Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Free Standing Bridge Crane & Overhead Crane

with Top running & Underhung Crane Designs

Free standing bridge crane, with top running & underhung crane designs. Types of free standing bridge crane for sale. 2 ton, 5 ton freestanding bridge cranes

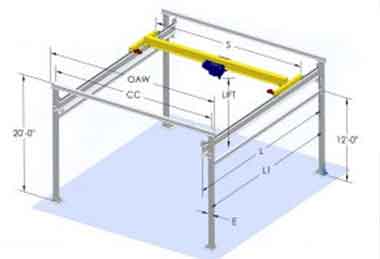

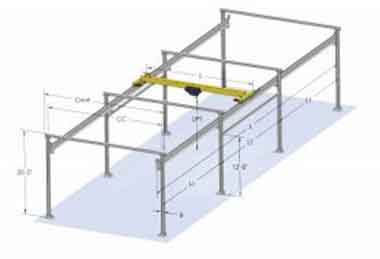

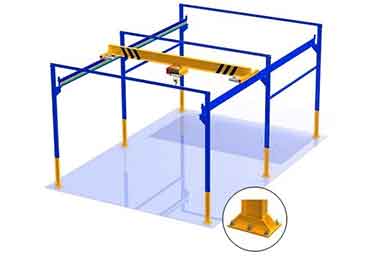

A free-standing bridge crane system is an efficient, economical modular crane system that is simple to install, dismantle, relocate, expand, or change production layouts. It is advantageous when used in concrete facilities and leased buildings, outdoors, or in any other structure not specifically designed for overhead cranes. There is no need for field welding because runway beam connections are bolted down for structural rigidity.

Our free-standing bridge cranes are designed and built with structural steel columns that form a unique frame design, eliminating the need for A-frame legs, X-bracing, or tie-offs to a building or structure. Furthermore, because there are no crane loads imposed into the building structure, less facility production cost is required when the free standing bridge crane system is adopted.

All freestanding crane systems are engineered to meet rugged seismic design requirements with a durable and reliable crane structure, which will meet or exceed your national regulations and application requirements.

Free-standing bridge cranes that can lift up to 10 tons for single girder designs and 50 tons for double girder designs are available. These bridge cranes are preengineered and fully stocked for quick turnaround and low cost. On request, free standing overhead cranes with capacities up to 50 tons are available for larger spans, heights, and capacities. All Free-Standing Bridge Cranes come with a one-year limited warranty against faults in material and workmanship if properly installed and maintained.

In circumstances where installing a general use overhead crane would be difficult or impractical, the free standing overhead crane is the ideal solution. The freestanding cranes function well in pre-cast concrete structures because the runways are typically installed above the floor without footers. The freestanding cranes is advantageous when used in a leased building because it can be easily disassembled and moved because all connections are bolted rather than welded. When headroom is at a premium, the free standing cranes' low headroom design maximizes lift.

Freestanding Bridge Crane 2 ton for Sale Cyprus - Featured Crane Project

- Main bridge crane configuration: single girder overhead crane with free standing structure

- Main specifications: 2 ton capacity, 6 m span, lifting height 7.9 m

- Crane control: remote control + pendent control

- Application:outdoor use

- Project location: Cyprus

- Note: Special tailored freestanding overhead cranes are available. Please feel free to contact us by leaving a message below.

Key features and benefits of freestanding crane systems:

- Capacities from 2 to 10 tons, up to 40 ton

- Low headroom design

- Easily moved and relocated

- Great for buildings or facility, which are not originally designed for supporting the bridge cranes.

Each free standing crane system includes:

- Free standing steel structure.

- Standard radio controls for handheld devices or pendant controls.

- Hoist trolley and bridge with end trucks controlled by an inverter.

- Runway lengths range between 20 and 120 feet.

- Runway electrification.

- Instructions for building a bridge and assembling a crane, as well as a maintenance manual.

Modular Free Standing Bridge Crane Cells are available in runway lengths of 20, 25 and 30 feet. Multiple cells can be combined for long runways; existing systems can be retrofitted with additional cells.

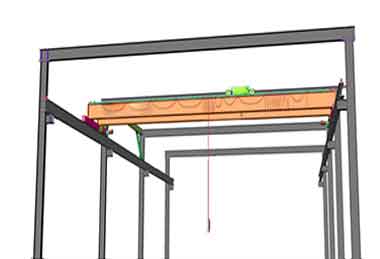

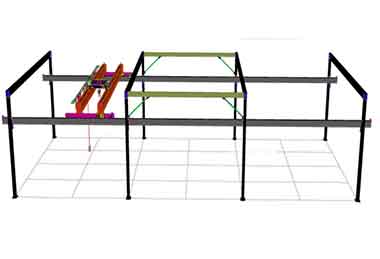

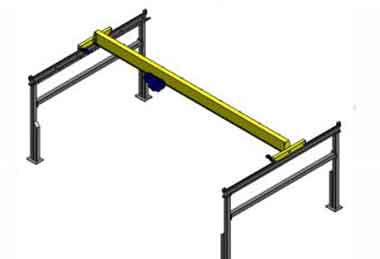

Top Running Freestanding Bridge Crane

Semi-free standing overhead crane , top running crane system

High capacity free standing overhead crane system

Freestanding overhead crane, double girder design

Freestanding bridge crane, with double beam design

Double girder top running free standing overhed crane

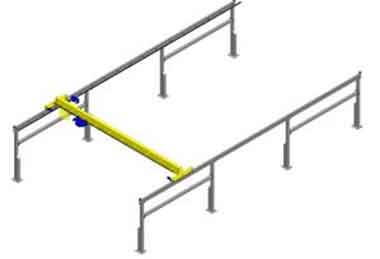

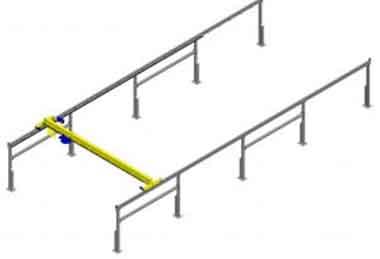

Underhung Freestanding Bridge Crane

- Underhung free standing overhead crane structures are designed with capacities ranging from 2 to 10 tons. Customized single girder freestanding bridge cranes are available with capacity of 15 tons.

- For ease of installation, all connections are bolted. Footings are not required for capacities up to 5 tons.

- Bolted connections allow for simple relocation.

Ideal for buildings that were not originally designed for overhead cranes.

Undehrung free standing overhead crane system

Underhung overhead crane with freestanding crane design

Underhung freestanding overhead crane

Features and benefits of free standing bridge crane

- The free standing bridge cranes are similar to a workstation crane, but intended to transport heavier loads.

- The bridge cranes are installable in any reinforced concrete floor

- Custom configurations are available, as well as pre-engineered modular designs that can be moved and expanded as needs change.

Applications of the freestanding overhead cranes

- Facilities lacking the necessary infrastructure for a traditional overhead bridge crane.

- Leased buildings and operations with frequently changing workflows.

- Capacity ranges from 2 to 10 tons, 15 tons, 20 tons, 30 tons, 40 tons, and 50 tons.

Single girder top running freestanding birdge crane with electric chain hoist

End carriages of freestanding bridge crane

Steel structures for top running overhead cranes

Freestanding bridge cranes are suitable for the following applications:

- Precast Concrete Buildings - Because freestanding cranes are often installed without footers, there is no need to dig through and damage existing floors.

- Leased Buildings - The connections of the freestanding bridge crane are bolted for easy disassembly and relocation. If you anticipate moving in the future, you can easily relocate the overhead crane.

- Buildings not specifically designed for overhead cranes.

- The freestanding structure can withstand loads that your building's steel cannot. Furthermore, the low overhead design allows it to fit into locations where headroom would otherwise be an issue.

Types of free standing overhead crane configurations

Freestanding cranes configurations for 1 cell

Freestanding overhead cranes configurations for 2 cell

Freestanding bridge cranes configurations for 3 cell

Freestanding bridge cranes configurations for 3 cell

Freestanding cranes configurations for 1 cell

Freestanding bridge configurations for 2 cell

Freestanding overhead crane system configurations for 3 cell

Freestanding bridge crane system configurations for 3 cell

Why to use freestanding bridge crane

- The freestanding overhead crane can be installed successfully in a pre-cast concrete setting.

- Bolting, not welding, is required for all connections.

- The bridge cranes can be disassembled when not in use.

- The best choice for freestanding crane insurance protection.

Why is the free standing bridge crane the better choice as an overhead crane?

Simple to disassemble. The freestanding bridge crane is bolted rather than welded, making it simple to remove when not in use. It's ideal for a temporary environment because it doesn't require extensive dismantling after use.

- It is simple to relocate to a new project site. When you have multiple project sites that require the use of a bridge crane on-site, these bridge cranes are the best option to use as a business. The ease with which it can be dismantled allows it to be moved from one location to another at a low cost.

- Indoor use . A free-standing bridge crane is the ideal tool when you need a crane in a rented building or while working in a temporary location. You won't have to worry about additional removal costs.

- A free-standing bridge crane is extendable to any length to provide an immediate need for the overhead travelling crane use without adding additional weight to the project when a large area up to 40 feet or more needs to be covered.

- Simple to set up.A free standing bridge crane does need much time to assemble or installed since they are bolt connected. time-consuming tool.

- Highly flexible. The benefit of a free standing bridge crane is that it is flexible and more productive. It is appropriate for applications in manufacturing, engineering, and construction industries.the Free standing bridge crane can be used in applications, such as Process Equipment Maintenance, Parts Assembly, Palletizing loads, Warehouse loading docks, Machining, Truck Service Centers, Injection Molding , etc.

The best way to get work done without worrying about space restrictions is with a free standing bridge crane in a workplace where dealing with the movement of large objects is a necessary part of daily operations. Since the bridge on the crane rides on top of the structure for a secure hook height, it is safe and reliable for handling loads and poses less risk. It guarantees maximum work throughput and promises fewer workplace injuries.

Comparison of types of freestanding cranes

Freestanding overhead crane

Freestanding gantry cranes -types of freestanding gantry cranes

Your Trusted Overhead Travelling Crane Manufacturer & Supplier