A Buyer’s Guide to Crane Design: From Initial Concept to Final Construction

Focus: A practical guide for crane buyers to understand the step-by-step process of crane design, from the initial idea to the final construction and fabrication drawings.

Why Should You Know It: Understanding the design stages helps crane buyers make informed decisions, prevent mistakes, and ensure the crane meets their needs before installation begins.

Crane Design Process

Purpose of the Guide

This guide is designed to help crane buyers understand the entire crane design process, from the initial concept to the final construction and installation. The crane design process involves several stages, each critical to ensuring the final product meets your operational needs. Whether you're purchasing your first crane or replacing an old one, knowing what happens at each stage helps you make more informed decisions.

Why It's Essential for Crane Buyers to Understand the Stages of Design

Understanding the design stages allows you to see exactly how your crane is being built, step by step. Each stage offers opportunities to adjust and refine the design to suit your specific needs. When you are familiar with the process, you can identify potential issues early, preventing costly mistakes or delays later on. This knowledge helps you:

- Prevent Misunderstandings: Knowing what to expect at each stage ensures you're not caught off guard by changes or setbacks.

- Ensure Accuracy: By understanding the design phases, you can make sure the crane is being built to the exact specifications you need.

- Make Better Decisions: You'll be able to ask the right questions and make decisions that align with your requirements, timeline, and budget.

Why This Guide Matters to You as a Buyer

This guide is not just about understanding how cranes are designed; it's about giving you the tools to be an informed buyer, so you can make the best decisions for your business. Here's how it helps you:

- Helps You Set Realistic Expectations

Understanding each stage of the design process ensures you have realistic expectations for timelines, costs, and outcomes. Instead of being left in the dark, you'll know exactly what to expect and when. - Prepares You for Each Stage of the Design

The crane design process is complex and involves many detailed steps. This guide breaks it down clearly, helping you stay prepared for every stage — from the initial concept to the final construction drawings. You'll be able to review the plans with confidence, knowing how each part fits into the bigger picture. - Ensures the Crane Meets Your Operational Needs, Budget, and Timeline

One of the most important aspects of crane buying is ensuring that the crane will serve your exact operational needs. By understanding the design process, you can monitor how the crane's specifications evolve to meet those needs, while also staying within your budget and timeline. Whether you're lifting heavy materials or working in a restricted space, understanding the design stages ensures your crane will be built to perform exactly how you expect.

By following this guide, you'll gain the knowledge necessary to guide the entire process, from initial inquiry to the final installation, helping you make informed decisions that lead to a crane that works efficiently, safely, and within budget.

Initial Concept and Requirements Gathering

Identifying Your Needs

Before the crane design process begins, it's essential to thoroughly understand and define the specific requirements of your project. The initial concept is shaped by several critical factors that help determine the crane's specifications and design. This step lays the foundation for ensuring that the crane meets your operational goals and fits within your facility's physical constraints.

- Determining the Crane's Purpose:

Start by identifying what the crane will be lifting. Are you handling heavy machinery, lightweight materials, or specialized items? The crane's lifting capacity will be based on the weight and type of materials it needs to move. - Where the Crane Will Operate:

Consider the environment where the crane will be used. Will it be an indoor crane in a warehouse, an overhead crane in a factory, or a mobile crane operating on a construction site? The design must align with the location and nature of the work. - Establishing Crane Capacity, Span, and Lifting Height:

Define the crane's required capacity (how much weight it needs to lift), span (the distance between its supporting structures), and lifting height (how high the crane hook must be able to reach). These specifications are crucial in determining the type and size of crane required for your operation. - Understanding Your Facility's Constraints:

Assess the physical limitations of your facility, including headroom (the space available between the crane's components and the ceiling), runway systems (the tracks or beams the crane will move along), and any other structural elements that may affect crane installation and operation. These factors influence how the crane will be integrated into your existing infrastructure.

Preliminary Design Discussions with Engineers

Once your needs have been clearly defined, it's time to collaborate with crane designers or engineers. This phase ensures that all your requirements are considered and sets the stage for creating an effective and efficient crane design.

- Collaboration Between Buyer and Designers/Engineers:

During this stage, the buyer communicates their requirements to the design team. The crane's specifications, including load capacity, dimensions, and operational requirements, are discussed in detail. The engineering team will also explore various crane types and configurations that best suit your needs, whether it's a bridge crane, gantry crane, jib crane, or a custom solution. - Discussing Potential Designs and Equipment Types:

Together with the engineers, you will explore different types of cranes and decide which design best fits your operational environment. Consideration of any special requirements, such as explosion-proof cranes for hazardous environments, or anti-corrosion coatings for cranes used in harsh outdoor or marine settings, is essential to ensure the crane is built for longevity and safety. - Special Requirements:

If you have any unique needs, such as cranes designed to operate in extreme temperatures, specific load handling requirements, or customization for tight spaces, these should be discussed early in the design phase. The design team can then incorporate these considerations into the design from the outset.

