Custom Jib Cranes: Cheaper Jib Crane Solution for Your Needs

Custom jib crane for unique needs. Custom jib crane designed on capacity, lifting height, arm length are the cheaper jib crane solution for your needs.

The Versatility of Custom Jib Cranes

Custom jib cranes, the workhorses of many industries, offer a versatile approach to material handling. Unlike their off-the-shelf counterparts, custom jib cranes are uniquely designed to cater specifically to your requirements. These lifting systems are capable of adapting to a wide range of applications and industries, making them an ideal choice for various work settings.

Understanding Their Adaptability to Various Applications

Custom jib cranes are like chameleons in the world of lifting equipment. Their adaptability knows no bounds. Whether you need a solution for a compact manufacturing facility or a sprawling construction site, custom jib cranes can be tailored to fit seamlessly into your workspace. By customizing the crane, you can maximize the use of your available space, ensuring that every square inch is put to productive use.

Customization extends beyond spatial concerns. These cranes can be engineered to handle your specific load capacity needs, minimizing any excess capacity that would drive up your costs. The result? A tailored solution that's not only cost-effective but also incredibly efficient.

But custom jib cranes aren't just about space and capacity. They can be designed with the exact features you need for your operation, be it rotation, articulation, or other specialized functions. This means that you can increase your productivity by having the crane positioned exactly where you need it, streamlining your material handling processes.

Stay with us as we delve deeper into the world of custom jib cranes, exploring their types, features, benefits, and typical applications, answering common questions, and addressing the concerns of users like you who want the most efficient and cost-effective solutions for their material handling needs.

Types of Custom Jib Cranes Options

When it comes to custom jib cranes, the options are as diverse as your material handling needs. Let's take a closer look at the various types of custom jib cranes, each with its unique features, benefits, and typical applications.

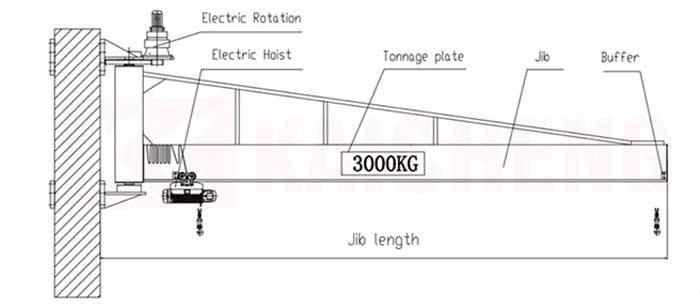

Wall-Mounted Jib Cranes

Wall-mounted jib cranes are the epitome of efficiency and space-saving solutions. These cranes are securely attached to your facility's walls and offer several advantages. With a focus on ergonomics and easy maneuverability, wall-mounted jib cranes are ideal for small to medium-sized workspaces.

The benefits are clear:

- Optimal Use of Space: Wall-mounted jib cranes save valuable floor space. They're perfect for environments where every inch counts.

- Quick and Precise Load Placement: These cranes provide easy access to hard-to-reach areas, making them perfect for assembly lines and production processes.

- Cost-Efficiency: Their space-saving design often results in lower construction and installation costs.

Typical industrial applications include small manufacturing units, workshops, and production lines where space efficiency is a priority.

Floor-Mounted Jib Cranes

Floor-mounted jib cranes, as the name suggests, are anchored to the floor.

Floor mounted jib crane with no foundations 500kg

They offer unique characteristics that cater to different needs:

- Heavier Load Capacities: Floor-mounted jib cranes are designed to handle heavier loads. They provide stability and strength for demanding tasks.

- Versatility: These cranes can rotate 360 degrees, offering broad coverage for material handling.

- Adaptability: They are well-suited for large workspaces and are commonly used in warehouses, shipyards, and construction sites.

Floor-mounted jib cranes are the go-to solution when you require heavy-duty lifting and precise positioning of materials. Check more on foundation jib crane and foundationless jib cranes.

Articulating Jib Cranes

Articulating jib cranes are the flexible performers of the custom crane world.

Free standing articulating jib crane

Wall mounted / column mounted articulating jib cranes

They offer unique features and benefits:

- Precise Positioning: These cranes provide pinpoint accuracy in load placement. Their articulating arm allows for fine-tuned control.

- Enhanced Reach: Articulating jib cranes can access tight spaces, making them perfect for assembly lines and workstation applications.

- Safety and Ergonomics: They are known for their ease of use and safety features, reducing the risk of strain or accidents.

Typical industrial uses include manufacturing facilities, laboratories, and maintenance workshops that demand a high level of precision.

Freestanding Jib Cranes

Freestanding jib cranes offer a robust and stable solution for material handling.

Fixed freestanding jib cranes 0.25 -16 ton

They stand independently, not relying on building structures. Here's why they stand out:

- Stability and Strength: Freestanding jib cranes are designed for heavy-duty tasks. They offer a solid foundation for lifting heavy loads.

- Versatility: They can be customized to meet specific height and reach requirements, making them adaptable to various settings.

- 360-Degree Rotation: These cranes can rotate a full 360 degrees, ensuring maximum coverage.

Their typical applications include large manufacturing facilities, construction sites, and any setting where heavy lifting and stability are paramount. Check more on fixed jib crane and mobile jib crane.

Each type of custom jib crane serves a distinct purpose, catering to the specific demands of your industry and workspace. In the following sections, we'll further explore the features, benefits, and typical applications of custom jib cranes to help you make the right choice for your unique needs.

Custom Options

Custom jib cranes can be tailored to meet the specific needs of your material handling application. Here are some of the custom options and features available for custom jib cranes:

- Load Capacity: Custom jib cranes can be designed to handle a wide range of load capacities, from a few hundred pounds to several tons, depending on your application's requirements.

- Arm Length: The length of the jib arm can be customized to reach the desired coverage area within your workspace. Longer arms provide a larger working radius.

- Rotation Range: You can choose the rotation range of the jib crane, whether it's 180 degrees, 270 degrees, or a full 360-degree rotation, to suit your material handling needs.

- Foundation Type: Custom jib cranes can be designed to be either wall-mounted, floor-mounted, or freestanding, depending on your workspace and load capacity requirements.

- Hoist Type: Different types of hoists, including electric chain hoists, wire rope hoists, or vacuum lifters, can be integrated into your custom jib crane to match your specific load handling needs.

- Control System: Custom jib cranes can be equipped with a variety of control systems, including pendant controls, radio remote controls, or automated systems for precise load positioning.

- Safety Features: You can request additional safety features, such as overload protection, anti-sway systems, and emergency stop buttons, to ensure a secure work environment.

- Material and Coating: The materials used for the crane's construction can be customized to meet specific environmental conditions, and coatings can be applied to enhance durability and resistance to corrosion.

- Modularity: Some custom jib cranes offer modular designs, making it easy to add or modify features and adapt to changing requirements in the future.

- Articulation: Articulating jib cranes offer enhanced flexibility, with adjustable booms that can be tailored to reach tight spaces or specific work areas.

- Special Attachments: Custom jib cranes can be equipped with various specialized attachments, such as hooks, spreader bars, vacuum lifters, or custom end-effectors, to handle specific loads.

- Compliance with Industry Standards: Custom jib cranes can be designed to meet or exceed industry standards and safety regulations specific to your application or location.

- Paint and Finish: You can choose the paint color and finish of the crane to match your facility's aesthetics or for additional protection against environmental factors.

- Ease of Maintenance: Custom jib cranes can be designed for easy access to service points, reducing maintenance downtime and costs.

- Load Monitoring Systems: Advanced load monitoring systems can be integrated to provide real-time data on load weight and prevent overloading.

These are just a few of the custom options available for jib cranes. The key is to work closely with the crane manufacturer or supplier to tailor the crane to your exact requirements, ensuring that it fits seamlessly into your application environment and optimizes your material handling processes.

Features and Benefits of Custom Jib Cranes

When it comes to custom jib cranes, the advantages go beyond just their types. These versatile lifting solutions offer a plethora of features and benefits that can significantly enhance your material handling operations.

Customization for Efficiency

Customization is the heart of the allure of custom jib cranes. When you opt for a tailored solution, you're investing in the efficiency of your material handling processes. Here's how:

- Maximized Efficiency: Custom jib cranes are designed with your specific application, space, and load capacity needs in mind. This tailored approach ensures that the crane is perfectly suited to your workflow, eliminating wasted space and redundant capacity.

- Cost-Efficiency: By customizing the crane, you avoid the added costs associated with features and capacity you won't use. It's an economical choice that doesn't compromise on performance.

Customization means you get precisely what you need, without excess costs, ensuring your operations run smoothly and cost-effectively.

Safety and Compliance

Safety is paramount in any industrial setting. Custom jib cranes are engineered to not only meet but often exceed safety standards. Here's what you can expect:

- Safety Features: These cranes can be equipped with safety features tailored to your specific application. From anti-sway systems to advanced operator controls, they are built with your safety in mind.

- Legal Adherence: Ensuring your workplace is compliant with safety regulations and standards is a priority. Custom jib cranes can be designed to meet or exceed these requirements, reducing the risk of accidents and potential fines.

With custom jib cranes, you're not just investing in efficiency; you're investing in the safety and well-being of your workforce.

Durability and Longevity

Custom jib cranes are built to last. Their durability and longevity are essential for a cost-effective material handling solution:

- High-Quality Materials: These cranes are constructed using high-quality materials and craftsmanship. This ensures they can withstand the rigors of your application, reducing wear and tear.

- Long-Term Cost Savings: While the initial cost may be higher compared to off-the-shelf options, the durability and longevity of custom jib cranes translate into lower maintenance and replacement costs over the long haul.

Investing in custom jib cranes isn't just about the here and now; it's about building a sustainable, cost-effective solution for your material handling needs that stands the test of time.

Typical Industrial Applications of Custom Jib Cranes

The true test of any material handling solution lies in its real-world application. Custom jib cranes have proven their worth in a wide array of industrial settings, transforming the way businesses handle materials. Let's explore how these versatile cranes are making a significant impact in various industries.

Manufacturing and Production

How custom jib cranes streamline manufacturing processes.

Manufacturing and production facilities are often bustling hubs of activity. Custom jib cranes play a pivotal role in these environments, streamlining processes, and ensuring that products move smoothly through each stage of production. Their contributions are evident in:

- Efficient Workstations: Custom jib cranes are strategically placed to support assembly lines, facilitating the precise positioning of components.

- Optimized Workflow: By customizing the crane's features, manufacturers can achieve the perfect synergy between their machinery and material handling, leading to a more efficient workflow.

- Precision and Speed: From automotive plants to electronics manufacturers, custom jib cranes enhance precision and speed, reducing production times and ensuring consistent quality.

These cranes have become indispensable tools in the world of manufacturing, illustrating their ability to cut costs and boost productivity.

Warehousing and Logistics

Enhancing warehouse operations with custom jib cranes.

Warehouses are the epicenters of logistics, where inventory management and material flow are critical. Custom jib cranes are adept at addressing the specific challenges that warehouses face:

- Quick and Accurate Picking: Jib cranes are customized to reach high shelves and narrow aisles, facilitating efficient picking and storage operations.

- Space Optimization: By taking advantage of vertical space, custom jib cranes maximize storage capacity, reducing the need for costly warehouse expansion.

- Reduction of Manual Labor: These cranes reduce the need for manual labor, enhancing employee safety and reducing the risk of injuries associated with heavy lifting.

The result is a warehouse operation that runs like a well-oiled machine, saving both time and money.

Construction and Heavy Industry

The role of custom jib cranes in construction and heavy industry.

The construction and heavy industry sectors demand rugged equipment that can handle hefty loads while ensuring safety. Custom jib cranes rise to the occasion:

- Heavy Lifting: Whether it's erecting steel structures or moving machinery, custom jib cranes handle the heaviest of loads, improving efficiency on construction sites.

- Safety First: These cranes can be customized with features like load monitoring systems and precision controls, reducing the risk of accidents and enhancing safety.

- Cost-Effective Solutions: Custom jib cranes are designed for specific projects, minimizing unnecessary costs associated with oversized equipment.

In construction and heavy industry, where every move must be carefully calculated, custom jib cranes prove their worth by providing the muscle, precision, and reliability needed for success.

The applications of custom jib cranes are diverse, ranging from manufacturing to logistics and heavy industry. In each setting, they optimize processes, enhance productivity, and contribute to cost savings. The next section addresses the top concerns often raised by users of custom jib cranes, offering insights and solutions to ensure a seamless experience.

Top Concerns of Custom Jib Crane Users

Custom jib cranes offer a multitude of benefits, but like any piece of equipment, they come with concerns and considerations. Here, we address the top concerns of custom jib crane users and provide insights and solutions to ensure that your investment is well worth it.

Maintenance and Downtime

Addressing concerns about maintenance and minimizing downtime.

Maintenance is a common concern for any machinery, and custom jib cranes are no exception. However, these cranes are designed with durability and ease of maintenance in mind:

- Regular Inspections: Scheduled inspections and maintenance checks can prevent major breakdowns. Consider investing in preventive maintenance programs to catch issues early.

- Quick Servicing: Custom jib cranes can be designed for easy access to service points, reducing downtime during maintenance.

- Downtime Planning: Schedule maintenance during off-peak hours or when your facility experiences lower activity to minimize disruptions.

With the right maintenance strategy, downtime can be kept to a minimum, ensuring your operations continue to run smoothly.

Cost vs. ROI

Balancing the initial cost with the long-term return on investment.

The initial cost of a custom jib crane may seem higher than off-the-shelf alternatives. However, it's essential to consider the long-term benefits:

- Longevity: Custom jib cranes are built to last. Their durability can lead to lower maintenance and replacement costs over time.

- Efficiency: Customization ensures that you're not paying for unnecessary features or capacity, saving you money in the long run.

- Productivity: The increased productivity and efficiency of custom jib cranes can have a direct impact on your bottom line.

By focusing on the overall return on investment, it becomes clear that custom solutions are a financially advantageous choice.

What factors contribute to the affordability of certain jib cranes?

A custom Jib Crane can be a cost-effective solution for your specific material handling needs for several reasons. Here are some key points to consider:

- Tailored to Your Requirements: Custom Jib Cranes are designed to meet your unique requirements. This means that the crane is built to suit your specific application, space, and load capacity needs, ensuring that you don't pay for unnecessary features or capacity that you won't use.

- Optimal Space Utilization: By customizing the Jib Crane, you can make the most efficient use of your available space. It can be designed to fit perfectly in your workspace, minimizing wasted space and avoiding the need for major structural modifications.

- Improved Productivity: Custom Jib Cranes are designed with your workflow in mind. This can lead to increased efficiency and productivity, as the crane can be positioned exactly where you need it, allowing for smooth and precise material handling.

- Long-Term Cost Savings: While custom Jib Cranes may have a higher upfront cost compared to off-the-shelf solutions, they are often more cost-effective in the long run. Their design can take into account your specific load handling requirements, reducing wear and tear, and potentially leading to lower maintenance and replacement costs.

- Safety and Compliance: Custom Jib Cranes can be designed with safety features tailored to your specific application and workplace regulations. This can help you maintain a safer work environment and avoid costly fines for non-compliance.

- Durability and Reliability: Custom Jib Cranes can be constructed with high-quality materials and craftsmanship to ensure they withstand the demands of your application, potentially extending their lifespan and reducing the need for frequent replacements.

- Future-Proofing: When you invest in a custom solution, you can plan for future expansion or changes in your material handling needs. The Jib Crane can be designed with flexibility in mind, making it easier to adapt to new requirements without the need for significant reconfiguration.

- Reduced Downtime: Custom Jib Cranes can be designed for easy maintenance access and quick servicing, reducing downtime when repairs or maintenance are required.

- Specialized Features: If your application requires specific features like rotation, articulation, or other specialized functions, a custom Jib Crane can be tailored to include these features, enhancing the efficiency of your operations.

- ROI: While custom Jib Cranes may have a higher initial cost, the return on investment (ROI) can be significant due to increased productivity, reduced downtime, and the longevity of the crane.

In summary, a custom Jib Crane is a cost-effective solution when it's designed to meet your unique material handling needs. While the upfront cost may be higher than an off-the-shelf option, the long-term benefits, including increased efficiency, safety, and durability, can make it the cheaper and more effective choice for your business.

Adaptability to Future Needs

How custom jib cranes can adapt to changing requirements.

The ability to adapt to changing requirements is crucial in the world of material handling. Custom jib cranes are designed with flexibility in mind:

- Modularity: Many custom jib cranes offer modular designs, making it easy to add or modify features as your needs change.

- Future Planning: Work with manufacturers to discuss potential future requirements. Custom cranes can often be adjusted to accommodate these changes.

- Growth Planning: Consider your business's growth trajectory and select a custom jib crane that can grow with you, saving costs in the long run.

How to Get Custom Jib Crane Design ?

Getting a custom jib crane involves several steps to ensure that the crane is tailored to your specific needs and application. Here's a general process to guide you in obtaining a custom jib crane:

- Determine Your Requirements: - Start by clearly defining your material handling requirements. Identify factors such as load capacity, the type of load you'll be handling, the working radius needed, the available space in your facility, and any unique features or functions required.

- Research and Choose a Manufacturer or Supplier: - Research reputable jib crane manufacturers or suppliers who have experience in providing custom solutions. Look for companies with a proven track record and good customer reviews.

- Consultation and Site Assessment: - Contact the chosen manufacturer or supplier to schedule a consultation. They will often send a representative to assess your site, understand your specific needs, and gather essential details about your application.

- Customization and Design: - Work closely with the manufacturer to customize the jib crane according to your requirements. This involves choosing the type of jib crane (e.g., wall-mounted, floor-mounted, articulating, freestanding), load capacity, rotation range, hoist type, control system, and any additional features or attachments.

- Detailed Proposal: - The manufacturer should provide you with a detailed proposal that outlines the specifications of the custom jib crane, including design drawings, cost estimates, and a timeline for fabrication and installation.

- Review and Approval: - Carefully review the proposal to ensure that it meets your requirements and budget. Discuss any necessary modifications or adjustments with the manufacturer. Once you are satisfied, approve the proposal.

- Manufacturing and Fabrication: - The manufacturer will begin the fabrication of your custom jib crane according to the approved design. This process may take several weeks, depending on the complexity of the crane.

- Quality Control and Testing: - The custom jib crane should undergo rigorous quality control checks and testing to ensure it meets safety and performance standards. This step is crucial to verify that the crane operates as expected.

- Delivery and Installation: - Once the custom jib crane is ready, it will be delivered to your facility, and the installation process will commence. Experienced technicians will install and commission the crane, ensuring it functions correctly.

- Training and Operator Certification: - The manufacturer should provide training for your crane operators to ensure safe and efficient use of the custom jib crane. Operator certification may also be necessary.

- Ongoing Support and Maintenance: - Establish a maintenance and support plan with the manufacturer to ensure the long-term reliability and performance of your custom jib crane. Regular inspections and preventive maintenance are essential.

- Final Inspection and Approval: - Conduct a final inspection of the installed crane to ensure that it meets your expectations. Once you are satisfied with the crane's performance, provide your approval.

Getting a custom jib crane is a collaborative process between you and the manufacturer or supplier. Effective communication, careful planning, and attention to detail are essential to ensure that the crane meets your specific material handling needs. Always work with a reputable and experienced provider to ensure a successful outcome.

Parameters and specification needed to get custom jib cranes

When you're considering getting a custom jib crane, it's important to provide detailed parameters and specifications to the manufacturer or supplier to ensure that the crane is tailored to your specific needs. Here are the key parameters and specifications you should provide:

- Load Capacity: - Specify the maximum load weight the crane should be able to handle. Ensure that this capacity accounts for the heaviest loads you anticipate lifting.

- Type of Load: - Describe the type of load you'll be handling. Is it a uniform load, irregularly shaped objects, or sensitive materials that require special handling equipment?

- Working Radius: - Define the required working radius or distance from the mast to the center of the hook or lifting attachment. This determines the crane's coverage area.

- Type of Jib Crane: - Choose the type of jib crane that best suits your application (e.g., wall-mounted, floor-mounted, articulating, freestanding) based on your space and load handling requirements.

- Rotation Range: - Specify the desired rotation range for the jib crane, whether it's 180 degrees, 270 degrees, or a full 360-degree rotation.

- Hoist Type and Capacity: - Select the type of hoist (e.g., electric chain hoist, wire rope hoist, vacuum lifter) and specify its capacity. The hoist's capacity should match or exceed the load capacity of the crane.

- Control System: - Indicate your preferred control system, whether it's pendant controls, radio remote controls, or an automated control system for precise load positioning.

- Safety Features: - Identify any specific safety features you require, such as overload protection, anti-sway systems, emergency stop buttons, or additional safety interlocks.

- Mounting Type: - Determine the mounting type for the crane, such as wall-mounted, floor-mounted, freestanding, or foundationless, based on your facility's configuration.

- Material and Coating: - Specify the materials used for the crane's construction, including structural materials, coatings, and finishes to match your facility's environment and protect against corrosion.

- Modularity and Adaptability: - If you anticipate future changes in your material handling needs, discuss the crane's modularity and flexibility to adapt to those changes.

- Industry Compliance: - Ensure that the crane is designed to meet or exceed industry standards and safety regulations applicable to your specific application or location.

- Electrical Requirements: - Provide information about your facility's electrical supply and voltage requirements to ensure the crane's electrical components are compatible.

- Site-Specific Conditions: - Share any site-specific conditions that the manufacturer should be aware of, such as floor conditions, ceiling height, or other spatial constraints.

- Special Attachments or End-Effectors:

- If your application requires special attachments or end-effectors, describe the specific requirements to handle unique load shapes or materials. - Paint and Finish: - Indicate your preferences for the paint color and finish of the crane to match your facility's aesthetics and provide additional protection against environmental factors.

- Budget and Timeline: - Clearly communicate your budget constraints and project timeline to ensure that the manufacturer can work within your financial and scheduling parameters.

Providing comprehensive and accurate parameters and specifications is essential to get the custom jib crane that best meets your material handling needs. Effective communication with the manufacturer or supplier is key to the successful customization and installation of the crane.

Custom jib cranes are investments in the future, capable of evolving with your changing demands and ensuring your operations remain efficient and cost-effective.

In conclusion, the concerns of custom jib crane users are valid, but with the right approach, these concerns can be transformed into opportunities for greater efficiency and cost savings. Custom solutions, when well-maintained and supported by a clear understanding of their long-term advantages, offer a reliable, adaptable, and cost-effective material handling solution for your unique needs.

Related Questions and Answers on Custom Jib Cranes

Q&A: Your Custom Jib Crane Queries

Q1: What factors should I consider when choosing the type of custom jib crane for my business?

A: When selecting a custom jib crane, it's essential to evaluate your specific material handling needs, available workspace, load capacity requirements, and the level of flexibility you require. Each type of custom jib crane offers unique benefits, so your choice should align with your industry and application.

Q2: How do custom jib cranes compare to standard, off-the-shelf models in terms of cost-efficiency?

A: Custom jib cranes can appear to have a higher upfront cost than standard models. However, they often provide better long-term cost efficiency by offering tailored features, optimized space utilization, and lower maintenance and replacement costs. Your investment in customization leads to higher productivity, better safety, and ultimately a more cost-effective solution.

Q3: What are the key safety features I should look for in a custom jib crane?

A: Safety is a paramount concern. Look for features like anti-sway systems, overload protection, precision controls, and operator training options. Custom jib cranes can be tailored to meet or exceed safety regulations specific to your industry.

Q4: How can I ensure minimal downtime and efficient maintenance for my custom jib crane?

A: Scheduled maintenance, preventive checks, and quick servicing are essential for minimizing downtime. Ensure that your custom jib crane is designed for easy access to service points. Additionally, plan maintenance during off-peak hours to reduce disruptions.

Q5: Can a custom jib crane adapt to changing requirements as my business grows?

A: Yes, many custom jib cranes offer modularity and flexibility. You can discuss potential future requirements with the manufacturer to ensure your crane can be adjusted or modified as your business evolves. Custom solutions are designed to adapt and grow with your changing demands.

Q6: Are custom jib cranes suitable for small businesses, or are they primarily for large industries?

A: Custom jib cranes can be tailored to suit the needs of businesses of all sizes. They are versatile and can be designed for compact spaces and smaller load capacities, making them a viable solution for small businesses looking to improve their material handling efficiency.

Custom jib cranes provide flexibility, adaptability, and efficiency for a wide range of industries. If you have any more questions or require further information, don't hesitate to reach out to our experts. We're here to help you find the perfect custom jib crane solution for your unique needs.