Clamshell Buckets Gantry Crane 10 Ton for Sugarcane Ash Handling

10 ton double girder gantry crane with clamshell grab bucket in Thailand for sugarcane ash handling. Check 10 ton gantry crane case to get your design.

| Crane type | Double girder gantry crane with clamshell grab bucket |

| Crane capacity | 10 ton |

| Crane span | 27 meters |

| Lifting height | 10 m |

| Below hook device | clamshell grab bucket |

| Object handling | sugercane ash |

Category: 10 Ton Gantry Crane

Your Trusted Goliath Gantry Crane and Portal Crane Manufacturer & Supplier

Clamshell Buckets Gantry Crane 10 Ton for Sugarcane Ash Handling

10 ton double girder gantry crane with clamshell grab bucket in Thailand for sugarcane ash handling. Check 10 ton gantry crane case to get your design.

Clamshell BucketspGantry Crane 10 Ton for pSugarcane Ash Handling

10 Ton Double Girder Gantry Crane with Clamshell Grab Bucket in Thailand for Optimizing Sugarcane Ash Handling. Check 10 ton gantry crane case study to get your cost-effective solution.

Handling sugarcane ash presents several challenges that can impact both productivity and safety. Sugarcane ash, a byproduct of the sugar manufacturing process, can be bulky and heavy, requiring effective management to prevent operational delays. The material's composition can also lead to dust and particulate matter, creating hazardous working conditions if not handled properly. Additionally, outdoor environments can introduce variables such as weather, which further complicate handling operations.

Efficient crane systems play a vital role in overcoming these challenges. In outdoor applications, cranes must be robust, reliable, and capable of handling significant loads while maintaining safety standards. An effective crane solution can streamline the loading and unloading processes, minimize downtime, and enhance overall operational efficiency. By automating material handling tasks, cranes reduce manual labor and the risk of injuries, making them essential in industries dealing with heavy materials like sugarcane ash.

This case study focuses on the implementation of a 10-ton double girder gantry crane equipped with a clamshell grab bucket specifically designed for sugarcane ash handling in Thailand. By examining this project, we will explore how this crane system addresses the unique challenges of outdoor operations, enhances material handling efficiency, and contributes to a safer work environment. Through this detailed analysis, we aim to highlight the benefits of investing in advanced crane technology for similar industrial applications.

10 ton gantry crane with grab bucket for sugercane handling in Thailand

Project Overview

The project is situated in Thailand, a country with a thriving sugarcane industry that generates substantial quantities of sugarcane ash as a byproduct. This project aims to enhance the efficiency and safety of handling sugarcane ash at a processing facility, which is crucial for maintaining smooth operations and meeting production targets.

The primary purpose of installing the 10-ton double girder gantry crane is to streamline the loading and unloading of sugarcane ash. Previously, manual handling methods were labor-intensive and time-consuming, leading to operational bottlenecks and increased safety risks for workers. By integrating a modern crane system, the facility seeks to automate these processes, allowing for quicker, safer, and more efficient movement of materials.

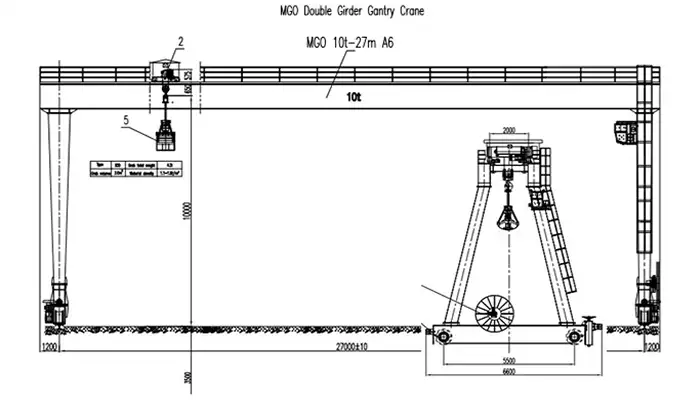

The specific outdoor application involves using the crane to lift and transport sugarcane ash from storage areas to loading trucks for disposal or further processing. The crane operates in a designated outdoor zone, where its capabilities can be fully utilized. With a span of 27 meters and a lifting height of 10 meters, the crane is ideally suited for the facility's layout, enabling it to reach necessary locations without obstruction. The clamshell grab bucket, as a below-hook device, allows for effective gripping and handling of the bulk material, minimizing spillage and improving overall handling efficiency. This setup not only enhances productivity but also helps maintain a cleaner and safer work environment.

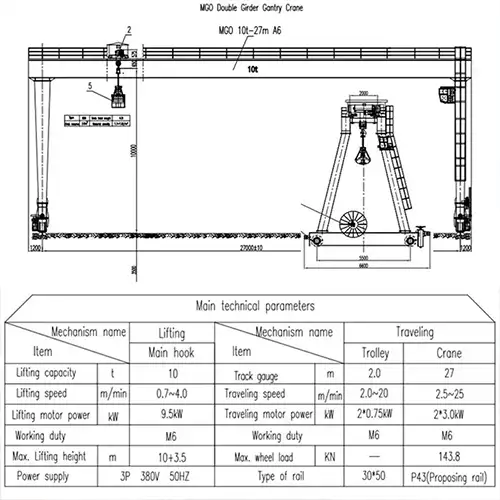

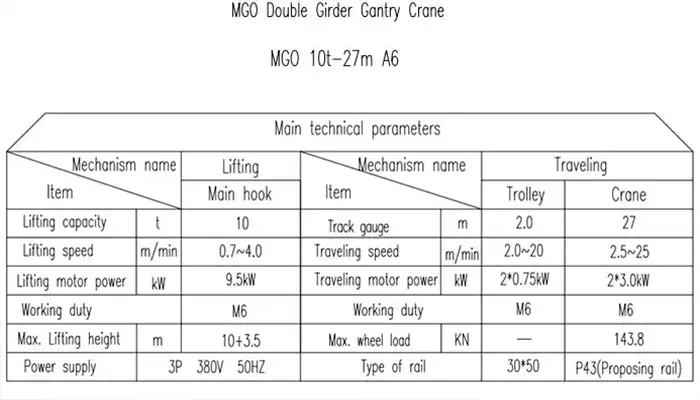

Ash Handling Crane Solution: Confirmed Crane Specifications

- Crane Type: Double Girder Gantry Crane The double girder design provides enhanced stability and strength, making it ideal for handling heavy materials like sugarcane ash. This structure allows for smooth movement across its span, reducing wear and tear on components.

- Capacity: 10 Tons With a lifting capacity of 10 tons, this crane can efficiently manage substantial loads of sugarcane ash, ensuring that operations run smoothly without the risk of overload.

- Span: 27 Meters The 27-meter span enables the crane to cover a large area, allowing for flexible operation in outdoor settings. This wide reach minimizes the need for multiple lifting points, streamlining the handling process.

- Lifting Height: 10 Meters The crane's lifting height of 10 meters is designed to facilitate the transfer of ash into storage containers or trucks, optimizing the workflow and reducing the risk of spills during loading.

- Below Hook Device: Clamshell Grab Bucket The clamshell grab bucket is specifically designed for bulk material handling. Its efficient design allows for quick and secure loading and unloading of sugarcane ash, enhancing the overall efficiency of the operation while minimizing material loss.

10 ton goliath gantry crane with double girder specification

Clamshell Grab Bucket Functionality

Design and Operation of the Clamshell Grab Bucket The clamshell grab bucket features a two-part design with hinged jaws that open and close to grasp materials. This mechanism is actuated by hydraulic cylinders, allowing for precise control during operation. When the bucket descends, its jaws can be opened to scoop up sugarcane ash, and as it lifts, the jaws close securely around the load. The design ensures that even loose or granular materials are contained without spilling, making it ideal for handling ash in various outdoor conditions.

The clamshell bucket is also typically equipped with a robust, reinforced structure to withstand the wear and tear associated with handling abrasive materials like ash. Its versatility allows it to adapt to different lifting requirements, whether it's scooping, transferring, or dumping loads.

Advantages of Using a Clamshell for Sugarcane Ash Handling Using a clamshell grab bucket for sugarcane ash offers several key advantages. First, its ability to efficiently scoop and release material minimizes loading and unloading times, significantly improving overall operational efficiency. The design reduces the risk of spillage, which can be a common issue when handling loose materials, thereby minimizing waste and maintaining a cleaner work environment.

Additionally, the clamshell's hydraulic operation allows for smooth, controlled movements, reducing the risk of accidents during loading. This is particularly important in outdoor applications where environmental factors can impact stability and safety. The clamshell's versatility also means it can be used for various types of bulk materials, providing flexibility in operations.

Efficiency in Load Handling and Material Transfer The clamshell grab bucket excels in load handling, capable of lifting heavy loads quickly and securely. Its design allows for optimal load distribution, ensuring that the crane maintains stability during operation. This efficiency translates to faster cycle times—loading, transporting, and unloading can be completed with minimal downtime.

In terms of material transfer, the clamshell bucket ensures precise placement of sugarcane ash into designated areas, such as storage bins or trucks. Its ability to open fully allows for complete unloading, reducing the chances of leftover material in the bucket. This efficiency in material handling not only enhances productivity but also contributes to safer working conditions by minimizing manual intervention and reducing the potential for accidents associated with traditional handling methods.

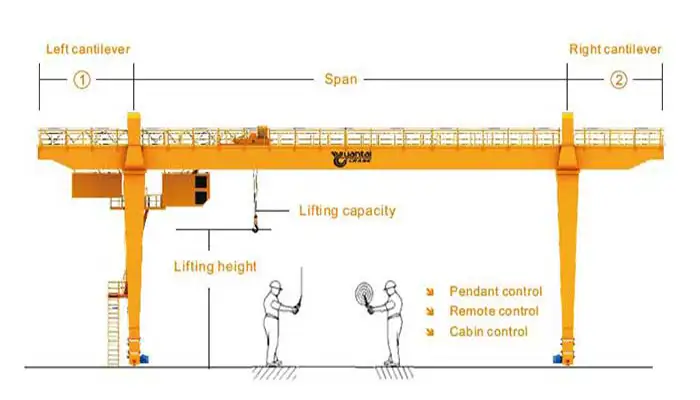

Overall Design Features of 10-Ton Gantry Crane (Double Girder, European Style)

The 10-ton double girder gantry crane embodies several design features that enhance its functionality and efficiency. Its robust construction provides exceptional stability and strength, allowing it to handle heavy loads with ease. The European style emphasizes a compact and streamlined design, which reduces the overall footprint while maximizing lifting height and span. This design is not only aesthetically pleasing but also enhances maneuverability within confined spaces.

The crane typically includes advanced safety features, such as overload protection systems and limit switches to prevent over-travel. Additionally, it may be equipped with variable frequency drives (VFDs) for smooth acceleration and deceleration, improving operational efficiency and reducing wear on components. The use of high-quality materials ensures durability and resistance to environmental factors.

Special Design Features for Outdoor Gantry Crane Application

For outdoor applications, the gantry crane is specifically designed to withstand varying weather conditions and environmental stresses. Key features include:

- Corrosion-Resistant Coatings: The crane is often treated with protective coatings to prevent rust and degradation due to exposure to moisture and UV rays.

- Weatherproof Electrical Components: Electrical systems are designed to be weatherproof, ensuring reliable operation even in rain or extreme temperatures.

- Enhanced Stability: Features such as wider bases or adjustable legs may be included to improve stability on uneven terrain.

- Wind Bracing: Additional structural reinforcements may be integrated to withstand high winds, ensuring safe operation during adverse weather.

Special Design Features for Sugarcane Ash Handling

When tailored for sugarcane ash handling, the gantry crane incorporates specific design elements to enhance its effectiveness:

- Customized Clamshell Grab Bucket: The crane is equipped with a specialized clamshell bucket designed to efficiently handle the unique properties of sugarcane ash, allowing for secure scooping and unloading.

- Optimized Lifting Mechanism: The lifting mechanism is calibrated to handle the specific weight and density of sugarcane ash, ensuring smooth operation without overloading.

- Dust Control Features: To mitigate dust emissions during operation, the crane may include enclosures or water spray systems that help manage airborne particles.

- Flexible Reach: The crane's span and lifting height are optimized to access various storage locations, ensuring efficient transfer and placement of sugarcane ash in outdoor settings.

These design features collectively enhance the performance and reliability of the gantry crane, making it well-suited for both outdoor environments and the specific requirements of sugarcane ash handling.

Productions of Main Parts and Components of a 10 Ton Gantry Crane

The key components of a 10-ton gantry crane is essential for effective operation and maintenance. Each part plays a crucial role in the overall functionality and safety of the crane.

electrical box of 10 ton goliath gantry crane with double girder design

The girders are the horizontal beams that form the main structure of the crane. They support and distribute the load evenly across the entire system. Legs are the vertical supports extending from the girders to the ground, providing necessary stability and structural integrity.

Wheels enable movement along the rails, allowing the crane to traverse the workspace. The hoisting mechanism is responsible for lifting and lowering loads, consisting of an electric hoist, drum, and lifting cable or chain. This system delivers the power needed for efficient load handling.

The grab bucket serves as a below-the-hook attachment for bulk material handling, facilitating precise loading and transfer of materials such as ash. Operators manage crane functions through a control system, which may include pendant controls, remote systems, and programmable logic controllers (PLCs), ensuring safe and accurate operation.

To enhance stability and prevent lateral movement during operation, bracing and supports are integrated into the crane's design. The power supply system includes electrical components like cables, transformers, and power distribution units, supplying the necessary energy for both hoisting and movement.

Safety is a top priority, and various safety features are implemented, including emergency stop buttons, overload protection, and limit switches to protect operators and equipment from accidents. Lastly, the track system comprises the rails on which the crane wheels travel, providing a defined path for smooth movement.

Each component of a 10-ton gantry crane contributes to its overall functionality and safety. Familiarity with these parts and their respective roles is crucial for ensuring efficient operation and maintenance, ultimately enhancing the crane's reliability in various industrial applications.

10-Ton Gantry Crane Installation, Commissioning, and Operation

Installation The installation of a 10-ton gantry crane is a critical process that ensures safe and efficient operation in handling materials like sugarcane ash. It involves several key steps:

- Site Preparation: The installation site must be assessed for stability and accessibility. A suitable foundation is prepared to support the crane's weight, complying with local regulations and safety standards.

- Delivery and Assembly: Crane components, including girders, legs, hoist, and clamshell grab bucket, are delivered to the site. Assembly begins with erecting the main structure, where the girders are bolted or welded to the vertical supports to ensure proper alignment and stability.

- Installation of Systems: The lifting mechanism and electrical systems are installed, including wiring for controls and safety features. Care is taken to ensure that all components are securely fastened and calibrated for optimal performance.

- Final Adjustments and Inspections: Final adjustments are made to align all moving parts, followed by a comprehensive inspection of the crane system to identify any potential issues and ensure compliance with safety standards.

Commissioning Commissioning is the testing phase that confirms the crane operates correctly:

- Initial Testing: A series of functional tests are conducted, including hoisting, lowering, and lateral movement across the span. The clamshell grab bucket is also tested for proper functionality, ensuring it can lift and securely release loads.

- Safety System Checks: All safety features, such as overload protection and limit switches, are verified for operational effectiveness. Emergency stop systems are checked to ensure they are in place and functional.

- Operational Training: Personnel are trained on crane operation and safety protocols, focusing on load management and emergency procedures to promote safe use.

Operation Operating the 10-ton gantry crane requires strict adherence to established protocols:

- Pre-Operation Inspection: Operators conduct daily inspections to check for signs of wear or malfunction. They confirm that all controls and safety features are operational before use.

- Loading and Unloading: Proper techniques for using the clamshell grab bucket are followed, ensuring it is positioned correctly over the load before lifting. Operators monitor weight limits to prevent overloading.

- Maneuvering the Crane: Smooth and controlled movements are essential when lifting, lowering, and moving loads to maintain stability and prevent accidents. Effective communication with ground personnel is crucial to coordinate movements safely.

- Post-Operation Procedures: After operations, the crane is secured, and a brief post-operation inspection is performed to identify any issues that may have arisen during use. Operators document any maintenance needs or safety concerns for follow-up.

By following these guidelines for installation, commissioning, and operation, the 10-ton gantry crane can efficiently and safely handle materials like sugarcane ash, contributing to overall operational success.

Performance Analysis

Efficiency Metrics (Loading Time, Handling Speed) The performance of the 10-ton gantry crane can be measured through various efficiency metrics. Loading time refers to the duration it takes to scoop up sugarcane ash using the clamshell grab bucket. Typically, this process can be completed in a matter of minutes, significantly faster than manual loading methods. The handling speed, which encompasses the time taken to lift, transport, and unload the material, is also notably improved. With the crane's ability to move loads quickly and smoothly, the overall cycle time for operations is greatly reduced, allowing for more frequent and efficient handling of materials.

Comparison with Traditional Handling Methods When compared to traditional handling methods, such as manual labor or using less advanced equipment, the gantry crane demonstrates a substantial improvement in efficiency. Traditional methods often involve more labor-intensive processes, leading to longer loading and unloading times. Moreover, the risk of spills and accidents is higher when relying on manual handling. In contrast, the clamshell grab bucket provides a controlled and secure way to handle sugarcane ash, reducing waste and enhancing safety. This shift from manual to mechanized handling not only streamlines operations but also lowers the physical strain on workers.

Impact on Productivity and Cost-Effectiveness The implementation of the gantry crane has a significant positive impact on productivity and cost-effectiveness. With reduced loading times and enhanced handling speed, the crane allows for increased throughput, enabling the facility to process more sugarcane ash within the same timeframe. This increase in operational capacity translates to higher productivity levels, contributing to overall business growth.

Additionally, the cost-effectiveness of using the gantry crane becomes apparent through decreased labor costs and reduced material waste. The efficiency gained through mechanization minimizes the need for extensive labor resources and lowers the risk of costly accidents or spills. Over time, the initial investment in the crane is offset by these operational savings, making it a financially sound decision for sugarcane ash handling operations.

In summary, the performance analysis highlights the efficiency, productivity, and cost-effectiveness of using the 10-ton gantry crane, demonstrating its superiority over traditional handling methods and reinforcing its value in outdoor applications.

Challenges and Solutions

Identifying Operational Challenges in Outdoor Settings Operating a 10-ton gantry crane in outdoor environments presents several challenges. Weather conditions such as high winds, rain, and extreme temperatures can affect stability and operational efficiency. Additionally, uneven ground or soft soil may pose risks to the crane's foundation, potentially leading to tipping or instability. Dust and debris from sugarcane ash handling can also interfere with mechanical components, impacting performance and safety.

Solutions Implemented to Mitigate Risks To address these challenges, several solutions were implemented:

- Weatherproofing Measures: The crane and its electrical systems were designed with weatherproof materials to withstand harsh environmental conditions. Regular maintenance checks ensure that all protective measures remain effective.

- Stabilization Techniques: To counteract ground instability, the crane was equipped with adjustable legs and wider bases for improved support on uneven terrain. This design enhances stability, reducing the risk of tipping.

- Dust Control Systems: Implementing dust control measures, such as water spray systems, helped minimize airborne particles during operations, protecting both equipment and personnel while maintaining a cleaner work environment.

Lessons Learned from the Project Several valuable lessons emerged from the project:

- Importance of Site Assessment: Thorough site evaluations before installation proved crucial for identifying potential challenges and planning appropriate solutions. Understanding ground conditions and environmental factors can significantly impact crane performance.

- Regular Maintenance is Essential: Continuous maintenance and inspections are vital for ensuring the crane operates safely and efficiently. Early identification of wear and tear can prevent more significant issues down the line.

- Training and Communication: Emphasizing the importance of personnel training and clear communication among operators and ground staff proved to be critical. Well-trained operators are better equipped to handle unexpected situations, enhancing overall safety and efficiency.

In summary, while outdoor operations present unique challenges, the proactive solutions and lessons learned from this project underscore the effectiveness of the 10-ton gantry crane in handling sugarcane ash, ensuring safe and productive operations in various conditions.

Conclusion: Customized Gantry Crane For Your Needs

The implementation of the 10-ton double girder gantry crane with a clamshell grab bucket for sugarcane ash handling has demonstrated significant improvements in efficiency, safety, and productivity. Key findings include reduced loading and handling times compared to traditional methods, leading to increased operational throughput. The crane's design and operational protocols effectively addressed challenges associated with outdoor environments, ensuring reliable performance despite adverse weather conditions.

Future Recommendations for Similar Projects For future projects involving outdoor crane operations, several recommendations can enhance success:

- Thorough Site Assessments: Conduct comprehensive evaluations of the installation site to identify potential challenges and inform design decisions.

- Integrated Safety Measures: Implement advanced safety systems and regular training programs for personnel to promote safe practices and minimize risks.

- Regular Maintenance Protocols: Establish a routine maintenance schedule to monitor and address wear and tear, ensuring the crane operates at optimal efficiency throughout its lifespan.

Importance of Investing in Robust Crane Systems for Outdoor Applications Investing in robust crane systems is essential for outdoor applications, as these systems are designed to withstand environmental challenges while maximizing operational efficiency. A well-designed crane not only enhances productivity but also significantly reduces labor costs and the risks associated with manual handling. Ultimately, investing in high-quality crane systems is a strategic decision that can lead to long-term operational success and a competitive edge in the industry.

Further Reading : 10 Ton Gantry Crane Design Options

When selecting a gantry crane for handling materials like ash, several design options are available, each tailored to specific operational needs. Here's an overview of the three primary types of gantry cranes suitable for a 10-ton capacity:

Single Girder Gantry Cranes

Overview: Single girder gantry cranes consist of a single horizontal beam supported by two vertical legs. This design is often more compact and lightweight than its double girder counterpart.

Advantages:

- Cost-Effective: Generally less expensive to manufacture and install, making it a budget-friendly option.

- Space-Saving: Requires less headroom and floor space, ideal for facilities with limited vertical clearance.

- Simplicity in Design: Fewer components mean easier maintenance and quicker repairs.

Applications: Single girder gantry cranes are suitable for light to medium-duty applications, including light assembly, warehousing, and material handling in smaller spaces.

Double Girder Gantry Cranes

Overview: Double girder gantry cranes feature two horizontal beams (girders) that provide enhanced stability and load capacity. This design allows for greater lifting heights and spans.

Advantages:

- Increased Capacity: Better suited for heavy loads and longer spans, ideal for applications requiring high lifting capacities.

- Higher Lifting Heights: The configuration allows for increased hook height, beneficial for handling taller materials or machinery.

- Improved Stability: The dual girder design offers enhanced stability during operation, reducing sway and improving precision.

Applications: Double girder gantry cranes are commonly used in heavy-duty applications, such as steel mills, large warehouses, and manufacturing facilities where high capacity and durability are essential.

Semi Gantry Cranes

Overview: Semi gantry cranes combine features of both overhead and gantry cranes, typically with one leg mounted on a rail or ground and the other supported by a building structure or wall.

Advantages:

- Space Efficiency: Can utilize existing building structures, making it a good option for facilities with limited floor space.

- Versatile Installation: Ideal for applications where full gantry cranes may not fit, allowing for greater flexibility in design.

- Cost-Effective in Certain Settings: Reduces the need for extensive foundation work or additional structural support.

Applications: Semi gantry cranes are well-suited for indoor operations where part of the crane can be anchored to a wall or column, commonly used in workshops, warehouses, and assembly lines.

Selecting the right gantry crane design for handling materials like ash involves assessing your specific operational needs, space constraints, and budget considerations. Single girder, double girder, and semi gantry cranes each offer unique advantages that can enhance efficiency and productivity in various industrial applications. By carefully evaluating these options, you can choose a crane that best meets your requirements for optimal performance and safety.

Gantry Crane for Ash Handling in Different Industrial Sectors

Power Generation Sector In power plants utilizing coal or biomass, effective ash handling is essential for maintaining operational efficiency and environmental compliance. Gantry cranes equipped with specialized grab buckets designed for bulk material handling play a critical role in managing both fly ash and bottom ash. These cranes can quickly transfer ash from silos or hoppers to trucks or disposal areas, significantly reducing loading times.

Custom Features:

- Weatherproof Design: These cranes often feature weather-resistant materials and coatings to withstand harsh outdoor environments.

- High-Speed Hoisting Mechanism: Enhanced hoisting speeds allow for quicker loading cycles, improving overall throughput.

- Integrated Dust Control Systems: Built-in dust suppression mechanisms, such as misting systems, minimize airborne particles during operation, ensuring compliance with environmental standards.

Cement Manufacturing The cement industry generates substantial amounts of ash, primarily as a byproduct from fuel combustion. Gantry cranes fitted with grab buckets are essential for transporting this ash efficiently. They facilitate the smooth movement of ash to storage silos or directly into mixing areas, improving the material flow in the production process.

Custom Features:

- Adjustable Span Widths: Customizable span dimensions enable the crane to adapt to various facility layouts, maximizing efficiency.

- Automated Load Monitoring: Integrated load sensors provide real-time data on ash quantities, helping to optimize material handling and reduce waste.

- Enhanced Control Systems: Advanced control interfaces allow operators to program precise movements for complex loading tasks, improving accuracy and safety.

Waste Management In waste-to-energy facilities, managing incinerator ash is crucial for environmental sustainability and compliance. Gantry cranes are instrumental in handling this ash, utilizing grab buckets for precise loading into containers designated for transport or further processing.

Custom Features:

- Low-Profile Design: A lower overall height helps accommodate facilities with height restrictions, making it easier to fit into existing infrastructure.

- Robust Structural Integrity: Reinforced frames and components designed to handle the abrasive nature of incinerator ash ensure long-term reliability.

- Remote Control Operation: Options for remote control enhance safety by allowing operators to manage crane functions from a safe distance.

Metal Production In foundries and smelting operations, the handling of ash and slag generated during metal processing is critical. Gantry cranes equipped with grab buckets provide an efficient means of transferring these materials from processing areas to recycling or disposal sites.

Custom Features:

- High-Temperature Tolerance: Crane materials designed to withstand high temperatures and resist wear from hot slag ensure longevity and reduce maintenance costs.

- Quick-Change Grab Bucket Mechanism: Allows for fast swapping of different attachments, increasing versatility for handling various materials.

- Advanced Safety Features: Emergency stop systems, safety interlocks, and overload protection mechanisms enhance safety during operations.

Mining and Mineral Processing Mining operations produce significant amounts of ash and tailings during mineral extraction. Gantry cranes with grab buckets are employed to transport these materials to designated storage or disposal locations efficiently.

Custom Features:

- Heavy-Duty Wheels and Tracks: Designed for rugged terrain, these cranes are equipped with robust wheels or tracks to facilitate movement in challenging environments.

- Customizable Reach and Height: Adjustable boom lengths and lifting heights accommodate different site layouts and material handling requirements.

- Enhanced Stability Features: Outriggers or stabilizing legs can be incorporated to provide additional support and prevent tipping during operation.

Chemical Processing In the chemical industry, ash byproducts can arise from various processes, necessitating effective handling solutions. Gantry cranes equipped with grab buckets ensure the safe transport of these materials to waste storage facilities or recycling processes.

Custom Features:

- Corrosion-Resistant Materials: The use of specialized coatings and materials helps protect against chemical exposure, prolonging the crane's lifespan.

- Integrated Chemical Spillage Containment: Features such as containment trays help manage accidental spills, ensuring compliance with environmental regulations.

- Real-Time Monitoring Systems: Sensors that provide data on operational conditions, including load weight and crane health, enhance safety and operational efficiency.

Gantry cranes with grab buckets are versatile solutions for ash handling across various industrial sectors. By integrating customized features tailored to the specific challenges of each sector, these cranes enhance operational efficiency, improve safety, and reduce environmental impact. Investing in such specialized gantry crane systems enables industries to optimize their operations while maintaining compliance with regulatory standards.

How to Custom Design a Crane for Your Ash Handling Needs

Customized double girder gantry crane specification: capacity, lifting height and cane span, and cantilever design

Assessing Your Requirements Begin by evaluating the specific requirements of your ash handling operations. Consider factors such as:

- Type of Ash: Identify the kind of ash (e.g., fly ash, bottom ash) you will be handling, as this may affect the crane's design and capacity.

- Load Capacity: Determine the maximum weight the crane needs to lift, which will influence the overall specifications.

- Operational Environment: Assess the site conditions, including space limitations, ground stability, and potential environmental factors (e.g., exposure to elements).

Selecting the Right Crane Type Choose the most suitable crane type based on your operational needs:

- Gantry Cranes: Ideal for outdoor applications and large spans.

- Overhead Cranes: Best for indoor operations with precise movement requirements.

- Jib Cranes: Useful for localized tasks with limited space.

Defining Specifications Once you've chosen a crane type, define its key specifications:

- Capacity and Span: Specify the lifting capacity (e.g., 10 tons) and the span of the crane to ensure it can cover the necessary operational area.

- Lifting Height: Determine the required lifting height based on the layout of your facility and the height of storage silos or transport vehicles.

- Below Hook Device: Decide on the type of grab bucket or other lifting device that will best suit your ash handling needs.

Incorporating Safety Features Integrate safety measures into the crane design:

- Overload Protection: Ensure the crane has systems in place to prevent lifting beyond its capacity.

- Emergency Stop Controls: Install easily accessible emergency stop buttons for immediate shutdown in case of emergencies.

- Safety Interlocks: Use interlock systems to prevent unsafe operation conditions.

Enhancing Durability and Maintenance Design the crane with durability in mind, particularly in harsh environments:

- Material Selection: Use corrosion-resistant materials to enhance longevity, especially if exposed to ash and moisture.

- Maintenance Access: Incorporate features that allow for easy access to components for routine inspections and maintenance.

Custom Features for Specific Applications Consider additional custom features that may enhance functionality:

- Automated Controls: Implement automated systems for more precise handling and reduced labor costs.

- Remote Control Options: Allow for crane operation from a distance to improve safety and efficiency.

- Dust Control Systems: Integrate systems to minimize dust generation during ash handling operations.

Working with a Crane Manufacturer Collaborate closely with a crane manufacturer experienced in custom designs. Provide them with detailed specifications and requirements to ensure the final product meets your needs. Regular communication throughout the design and manufacturing process will help address any concerns and facilitate adjustments.

Custom designing a crane for ash handling involves careful assessment of your operational needs, selecting the right type and specifications, and incorporating safety and durability features. By working with a knowledgeable manufacturer, you can create a tailored crane solution that enhances efficiency and safety in your ash handling operations.

Others Types of Industrial Cranes for Ash Handling

- Gantry Cranes Gantry cranes are ideal for outdoor ash handling applications. Their design allows for easy movement across large areas, making them effective for loading and unloading operations. They can be equipped with various lifting devices, including clamshell buckets, to handle bulk materials like ash efficiently.

- Overhead Cranes Overhead cranes, particularly double girder types, provide excellent lifting capacity and stability. They can be installed indoors or outdoors and are suitable for precise movements in confined spaces. With appropriate attachments, they can handle ash quickly and safely.

- Jib Cranes Jib cranes are versatile and can be used in areas where space is limited. Their rotating arm allows for effective material handling without needing to move the entire crane. This type is particularly useful for localized ash handling tasks.

Selecting the right type of crane for ash handling depends on various factors, including site conditions, required lifting capacity, and specific operational needs. Each crane type offers unique advantages, making it essential to evaluate the specific requirements of the project before making a decision.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch