures, keeping your operations running efficiently.

By adhering to these installation and maintenance guidelines, you can ensure that your gantry crane remains in top condition, providing reliable performance and safety for your scrap yard operations.

Conclusion

Customizing your gantry crane for a scrap yard brings significant advantages. Tailored solutions enhance efficiency by streamlining material handling and boosting productivity. With a crane designed to handle the specific types and volumes of scrap you deal with, operations become smoother and faster. Safety is also greatly improved; custom features and proper maintenance reduce the risk of accidents and equipment failures. Overall, a well-designed crane can transform a chaotic scrap yard into a well-oiled machine.

If your scrap yard could benefit from enhanced efficiency and safety, it's time to assess your needs and explore custom crane solutions. Consider the specific challenges you face and consult with experts to design a crane that meets your exact requirements. Investing in a customized gantry crane not only improves your current operations but also prepares you for future advancements. Don't wait—take the step towards a more efficient and safer scrap yard today.

Related Advanced Scrap Handling Crane Solutions for Steel Recycling

gantry crane with electromagnetic chuck for steel scrap handling

Gantry Crane with Electromagnetic Chuck for Steel Scrap Handling

This crane utilizes a powerful electromagnetic chuck specifically designed for lifting and transporting ferrous metal scrap. The electromagnetic feature allows for quick attachment and release, ensuring efficient handling of heavy steel materials.

Ideal for scrap yards, metal recycling facilities, and manufacturing plants, it excels in environments where bulk steel scrap is prevalent. The gantry design provides excellent stability and flexibility in movement, making it suitable for both indoor and outdoor operations.

Its robust structure can handle heavy loads, while the electromagnetic chuck minimizes manual labor and speeds up the loading and unloading process, enhancing overall operational efficiency.

Overhead Crane with Orange Peel Grab for Steel Scrap Handling

This crane is equipped with an orange peel grab, specifically designed for grasping and lifting irregularly shaped steel scrap. The grab's multiple jaws allow it to securely hold various scrap sizes and shapes.

Commonly used in scrap yards and recycling centers, it is perfect for handling mixed steel scrap, including car parts, beams, and sheets. The overhead design maximizes vertical space, making it suitable for high-stacking operations.

The orange peel grab provides a secure grip on heavy loads, reducing the risk of slippage. Additionally, the crane's ability to navigate tight spaces enhances efficiency in busy environments.

Electric Overhead Crane with Magnetic Chucks for Steel Scrap Handling

This crane features electric magnetic chucks that efficiently lift and transport steel scrap using electromagnetic force. The electric system allows for precise control and quick activation of the lifting mechanism.

Perfect for environments with a high volume of ferrous metals, such as steel manufacturing plants and scrap yards, it can easily handle heavy steel sheets, beams, and mixed scrap.

The electric overhead crane offers minimal downtime with its fast operation, while the magnetic chucks simplify the lifting process by eliminating the need for manual attachment and release. This enhances safety and productivity in material handling.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch