Wheel Blocks and Assemblies Guide: Types, Specifications, and Applications

Definition and Key Components

Crane wheel and crane wheel block assemblies are integral to the operation and efficiency of cranes. These assemblies are designed to support the movement of cranes along their tracks, ensuring smooth and reliable operation. Each assembly typically consists of several key components that work together to provide stability and functionality. Here’s a detailed look at these components:

Wheel Axle

The wheel axle is a central component of the crane wheel block assembly. It serves as the core support structure that connects the wheels to the crane’s frame.

- Function: It supports the load and allows the wheels to rotate smoothly. The axle transmits the weight of the crane and its load to the wheels, ensuring even distribution.

- Material: Usually made from high-strength steel to handle heavy loads and resist deformation.

Wheel Disc

The wheel disc is the part of the assembly that makes direct contact with the crane tracks or rails. It is crucial for ensuring stable and efficient movement.

- Function: It provides a surface for rolling on the tracks, facilitating smooth movement and reducing friction.

- Material: Often manufactured from cast steel or forged steel, with surfaces heat-treated for increased hardness and durability.

Bearing Box

The bearing box houses the bearings and provides structural support for the wheel axle. It plays a critical role in maintaining the alignment and stability of the wheels.

- Function: It supports the bearings, ensuring they remain properly aligned and protected from external elements. This helps in maintaining smooth rotation and reducing wear.

- Material: Typically made from durable cast iron or steel, designed to withstand significant loads and stresses.

Bearings

Bearings are essential components that enable smooth and efficient rotation of the wheels. They reduce friction between the wheel axle and the wheel disc, ensuring fluid movement.

- Function: They support the wheel axle and facilitate smooth rotation by minimizing friction. High-quality bearings contribute to the longevity and performance of the wheel assembly.

- Material: Often made from high-grade steel or ceramic materials, depending on the load requirements and operational environment.

The crane wheel block assembly integrates these components into a cohesive unit, designed to handle the specific demands of various crane operations. Proper assembly and maintenance of these components are crucial for the optimal performance and safety of the crane.

Gear Crane Wheel Assembly

Components and Features

- Gear Wheel: The gear crane wheel assembly includes a gear wheel integrated into the design. This gear wheel meshes with the crane's drive system, enabling precise control over movement.

- Gearbox: A gearbox is often incorporated to manage the speed and torque transmitted from the motor to the wheel assembly.

- Bearing System: High-quality bearings support the gear wheel and axle, ensuring smooth and reliable operation.

- Wheel Disc: The wheel disc is designed for durability and optimized for interaction with crane rails or tracks.

Applications and Benefits

- Applications: Gear crane wheel assemblies are commonly used in applications requiring precise movement and control, such as in overhead cranes, gantry cranes, and other heavy-duty lifting equipment.

Benefits:

- Precision: The integrated gear system allows for accurate control of crane movements, crucial in environments where precision is key.

- Durability: Robust construction ensures long-lasting performance under heavy loads.

- Efficiency: Gearboxes help optimize power transmission, reducing energy consumption and improving overall efficiency.

L Block Crane Wheel Assembly

Components and Features

- L Block Design: The L Block crane wheel assembly features a distinctive L-shaped block that houses the wheel axle and bearing system. This design enhances stability and load distribution.

- Wheel and Axle: The assembly includes a sturdy wheel and axle system, often made from high-strength steel.

- Bearing System: Bearings are housed within the L block to support the axle and allow smooth wheel rotation.

- Mounting Brackets: Integrated mounting brackets facilitate secure attachment to the crane frame.

Applications and Benefits

- Applications: L Block crane wheel assemblies are ideal for use in environments where space is limited and a compact design is advantageous. They are commonly used in small to medium-sized cranes, such as those in workshops or manufacturing facilities.

Benefits:

- Compact Design: The L block design is space-efficient, making it suitable for applications with restricted installation space.

- Enhanced Stability: The L-shaped block provides additional stability and load distribution, improving overall crane performance.

