Calculating Cantilever Length for Container Gantry Cranes

Proper cantilever length ensures efficient, safe container handling, optimizing crane reach, stability, and operational capacity in port logistics.

Overview of Rail Mounted Container Gantry Cranes in Port Operations

Container gantry cranes are vital in port operations for loading and unloading containers from ships. They move containers from the ship to the dock or onto trucks, helping transfer goods quickly between different areas. These cranes are a key part of modern ports and are used to handle large volumes of cargo as global trade continues to grow.

- Movement on Rails: The cranes move along rails, positioning themselves to pick up or drop off containers where needed.

- Reaching the Ship: These cranes are designed to extend over the side of a ship, allowing them to pick up containers from the ship’s hold or place them back onto the ship.

- Versatile Capacity: They handle containers of various sizes and weights, making them crucial for efficient port operations.

Importance of Calculating the Appropriate Cantilever Length

The cantilever is the overhanging part of the crane that extends beyond its supporting legs. It allows the crane to reach containers that are placed further away, either at the edge of the ship or on the dock. Calculating the right cantilever length is essential for the crane's effectiveness and stability.

- Short Cantilever: A cantilever that is too short limits the crane’s reach, reducing its ability to access all areas of the ship or dock.

- Long Cantilever: A cantilever that is too long can cause stability issues, placing more stress on the crane and making it vulnerable to swaying or tipping, especially in windy conditions.

- Balance: It’s crucial to find a balance, ensuring the crane can reach all necessary areas while maintaining stability and structural integrity.

Maximizing Efficiency, Safety, and Operational Capacity

The main objective when determining the cantilever length is to enhance the crane's efficiency while keeping it safe and stable. A well-calculated cantilever helps the crane perform its tasks quickly and safely, increasing port productivity.

- Maximizing Efficiency: A properly sized cantilever allows the crane to cover a larger area, reducing the need for repositioning and speeding up operations.

- Ensuring Safety: A correct cantilever design prevents overload and instability, ensuring safe operations when handling containers.

- Improving Capacity: A crane with the right cantilever can handle more containers, making operations more effective without the need for extra equipment or delays.

In summary, the correct cantilever length is key to making container gantry cranes work efficiently and safely, supporting the growing demands of global container shipping.

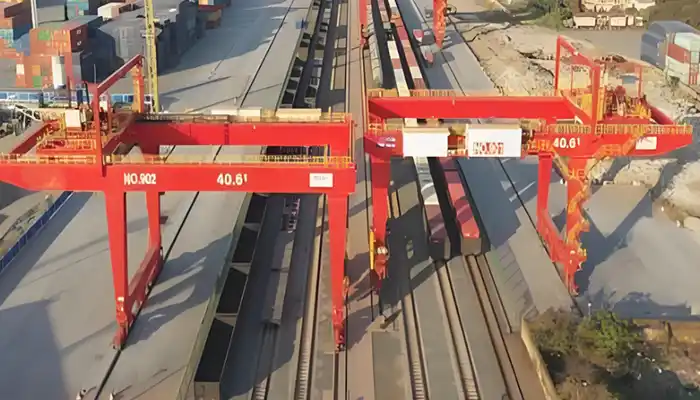

double cantilevered rail mounted gantry crane for container handling

double cantilevered rail mounted gantry crane for container handling

Cantilever Length

Definition of the Cantilever on a Container Gantry Crane

The cantilever on a container gantry crane refers to the portion of the crane that extends beyond its supporting legs or frame. This overhanging structure allows the crane to reach areas that are outside the direct span of its base, such as the far edges of a ship or dockside storage areas. The cantilever is a crucial design feature because it provides the crane with additional range, enabling it to lift and transport containers from places that would otherwise be out of reach.

- Overhanging Structure: The cantilevered portion extends outward, beyond the supporting structure of the crane.

- Crane Extension: The cantilever allows the crane to extend further over ships or the dock to lift containers that are not directly in line with its base.

Role of the Cantilever in Extending the Crane’s Reach

The cantilever plays a key role in enhancing the crane’s reach by allowing it to access areas beyond the base of the crane. This increased reach is especially important in ports with large ships or limited dock space. The longer the cantilever, the further the crane can extend, which is critical for handling containers placed at the edges of a ship or far along the dock.

- Access to Wider Areas: The cantilever allows the crane to lift containers from further distances, both from the ship’s hold and from distant parts of the dock.

- Efficiency in Limited Space: In crowded or smaller ports, a longer cantilever can reduce the need to reposition the crane, allowing for faster operations and handling of containers.

Impact of Cantilever Length on Crane Performance and Container Handling

The length of the cantilever has a significant impact on both the performance of the crane and its ability to handle containers. While a longer cantilever allows for greater reach, it can also affect the crane’s stability, load capacity, and lifting efficiency. Properly calculating the cantilever length is essential to ensure the crane operates safely and efficiently, especially when handling heavy containers at maximum extension.

- Performance: A longer cantilever increases the crane's ability to cover a larger area, reducing the time needed to move containers between the ship, dock, and storage.

- Stability: A longer cantilever can create additional stress on the crane, making it more susceptible to instability, particularly when lifting heavy containers at full reach.

- Load Handling: The cantilever length influences how much weight the crane can safely lift at a given extension. A well-calculated cantilever ensures the crane can handle containers without compromising safety or performance.

In conclusion, understanding the role and impact of the cantilever on a container gantry crane is critical for optimizing the crane’s reach, performance, and ability to handle containers efficiently and safely. Properly designing the cantilever ensures the crane can meet the operational demands of busy ports while maintaining stability and safety.

Key Specifications of Raill Mounted Container Gantry Cranes

- Capacity (without spreader): 30.5 to 40.5 tons

- Span: 15.4 to 23.47 meters

- Lifting Height: 18.2 meters

- Lifting Speed: 12 to 46 meters per minute

- Cross Traveling Speed: 45 to 70 meters per minute

- Long Traveling Speed: 45 to 100 meters per minute

- Working Class: ISO A6-A7 / FEM 3M-FEM 4M

- Power Source: Customized to specific needs

- Customization: Adapted to port layout, ship size, and operational requirements

Key Specifications of Rail Mounted Container Gantry Cranes

Capacity (without Spreader): 30.5 to 40.5 Tons

The capacity of a rail-mounted container gantry crane refers to the maximum load the crane can lift, excluding the spreader. This range of 30.5 to 40.5 tons is designed to handle containers of various sizes and weights commonly found in international shipping.

- Flexible Load Handling: With this capacity, the crane can manage large containers, making it suitable for high-volume ports.

- Excludes Spreader Weight: The listed capacity does not include the weight of the spreader, which is used to lift and secure containers.

Span: 15.4 to 23.47 Meters

The span defines the distance between the rails on which the crane travels, indicating how wide the crane can operate. This range of 15.4 to 23.47 meters ensures that the crane can cover a broad area, enabling it to reach a variety of positions along the dock and ship.

- Adaptable to Different Layouts: The adjustable span allows for customization based on the port’s specific layout and the ship’s size.

- Efficiency in Space-Constrained Areas: The variable span helps optimize crane movement and container handling in tight or expansive dock spaces.

Lifting Height: 18.2 Meters

The lifting height refers to the maximum height the crane can lift containers from the dock to the ship or vice versa. With a lifting height of 18.2 meters, this crane is capable of reaching the upper holds of larger vessels.

- Suitable for Larger Ships: This height allows for effective handling of containers from ships of various sizes, including large container ships.

- Efficient Container Handling: The high lifting capacity ensures that containers can be handled efficiently without the need for additional equipment.

Lifting Speed: 12 to 46 Meters Per Minute

The lifting speed determines how quickly the crane can lift containers. The range of 12 to 46 meters per minute allows the crane to perform at varying speeds depending on the load being lifted.

- Variable Speeds: Slower speeds can be used for heavier loads, while faster speeds are possible for lighter containers, enhancing operational flexibility.

- Faster Turnaround Time: The faster lifting speeds help reduce downtime between container transfers, improving port efficiency.

Cross Traveling Speed: 45 to 70 Meters Per Minute

The cross traveling speed refers to how fast the crane can move horizontally across the dock. With speeds ranging from 45 to 70 meters per minute, the crane can quickly position itself to pick up or drop off containers.

- Quick Dock Positioning: Faster cross traveling speeds allow the crane to move quickly between different container stacks and ships, reducing delays in port operations.

- Increased Efficiency: This speed ensures that the crane can cover a larger area with minimal repositioning.

Long Traveling Speed: 45 to 100 Meters Per Minute

The long traveling speed describes how fast the crane moves along the entire dock, across a longer horizontal distance. This speed range of 45 to 100 meters per minute provides flexibility for the crane to adjust to various operational conditions.

- Adaptability to Port Needs: The long traveling speed allows the crane to cover large stretches of dock, facilitating container handling across expansive areas.

- Improved Productivity: The high speed ensures that the crane can handle multiple containers quickly without losing operational efficiency.

Working Class: ISO A6-A7 / FEM 3M-FEM 4M

The working class indicates the crane’s duty cycle and operational intensity, based on ISO and FEM standards. The range of ISO A6-A7 / FEM 3M-FEM 4M reflects the crane’s ability to perform at medium to heavy-duty levels.

- Heavy Duty Operations: The crane is designed for high-frequency operations, making it suitable for busy ports where continuous loading and unloading are required.

- Standard Compliance: Adhering to ISO and FEM standards ensures reliability and safety in various port environments.

Power Source: Customized to Specific Needs

The crane’s power source can be tailored to meet specific operational requirements, offering flexibility in terms of energy supply and environmental considerations. This customization ensures the crane can work efficiently under different conditions, whether on-grid or off-grid, depending on the port’s needs.

- Energy Efficiency: Customizing the power source allows for more sustainable operations, potentially reducing energy costs and minimizing environmental impact.

- Adaptable to Port Infrastructure: Ports can select power solutions that best suit their existing infrastructure, ensuring seamless integration with the overall port system.

Customization: Adapted to Port Layout, Ship Size, and Operational Requirements

Rail-mounted container gantry cranes can be customized to meet the unique demands of each port. Adjustments can be made to the crane’s size, span, lifting capacity, and features to suit the port layout, ship dimensions, and specific operational goals.

- Port-Specific Design: Cranes can be tailored to fit the available space and specific container handling needs of a particular port.

- Optimized Performance: Custom designs enhance the crane’s ability to meet unique operational challenges, improving overall efficiency and capacity.

In summary, rail-mounted container gantry cranes with these specifications are highly adaptable, efficient, and capable of meeting the complex demands of modern port operations. From capacity and span to speed and customization, these cranes are designed to optimize container handling and ensure smooth, safe, and efficient port operations.

single cantilever gantry crane used in space limited application , learn more on cantilever gantry crane

Factors Influencing Cantilever Length Calculation

Port Layout and Space Constraints

The layout and available space within a port play a major role in determining the optimal cantilever length for container gantry cranes. Ports with limited space for maneuvering containers require longer cantilevers to extend the crane’s reach without needing extra infrastructure. On the other hand, more spacious ports may not need extended cantilevers, as there is sufficient room for crane repositioning and container handling.

- Compact Ports: In narrow or constrained spaces, a longer cantilever allows the crane to service multiple lanes or reach areas farther from the crane base, minimizing the need for repositioning.

- Spacious Ports: Larger ports with ample maneuvering room may require shorter cantilevers, as the crane can work more freely within the available space, making longer cantilevers unnecessary.

Container Ship Size and Type

The size and type of the container ships being handled significantly influence the cantilever length. Larger ships with deeper holds and extended loading/unloading areas require cranes with longer cantilevers to reach containers located at the far edges or bottom of the ship.

- Larger Ships: Container ships with multiple decks or vast hulls need longer cantilevers to effectively lift containers from all sections of the ship.

- Smaller Ships: For smaller vessels, a shorter cantilever may suffice, as the crane does not need to reach as far beyond its base to service the ship's containers.

Dockside Storage Areas

The distance between the crane’s rail track and the dockside storage areas also affects the calculation of cantilever length. If storage areas are positioned farther from the crane’s base, a longer cantilever will be necessary to transport containers from the ship to the storage site or vice versa.

- Distant Storage Areas: For ports with far-off container storage areas, a longer cantilever will be needed to bridge the gap and facilitate smooth container movement.

- Proximity to Crane: If the storage areas are close to the crane, the cantilever can be kept shorter, as the crane can reach the containers more easily without extending too far.

Operational Load and Crane Capacity

The crane’s load capacity directly affects the maximum feasible length of the cantilever. Longer cantilevers place additional stress on the crane’s structure, so it is crucial to ensure the crane can handle the weight of containers at maximum extension. This requires careful consideration of both the load the crane will lift and the structural integrity required to support that load.

- Load Distribution: A longer cantilever requires careful calculation to ensure that the load is evenly distributed, preventing undue stress or instability.

- Crane Stability: The crane must be designed to maintain stability while operating with maximum reach, accounting for both the load and the cantilever extension.

Environmental Factors

Environmental factors such as wind, tides, and weather conditions must be accounted for when determining the cantilever length. Cranes operating in areas with high winds or unstable weather conditions may require shorter cantilevers or additional structural reinforcements to maintain stability and safety.

- Wind Conditions: Wind can cause sway or vibrations in the crane when operating at the maximum cantilever extension, increasing the risk of accidents or operational inefficiencies. Cranes in windy areas may require a shorter cantilever or enhanced stabilization features.

- Tidal and Weather Considerations: Cranes operating in coastal areas or regions affected by tides and extreme weather conditions must be designed to remain stable even when reaching out to full cantilever capacity.

By carefully considering these factors—port layout, ship size, storage distances, load capacity, and environmental conditions—the correct cantilever length can be calculated to ensure optimal crane performance, safety, and efficiency. Each factor is critical in determining the crane’s ability to operate effectively under the specific conditions of the port and the ships it serves.

Steps to Calculate the Correct Cantilever Length

Assessing Port Requirements

The first step in determining the correct cantilever length is to thoroughly assess the port's operational requirements. This involves mapping out the flow of containers from ships to storage areas and identifying key operational zones such as ship berths, container yards, and truck lanes. Understanding how containers move between these points will help define the crane’s necessary reach and its required coverage area.

- Mapping Ship Berths: Identify the positions and layout of ship berths to determine where containers will be loaded and unloaded.

- Container Flow: Analyze the flow of containers between ships, storage areas, and trucks to understand the distances and reach the crane must cover.

- Storage Areas: Identify the location and distance of dockside container storage areas, which will influence the crane's reach to unload containers efficiently.

Defining the Maximum Reach Distance

Once the port's operational flow has been assessed, the next step is to define the maximum reach distance. This is the furthest point the crane needs to extend to in order to service the entire range of containers, from those on the farthest side of the ship to those in distant storage areas.

- Identify Farthest Points: Determine the most distant containers the crane needs to lift and transfer, considering both the ship and the storage area layout.

- Plan for Longest Reach: The crane’s cantilever must be long enough to cover this maximum reach, ensuring no areas are left out of its operational range.

Analyzing Load Capacity

The next step is to evaluate the crane’s load capacity, particularly how it will handle containers at maximum extension. Longer cantilevers place greater stress on the crane’s structure, so the crane must be able to lift containers at full extension without compromising its stability or lifting performance.

- Load at Maximum Reach: Assess the weight of containers at the maximum cantilever extension, as the crane will need to operate with its full capacity under these conditions.

- Structural Integrity: Ensure that the crane’s design accounts for the additional forces at play when operating at full extension, maintaining both stability and performance.

Considering Environmental Conditions

Environmental conditions such as wind, tides, and weather must also be taken into account when calculating the cantilever length. Cranes operating in harsh weather conditions or areas prone to high winds may need a shorter cantilever or additional reinforcement to maintain stability during operations.

- Wind Considerations: Determine the typical wind speeds in the area and how they might affect the crane’s stability when operating at full cantilever extension.

- Weather and Tide Impact: Assess the local climate, including tide variations and other weather-related factors that could influence crane operation, and make adjustments to the cantilever design accordingly.

Optimizing for Efficiency

Finally, the cantilever length must be optimized for efficiency. The goal is to balance the crane’s operational reach with safety, stability, and cost-effectiveness. An overly long cantilever may be unnecessary and costly, while too short a cantilever could hinder operations, requiring more crane movements and increasing turnaround time.

- Operational Reach vs. Safety: Ensure that the crane's reach is sufficient for all operational needs without overextending it, which could impact stability.

- Cost-Effectiveness: Consider the cost implications of the cantilever design. Longer cantilevers may require additional structural reinforcements, leading to higher costs in terms of both materials and maintenance. Balancing cost and operational efficiency is key to optimizing the crane’s design.

By following these steps—assessing port requirements, defining the maximum reach distance, analyzing load capacity, considering environmental conditions, and optimizing for efficiency—port operators and engineers can calculate the correct cantilever length for container gantry cranes. This ensures that the crane will perform effectively, safely, and efficiently within the specific operational parameters of the port.

Importance of Proper Cantilever Length for Port Operations

Operational Efficiency

A properly calculated cantilever length directly contributes to maximizing operational efficiency in port operations. By ensuring the crane can reach all necessary areas within the port, including ship decks and distant storage zones, the container gantry crane can handle more containers in less time. This reduces the need for repositioning the crane or additional equipment, significantly speeding up the loading and unloading processes.

- Increased Handling Speed: A crane with the right cantilever length can quickly and efficiently load or unload containers from ships to storage or trucks, reducing idle time.

- Minimized Downtime: With a proper reach, the crane operates smoothly without delays due to repositioning, which is critical for maintaining a high throughput in busy ports.

Maximizing Coverage

A well-designed cantilever length extends the crane’s operational range, allowing it to cover multiple lanes or storage areas without requiring the crane to be repositioned. This is especially important in ports with limited space or a high volume of containers.

- Extended Reach: By increasing the cantilever length, the crane can service a larger area, covering several truck lanes or stacks of containers in one cycle.

- Reduced Crane Movements: With the ability to cover more ground without relocation, the crane can process containers more efficiently, enhancing overall port productivity.

Safety Considerations

Safety is a major factor in crane design, and the cantilever length plays a vital role in ensuring stable and balanced operations. A cantilever that is too short can limit the crane’s reach and operational flexibility, while a cantilever that is too long can lead to structural instability, imbalanced load distribution, or even accidents.

- Stable Load Distribution: A properly sized cantilever ensures that the load is evenly distributed, reducing the risk of tipping or damaging containers and equipment.

- Structural Integrity: Ensuring the crane’s cantilever is well-calculated helps prevent excessive strain on the crane’s structure, ensuring safe operation under heavy loads and at full extension.

Cost-Effectiveness

While the cantilever length affects operational efficiency and safety, it also impacts the cost-effectiveness of port operations. An ideal cantilever length reduces the need for additional infrastructure investments, such as extra cranes or storage area modifications. Furthermore, it helps optimize the crane’s operational capacity, leading to cost savings in both equipment and maintenance.

- Lower Infrastructure Costs: A crane with the correct cantilever length can eliminate the need for additional infrastructure, such as extra cranes or extended rail tracks.

- Reduced Operating Costs: By reducing crane repositioning, minimizing downtime, and increasing throughput, ports can lower their operating costs while maintaining high levels of performance.

In summary, a properly calculated cantilever length is critical to optimizing port operations. It enhances operational efficiency, maximizes coverage, ensures safety, and delivers cost-effectiveness, all of which contribute to smoother, more profitable port logistics.

Conclusion

In container port operations, the proper calculation of the cantilever length is essential for ensuring that gantry cranes can effectively and efficiently perform their tasks. A well-designed cantilever allows cranes to reach far distances, maximizing their ability to handle containers with minimal downtime. Without the right cantilever length, cranes may struggle to service all necessary areas, affecting the overall efficiency and speed of operations.

Optimal Cantilever Length: Enables cranes to perform efficiently across the entire port, minimizing delays and optimizing container handling.

Emphasis on Balancing Safety, Efficiency, and Cost in Port Operations

When calculating cantilever length, it’s crucial to balance operational efficiency, safety, and cost-effectiveness. While maximizing crane reach can speed up container handling and reduce downtime, it’s equally important to ensure that the crane remains stable and safe to operate. A cantilever that is too long may compromise structural integrity, while one that is too short could limit the crane’s capabilities. Additionally, careful planning of the crane’s design helps reduce infrastructure and operating costs.

- Balancing Efficiency and Safety: Ensures that cranes can perform at their best without risking safety or stability.

- Cost-Effectiveness: Proper design minimizes the need for additional infrastructure and reduces long-term operating costs.

The ever-growing demands of global container shipping require ports to operate at maximum capacity, with cranes playing a central role. A properly designed container gantry crane, with the correct cantilever length, is fundamental to meeting these demands. By optimizing crane design and carefully calculating the cantilever length, ports can improve efficiency, ensure safety, and reduce costs, allowing them to handle larger ships and higher container volumes.

In conclusion, taking the time to calculate and design the optimal cantilever length is a critical step in improving port operations. It contributes to enhanced crane performance, better container handling, and smoother, more cost-effective logistics, which are all essential to staying competitive in the rapidly evolving global shipping industry.