Clamshell Grab Bucket & Orange Peel Grab Crane

Grab Bucket EOT Crane, Overhead Crane & Gantry Crane for

Bulk Cargo, Minerals, Coal, Sand & Gravel Materials Handling

Grab cranes come in a range of capacities and sizes for massive bulk material handling efficiently and safely. We can provide customers with superior quality grab cranes including the grab bucket eot cranes and gantry cranes, tailored to fulfill all kinds of lifting requirements with our extensive crane manufacturing experience.

A grab crane is used for handling large volumes of different materials, which are widely used in various industrial applications. For different loads handling, the grab bucket overhead crane and gantry crane are all custom-made and have a unique design to meet the specific application environment. They are widely used in ports, docks, station yards, mines, etc. to load all kinds of bulk cargo, logs, minerals, coal, sand and gravel materials, earth and stone.

Based on different catogories, the grab cranes can be grouped into the following types:

Crab crane types based on crane designs

According to crane designs, the grab cranes can be classified in the grab overhead crane, grab gantry crane and folding arm grab crane.

- Grab overhead cranes are one type of overhead cranes, which are dedicated to bulk and granular materials, which can be divided into single girder grab overhead crane & double girder grab overhead crane.

- Grab gantry cranes is mainly used in outdoor material handling for the loading and unloading mines, coal, wood, wastes, biomass, etc.

Videos of Clamshell Grab Bucket & Orange Peel Grab Crane

Grab Bucket EOT Crane, Overhead Crane & Gantry Crane for

Bulk Cargo, Minerals, Coal, Sand & Gravel Materials Handling

Clamshell Grab Bucket Eot Crane for Mining Factory- Grab bucket Overhead Crane

Four Rope Grab Bucket Overhead Crane- Grab Overhead Crane

Grab cranes based on types of crane grabs and crane buckets

A grab is a pick-up device for grabbing bulk materials. It is an automatic picking device with high loading and unloading productivity, because its grasping and unloading actions are all controlled by the crane driver, which not only avoids auxiliary personnel and manual labor, but also saves auxiliary time. Therefore, it is widely used in mines, metallurgical plants, ports, stations and other bulk material warehouses. The disadvantage of crane grab is the heavier dead weight of grab.

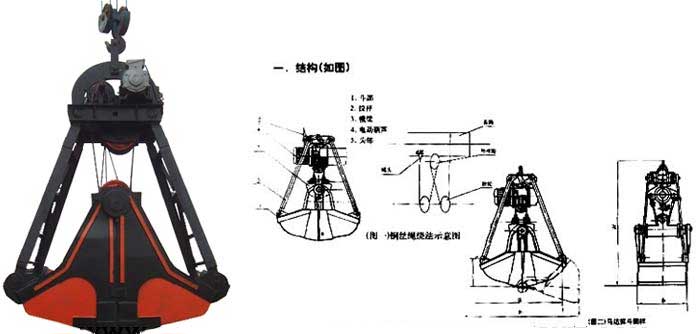

Multi-petal orange peel grab crane

Main types of grab buckets & grab cranes

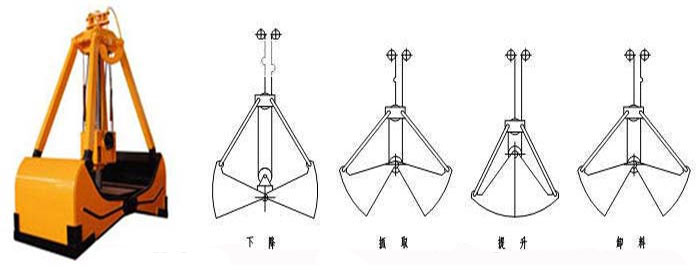

The types of crane grabs can be classified based on the driving mode of the jaw plate's closure and opening:

- Rope grab bucket & cable grab bucket :The rope grab uses the wire rope to create a closed force in order to grasp the material. The rope grab is classified as single rope, double rope, or four rope.

- Power grab bucket:To open and close the jaw plate, power grabs use the load on the power unit and the transmission device, such as electric grabs and motor grabs.

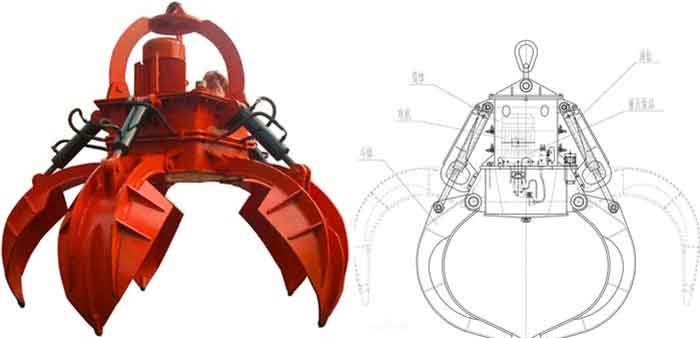

The grab can be divided into two types based on the number of jaw plates: double jaw plate grab/clamshell grab bucket and multiple jaw plate grab/orange peel grab bucket.

- Clamshell grab crane:It is appropriate for loading bulk cargo, minerals, coal, sand and gravel materials, earth and stone, and so on in ports, docks, station yards, mines, and so on. It's also useful for earth and stone excavation, foundation and trench excavation, road construction, rail laying, and other tasks.

- Multi-petal orange peel grab crane: The orange peel grabs are designed with multiple jaws designs ranging from 4 to 8 tines, which cannot be completely closed and are widely used for large irregular piece loads handling such as steel scrap, big iron, and wastes, garbage, and so on.

Mechanical grab crane Single Cable Grab, Double Rope Grab, Four cable grab

Mechanical grab crane

The mechanical grab has no opening and closing structure and is usually powered by a rope or a connecting rod. It is classified as a double rope grab or a single rope grab based on its operation characteristics. A double rope grab is the most common.

A support rope and an opening and closing rope are wound around the support mechanism and the reel of the opening and closing mechanism, respectively, in the double rope grab. The double rope grab is dependable, simple to use, productive, and widely used. When two sets of double ropes are used, it becomes a four-rope grab, with the same working process as the double rope grab.

The single rope grab uses the same rope for the support rope, as well as the opening and closing rope. The wire rope rotates to provide support and is opened and closed by a special locking device. The single rope grab's winding mechanism is simple, but its productivity is low, and it is rarely used in a large number of loading and unloading operations.

Single Cable Grab

The single rope grab is applicable for cranes equipped with only one lifting drum (single hook). It is free to open and close for material loading and unloading. Single cable grab cranes are simple to use. It can be used for material grabbing and transferring both underwater and on land.

Radio Controlled Single Rope Grabs

Radio controlled single line grabs are one of the oldest and most dependable types of ship gear grabs available today. Any grab that connects to a ship's cranes is referred to as a ships gear grab. These cranes typically have a single hook point with no additional cable or hydraulics running to the hook. Some will have enough power to power an electro hydraulic. Radio Controlled Single Line Grabs are entirely self-contained, requiring no external power source, hydraulics, or cables.

These grabs are ideal for the following materials:Grains,Coal,Pet Coke,Other loose flowing material,

Pro's:

- Inexpensive

- Reliable Operation

- Easy to maintain

- Simple installation

Con's:

- Slower

- Capacity Restrictions - Not ideal for heavy materials

- Only available in clamshell bucket syle

- Require substantial working height for cables to close bucket

Options:

- Patented Cluster Sheave

- Bolt-On Edges

- Bolt-On Sealed Lips

- Spillways

- Splillplates

- Environmental Covers

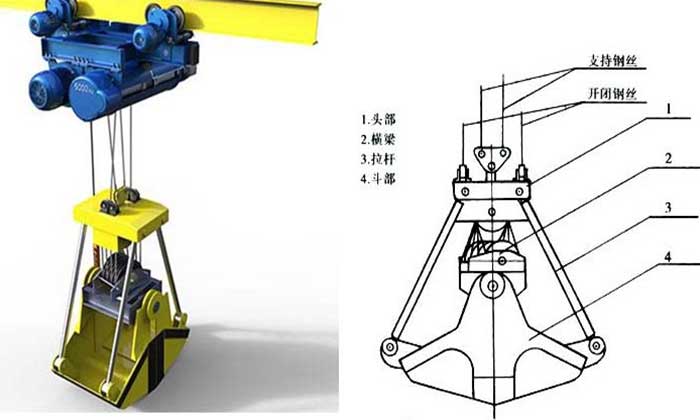

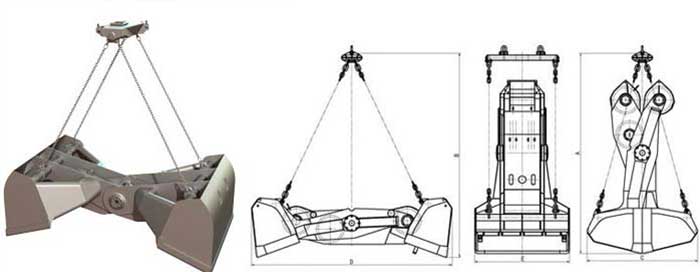

Double Rope Grab

The double rope grab is designed for cranes that have a double lifting device structure and are commonly used in port, dock, and bridge construction. Choose light, medium, heavy, or over-heavy grabs for various loose accumulations based on material characteristics.

Four Rope Cable Crab

The four cable grab is primarily used in conjunction with bridge or door cranes equipped with two groups of lifting drums to grab various loose accumulations for loading and unloading, store transfer, and so on. Serial product types such as toothed, parallel cross beam opened, and underwater operations can be designed based on material conditions and client requirements.

Cable-operated grabs can be customized to handle any material; grabs are optimized for the crane and material.

Depending on the crane and the material, these grabs are typically designed for large capacities of up to 65 cubic yards (50 cubic meters). These grabs can be of the clamshell bucket or grapple variety.

These grabs are ideal for the following materials:Grains,Coal,Pet Coke,Other loose flowing material,

Pro's:

- Greatest production– these grabs are very large compared to other types

- Purpose built for the material being handled

- Often mounted on a barge for mobility on rivers

Con's

- High upfront cost

- Require large expensive crane

Clamshell Grab Bucket & Orange Peal Grab Bucket

Double Jaw Plate Grab - Clamshell grab bucket crane

The double jaw plate grab has a novel shape, logical structure, a rate of 1.5-1.92 between grabbed material and grab dead load, and a filling degree of 95-100 percent, making it an ideal grab for loose granule materials.

In comparison to the traditional four-cable grab, the product has the following characteristics: The through beam is designed with a compact structure, high strength, and a low dead load; the lining material of the main swivel is bearing steel, and its service life is increased by 4-5 times.

To reinforce impulse force and abrasion strength, the cutting edge sheet is welded using overlaying techniques. To prevent dust and water from entering the chain wheel during underwater operation, multi-lay techniques are used. To keep the working area clean, the commissural clearance between cutting edge sheets can reach 0.3-1mm. With two cables, the structure is difficult to deform or stagger the type of grab.

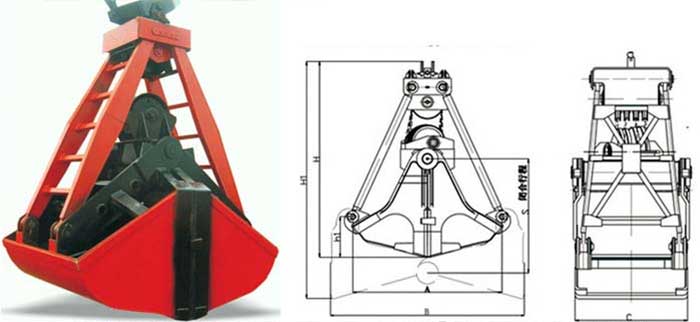

Multi-valve Type Grab Bucket - Orange Peal Grab Bucket

The multivalve type grab bucket is primarily used for efficiently loading and unloading largely wasted steel materials under appalling conditions. It is widely used in port, railway, metallurgy, mining, and construction. Its structure is classified into four types: sing-cable, double-cable, four-cable, and electric. The jaw can open and close according to material shapes and sizes to help grab large amounts of material; the number of jaws can be designed with 48 valves depending on material sizes and client requirements.