- Ease of Maintenance: The design simplifies access to components for maintenance and repair, reducing downtime and operational costs.

45° Split Bearing Box Crane Wheel Assembly

Components and Features

- Split Bearing Box: The 45° split bearing box design allows for easier installation and maintenance of bearings. It is split at a 45-degree angle to facilitate quick access to the bearings for inspection and replacement without disassembling the entire wheel assembly.

- Bearing System: The assembly includes high-quality bearings housed within the split bearing box, designed to support the wheel axle and ensure smooth rotation.

- Wheel Disc: The wheel disc is robust and typically made from high-strength materials to withstand heavy loads and harsh operational conditions.

- Wheel Axle: The wheel axle is precisely engineered to fit within the split bearing box and ensure stable and reliable performance.

Applications and Benefits

- Applications: This type of crane wheel assembly is used in environments where frequent maintenance is required, such as in heavy-duty industrial cranes and overhead cranes in manufacturing plants.

Benefits:

- Ease of Maintenance: The split design allows for quicker and more convenient access to the bearings, minimizing downtime and maintenance costs.

- Improved Durability: The high-quality materials and design enhance the assembly’s resistance to wear and tear, extending its service life.

- Efficiency: Smooth rotation and reliable performance improve the overall efficiency of crane operations.

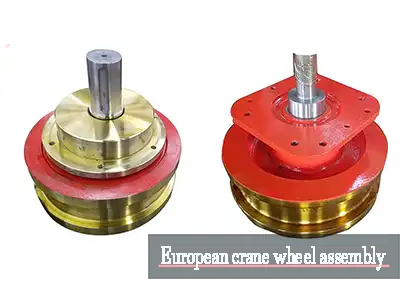

European Crane Wheel Assembly

Components and Features

- European Design Standards: This assembly adheres to European design standards, which often include specific dimensions, tolerances, and safety features to meet rigorous quality and performance criteria.

- Wheel and Axle: The wheel and axle are designed to meet European specifications, often featuring high-strength materials and precise engineering to ensure reliable performance.

- Bearing System: Equipped with high-quality bearings that comply with European standards, providing smooth operation and reducing maintenance needs.

- Mounting and Brackets: Designed to fit European crane systems, with specific mounting configurations and brackets that ensure compatibility and ease of installation.

Applications and Benefits

- Applications: The European crane wheel assembly is commonly used in cranes and lifting equipment across Europe and other regions that follow similar standards. It is suitable for overhead cranes, gantry cranes, and other lifting systems in industrial settings.

Benefits:

- Standard Compliance: Adherence to European standards ensures high quality, safety, and performance, meeting the requirements of various industrial applications.

- Reliability: The precise engineering and high-quality materials result in dependable performance and durability.

- Compatibility: The design is tailored for compatibility with European crane systems, facilitating easier integration and installation in regions following these standards.

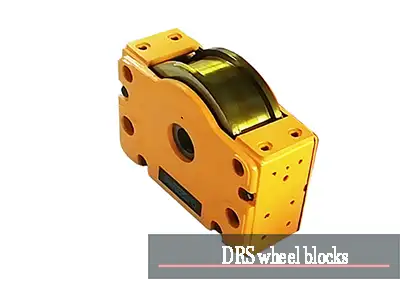

DRS Wheel Assembly

Components and Features

- Modular Design: The DRS wheel assembly features a modular design that allows for customization and flexibility in various crane systems. It consists of separate, interchangeable components that can be adjusted or replaced as needed.

- High-Strength Wheels: Equipped with durable wheels made from high-strength materials designed to handle significant loads and resist wear.

- Precision Bearings: Incorporates precision bearings that provide smooth rotation and reduce friction, contributing to efficient crane operation.

- Adjustable Axle: The axle can be adjusted to fit different crane configurations, ensuring compatibility with various systems and improving ease of installation.

Applications and Benefits

- Applications: The DRS wheel assembly is widely used in modern crane systems, including industrial cranes, gantry cranes, and large-scale overhead cranes. It is particularly beneficial in environments where flexibility and adaptability are crucial.

Benefits:

- Flexibility: The modular design allows for easy customization and adaptation to different crane types and configurations.

- Durability: High-strength wheels and precision bearings enhance the assembly's longevity and performance, even under heavy loads.

- Ease of Maintenance: The design facilitates straightforward maintenance and adjustments, reducing downtime and operational costs.

Specifications and Technical Parameters

Size and Dimensions

- Wheel Diameter: Varies depending on the crane's design and load requirements. Typical diameters range from 150 mm to 600 mm.

- Axle Length: Adjustable to accommodate different crane widths and configurations, with standard lengths often ranging from 300 mm to 1,200 mm.

- Bearing Housing Dimensions: Designed to fit the specific bearing sizes used in the assembly, ensuring compatibility and proper function.

Material and Construction

- Materials: Common materials include high-grade steel, cast iron, and alloy metals for the wheels and axles. Bearings are typically made from stainless steel or high-performance alloys.

- Construction: Components are manufactured with precision to ensure durability and performance. Surface treatments such as heat treatment and coating may be applied to enhance resistance to wear and corrosion.

Load Capacities and Performance

Load Capacities: Crane wheel assemblies are designed to handle a wide range of load capacities. For instance:

- Light Duty: Typically up to 5 tons, suitable for smaller cranes or lighter loads.

- Medium Duty: Generally ranges from 5 to 20 tons, suitable for standard industrial cranes.

- Heavy Duty: Can support loads from 20 tons up to 100 tons or more, used in large-scale or heavy-duty crane applications.

Performance: Key performance metrics include:

- Rotation Smoothness: The assembly should offer smooth and reliable rotation, minimizing friction and enhancing operational efficiency.

- Durability: High-quality materials and construction ensure long-lasting performance and resistance to wear and environmental factors.

- Maintenance Requirements: The assembly should be designed for ease of maintenance, with components that are readily accessible for inspection and replacement.

Understanding these specifications and technical parameters is crucial for selecting the appropriate crane wheel block or assembly for specific crane applications, ensuring optimal performance and safety.

Typical Applications and Uses

Overhead Cranes

- Applications: Overhead cranes, also known as bridge cranes, are commonly used in manufacturing and assembly lines, warehouses, and distribution centers. They are ideal for lifting and moving heavy loads across large areas, such as moving raw materials, machinery, and finished products within a facility.

- Wheel Block Use: Crane wheel blocks for overhead cranes are designed to support the crane’s bridge and trolley systems. They ensure smooth movement along the runway and are critical for maintaining stability and load balance.

Benefits:

- Efficiency: Enhances the crane’s ability to move loads quickly and accurately.

- Safety: Ensures stable and controlled movement, reducing the risk of accidents or damage to materials.

Gantry Cranes

- Applications: Gantry cranes are widely used in outdoor environments such as construction sites, shipyards, and ports. They are designed to move heavy loads across open areas and are particularly useful for handling large items like containers, heavy machinery, and construction materials.

- Wheel Block Use: In gantry cranes, wheel blocks are crucial for supporting the crane’s gantry structure and enabling smooth travel along the rail tracks. They handle significant loads and must withstand harsh environmental conditions.

Benefits:

- Versatility: Suitable for various outdoor and indoor applications, offering flexibility in crane positioning and load handling.

- Durability: Designed to endure heavy-duty use and exposure to the elements, providing reliable performance in challenging conditions.

Bridge Cranes

- Applications: Bridge cranes are used in industrial settings for lifting and transporting materials across a wide span. They are commonly found in factories, assembly lines, and repair shops where high vertical lifting is needed.

- Wheel Block Use: The wheel blocks in bridge cranes support the bridge structure and facilitate movement along the crane’s rails. They play a key role in ensuring the crane operates smoothly and efficiently across its span.

Benefits:

- Precision: Allows for precise positioning of loads, which is essential in manufacturing and assembly processes.

- Heavy Load Handling: Capable of handling large and heavy loads with stability and control.

Specialized Cranes (e.g., Casting Cranes, Port Machinery)

- Applications: Specialized cranes, such as casting cranes used in foundries and port machinery for handling shipping containers, require specific wheel block assemblies to meet unique operational demands. Casting cranes are used to lift and transport molten metal, while port machinery handles heavy containers and cargo.

- Wheel Block Use: These cranes often use custom-designed wheel blocks to accommodate extreme loads, high temperatures, or corrosive environments. The wheel blocks must be engineered to withstand the specific stresses and conditions of their applications.

Benefits:

- Customization: Tailored designs to meet the unique requirements of specialized applications.

- Enhanced Performance: Improves operational efficiency and safety in demanding environments, ensuring reliable performance for critical tasks.

In each application, the choice of crane wheel block and assembly plays a crucial role in ensuring efficient and safe crane operation. Understanding the specific needs of each type of crane helps in selecting the appropriate components to match operational requirements and environmental conditions.

Installation and Maintenance

Installation Procedures

- Preparation: Ensure that all crane wheel block components are correctly specified and compatible with the crane model. Verify that the installation site meets the required specifications, including alignment and load-bearing capacity.

- Assembly: Begin by positioning the wheel blocks on the crane's rail system. Securely attach the wheel axle and wheel disc to the bearing box. Ensure proper alignment of the wheels with the rails to avoid any misalignment issues.

- Testing: Once assembled, perform a thorough test of the crane to check for smooth movement and proper load handling. Adjust the alignment if necessary to ensure the wheel blocks operate efficiently.

Maintenance Best Practices

- Regular Inspections: Conduct routine inspections of the crane wheel blocks and assemblies. Check for signs of wear, corrosion, or damage. Ensure that the wheels and bearings are clean and free of debris.

- Lubrication: Apply appropriate lubrication to the wheel bearings to reduce friction and wear. Follow the manufacturer's guidelines for the type and frequency of lubrication.

- Alignment Checks: Periodically verify the alignment of the wheel blocks with the crane rails. Misalignment can lead to uneven wear and potential operational issues.

- Replace Worn Parts: Replace any worn or damaged components promptly to maintain optimal performance and prevent further damage to the crane.

Common Issues and Troubleshooting

- Uneven Wear: Uneven wear on the wheel blocks can result from misalignment or improper load distribution. To address this, realign the wheel blocks and ensure proper load handling practices are followed.

- Noise and Vibration: Excessive noise or vibration during crane operation may indicate worn bearings or misalignment. Check and replace the bearings if necessary and realign the wheel blocks to resolve the issue.

- Sticking or Jamming: If the crane wheels stick or jam, inspect for debris or damage in the wheel tracks. Clean the area and check for any obstructions or malfunctions in the wheel block assembly.

- Corrosion: In corrosive environments, wheel blocks may suffer from rust and deterioration. Use anti-corrosion treatments and coatings to protect the components and replace any corroded parts as needed.

By following these installation and maintenance practices, you can ensure the reliable and efficient operation of crane wheel blocks, prolonging their lifespan and enhancing overall crane performance.

Conclusion

Crane wheel blocks and their assemblies play a crucial role in ensuring the smooth and efficient operation of various types of cranes. Understanding the different types—such as gear crane wheel blocks, L block crane wheel blocks, 45° split bearing box wheel blocks, European crane wheel blocks, and DRS wheel blocks—along with their specific components, materials, and applications, helps in selecting the right type for different crane systems. The wheel block assemblies, including key components like wheel axles, wheel discs, bearing boxes, and bearings, require proper installation and regular maintenance to prevent issues such as uneven wear, noise, and corrosion. By adhering to best practices in installation and maintenance, operators can enhance the longevity and performance of their crane systems.