Foundation Floor Mounted Jib vs. Foundationless floor Jib Crane

Floor mounted jib crane for sale. Foundation floor mounted jib crane vs. foundationless floor jib crane from design to installation. Check floor jib crane!

Floor mounted jib cranes

Floor mounted jib cranes are a type of lifting equipment that are used to move heavy loads horizontally or vertically within a limited area. They consist of a vertical mast or post that is mounted on a foundation, and a horizontal boom or arm that extends from the mast. The boom is equipped with a hoist or trolley that is used to lift and move the load.

A floor mounted jib crane is a type of crane that is fixed to the floor and has a horizontal arm (jib) that can rotate 360 degrees to move loads within a specific area. The purpose of floor mounted jib cranes is to provide a safe and efficient way to move heavy loads in areas where space is limited. They are commonly used in manufacturing facilities, warehouses, and construction sites, where they can be used to lift and move materials, equipment, and machinery.

Benefits of using a floor mounted jib crane

Floor mounted jib cranes offer several benefits, such as:

- Increased productivity: These cranes are designed to provide easy and efficient lifting and moving of heavy loads, which can help increase productivity in the workplace.

- Improved safety: Floor mounted jib cranes are built with safety in mind, and can help reduce the risk of accidents and injuries associated with lifting heavy loads.

- Versatility: These cranes can be used in a variety of settings and industries, making them a versatile option for businesses that need to move heavy loads.

- Costeffective: Floor mounted jib cranes are typically more affordable than other types of cranes, making them a costeffective choice for businesses that need to lift and move heavy loads on a regular basis.

Overall, a floor mounted jib crane can be a valuable asset for businesses that need to move heavy loads quickly, safely, and efficiently.

Foundation vs foundationless floor mounted jib cranes

Foundation floor mounted jib cranes

Main specifications of foundation mounted jib cranes

- can be used for handling loads with capacity of 0.25 t 16 ton .

- Arm length : 36m

- Foundation: customized concrete foundation.

Overview of foundation mounted jib cranes 500kg -16 ton

Floor mounted jib cranes are a type of lifting equipment that are used to move heavy loads horizontally or vertically within a limited area. They consist of a vertical mast or post that is mounted on a foundation, and a horizontal boom or arm that extends from the mast. The boom is equipped with a hoist or trolley that is used to lift and move the load.

- Definition: A foundation mounted jib crane is a type of jib crane that is mounted on a concrete foundation. The foundation provides a stable base for the crane and helps to distribute the weight of the load.

- Specifications: Foundation mounted jib cranes are available in a wide range of sizes and load capacities, depending on the specific application. They can rotate 360 degrees and provide maximum flexibility in terms of movement and range of motion.

- Design features: Foundation mounted jib cranes are designed with a vertical mast or post that is mounted on a concrete foundation, and a horizontal boom or arm that extends from the mast. The boom is equipped with a hoist or trolley that is used to lift and move the load.

- Advantages: Foundation mounted jib cranes provide a stable base for the crane and can support heavy loads. They are suitable for use in a wide range of applications, including manufacturing facilities, warehouses, and construction sites.

- Disadvantages: Foundation mounted jib cranes require excavation and can be timeconsuming to install. They are also difficult to relocate once they have been installed.

Foundationless floor mounted jib crane

Main specifications of foundationless jib crane

- for load handling no heavier than 500kg.

- Arm length : no longer than 4 m

- Floor requirement: concrete floor with thickness no less than 20 cm.

Overview of Foundationless floor mounted jib crane250kg 500kg

A foundationless floor mounted jib crane is a type of crane that does not require a concrete foundation for support. Instead, it is mounted on a base plate that can be bolted to an existing concrete floor.

- Definition: A foundationless floor mounted jib crane is a type of jib crane that is mounted directly on the floor, without the need for a concrete foundation. The crane is anchored to the floor using bolts or other fasteners.

- Specifications: Foundationless floor mounted jib cranes are available in a wide range of sizes and load capacities, depending on the specific application. They can rotate up to 360 degrees and provide maximum flexibility in terms of movement and range of motion.

- Design features: Foundationless floor mounted jib cranes are designed with a vertical mast or post that is mounted directly on the floor, and a horizontal boom or arm that extends from the mast. The boom is equipped with a hoist or trolley that is used to lift and move the load.

- Advantages: Foundationless floor mounted jib cranes are easy to install and do not require excavation. They are also easy to relocate if necessary. They are suitable for use in a wide range of applications, including manufacturing facilities, warehouses, and construction sites.

- Disadvantages: Foundationless floor mounted jib cranes may not be suitable for heavy loads or applications where a high degree of stability is required. The fasteners used to anchor the crane to the floor may also create trip hazards if not properly installed or maintained.

Overall, both foundation mounted jib cranes and foundationless floor mounted jib cranes have their own unique advantages and disadvantages, depending on the specific application and requirements. The choice of crane will depend on factors such as load capacity, stability requirements, and installation constraints.

Foundation design of floor mounted foundation jib cranes

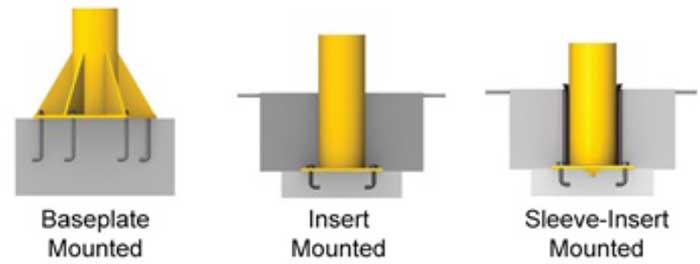

There are several types of foundation designs for floor mounted jib cranes. The most common types are:

- Concrete pier foundation: This type of foundation consists of a concrete pier that is poured into a hole in the ground. The jib crane is then anchored to the pier using bolts. This type of foundation is suitable for small to mediumsized jib cranes and provides a stable base for the crane. However, it requires excavation and can be timeconsuming to construct.

- Concrete slab foundation: This type of foundation consists of a concrete slab that is poured directly on the ground. The jib crane is then anchored to the slab using bolts. This type of foundation is suitable for small to mediumsized jib cranes and provides a stable base for the crane. However, it requires a level surface and can be difficult to construct in areas with poor soil conditions.

- Steel base plate foundation: This type of foundation consists of a steel plate that is bolted to a concrete pad or existing structure. The jib crane is then anchored to the steel plate using bolts. This type of foundation is suitable for small to mediumsized jib cranes and provides a stable base for the crane. However, it requires an existing structure or concrete pad and can be difficult to install in areas with limited access.

- Reinforced concrete foundation: This type of foundation consists of a reinforced concrete pad that is poured directly on the ground. The jib crane is then anchored to the pad using bolts. This type of foundation is suitable for large jib cranes and provides a very stable base for the crane. However, it requires excavation and can be expensive to construct.

Can foundation mounted jib crane be relocated?

In general, it is possible to relocate a foundationmounted jib crane, but it can be a complex and timeconsuming process. The relocation process will depend on several factors, such as the size and weight of the crane, the type of foundation, and the location of the crane.

If the crane is mounted on a concrete pier foundation, it may be possible to remove the anchor bolts and lift the crane off the pier using a crane or other lifting equipment. The pier can then be left in place or removed, depending on the requirements of the new location. If the crane is mounted on a concrete slab foundation or a steel base plate foundation, it may be necessary to cut the bolts and remove the foundation along with the crane.

Before relocating a foundationmounted jib crane, it is important to consult with a qualified engineer or crane manufacturer to ensure that the relocation process is safe and feasible. The engineer or manufacturer can also provide guidance on any modifications that may be required to the crane or foundation to accommodate the new location.

Footing of foundationless floor mounted jib cranes

Does a floor mounted column jib crane need to have a foundation? When a foundationless floor mounted jib crane design is applicable?

Foundationless floor mounted jib crane can be installed on the concrete floor with thickness no less than 20 cm

Generally speaking, foundationless floor mounted jib cranes design is only used for light load handling with lifting capacity below 500kg. The foundationless floor jib crane is designed to use the chemical bolts instead of making a foundation, to support the jib column. The footing requirements or floor requirement of foundationless jib crane is that the thickness of the existing concrete is not less than 20cm and the length of the jib crane arm does not exceed 4m.

The installation of a columnmounted jib crane can also be assisted by nearby walls or columns, using angle steel welded firmly to increase its safety. For floor mounted jib cranes with capacity above 500kg, a foundation must be made accordingly.

Can a foundationless floor mounted jib crane be relocated to a different location?

Yes, a foundationless floor mounted jib crane can be relocated to a different location. Since it doesn't require a foundation, it can be easily dismantled and moved to a new location. However, it's important to ensure that the new location meets the necessary requirements for the crane's installation and use, such as adequate space, appropriate loadbearing capacity, and compliance with local regulations and safety standards. Additionally, it's recommended to have the crane reinstalled and tested by a qualified professional to ensure proper functioning and safety.

Installation of floor mounted jib cranes

The floor mounted jib crane is a type of lightduty crane that boasts several features such as light weight, large span, high lifting capacity, economical and durable. It has a high mechanical efficiency, is easy to install, use and maintain, and comes with low costs. Now, let's take a better look at the structures of the floor mounted jib crane.

The primary structure of a floormounted jib crane is composed of a vertical pillar or post mounted on a foundation and a horizontal jib arm that extends from the pillar. The jib arm has a pivot point that connects it to the pillar, allowing it to rotate.

floor mounted jib cranes main parts and components

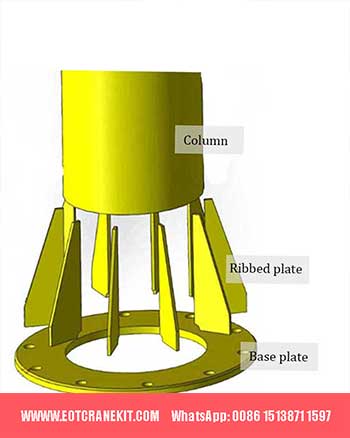

The components of a floor mounted jib crane include the following:

- Pillar: The vertical structure that supports the jib arm and permits it to rotate.

- Jib arm: The horizontal structure that extends from the pillar and holds the hoist and trolley.

- Pivot point: The connection between the pillar and jib arm that allows the jib arm to rotate.

- Hoist: The component that lifts and lowers the load.

- Trolley: The component that moves the hoist along the length of the jib arm.

- Control system: The component that enables the operator to regulate the crane's movement.

- Foundation: The base on which the pillar is mounted that provides stability for the crane.

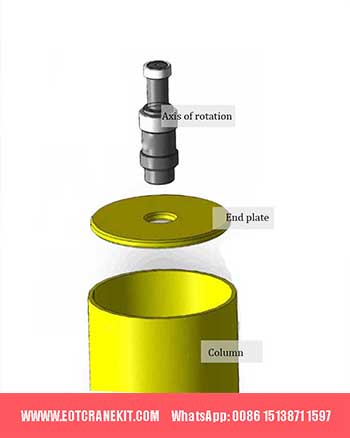

Floor mounted jib crane structure:

- The pillar of the slewing jib crane is made of a circular tube with the base plate and the ends of the rotating shaft welded to it, and an upper waist ring track fitted. To ensure the crane's stability, the base plate is secured to the cement ground with chemical bolts. To conceal the cable inside the column, a through hole is made on the spinning shaft. The spinning shaft can be equipped with a 360degree collector, allowing the jib to rotate 360 degrees. The floor mounted jib crane rotates on the waist ring track. Several tiny holes are drilled in the track to accommodate rotation restriction blocks with a 0360 degree angle constraint.

- The slewing jib's arm is made up of Ibeam and Hbeam. It is suitable for installing and operating various chain hoists. A moveable locking device is put at both ends of the hoist to ensure that it operates within a specific stroke.

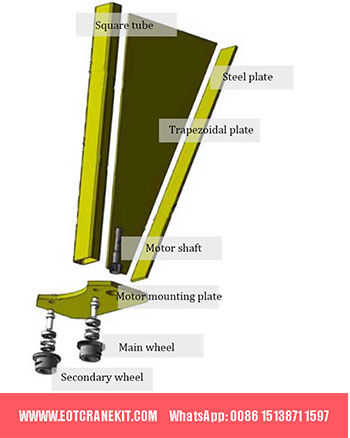

- The electric slewing jib crane's support bracket is welded with rectangular steel pipes and steel plates that support the jib. Superior mechanical structure, triangular support, small weight, and great safety. Under the bracket, there are two revolving wheels. The floor mounted jib crane's electric rotation is achieved by driving the active wheel with a lightduty worm gear reducer motor.

- To accomplish free rotation of the jib, the rotation mechanism of the floormounted jib crane uses a circular tube as the housing and installs a selfaligning roller bearing within. Because of the performance of the selfaligning roller bearing, even if there is a little variation in concentricity between the waist ring and the pillar, the slewing jib crane can be used safely.

- For attaching power cables for electric hoists, the Cshaped track can be mounted on the rotating arm of the slewing jib crane. It has a modest and lovely appearance as well as a wide range of applications.

Installation procedures of floor mounted jib crane

Here's a general guide to putting in a floormounted jib crane:

- Select a location: The first step is to determine where the floor mounted jib crane will be positioned. The site should be level, strong, and capable of supporting the weight of the crane and the cargo it will be hauling.

- Prepare the foundation: The next stage is to prepare the crane's foundation. To construct a stable basis for the crane, a pit must be dug and concrete poured. The size and depth of the foundation will be determined by the crane's size and weight.