Electric Motor Grab, Electric Hydraulic Grab

Hydraulic grab

The hydraulic grab has an opening and closing structure that is typically powered by a hydraulic cylinder. A hydraulic claw is another name for a hydraulic grab with multiple jaws. Hydraulic grabs are a common component of hydraulic equipment.

The electric hydraulic grab uses electric and hydraulic mechanical techniques for high grabbing forces and automation, making it an ideal load and unload tool for large materials such as ores, pig iron, and wastes.

Electric Motor Grab

The electric motor grab is primarily used on cranes that have their own switching mechanism for material load and unload at any height. It has a higher productivity than a single-cable machine, is simple to operate, and has a high efficiency in load and unload. It can be used to grab various loose accumulations. Cable winders are added to the grab during operation based on the lifting height.

Notes: the grab cannot be operated underwater.

Scissor Grab Bucket, Wood Grab Bucket & Customized grab buckets

Scissor Grab Bucket

When two jaws close the swivel, the scissor grab bucket opens by releasing the steel cable of the chain wheel near the scissor arm and frapping the bearing steel cable, and it closes by flipping the steel cable of the chain wheel group. Increasing force by using the lever principle to bring the jaw close to the grabbing material, whose closing force moment rises during closing, and it can grab materials completely without leakage, and it is primarily used on large bridge ships that are unloaded.

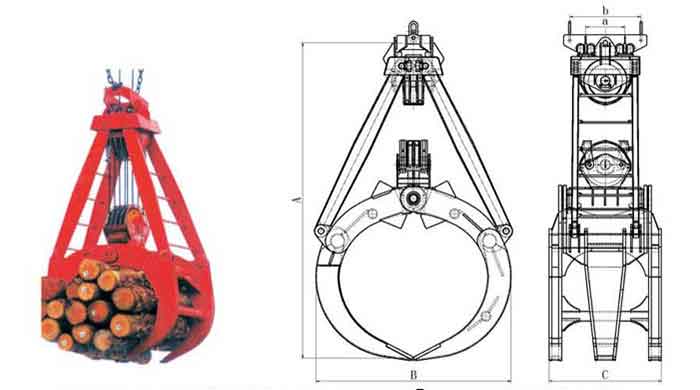

Wood Grab Bucket

The wood grab is primarily used to load, barge, log raft load trucks, and unpeel in wood markets, large wooden product factories, papermaking plants, and so on. Its structure includes single-cable, two-cable, four-cable, and electric types, and it can also be designed and manufactured at the request of clients.

Grab overhead crane and gantry cranes based on loading materials

According to the loading and unloading object, the grab crane can be classified into biomass grab crane, sand grab bucket crane, mining grab crane, log grab crane, sugar cane grab crane, wastes grab crane, garbage crane, etc. And also, with the development of science, China has developed a multi-purpose grab crane.

The grab crane are used to grab all kinds of loose debris, loading, unloading, transfer heap, feeding, and others.

- Light grab crane is adopted to handle materials with the bulk density of γ< 1.2t / m³ , such as dry grain, little bricks, lime, fly ash, aluminum oxide, sodium carbonate, dry slag , etc.

- Medium grab crane is adopted to handle materials with the bulk density of γ=1.2t/ m³~2.0t/ m³, such as, gypsum, gravel, pebbles, cement, large blocks, etc.

- Heavy bucket crane is adopted to handle materials with the bulk density ofγ= 2.0t / m³ ~2.6 t / m³, such as, hard rock, small and medium-sized ore and scrap steel, etc.

- Extra heavy grab crane is adopted to handle materials with the bulk density ofγ>2.6t / m³,such as, heavy ore, scrap steel, etc.

grab overhead crane for garbage handing

grab overhead crane for garbage handing

grab overhead crane for bulking material handling

Grab bucket gantry crane for wast handling

Grab bucket gantry crane for coal handling

Grab bucket gantry crane for wast handling

Clamshell Grab Bucket & Orange Peel Grab Crane