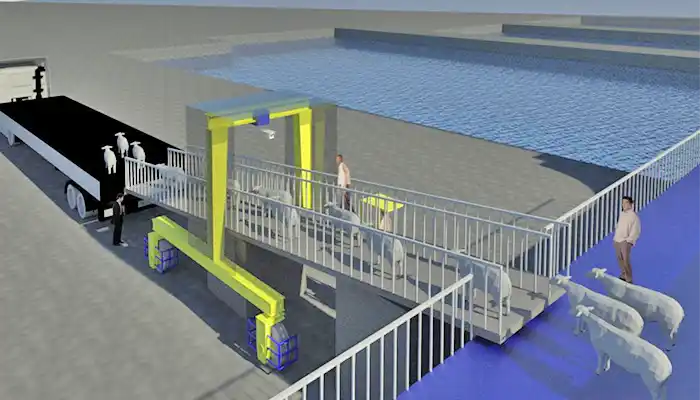

Creating the Initial Concept Drawing

The Initial Concept Drawing is the first visual representation of the crane's design. It outlines the crane's key specifications and how it will be positioned and operated within your facility.

Overview of What an Initial Concept Drawing Includes:

The initial concept drawing provides a basic layout of the crane, including its dimensions, general configuration, and placement in the workspace. It highlights critical elements such as the crane's movement area, load handling zones, and essential components like hoists, trolleys, and runway systems.

The concept drawing may also include basic notations for crane capacity, lifting height, and span, offering an early look at how the crane will fit within your facility's space.

Concept Drawings vs. Preliminary Drawings: What's the Difference?

The concept drawing is a high-level sketch or schematic, providing a basic idea of the crane's design and how it will function. It's not overly detailed but gives an overview of the system.

The preliminary drawing, on the other hand, provides a more detailed look at the crane's layout and design, including dimensions, materials, and components. It is based on the initial concept but refined with more technical details to form the foundation for the final construction and fabrication drawings.

In the next phase of the process, these concept and preliminary drawings are further developed and refined to create detailed engineering drawings that guide the fabrication and construction stages. However, understanding the initial concept helps crane buyers ensure the design aligns with their specific requirements before moving forward.

Preliminary Design Stage

What Happens in the Preliminary Design Phase?

The Preliminary Design phase is where your initial crane requirements start to come to life. After gathering the necessary information in the concept phase, the designers and engineers create a more detailed crane layout. This phase is crucial for laying the groundwork and ensuring the crane will meet operational needs while adhering to facility constraints.

Translating Requirements into a Functional Crane Layout:

During the preliminary design, the crane's specifications—such as capacity, span, lifting height, and movement system—are translated into a functional layout. This layout begins to consider how the crane will operate within the space, ensuring that the crane fits well with the facility's constraints and operational goals.

Key Elements in a Preliminary Design:

Preliminary crane designs focus on the basic structure of the crane, ensuring it meets the required specifications. Some of the key elements considered in the design include:

- Dimensions: The crane's size, including its height, width, and span, based on your space requirements.

- Load Capacity: The maximum weight the crane is designed to handle, factoring in both the crane's lifting capacity and the operational needs.

- Basic Structure: The structural components, such as the girder, hoist mechanism, and other key parts, that support the crane's operation.

Reviewing the Site Conditions

At this stage, it's critical to review the site conditions thoroughly. These conditions include the physical space where the crane will be installed, as well as any environmental factors that may affect crane operation.

- Space: The crane design must fit within the available space in your facility. Any obstructions, such as walls, machinery, or structural supports, need to be considered when placing the crane.

- Height Restrictions: Many facilities have strict height limits due to low ceilings, equipment, or HVAC systems. These height restrictions directly influence the crane's design, particularly the lifting height and hook clearance.

- Environmental Factors: Conditions like temperature extremes, humidity, or the presence of corrosive substances (e.g., chemicals or saltwater) need to be factored into the crane design. For instance, cranes working in marine or outdoor environments may require anti-corrosion materials or special protective coatings.

Preliminary Drawings

Preliminary crane design drawings are a visual representation of the layout, dimensions, and specifications that define the crane. These drawings are more detailed than the initial concept sketches but not as precise as final construction plans.

What Buyers Need to Look for in Preliminary Crane Design Drawings:

As a crane buyer, it's essential to understand what's included in these preliminary drawings. These documents show the crane's general design, placement within the facility, and layout of key components. Some important things to review include:

- Crane dimensions: Ensure the crane's size fits within your available space.

- Load capacity: Double-check the crane's weight handling capabilities against your operational needs.

- Movement system: Review how the crane will move along its tracks, including trolley and hoist operations.

- Clearances: Verify the crane's clearance from other structures to ensure safe operation.

How These Drawings Evolve into Detailed Construction Plans:

Preliminary drawings provide a foundation, but they will need to be refined and updated during the final design stages. As the design progresses, the preliminary drawing will evolve into more detailed construction plans, which include exact measurements, material specifications, and other vital details necessary for fabrication and installation.

Making Design Adjustments

During the preliminary design phase, there may be opportunities to make adjustments to the crane layout and functionality to ensure it perfectly meets your needs. It's essential to identify any tweaks or improvements that might be necessary before moving forward with detailed construction.

- Ensuring the Design Fits Your Needs:

If the preliminary design reveals any issues or discrepancies—whether related to size, capacity, or functionality—it's important to raise these concerns with your engineers and designers. Adjustments may include resizing the crane, adjusting clearances, or upgrading certain components to meet specific operational needs or safety standards. - Importance of Validating Load Capacities, Movement Systems, and Clearance Zones:

One of the most critical elements to review during this phase is the load capacity. Ensure the crane can safely handle the loads it will lift and move, taking into account dynamic forces, lifting speed, and load stability. Additionally, it's vital to validate that the crane's movement systems (e.g., hoist, trolley) will operate efficiently in the available space and that clearance zones (e.g., from the ceiling, walls, or other equipment) are sufficient to allow for safe crane operation without interference.

In summary, the Preliminary Design Stage is essential for ensuring that the crane's layout aligns with your operational requirements and facility constraints. By carefully reviewing preliminary drawings and making necessary adjustments, you can avoid costly mistakes and ensure that the crane design will function effectively in your space.

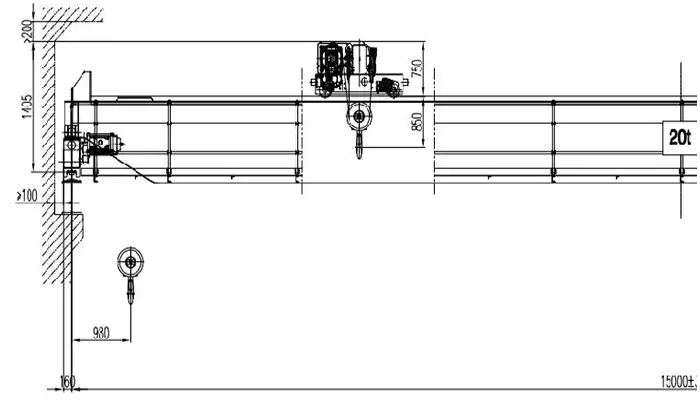

Construction Drawings: Turning Concepts into Reality

What Are Construction Drawings?

Construction drawings are the final, detailed plans used to guide the manufacturing, assembly, and installation of the crane. Unlike preliminary or conceptual drawings, which are more general, construction drawings are highly specific and precise. These drawings outline everything needed for the crane's construction and installation, ensuring that the crane meets safety, design, and functional requirements.

Detailed Specifications: Construction drawings show every dimension, material, and component that will be used in building the crane. They provide precise instructions on how the crane's components should be fabricated and assembled.

Key Components:

- Dimensions: Exact sizes and tolerances for each part of the crane.

- Materials: Specifications for the materials used in the crane's construction, including steel grades, coatings, and any other special materials.

- Load-bearing Structures: The design and materials for the crane's structural components, including beams, girders, columns, and other support systems that bear the loads during operation.

How Construction Drawings Address the Crane's Specifics

Construction drawings are where the general concepts from the preliminary design phase are translated into exact instructions for building the crane. These drawings provide a clear picture of how the crane will be put together and the specifications that ensure it meets all required standards.

Breakdown of Construction Drawing Components:

- Structural Details: The construction drawings show the precise layout of the crane's structural components, such as beams, girders, supports, and hoist mechanisms. These components must be detailed to ensure that they can support the intended loads.

- Assembly Instructions: These drawings guide how the crane's parts will be assembled, including the step-by-step instructions for putting together the crane once the parts are fabricated.

- Load Ratings: Each component of the crane, including the hoist, trolley, and structure, will be designed with specific load ratings to ensure the crane can handle its maximum weight capacity safely. The load ratings are marked clearly on the construction drawings.

Significance of Load Path, Safety Factors, and Foundation Requirements:

- Load Path: The load path refers to the route that the crane's load follows from the hook through the crane's structure. This is critical to understanding how the load will be distributed across different components of the crane and to ensuring that each part of the crane is capable of bearing its share of the weight.

- Safety Factors: Construction drawings will outline the safety factors that have been incorporated into the crane's design. These factors are used to ensure that the crane can safely handle the maximum expected loads under different conditions. This might include overload protection, stability during lifting, and safety margins.

- Foundation Requirements: The crane's base and any supporting structures must be designed to handle the loads and forces the crane will generate. Construction drawings will include detailed specifications for the crane's foundation, ensuring that it can support the weight of the crane itself and the loads it will lift.

Reviewing Construction Drawings

As a crane buyer, you play an essential role in reviewing construction drawings before moving forward with fabrication. It's crucial to carefully examine the drawings to ensure that everything meets your project's specifications.

What Buyers Should Pay Attention To:

- Dimensions: Ensure that the crane's dimensions match your space constraints, including height, span, and clearance. Review all size specifications for each crane component to verify they fit within your facility's layout.

- Strength and Material Choices: Confirm that the materials used for the crane's construction are appropriate for the intended use and environment. This includes verifying material grades, coatings (e.g., for corrosion resistance), and ensuring that structural components are capable of handling the crane's load capacity.

- Load Ratings and Safety Features: Ensure that the crane's design can safely lift the intended loads. Verify that the crane's safety features (e.g., overload protection, stability features) are incorporated in the design and comply with relevant safety standards.

- Assembly Instructions: Review the assembly instructions to ensure that all parts are included, and you understand how they will be assembled. This is critical to avoid any miscommunications during the installation phase.

Approval and Finalization

Before moving forward with fabrication, the construction drawings must be reviewed, finalized, and approved by all parties involved, including you (the buyer), your engineering team, and any third-party experts or inspectors.

Reviewing and Finalizing the Construction Drawings:

- Collaboration: Work closely with your engineers, crane manufacturers, and any consultants to ensure that all the details are correct. Double-check dimensions, load capacities, material choices, and safety features.

- Addressing Concerns or Discrepancies: If you notice any discrepancies between what you expect and what is in the construction drawings, address them immediately. Whether it's a dimension that doesn't fit or a material specification that needs to be updated, resolving issues at this stage is crucial to avoid delays or mistakes during construction.

- Final Approval: Once you're satisfied with the construction drawings and any issues have been resolved, sign off on the plans. This is the final step before the crane moves into the fabrication phase.

In summary, construction drawings are essential for turning the crane design from concept to reality. These drawings provide the precise details needed for fabrication, assembly, and installation. As a crane buyer, reviewing and approving these drawings ensures that the crane will meet your facility's needs, operate safely, and be built according to the specifications you require.

Fabrication Drawings: The Blueprint for Manufacturing

What Are Fabrication Drawings?

Fabrication drawings are the detailed plans that guide the actual manufacturing of each crane component. These drawings break down the crane design into individual parts that will be produced separately before being assembled into the final crane. They provide the detailed specifications needed to turn the design into tangible pieces, ensuring that each component is manufactured correctly.

Role in the Production Process: Fabrication drawings are the blueprint for the manufacturing phase. They help the production team understand exactly what parts need to be made and how they should be constructed. These drawings cover everything from the crane's structural elements, like steel beams and columns, to mechanical components such as hoists and motors.

Breaking Down the Crane: Each component of the crane is broken down into manageable pieces that can be individually fabricated. These might include:

- Steel Beams: The structural framework of the crane.

- Hoists and Motors: Mechanical systems that enable lifting and movement.

- Trolleys and Hooks: Parts that transport the load across the crane's span.

Key Features of Fabrication Drawings

Fabrication drawings are detailed and technical, providing everything needed for manufacturers to produce the crane components to specification.

- Detailed Measurements: Fabrication drawings include precise dimensions for each individual part. These measurements ensure that all components fit together as planned during the assembly stage.

- Material Specifications: The materials used for each part (such as steel type, coating, or finish) are clearly outlined. This ensures the right materials are used for strength, durability, and any specific environmental conditions (e.g., corrosion-resistant coatings for marine cranes).

