How to Select Crane Conductor Bar for Your Overhead Crane?

Conductor bar is a vital crane component of lifting equipment such as overhead cranes, which is widely used in the mining, machinery, and other industries. The conductor bar on a crane is little, but it has an impact on the overall efficiency of the overhead crane mechanism. How can you tell if a crane conductor bar is of good quality? This article explains how to use observation and how to touch to determine the quality of conductor wires.

What is conductor bar?

One of the most frequent methods of electrifying and supplying electricity to a crane and hoist is through conductor bars (also known as power bars, figure eight bars, or hot bars). When compared to other power systems, a conductor bar uses a sliding shoe collector system, which eliminates most of the exposed conductor safety issues while still supplying higher amperage power.

Most conductor bar electrification systems now have a cover to protect them from the elements. The conductor bar may or may not be insulated in some applications, but the most common types have insulated covers.

Conductor bar systems

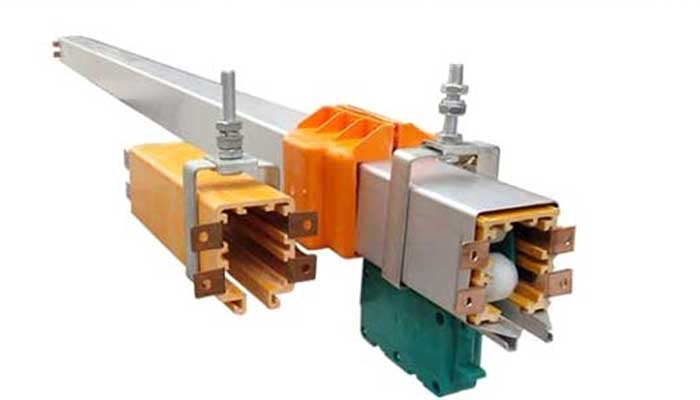

Crane conductor bars, also known as crane conductor line, crane security sliding line, or simply the sliding line, are a type of crane conductor. Crane conductor bars are made up of a series of insulated bars made of galvanized steel, copper, stainless steel, or aluminum that transport electricity through sliding collector assemblies to power motors, trolleys, and hoists, among other things.

Monorails, runways, and bridge cranes are all common uses for the crane conductor bar system. A curved shape is also available for some crane conductor bar systems. Crane conductor bar systems come in a variety of configurations, including side contact bars, hot conductors, cluster bars, and high duty bars, among others.

Drawing of typical crane conductor bar system

Components of Conductor Bar Electrification

- The supply of incoming power and/or control along the runway or bridge is known as the conductor bar.

- Power feed is the process of connecting incoming power to the conductor bar.

- Collector - a device that collects electrical current from a conductor bar and sends it to a machine.

- Brackets are a supporting structure that allows many hangers to be attached to the runway or bridge.

- Attach the conductor bar to the brackets with hangers.

- End cover is a safety feature that protects the conductor system at the end.

- Anchor clamp - a device that directs conductor movement during thermal expansion and contraction.

Brackets are typically web mounted (for top-running cranes), flange mounted (for monorails or under-hung cranes), or laterally placed (for monorails or under-hung cranes).

Advantages of Conductor Bars

Conductor bar systems for overhead cranes are often mounted on the crane's runway systems or monorail cranes, and can be utilized on both indoor and outdoor cranes. One of the most significant advantages of adopting a conductor bar system is that it may be used on runways with several bridges.

With a variety of brackets and hanger clamps, they're also highly cost-effective and simple to install. They're also great for low-headroom situations where cables can't dangle down, as well as systems with a curve or track switch.

Last but not least, conductor bars are ideal for crane configurations where future upgrades or extensions are a possibility. Because conductor bars are so easy to link together for installation, runway systems can be extended more easily and at a lower cost. Conductor bars are also ideal for ensuring power continuity in interlocking crane systems.

Disadvantages of Conductor Bars

One of the main disadvantages of a conductor bar system is that the collector shoes wear out quickly and must be serviced or replaced frequently depending on the severity of use.

Another disadvantage is that a conductor bar system should never be used in an environment where an explosion proof crane is required, and it should never be used to power transfer carts.

Crane conductor system selection

It is required to determine the following in order to appropriately select a bar system:

- The System Type (monorail, runway, bridge).

- 'Run Length' is a term that refers to the length of a race.

- Current Crane Requirements and Number of Cranes

- The number of conductors is the number of conductors in a group (calculate an extra for ground).

- Power Feed's location.

- System Voltage is a term used to describe the voltage present in a system.

- Environment. Temperature and Duty Cycle.

Crane conductor line quality checklist

Researchers at home and abroad have drawn performance indicators for crane conductor bars that are used by customers to check the quality of overhead crane conductor bars after ten years of development, based on statistics and analysis of crane conductor bars practical application. How can I tell if an overhead crane conductor bar is of good quality? The quality of an overhead crane conductor bar may generally be assessed using the following checklist:

1. Carbon brush of crane conductor bar

Based on statistics and analysis of crane conductor bars practical application, researchers at home and abroad have developed performance indicators for crane conductor bars that are used by customers to assess the quality of overhead crane conductor bars after 10 years of development. How can I tell if a conductor bar for an overhead crane is of good quality? The following checklist can be used to evaluate the quality of an overhead crane conductor bar:

Carbon brush

2. Crane conductor bar observation

How can the quality of an overhead crane conduct bar be determined? It's crucial to keep an eye on things. Examine the crane conduct bar's look in terms of ordinary type, corrosion type, abrasion type, high temperature sliding contact line type, and so on.

3. Workplace environment for conducting bar applications

The working environment has an impact on the conductor bar life of overhead cranes.

The overhead crane conduct bar should be chosen according on the sliding contact bar's usage environment. The conductor bar's outside surface or the quality of the conductor line shell should be utilized in a proper environment with appropriate temperature, as the conductor bar cannot be exposed and cannot withstand very low temperatures in the winter. If the conduct bar has been out of use for a long period, it should be properly collected to avoid weathering and other issues.

4. The performance of the conduct bar is influenced by several factors.

The performance of a sliding contact bar collector is mostly determined by the wheel's service life, turning wheel design, and if the conductor bar is suitable for use at the plant. Slope and downhill, on varied routes, turn round design, and collector bite are all things to consider.

5. Deformation of the contact bar

The length of the conductor bar affects contact bar deformation. The expansion problem should be considered if the length exceeds 100 meters.

When using the crane conductor bar, we must be aware of the issue of voltage drop, which changes depending on the length of the conductor bar. The crane conductor bar should be appropriately adjusted after erection to ensure good operation and efficiency.

4 points to identity conductor line quality

- The PVC shell's thickness. In general, the sliding contact line conductor and insulation functional components are protected by the sliding contact line shell. It can protect the conductor line from sunburn, moisture, rain and snow, and dust at the same time. The thickness of the sliding contact line's shell serves as a standard for determining the sliding contact line's quality. The safety performance can be considerably degraded if the sliding contact line is rather thin.

- Conductor thickness and cross-sectional area.It is self-evident that the larger the cross-sectional area of the conductor, the better the heat dissipation, and the thicker the conductor thickness, the better the conductive ability.

- Quality and source of conductor aluminum alloy materials.

- Overall design.The general design of the sliding contact line should conform to the majority of engineering environments, and the design is favorable to the protection of the sliding contact line, as well as an aesthetic plus. This will improve product competitiveness in the conductor line market.