Overhead Crane Parts, Components, Spare Parts Parts Supplier

Overhead crane part & overhead crane component to renew your eot crane. Types of overhead crane parts for sale,brake, motor, reducer, hoist, controland wheel, etc.

To keep your overhead cranes,bridge crane, eot crane and hoists, and trolleys in service, the availability of interchangeable replacement crane parts is paramount; But, first and foremost, having a comprehensive understanding of these overhead crane components and their diverse activities is critical to minimize production downtime and avoiding emergency circumstances.

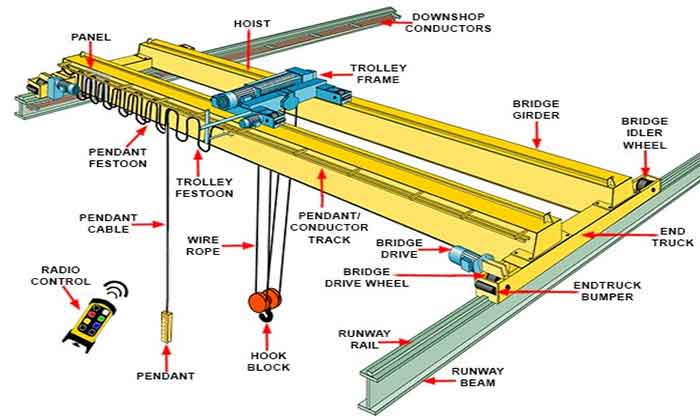

Overhead cranes are a type of material handling equipment that is used to handle bulky or heavy loads across industrial and commercial work sites. A bridge craneand overhead craneis defined as amaterial handling cranewhich move along a crane rails and crane trackshaving at least one primarily horizontal girder and equipped with at least one hoisting mechanism. Overhead travelling cranes are mainly classified into four main types of overheads cranes – top running, under running, single girder and double girder.

Types of overhead crane parts and components for all types of overhead travelling crane

Despite of thevariety of designs and combinations of overhead crane which is to suit diverse functions and applications, they all have the same four basic components, which include Power systems and motors,Electrical parts,Mechanical parts, and Controls,etc.

Each of these overhead crane components performs a unique function that, when worked with the other components, provides the overhead crane assembly to lift and position loads as designed.

Power Systems and Motor Replacements

Motor part replacements can help to reduce the short service life that is frequently caused by abuse or constant exposure to harsh conditions.

Electrical Components

Rewiring the electrical components of a crane or hoist provides an opportunity to modernize your equipment while staying within your budget. Overhauling your conducting, breaking, and switch systems can improve your equipment for a fraction of the expense of purchasing new equipment.

EOTCRANEKIT stocks and sells a wide range of overhead crane components, including circuit breakers, transformers, frequency drives, and surge suppressors.

Mechanical Parts

We provide hundreds of mechanical crane parts to support your overhead cranes and hoist systems, reducing the likelihood of unexpected system breakdowns.These parts include typical brake parts, bearings, retention rings, hook latches, and a slew of other bits and bobs.

Controls

Controls are required in automated systems in order to maintain efficient, repeatable processes, during which breakdowns occurfrequently in advanced cranes and monorails. EOTCRANEKIT stocks overhead crane parts such as crane inverter controls to adjust motor speed, and adjustable frequency crane controls, electric chain hoist remote control packages, and pendants for directional control.

Overhead Cranes Parts & Components in Stock, Short Lead Time and Quick Delivery

EOTCRANEKIT can provide universal overhead crane parts from these four categories. All varieties types of crane, hoist, and trolley replacement parts and components are in stock.

Our extensive inventory includes our own made overhead cranes parts & components and those from other well-known brands, and our crane parts service can meet your most urgent part replacement needs.

Bridge girder

Crane bridge or bridge girder is one of the most significantoverhead crane part and componentswhich supports the trolley or hoist. Overhead crane girders are classed into truss girders, box girders, single girders, and double girders, and other typesbased on the designs and structure.EOTCRANEKITcan provide a variety of girder designs, such as single girder, double girder, triple girder, box girder, truss girder, and so on. Please contact us if you require crane girder design.

Double bridge girder - overhead crane parts and components

End truck & ground beam

End beams, also known as end trucks, are critical components of overhead cranes.

With metallic structures, the end carriages support and hold the crane's bridge beams together, as well as house the bridge's driven and powered wheels.The heads can be built as a single unit to support the bridge beams or as small and separate units for each bridge beam.

EOTCRANEKITprovides a variety of crane end beams, including single girder end beams, gantry crane ground beams, hoist end beams, and overhead crane end beams.

