Variable Speed 12 Ton Electric Hoist for Sale in Singapore

Overview of the Electric Hoist

The 12-ton electric hoist is designed to meet the demands of heavy-duty lifting applications, offering powerful performance with advanced control and safety features. This hoist is a critical tool in industrial settings where precise and safe lifting is essential. With a lifting capacity of 12 tons and a lifting height of 38.5 meters, it is suited for handling heavy loads over significant vertical distances.

Hoist Features:

This hoist stands out because it combines robust lifting power with precision control and safety measures. The variable speed functionality allows operators to adjust lifting speeds to match the specific requirements of the task, whether it involves fine adjustments for placement or faster lifts for high-volume operations. The ability to control speed adds to the hoist's versatility, allowing it to be used in a range of different environments and for various types of lifting jobs.

In Singapore's industrial and manufacturing sectors, where operations often involve heavy machinery, large structures, or high-precision tasks, the 12-ton hoist plays an essential role in lifting heavy materials safely and efficiently. Whether used in construction, warehouse settings, or manufacturing plants, this hoist ensures reliable performance even in demanding environments.

The importance of having lifting equipment with variable speed and integrated safety features cannot be overstated. Variable speed control enables smoother operation and reduces the risk of sudden movements that can lead to accidents or damage to materials. Additionally, built-in safety features such as limit switches and alarms ensure that the hoist operates within safe parameters, reducing the risk of operational failures or hazardous incidents.

Key Specifications:

- Capacity: 12 Tons

This hoist is designed to handle heavy loads of up to 12 tons, making it suitable for industries that regularly move large materials or heavy machinery components. - Lifting Height: 38.5 Meters

With a lifting height of 38.5 meters, this hoist offers significant vertical reach, allowing it to move heavy items to great heights in warehouses, construction sites, or manufacturing facilities. - Hoist Power Supply: 415V, 50HZ, 3-phase

The hoist is powered by a standard 415V 3-phase power supply, ensuring reliable performance and energy efficiency in large-scale industrial applications.

Safety Features:

- Huichuan Inverter: The inverter controls the speed of the hoist, allowing for smooth acceleration and deceleration. This reduces the strain on both the hoist and the load, extending the life of the equipment and improving safety during operation.

- Schneider Cross Limit Switch: This safety device ensures the hoist doesn't exceed its designated lifting limits, preventing over-travel that could damage the equipment or cause accidents.

- Audible and Visual Alarms: The audible and visual alarms serve as early warnings to operators and workers nearby, alerting them to any safety concerns such as approaching weight limits or malfunctioning parts, ensuring quick response times and preventing accidents.

These specifications make the hoist an excellent choice for industries in Singapore that require reliable, safe, and efficient lifting equipment for heavy-duty operations.

variable speed electric hoist for sale Singapore

variable speed electric hoist for sale Singapore

Electric hoist 12 ton for sale for your reference

Electric hoist 12 ton for sale for your reference

Customization of the 12 Ton Electric Hoist

Tailored Specifications for Client Needs

The 12-ton electric hoist can be tailored to meet specific operational demands, making it an ideal choice for industries that require reliable, heavy-duty lifting solutions. Customizing key features such as lifting height, capacity, and power supply allows the hoist to be integrated seamlessly into diverse environments.

Lifting Capacity, Height, and Power Supply Customization

- Lifting Capacity (12 Tons): The 12-ton capacity ensures this hoist can handle large and heavy loads, making it suitable for industries like construction, manufacturing, and heavy machinery transport.

- Lifting Height (38.5 Meters): With a lifting height of 38.5 meters, this hoist can reach elevated levels, ideal for construction sites or multi-story warehouses. The extended height ensures that the hoist can move materials or equipment across various levels in a facility, maximizing the use of vertical space.

- Power Supply (415V, 50Hz, 3-phase): The standard 415V, 3-phase power supply makes the hoist compatible with most industrial setups in Singapore. However, for specialized applications or facilities with unique power specifications, the hoist can be adjusted to meet different voltage and phase requirements.

Adaptations for Specific Environments

In Singapore's diverse industrial landscape, environments vary from construction sites to manufacturing plants and warehouses. This hoist can be adapted to suit the specific needs of each:

- Construction Sites: Durability and lifting power are essential in construction environments where heavy materials need to be moved across elevated areas. The hoist can be configured with reinforced components to handle harsh conditions and meet the high lifting demands of construction projects.

- Manufacturing Plants: Precision is often required in manufacturing settings. The hoist can be adapted with finer speed control and specialized lifting attachments to handle delicate machinery or heavy components with accuracy.

- Warehouse Operations: In warehouse environments, speed control and smooth operation are critical. The hoist's customization options allow it to be fine-tuned for more efficient material handling in tight spaces or over long distances, improving overall warehouse productivity.

Variable Speed Control

The Role of Variable Speed in Hoisting Applications

Variable speed control is one of the standout features of the 12-ton electric hoist, offering flexibility that standard hoists lack. This feature allows operators to adjust the lifting speed based on the load and the nature of the task. Whether lifting large, heavy materials or making fine adjustments for placement, variable speed provides more precise control over the hoisting operation.

Enhancing Operational Efficiency with Variable Speed

- Improved Workflow: Variable speed enables operators to tailor lifting speeds according to the task. Lifting smaller loads can be done quickly, while heavier or more complex lifts can be done at a slower, more controlled speed. This customization leads to smoother, faster workflows and better time management in high-demand operations.

- Energy Efficiency: By adjusting the speed based on the load and operational need, the hoist can operate more efficiently, using less power when lifting lighter loads and conserving energy during slower movements. This contributes to overall operational cost savings, making the hoist a cost-effective choice for long-term use.

Safety Benefits of Variable Speed Control

- Smooth Operation: The smooth start and stop capabilities of the hoist reduce sudden movements that could lead to equipment damage, load instability, or accidents. For example, in high-rise construction or in tight warehouse aisles, the ability to slow the hoist down when nearing the load's final position reduces the risk of mishaps.

- Precise Load Placement: Variable speed control also enhances precision, which is crucial in environments where load placement is critical, such as in manufacturing or when lifting sensitive equipment. Operators can adjust the speed to ensure that loads are placed accurately without causing harm to the load or surrounding infrastructure.

- Operator Control and Safety: With the ability to adjust speeds, operators are better equipped to manage challenging or complex lifting tasks, improving their ability to maintain control over the hoisting process. This added control reduces the likelihood of accidents, protecting both the load and workers in the area.

The customization of the 12-ton electric hoist, especially in terms of lifting height, capacity, and power supply, makes it highly adaptable to the diverse industrial needs in Singapore. Its variable speed control offers both operational and safety advantages, enhancing productivity while minimizing risks. Whether used in construction, manufacturing, or warehouse operations, this hoist delivers efficiency, precision, and safety, making it a reliable choice for heavy-duty lifting applications.

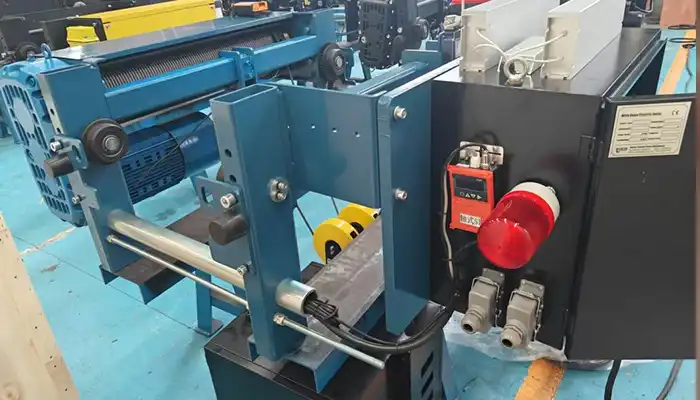

cross travelling limit

cross travelling limit

light and sound alarm , hoist and crane safety devices

light and sound alarm , hoist and crane safety devices

Advanced Safety Features

The 12-ton electric hoist is equipped with a range of advanced safety features designed to enhance operational reliability, minimize risk, and protect both equipment and personnel. These features work in tandem to ensure smooth and efficient hoisting operations, particularly in demanding industrial environments.

Huichuan Inverter Technology

Function and Role in Hoist Speed Control

The Huichuan inverter is a key component in controlling the speed of the 12-ton electric hoist. It allows operators to adjust the lifting and lowering speeds smoothly and precisely. By modulating the motor speed, the inverter ensures that the hoist operates without sudden starts or stops, which can cause strain on the system or lead to accidents. This control is particularly valuable when lifting heavy or delicate loads, where precision and gradual movement are crucial.

Benefits for Energy Efficiency and Smooth Operation

In addition to controlling speed, the inverter contributes to energy efficiency. It adjusts the power supplied to the hoist based on the load being lifted, ensuring that energy is used only when necessary. This results in lower electricity consumption, reducing operational costs over time.

Furthermore, the inverter helps maintain smooth operation, reducing mechanical stress on the hoist's components. By minimizing abrupt changes in speed, the inverter enhances the longevity of the hoist, reducing wear and tear, and extending the time between necessary maintenance.

Schneider Cross Limit Switch

Purpose and Importance of Cross Limit Switches

The Schneider cross limit switch is designed to enhance hoist safety by preventing the hoist from traveling beyond its designated limits. It ensures that the hoist does not exceed its maximum or minimum travel range, avoiding potential damage to the equipment and ensuring safe operation.

How the Schneider System Works

The cross limit switch is installed at both ends of the hoist's travel path. If the hoist reaches its travel limits, the system automatically cuts power to the motor, halting any further movement. This prevents over-travel, where the hoist moves too far and potentially damages the load or hoist mechanism. Similarly, it prevents under-travel, ensuring the hoist doesn't stop too early and cause incomplete lifts or instability in the load.

This system not only protects the hoist and load but also minimizes mechanical strain on the equipment, reducing the risk of failure and increasing the hoist's operational lifespan.

Audible and Visual Alarm Systems

Importance of Alarms in Busy Industrial Environments

In bustling industrial settings, such as manufacturing plants or construction sites, clear communication is crucial to maintaining a safe and efficient environment. The audible and visual alarm systems on the 12-ton electric hoist ensure that operators are immediately alerted to potential issues, even in noisy or high-traffic environments. These alarms are essential for drawing attention to potential safety concerns that could otherwise go unnoticed.

How the Alarm Systems Work

The hoist is equipped with both visual and audible alarms that activate when certain conditions are met, such as exceeding load limits, triggering a limit switch, or detecting a fault in the system. The audible alarm emits a loud sound, while the visual alarm typically involves a flashing light. These alerts quickly capture the attention of operators and nearby workers, enabling them to take immediate action.

Key Benefits of Alarm Systems

- Immediate Action: The combination of sound and visual signals ensures that issues are addressed promptly, preventing more serious problems from arising.

- Improved Safety for Workers: The alarms not only warn operators but also alert nearby personnel to potential hazards, reducing the risk of accidents or injuries.

- Operational Continuity: By providing early warnings, the alarms help prevent delays and equipment damage, allowing for quick resolutions and minimizing downtime.

The 12-ton electric hoist is equipped with a suite of advanced safety features, including the Huichuan inverter, Schneider cross limit switches, and audible/visual alarm systems. These technologies work together to enhance operational efficiency, ensure safety, and protect both the hoist and surrounding personnel. The integration of these safety features makes the hoist a reliable, safe, and durable choice for demanding industrial applications, providing peace of mind for both operators and facility managers.

Applications and Industry Sectors

The 12-ton electric hoist is a versatile and reliable lifting solution, ideal for a variety of industries. Its robust features, including customizable specifications, variable speed control, and advanced safety devices, make it suitable for demanding applications in sectors such as construction, manufacturing, heavy machinery handling, and warehousing.

Industries Using the 12-Ton Hoist

The 12-ton electric hoist is utilized across a wide range of industrial and commercial sectors, including but not limited to:

- Construction

In construction, hoists are essential for lifting heavy materials, tools, and equipment to elevated areas. The 12-ton hoist, with its powerful lifting capacity and extended height (38.5 meters), is well-suited for high-rise construction projects, where it can safely lift heavy building materials such as steel beams, concrete blocks, and pre-cast elements. The customizable lifting height and variable speed also ensure that materials are moved precisely and efficiently, even in busy, fast-paced construction environments. - Manufacturing

The hoist is widely used in manufacturing plants, where heavy-duty lifting of raw materials, components, or finished products is required. The variable speed control and advanced safety features allow for precise and controlled lifts, which is especially important in sectors such as automotive or machinery production. In these environments, lifting large, heavy, or delicate components without causing damage to the load is crucial, and the hoist's features ensure smooth operation in complex production lines. - Heavy Machinery Handling

The 12-ton hoist plays an integral role in the heavy machinery sector, where it is used to transport large machinery parts, engines, or industrial tools. With its high lifting capacity and long lifting height, this hoist can be used to move large components from one area to another or load them onto trucks for transport. The smooth and controlled operation is essential when moving heavy machinery to prevent accidents and equipment damage. - Warehousing and Logistics

In warehouses and logistics centers, the hoist facilitates the efficient movement of goods, especially in facilities with limited floor space. The hoist can lift materials vertically, optimizing space utilization, and the variable speed control makes it possible to adjust the lifting and lowering rates according to the load size. This allows for more efficient stacking, retrieval, and storage of goods, reducing turnaround time and increasing overall productivity.

Examples of How the Hoist is Applied in Specific Sectors

- Construction: On a high-rise construction site, the 12-ton hoist is used to lift and position steel beams. Its variable speed control allows workers to position these heavy components with great precision. The hoist's lifting height of 38.5 meters ensures that it can reach multiple floors of the building, moving materials between different levels with ease.

- Manufacturing: In an automotive manufacturing plant, the hoist is used to transport car engine components from assembly stations to storage areas. The precise control offered by the inverter ensures that delicate parts are handled without damage, while the high lifting capacity helps move larger components effortlessly.

- Heavy Machinery Handling: In a machinery repair facility, the hoist is used to lift large motors or industrial equipment for maintenance. The adjustable lifting speed allows operators to move heavy equipment into position gradually, minimizing the risk of damage to sensitive machinery.

- Warehousing: In a logistics center, the hoist is used to load and unload goods from storage racks. With its variable speed, operators can control the speed of the hoist depending on the load and the distance to be traveled, ensuring smooth and efficient movement of products.

Benefits to the Client

The 12-ton electric hoist offers significant benefits to clients in various industrial sectors. These advantages go beyond just lifting capacity and include improvements in productivity, safety, and cost-effectiveness.

- Increased Productivity with Custom Specifications and Variable Speed

One of the primary benefits of the 12-ton hoist is the customization options it offers. By tailoring the hoist to specific lifting requirements, clients can ensure that the hoist fits perfectly into their operations. The adjustable lifting height, capacity, and power supply options allow the hoist to be seamlessly integrated into different facilities, whether in a warehouse, construction site, or manufacturing plant. Additionally, the variable speed control enhances productivity by allowing operators to adjust lifting speeds depending on the load, reducing downtime and increasing operational efficiency. - Enhanced Worker Safety Due to Advanced Safety Features

The hoist's advanced safety features, including the Huichuan inverter, Schneider cross limit switches, and audible/visual alarm systems, significantly enhance worker safety. The inverter ensures smooth, controlled movements, while the limit switches prevent over-travel and under-travel, which could lead to accidents or equipment damage. The audible and visual alarm systems provide immediate alerts, helping operators quickly identify and address any issues, reducing the likelihood of accidents and improving the overall safety of the work environment. - Cost Savings Through Efficient Power Usage

The 12-ton hoist's energy-efficient design, driven by the Huichuan inverter, results in reduced electricity consumption. The inverter adjusts the motor speed to match the load, ensuring that the hoist uses only the necessary amount of power. This not only reduces operational costs but also prolongs the lifespan of the hoist by minimizing wear on the motor and mechanical components. Clients benefit from lower energy bills and reduced maintenance costs, making the hoist a cost-effective solution in the long run.

The 12-ton electric hoist is an indispensable asset across a wide range of industries, including construction, manufacturing, heavy machinery handling, and warehousing. Its customizable specifications, variable speed control, and advanced safety features offer clients increased productivity, enhanced safety, and long-term cost savings. Whether lifting heavy machinery, materials, or goods, this hoist provides a reliable, efficient, and safe solution for a variety of demanding applications.

Conclusion

The 12-ton electric hoist offers a comprehensive and highly reliable solution for various industrial sectors, combining powerful lifting capacity with advanced features to ensure smooth, safe, and efficient operations.

- Customized Specifications: Tailored to meet specific lifting requirements, including adjustable lifting height, capacity, and power supply. This customization ensures the hoist fits seamlessly into any facility, optimizing space and performance for construction, manufacturing, heavy machinery handling, and warehousing applications.

- Advanced Safety Features: Equipped with state-of-the-art safety devices, including the Huichuan inverter, Schneider cross limit switches, and audible/visual alarms, the hoist prioritizes worker safety and equipment protection. These safety features prevent accidents, minimize equipment damage, and improve overall operational safety.

- Variable Speed Control: The variable speed functionality enhances efficiency by allowing operators to adjust the lifting speed based on the load. This feature ensures smoother, more controlled movements, particularly in sensitive or complex lifting tasks. It reduces the risk of load damage and enhances operational flexibility.

Positive Outcomes for the Client

- Increased Efficiency: The hoist's customizable specifications, variable speed control, and smooth operation lead to faster, more precise lifting, significantly improving productivity in diverse industrial environments. Whether handling heavy materials or complex components, the hoist helps streamline processes, minimizing downtime.

- Enhanced Safety: The advanced safety features ensure that the hoist operates within secure parameters, reducing the risk of accidents and improving the overall safety culture at the workplace. Operators and surrounding personnel can work with confidence, knowing that the hoist is designed to prioritize their protection.

- Positive ROI: The 12-ton hoist delivers excellent return on investment (ROI) due to its energy efficiency, reduced maintenance needs, and long lifespan. The combination of customized features, energy-saving controls, and robust safety features results in cost savings over time, making it a highly economical choice for businesses.

In conclusion, the 12-ton electric hoist stands out as a versatile, efficient, and safe lifting solution. Its customization options, advanced safety features, and energy-efficient design not only meet the demanding needs of industrial clients but also deliver tangible benefits in terms of productivity, safety, and long-term cost savings.