Underhung Single Girder Crane with Electric Chain Hoist

Underhung single girder crane for sale. Electric chain hoist underhung crane, with single girder crane design. Check electric chain hoist single girder crane!

Category: Underhung Bridge Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Underhung Single Girder Crane with Electric Chain Hoist

Your Workshop & Warehouse Space

Underhung single girder crane for sale. Electric chain hoist underhung crane, with single girder crane design. Check electric chain hoist single girder crane!

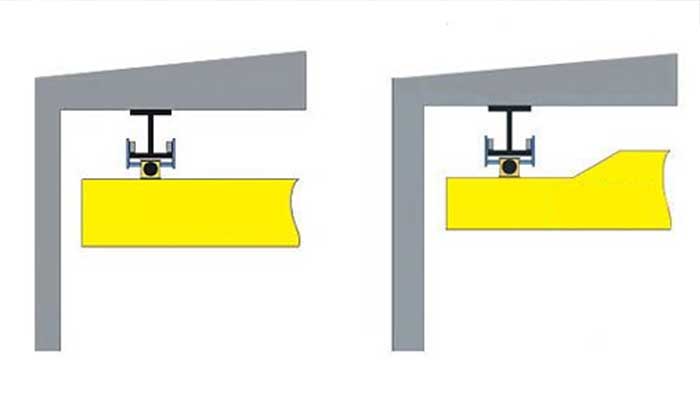

The underhung single girder crane is a light and small rail travelling overhead crane. It can be directly installed on the roof structure of the existing factory building without corbels, so it can save space, and improve your hook height , and use the entire factory space for production. The suspension single girder crane has the characteristics of compact structure, good rigidity, sensitive operation, low noise, etc.

Due to the compact size, the running limit of the underhung single girder crane is small, and heavy objects can be hoisted to a position very close to the wall of the factory building, and the traveling range of the electric chain hoist trolley can exceed the span of the underhung bridge crane through the side cantilever.

The electric chain hoist under running single girder cranes can be used in various industrial use and applications such as warehouses, stockyards and other places, etc.

Ceiling mounted or roof suspension underhung single girder overhead crane with electric chain hoist

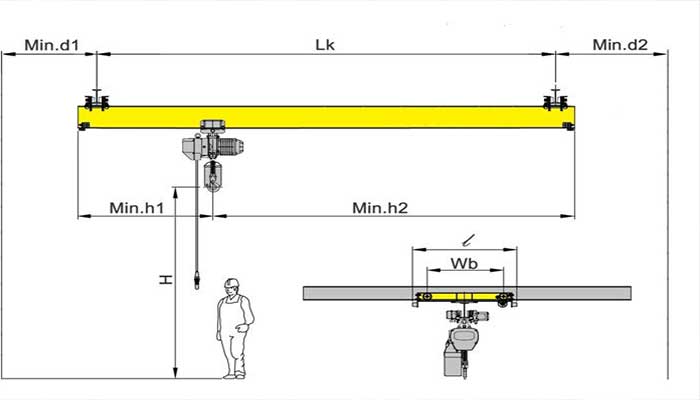

Main specifications of electric chain hoist underhung single girder crane

- Crane Type: Underhung Bridge Crane with Electric Chain Hoist

- Model: HLX

- Rated lifting capacity of single girder underhung crane : 1-10 tons

- span: Customized based on your needs and lifting requirement

- Cantilever length of underhung bridge crane : 2.5

- Operation form: floor control, remote control & pendant control

- Scope of application: the whole industry

- Custom design: Customized underhung single girder crane are available.

Single girder underhung crane system

- Drives, brakes, bumpers, drop stops, and rail sweeps are included with end trucks as standard equipment.

- Crane control panel with a lock-out disconnect switch and an adjustable Electronic Acceleration Control.

- Crane wiring set up in conduit that complies with codes.

- Standard bridge beam assembly with capacity signs and bracing.

- Trolley hoist comes with a control pendant for the operator.

- documentation that covers installation and assembly.

- Instructions, a manual for the crane operator, and owner's manuals.

- Paint for touch-ups.

- One-year guarantee.

Structures of underhung overhead crane with low headroom girder design and camber design

Starndard features

- Bolted assembly for a simple installation process.

- Minimal welding required.

- The majority of wiring connections are plug-in or factory fitted.

- Rail sweeps.

- Drop halts.

- Rubber bumpers.

Option features

- Radio remote controls with two speeds or variable frequency control.

- Moveable pendants.

- A variety of hoist configurations and options.

- Runway electrification.

- Plug and Play connections.

Applications of underhung single girder crane

- Equipment Assembly

- Die Handling

- Production

- Loading and Unloading

- Metal Grinding Cells

- Maintenance

- Suitable to run on I-beams, W-flanged beams and patented track runways

3 ton underhung single girder crane with electric chain hoist for steel structured workshops and warehouses

3 ton underhung single girder crane with electric chain hoist for steel structured workshops and warehouses

2 ton underhung single girder crane with low headroom electric chain hoist for conceret structured workshops and warehouse

1 ton electric chain hoist underhung crane with free standing crane design

Advantages of electric chain hoist underhung single girder crane

- Reasonable main beam structure - Rigid I-beam or welded box girder designed by computer optimization is used as the main beam, and the load is evenly distributed.

- Compact end beam design - The optimized design of the end beam of single girder underhung chain hoist is suitable for various types of factory building structures, the limit size of the hook is small, and the heavy objects can be quickly lifted to a position very close to the wall of the factory building.

- Full use of workshop and warehouse space - By using the outrigger cantilever, the travelling range of the electric chain hoist trolley can exceed the span of the undehrung crane, so that the workshop space can be fully utilized.

- Economical use - The main parts are produced in a standardized manner, with stable quality and good versatility, and avoid the problems of less maintenance parts and high costs in the later period.

- Efficient Service Guarantee - We not only provide you with pre-sales consultation and program design for free, but also have an after-sales team ready to serve you at any time, so that you can truly enjoy it.

Features of underhung single girder cranes

- The end beam is driven by hot-rolled and double-sided crane wheels to ensure smooth travelling and stable overhead crane operation.

- Simple and lightweight structure, high space utilization.

- Three-in-one motor, compact structure, smooth start, low noise.

- Rigid I-beam for optimized load distribution.

- The single girder undehrung bridge cranes can be used in specific areas of the workshop.

- The limit size of the hook is small, and the load can be quickly lifted to a position very close to the wall of the factory building.

- The use of outriggers allows the trolley to travel beyond the under running overhead crane span.

Get your customized underhung single girder crane design and price

Based on the local area, adopting international advanced lifting technology, we will continue to pursue and provide customers with comprehensive solutions for material lifting and handling projects with high performance and high quality.

Main parameters needed to get specific crane price

- Crane capacity: ___ ton

- Crane lifting height:___m

- Crane span: ____m

- Crane travelling: ____m

A full range of material handling cranes such as cantilever cranes, KBK combined cranes, bridge cranes, suspension cranes, gantry cranes, electric hoists, crane drive motors, and crane accessories are provided for your applications. They are widely used in equipment manufacturing, paper making, energy and electricity, automobile and ship, metal processing, aerospace and other fields, etc.

We have advanced production equipment, complete testing methods, and a very experienced and design team. While saving customers' plant infrastructure investment, improving production efficiency, reducing energy consumption, and reducing maintenance, our experienced engineers and manufacturing people pay more attention to customers' requirements and needs, and continuously improving customer satisfaction. If you have any need or any problem about the under hung electric chain hoist crane, or other types of overhead crane, please feel free to contact us.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch