Your Trusted Goliath Gantry Craneand Portal Crane Manufacturer & Supplier

10 Ton Gantry Crane for Sale, Heavy Duty Goliath Gantry & Portal Crane

Heavy-duty single girder & double girder goliath gantry cranes & portal cranes for indoor & outdoor use. Get custom 10 ton gantry crane specifications!

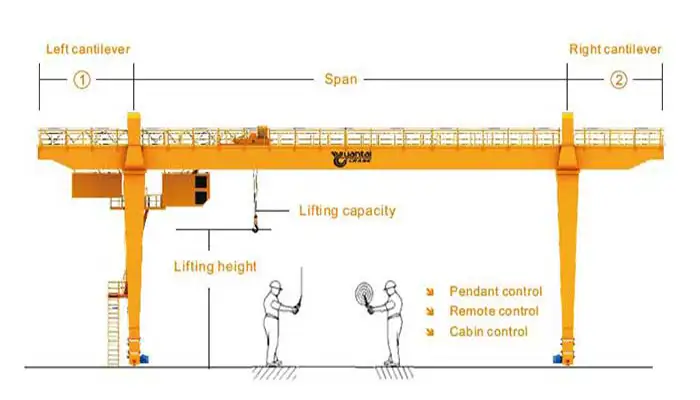

10 ton gantry cranes, commonly referred to as 10 ton goliath cranes or 10 ton portal cranes, are widely used in various industries for heavy lifting tasks. These cranes are designed for both indoor and outdoor applications, making them versatile for different work environments. This guide will outline the types of 10 ton gantry cranes available, key specifications, pricing information, and practical tips for obtaining custom specifications tailored to your needs.

Overview of 10 Ton Gantry Cranes Design Options

10 ton gantry cranes, including 10 ton goliath gantry cranes and 10 ton portal cranes, are crucial for efficient load movement in various industries. Their design consists of two vertical legs supporting a horizontal beam, enabling them to lift and transport heavy materials with ease.

Types of 10 Ton Gantry Cranes for Sale

10 Ton Single Girder Gantry Crane for Sale

- Design: Features a single horizontal girder supported by two vertical legs.

- Applications: Best suited for lighter-duty tasks, such as loading and unloading in warehouses.

Advantages:

- Cost-effective and easier to install.

- Greater headroom, enhancing operator visibility.

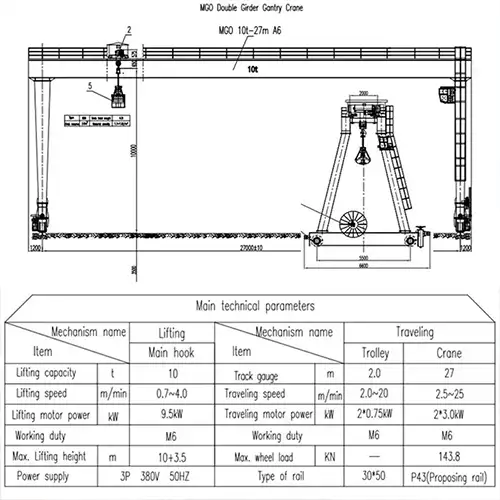

10 Ton Double Girder Gantry Crane for Sale:

- Design: Consists of two parallel girders, providing additional stability.

- Applications: Ideal for heavy-duty lifting in industrial settings, such as manufacturing and construction.

Advantages:

- Higher load capacity and increased rigidity.

- Suitable for demanding operations requiring safety and reliability.

10 Ton Semi Gantry Crane for Sale

- Design: Combines one fixed leg and one track-mounted leg, allowing for flexible movement.

- Applications: Perfect for workshops with limited headroom or space constraints.

Advantages:

- Versatile design that adapts to various layouts.

- Maximizes usable workspace while efficiently transporting loads.

Compariong with light Duty 10 Ton Portable Gantry Crane

- Design: Utilizes lightweight materials with a portable a frame gantry crane for enhanced stability.

- Applications: Suitable for various environments, especially workshops and small construction sites.

Advantages:

- Excellent maneuverability and ease of relocation.

- Combines functionality with the ability to lift significant loads.

Each type of 10 ton gantry crane is designed to meet specific lifting requirements, allowing operators to choose the best option for their operational needs. Whether for light-duty tasks or heavy industrial lifting, these cranes provide the versatility and efficiency necessary for effective material handling.

Key Features of 10 Ton Gantry Cranes

Heavy-Duty Construction

10 ton gantry cranes are constructed using high-quality materials such as structural steel or aluminum, ensuring robust performance in demanding environments. The heavy-duty design includes:

- Reinforced Frame: The frame is engineered to provide maximum strength and stability, minimizing deflection and ensuring safety during lifting operations.

- Durable Coatings: Many cranes come with protective coatings that resist corrosion, especially important for outdoor or harsh environments. These coatings enhance the crane's lifespan and reduce maintenance costs.

- Load-Bearing Components: Critical components like the hoist, wheels, and supports are designed to handle heavy loads consistently, providing reliability during operations.

Versatility for Indoor and Outdoor Use

The design of 10 ton gantry cranes allows them to function effectively in a variety of settings, including:

- Construction Sites: Their mobility and lifting capabilities make them ideal for lifting materials and equipment at construction sites, where conditions can vary.

- Warehouses: These cranes facilitate the efficient loading and unloading of goods, optimizing warehouse operations and improving productivity.

- Manufacturing Facilities: In manufacturing, gantry cranes are often used for assembly lines, material handling, and transporting heavy components, enhancing workflow efficiency.

- Adaptability to Environments: Whether exposed to outdoor elements or confined indoor spaces, these cranes are designed to perform consistently, with features such as weather-resistant materials and adjustable height settings.

Customization Options

10 ton gantry crane specifications can be tailored to meet unique operational requirements, allowing for a more efficient workflow. Customization options include:

- Height Adjustability: The lifting height can be adjusted to accommodate different load sizes and workspace limitations, ensuring optimal operation.

- Span Width: The distance between the legs can be customized to fit specific spaces, allowing the crane to operate in tighter areas without compromising performance.

- Lifting Mechanisms: Users can choose between different hoisting systems, such as electric or manual hoists, depending on the type of loads and operational preferences. Additional features like variable speed controls can enhance precision during lifting.

- Accessories and Add-Ons: Cranes can be equipped with various attachments, such as spreader bars or lifting beams, to handle different load types safely. Custom control systems can also be integrated for improved usability.

These key features make 10 ton gantry cranes a valuable asset for various industries, providing the strength, versatility, and adaptability needed for efficient material handling.

Pricing of 10 Ton Gantry Cranes

The pricing of a 10 ton gantry crane can vary significantly based on various factors. Here's a detailed breakdown to help buyers understand what influences these costs.

Portable Gantry Crane

- Specifications: Lifting capacity of 0.25 to 10 tons, lifting height from 1 to 9 meters, and spans ranging from 2 to 12 meters.

- Price Range: Approximately $7,000 to $65,000 for a 10 ton portable gantry crane, depending on additional features and specifications.

- Benefits: Mobility and flexibility to be moved to different locations make it ideal for handling materials under 10 tons in various environments.

Single Girder Gantry Crane

- Specifications: Lifting capacity from 1 to 20 tons, lifting height between 6 to 30 meters, and spans of 7.5 to 35 meters.

- Price Range: For a 10 ton single girder gantry crane, prices typically range from $4,000 to $45,000.

- Benefits: This design is economical and widely used in workshops, storage facilities, and outdoor environments, equipped with a dual-speed electric hoist.

Double Girder Gantry Crane

- Specifications: Capable of lifting between 5 and 500 tons, with heights from 6 to 30 meters and spans of 7.5 to 35 meters.

- Price Range: A 10 ton double girder gantry crane generally falls between $6,500 and $79,000.

- Benefits: These cranes offer robust performance for heavy-duty applications, making them suitable for open warehouses and rail handling.

Customization Options: How to Custom Gantry Crane for Your Needs

Customization can significantly influence the overall cost:

- Height and Span Adjustability: Cranes with adjustable heights or spans often come at a premium, reflecting their enhanced versatility.

- Lifting Mechanisms: Options for electric or hydraulic hoists can affect pricing, with electric systems typically costing more due to their efficiency and ease of use.

- Special Features: Additional safety systems, remote control capabilities, and enhanced technology for load monitoring can further increase costs.

Manufacturer and Brand Reputation

The manufacturer's reputation can impact pricing:

- Established Brands: Well-known manufacturers often charge more for their cranes due to quality assurance, durability, and strong after-sales support.

- Emerging Brands: New or lesser-known brands may offer competitive pricing, but buyers should assess the quality and reliability of their products.

Average Price Summary

- Portable Gantry Crane: $7,000 to $65,000 for a 10 ton model.

- Single Girder Gantry Crane: $4,000 to $45,000 for a 10 ton model.

- Double Girder Gantry Crane: $6,500 to $79,000 for a 10 ton model.

Prices may fluctuate with market conditions and may not include shipping or installation costs. It is advisable to contact suppliers for accurate, up-to-date pricing tailored to specific needs.

When considering the purchase of a 10 ton gantry crane, potential buyers should evaluate their specific operational requirements and budget constraints. Understanding the various factors affecting pricing will help in making an informed decision that aligns with both immediate and long-term needs.

Price Comparison: 10 Ton vs. 5 Ton Gantry Cranes

The pricing and specifications of 10 ton and 5 ton gantry cranes is vital for making informed purchasing decisions. Below, we detail the various types of gantry cranes, their specifications, and associated price ranges to guide your selection process.

Here's a comparison table showcasing the prices of 10 ton and 5 ton gantry cranes across different types, highlighting their specifications and pricing differences:

| Crane Type | Lifting Capacity | Lifting Height (m) | Span (m) | Power Supply (V) | Price Range (USD) |

|---|---|---|---|---|---|

| Portable Gantry Crane | 5 ton | 1 - 9 | 2 - 12 | 220-480/3/50 | $4,500 - $46,000 |

| 10 ton | 1 - 9 | 2 - 12 | 220-480/3/50 | $7,000 - $65,000 | |

| Single Girder Gantry Crane | 5 ton | 6 - 30 | 7.5 - 31.5 | 220-480/3/50 | $3,000 - $41,500 |

| 10 ton | 6 - 30 | 7.5 - 31.5 | 220-480/3/50 | $4,000 - $45,000 | |

| Double Girder Gantry Crane | 5 ton | 6 - 30 | 7.5 - 31.5 | 220-480/3/50 | $5,800 - $72,000 |

| 10 ton | 6 - 30 | 7.5 - 31.5 | 220-480/3/50 | $6,500 - $79,000 |

Portable Gantry Cranes are known for their mobility and flexibility, making them ideal for diverse environments. The 5 ton portable gantry crane typically features a lifting height ranging from 1 to 9 meters and a span of 2 to 12 meters, with a power supply of 220-480/3/50. Prices for this model can vary from $4,500 to $46,000. In contrast, the 10 ton portable gantry crane shares similar specifications in terms of height and span but is priced higher, ranging from $7,000 to $65,000.

When it comes to Single Girder Gantry Cranes, the 5 ton model is designed for lifting heights of 6 to 30 meters and spans of 7.5 to 31.5 meters, also operating on a 220-480/3/50 power supply. The price for this crane generally falls between $3,000 and $41,500. The 10 ton single girder gantry crane offers the same lifting height and span specifications but is priced from $4,000 to $45,000, reflecting its greater lifting capacity.

For those needing higher stability and load capacity, Double Girder Gantry Cranes are an excellent option. The 5 ton model also has a lifting height of 6 to 30 meters and a span of 7.5 to 31.5 meters, with prices ranging from $5,800 to $72,000. The 10 ton double girder gantry crane maintains similar height and span specifications, priced higher between $6,500 and $79,000 due to its enhanced structural design and lifting capabilities.

Key Insights

- Price Difference: There is a notable price difference between 10 ton and 5 ton gantry cranes, typically ranging from $1,000 to $25,000 based on crane type and specifications.

- Flexibility: Portable gantry cranes provide excellent flexibility for various applications, with the 10 ton model being more versatile but at a higher cost.

- Economic Considerations: While single girder cranes offer a more economical option, double girder cranes provide additional stability and capacity, which is reflected in their higher price point.

This detailed overview serves as a valuable resource for understanding the pricing and specifications of 10 ton gantry cranes, helping you to make the best choice for your material handling needs.

Obtaining Custom 10 Ton Gantry Crane Specifications

Importance of Custom Specifications

Custom specifications are critical for ensuring that a 10 ton gantry crane is tailored to fit the unique operational needs of your facility. These specifications can significantly impact:

- Performance: Tailored designs enhance the crane's efficiency in handling specific loads and tasks, leading to improved productivity.

- Safety: Proper specifications help mitigate risks associated with lifting operations, ensuring compliance with safety standards and regulations.

- Space Optimization: Customized dimensions ensure that the crane fits seamlessly into your workspace, avoiding potential obstructions and maximizing usable area.

Steps to Obtain Custom Specifications for a 10 Ton Gantry Crane

Getting custom specifications for a 10 ton gantry crane involves a series of structured steps to ensure the crane meets your operational needs effectively. Here's a comprehensive guide to facilitate the process.

Contact Manufacturers or Suppliers: Start by identifying reputable crane manufacturers or suppliers known for their custom solutions. You can accomplish this through online research, seeking industry referrals, or attending trade shows. Once you have a list of potential suppliers, prepare a detailed list of your operational requirements, including lifting capacity, preferred height, and span. This will help facilitate effective communication during discussions.

Discuss Your Needs: Schedule a meeting or consultation with the selected manufacturer or supplier to discuss your specific needs. Clearly articulate the intended application of the crane—whether it will be used in a warehouse, on a construction site, or for outdoor activities. Provide details about the types of materials to be lifted, their weights, and any environmental factors that may affect operation, such as temperature and humidity.

Request Quotes and Specifications:

After discussing your requirements, request detailed specifications for the 10 ton gantry crane from the manufacturer. Ensure that the specifications include crucial information such as lifting height and span to match your workspace constraints. Ask about the materials and construction quality to confirm their suitability for your operational environment. Additionally, inquire about safety features, including overload protection, emergency stop buttons, and any relevant safety certifications.

Tips for Successful Customization

Customizing your 10 ton gantry crane requires careful consideration and attention to detail. Here are some essential tips to ensure your crane meets your operational needs while prioritizing safety and efficiency.

Be Specific About Your Load Types and Weights

When discussing your requirements with manufacturers, provide comprehensive details about the loads you intend to lift. This includes:

- Load Characteristics: Specify the weight, dimensions, and shape of the materials. For example, if you are lifting bulky items or fragile components, this information will help in designing a suitable lifting mechanism.

- Actual Load Scenarios: If possible, share examples or case studies of typical loads. This context enables manufacturers to tailor the crane's features to your unique handling needs, ensuring optimal performance.

Buying Guide and Tips of 10 Ton Portal Cranes

Purchasing a 10 ton gantry crane is a significant investment that can greatly enhance your material handling capabilities. To ensure you choose the right crane for your needs, follow this comprehensive buying guide.

Assessing Your Needs

Before making a purchase, it's crucial to evaluate your specific requirements. Consider the following factors:

- Type of Loads: Determine the types of loads you will be lifting. Are they bulky, heavy items, or smaller, lighter components? This will influence the type of gantry crane you need, as different models are designed for varying load characteristics.

- Weight and Dimensions: Analyze the maximum weight and dimensions of the loads. Knowing the heaviest load you will lift helps in selecting a crane with adequate capacity.

- Available Space: Measure the installation area to understand the available space for both the crane and its operation. Consider vertical height restrictions, overhead obstacles, and the width of the workspace to ensure seamless integration.

- Operational Environment: Consider whether the crane will be used indoors or outdoors. Different environments may require specific features, such as weatherproofing for outdoor use.

Comparing Different Models of Goliath Gantry Cranes

The distinctions between various models of 10 ton gantry cranes is essential for making an informed decision. Here are key comparisons:

Single vs. Double Girder Gantry Cranes:

- Single Girder Gantry Crane: Typically lighter and more economical, this model is ideal for lighter-duty applications. Its simpler design makes installation easier and often results in lower initial costs.

- Double Girder Gantry Crane: Offers greater stability and lifting capacity, making it suitable for heavy-duty operations. The double girder design allows for a wider span and increased lifting height, making it ideal for larger, heavier loads.

Full Gantry Crane vs. Semi Goliath Cranes:

- Full Gantry Crane: Utilizes two legs that support the bridge girder completely, allowing for maximum versatility and stability.

- Semi Gantry Crane: Features one leg on the ground and another that travels on a rail. This design is advantageous in facilities with height restrictions or limited space, providing flexibility in positioning.

Rail Traveling vs. Roller Traveling Portable Gantry Cranes:

- Rail Traveling Gantry Crane: Operates on fixed rails, allowing for smooth movement over long distances. This type is often used in outdoor settings and large warehouses.

- Roller Traveling Portable Gantry Crane: Mobile and flexible, this type can be moved easily from one location to another. It's suitable for lighter loads and various environments, making it a versatile option for many operations.

single girder 10 ton gantry crane

10 ton portable gantry crane

Checking Gantry Crane Manufacturer Reputation

Choosing a reputable manufacturer is critical for ensuring quality and reliability. Here are some steps to follow:

- Research Experience: Look for manufacturers with a solid track record in producing gantry cranes. Established companies often have refined designs and proven reliability.

- Customer Reviews: Read reviews and testimonials from previous customers to gauge their satisfaction with the product and service. Positive feedback can indicate a manufacturer's commitment to quality.

- Industry Certifications: Check for industry certifications that the manufacturer holds, such as ISO standards. These certifications often reflect adherence to safety and quality protocols.

- After-Sales Support: Investigate the level of support provided after the sale, including warranty coverage and availability of replacement parts. A manufacturer that offers robust support can save you time and money in the long run.

Installation and Maintenance of Gantry Cranes

The installation and maintenance requirements is vital for ensuring the crane operates efficiently over its lifespan:

- Installation Requirements: Discuss installation options with the manufacturer. Some models may require specialized tools or skills for setup, while others can be installed easily with standard equipment.

- Maintenance Support: Inquire about maintenance services offered by the manufacturer. Regular maintenance is essential for keeping the crane in optimal working condition and preventing costly downtime.

- Maintenance Schedule: Request a recommended maintenance schedule that outlines necessary inspections and servicing tasks. Following this schedule will help extend the life of your crane and maintain safety.

- Operator Training: Ensure that the manufacturer provides training for your operators on how to use and maintain the crane properly. Well-trained operators are crucial for safe and effective crane operation.

Investing in a 10 ton gantry crane can significantly enhance your material handling efficiency across various settings. By carefully assessing your needs, comparing different models, checking the manufacturer's reputation, and understanding installation and maintenance considerations, you can make an informed decision that best suits your operational requirements. This thoughtful approach will not only ensure that you select the right crane but also maximize your investment in material handling solutions.

Your Trusted Goliath Crane & Portal Crane and Manufacturer & Supplier