- Install the pillar: The pillar can be erected after the foundation has been constructed. To maintain stability, the pillar should be securely attached to the foundation.

- Install the jib arm: The jib arm should now be installed onto the pillar. The jib arm should be properly aligned with the pillar and securely secured in place.

- Install the hoist: The last step is to attach the hoist to the jib arm. To ensure safe functioning, the hoist should be firmly linked to the jib arm and correctly wired.

- Test the crane: After the installation is complete, it is critical to test the crane to check that it is operational. This entails lifting a test load and ensuring that the crane can move smoothly and safely.

It is critical to remember that the installation of a floor mounted jib crane should only be performed by competent specialists who have prior expertise installing and operating these types of cranes. To ensure safe and effective operation, all safety recommendations and regulations must be followed when installing and operating a floor mounted jib crane.

Presentation of Floor Mounted Jib Crane Installation

The most often utilized lifting equipment in manufacturing today is the floor mounted jib crane. What are the benefits of using a floor mounted column jib crane? It is highly reliable and ideal for regular shortdistance lifting activities. It is easy to use and increases work efficiency significantly. So, how does a floor mounted column jib crane get installed? Here's a diagram to help you understand.

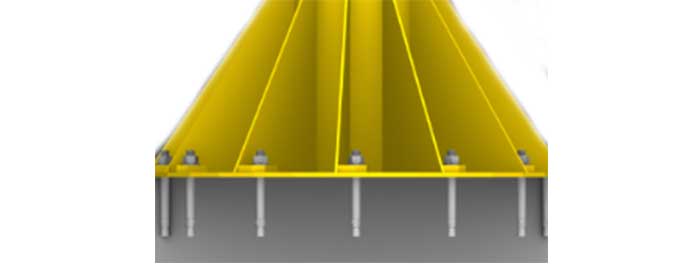

Column Installation

Sleeve the column into the inner ring of the bottom plate, weld and fix the bottom plate and the column on both sides of the bottom plate, then weld a number of ribs to the bottom plate and the column to complete the cantilevered bottom plate installation of the column.

Installation of End Plate and Waist Ring Track

Adjust the location of the rotating shaft of the column jib crane and the end plate first, then weld and fix it to ensure the rotating shaft's verticality. Then insert the end plate into the column, weld it, and secure it to the column according to the dimensions shown in the drawing. To complete the installation, sleeve the waist ring track into the column, adjust the correct location according to the size of the drawing, weld and fix it to the column.

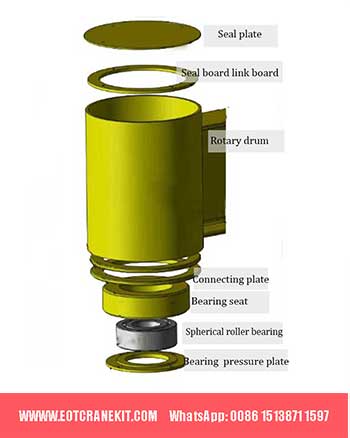

Installation of Rotary Sleeve

The bearing seat and the revolving cylinder are welded and fixed according to the size of the drawing through the connecting plate, and pressed into the spherical roller bearing, and then the left side of the revolving sleeve is sealed with the bearing pressure plate. The connecting plate of the sealing plate is welded on the right side of the rotating cylinder, and the sealing plate is connected by bolts. The sealing plate is removed during onsite installation, and the current collector is installed inside the rotating sleeve. After the internal parts of the rotating sleeve of the column cantilever crane are installed, the sealing plate is installed and the installation is completed.

Bracket Installation

The bearing seat and revolving cylinder are welded and fastened according to the drawing size through the connecting plate, and then pressed into the spherical roller bearing, with the bearing pressure plate sealing the left side of the revolving sleeve. The sealing plate's connecting plate is welded to the right side of the rotating cylinder, and the sealing plate is bolted together. During onsite installation, the sealing plate is removed and the current collector is inserted inside the spinning sleeve. The sealing plate is placed after the internal pieces of the rotating sleeve of the column mounted jib crane have been mounted.

Onsite Installation of The Free Standing Jib Crane

Remove the round nut from the column, secure the cantilever on the column through the rotating shaft and waist ring track, then install the round nut on the rotating shaft from the inside of the slewing device, and finally install the slip ring and lock in turn Polyurethane nuts. The round cable enters the slip ring slewing mechanism after passing through the inside of the column and the center hole of the rotating shaft. Inside the slewing mechanism, the slip ring bracket and carbon brushes are installed. Through the contactor switch in the electric control cabinet in the control cabinet.