Under running crane end truck - overhead crane parts and components

Top running double girder end truck - overhead crane parts and components

Double girder under running crane end truck - overhead crane parts and components

Hoist Trolley

The hoist trolley is the travelling mechanism that moves the hoist along the bridge girder of an overheadcrane. With hoist trolley, the overhead hoist is moved horizontally along the top or underside of the bridge girder to handle the loads

Manual hoist Trolley - overhead crane parts and components, including Plain Hoist Trolley and Geared Hoist Trolley

Overhead Hoist

The hoist is adopted to lift, hold and lower the loads with the wire rope/ chain fall and crane hook. Hoists can be powered by hand, electricity, or compressed air.According to designs and configurations, the overhead hoists can be grouped into the following types;

Crane Crab Trolley and Trolley frame

Crane crab is the lifting equipmentfor double girder overhead cranes which is mounted on hoist trolley frame and moves on and along on the top of overhead travelling crane. Based on the structure of crane crab, it can be grouped into hoist trolley and open winch trolley

Overhead crane trolley- overhead crane parts and components

Overhead crane trolley- overhead crane parts and components

Overhead crane trolley- overhead crane parts and components

Hook Block

A crane hook block is a assemblyto which the hook of a hoist or crane is attached; it typically consists of a steel shell housing a number of sheaves or pulleys that carry the ropes or chains used to lift a load weight. Although this may appear overly complicated, it would be difficult for a bridge crane or overhead hoist to work properly and safely if the crane hook was simply linked to a rope and lifted or lowered by the crane's boom and winch mechanism. In comparison to a direct connection, a hook block provides significantly more flexibility and safety in lifting activities.

It isused tolift and lower operations of theloadweight.

Crane Runway

Crane runway is what theoverhead crane and bridge crane uses to travel up and down the bays.

Crane runway - overhead crane parts and components

- The rails, beams, and columns on which the crane moves are referred to as the runway of overhead cranes.

- The crane rails are fixed to the runway beam and are where the end trucks travel. The runway beam is supported by the columns of the top running overhead crane or the roof structure of the under running overhead crane.

- The existing building columns can be used in the design of the crane runway system. It is thus necessary to supply the down shop center to center gap between them.

- Furthermore, the conductors are attached to the runway beam and provide electricity to the overhead crane.

Please visit our Crane Runways section to learn more about runway alternatives.

Runway Rail

A structure that serves to support the crane's bridge beams and influences the crane's displacement and steering.According to your requirements, the following types of crane rails are selected to meet your needs.

Crane rails - Overhead crane parts and components

Wheels and Modules

The crane wheelpartsare housed within the heads that move the crane's bridge.

Crane Wheel- overhead crane parts and components

Crane Control

Overhead crane control is in charge of your crane's safety and dependability. Overhead crane control must be flexible and dependable. On overhead cranes, the following controls are commonly utilized.

- Pendant control:The pendent overhead control can provide the crane operator with fine control over the crane's motion. The pendant control can be configured in a variety of ways depending on the function. The pendant control may be suspended from the Trolley Hoist, requiring the crane operator to walk alongside and alongside the load, or it could be mounted on a separate sliding track system, allowing the operator to move independently of the weight..

- VFD: A pendant overhead crane control can also be utilized in conjunction with a Variable Frequency Drive, which regulates motion for smooth acceleration and deceleration by varying motor frequency. The controls for the VFD might be substantially tweaked.

- Radio control: A radio control for an overhead crane is similar to a pendant control, except that the operator uses a radio frequency rather than a pendant. The radio control has a higher level of safety and offers the user a larger range of operational motions than a pendant.

- Power supply: The building's electrical power supply should be adjusted to the intended rate of the overhead crane.

- Electrical cabin: The overhead crane's electrical components could be housed and protected in the control cabin.

- Protection against unintentional contact, electrical shock, enclosed equipment, and indoor protection against filth, dust, oil, and water, among other things, assure the safety of the overhead crane.

Bumpers & Rubber Stops

The rubber stops serve to buffer the impact of the bridge's or trolley's structure.

Bumpers are designed to absorb the crane's energy and lessen impact, allowing the crane to come to a controlled stop and limiting forces when it reaches the end of its travel. Bridge, trolley, and runway stops can all be outfitted with bumpers.

Crane spring bumper- overhead crane parts and components

Electrification

Insulated conductor bars, festoon systems (flat cables), or cable reels transport power from the structure to the crane.

The festoon is the wiring and support system that powers a trolley and hoist that travels across the bridge. Power is drawn from the runway busbar and sent to the main bridge panel, which powers all of the crane's electronics. Festoon cables then carry power to the hoist panel and bridge drives, which power the hoist, trolley, and bridge drive. Most crane operators use a pendant or radio to control the crane's movement for best productivity and safety.

End Effector / Blow Hook Devices

End effectors are the below hook devices or lifting devices part of the crane system. It is safer, faster, and more precise to use a tailored end effector for your load lifting. Custom below-the-hook alternatives are appropriate, and you can view some of the various end effector possibilities right here.

Made-to-order Parts for Your Overhead Cranes

With our large inventory and deep industry connections, EOTCRANEKIT can deliver overhead crane parts and crane components anywhere accurately and efficiently. Our whole focus is on your complete satisfaction. We have a large inventory of overhead crane parts, including Gears, Gear Boxes, Wheels Wire Rope, Motor Brakes, Bottom Blocks Bearings, Drum Assemblies, and so on. You can have your items shipped and fitted within your time frame.