- Welding and Assembly Instructions: These drawings provide step-by-step instructions on how each part is welded, assembled, or fastened. This is crucial for ensuring that each component is correctly manufactured and assembled without errors.

Final Buyer Review of Fabrication Drawings

Before the manufacturing process begins, crane buyers should review the fabrication drawings to confirm that everything is in line with their expectations and specifications. This final review is crucial to avoid any issues during production and to ensure that the crane components meet the project's requirements.

What to Expect in the Review:

- Consistency with Earlier Specifications: Buyers should verify that the fabrication drawings reflect all the specifications agreed upon during the preliminary design and construction drawing phases. This includes confirming the dimensions, materials, and design features.

- Confirming Part Details: Check that all components listed in the drawings are present and match the expected specifications. This includes structural components, hoisting systems, and safety features.

- Addressing Concerns Before Manufacturing: If there are any discrepancies or concerns about the fabrication details, the buyer should raise them before production begins to ensure smooth manufacturing and assembly.

In conclusion, fabrication drawings are a critical part of the crane manufacturing process, detailing how each component should be made and assembled. Buyers must carefully review these drawings to ensure that every detail aligns with their project needs and the earlier design stages. This final review helps prevent errors and ensures that the crane is built to specification before moving on to the assembly and installation stages.

From Design to Manufacturing: What Happens Next

Manufacturing and Production

Once the fabrication drawings have been finalized and approved, the process shifts to manufacturing the crane's components. This phase involves the actual production of the crane's individual parts, such as beams, motors, hoists, and other structural elements.

Manufacturing Process: Crane components are produced according to the specifications provided in the fabrication drawings. Each part is carefully fabricated using the correct materials, dimensions, and assembly methods. Common steps in the manufacturing process include:

- Cutting and Shaping: Steel beams and components are cut and shaped according to the design specifications.

- Welding and Assembling: Parts are welded together to form larger sections of the crane.

- Machining: Precision components like gears and motors are machined for exact fit and performance.

Timeline and Challenges: The manufacturing process can take several weeks or months, depending on the crane's complexity and the size of the order. Potential challenges during this phase may include:

- Material Sourcing: Availability of materials or specialized components.

- Production Delays: Issues with equipment or labor shortages can delay production.

- Customization: If the crane includes custom features (e.g., explosion-proof components), these may take longer to manufacture.

Inspection and Quality Assurance

Inspection and quality assurance are critical in ensuring that every component meets the required standards before the crane is shipped and assembled. Quality control helps catch issues early and ensures the crane will perform as expected when installed.

Quality Control During Fabrication: Manufacturers will carry out multiple quality checks during the production process, such as:

- Dimensional Accuracy: Ensuring that all parts are made to the correct dimensions and tolerances.

- Material Testing: Verifying the materials used (e.g., steel strength, coatings) meet the necessary standards.

- Welding and Structural Integrity: Inspecting welds and structural joints to ensure they are strong and secure.

Role of the Buyer in Quality Assurance: As a crane buyer, you have a role to play in quality control by:

- Reviewing Inspection Reports: Requesting regular updates on the manufacturing progress and inspection results.

- Conducting On-Site Visits: If possible, visiting the manufacturing site or requesting photos and videos of key milestones to ensure quality.

- Final Approval: Giving final approval for the crane to be shipped after confirming it meets all requirements.

Delivery and Installation

Once the crane is manufactured and passes quality control, it's ready for delivery and installation. Coordinating this stage efficiently is essential to avoid delays and ensure the crane is installed correctly.

Coordinating Delivery: The crane's components will be carefully packed, labeled, and delivered to the installation site. This step often involves:

- Logistics Coordination: Ensuring transportation is arranged for large or heavy components.

- Inspection Upon Arrival: Verifying that all parts have arrived in good condition and match the design specifications.

Ensuring Specifications Are Met: Before installation begins, it's important to:

- Check for Accuracy: Confirm that all components delivered are as specified in the design and fabrication drawings.

- Resolve Any Issues: If any parts are damaged or there are discrepancies in the delivery, address them immediately with the manufacturer before proceeding.

Final Installation: Once everything is confirmed, the crane components are assembled and installed by professional technicians. This phase includes:

- Structural Assembly: Crane beams, trolleys, hoists, and other elements are assembled at the installation site.

- Electrical and Mechanical Setup: Power systems, control systems, and safety features are set up and tested.

- Final Testing and Calibration: The crane is tested for performance, ensuring it operates as expected under load conditions.

In conclusion, from design to manufacturing, each stage in the process plays a crucial role in ensuring that the crane meets the buyer's expectations and is ready for safe, efficient operation. Understanding these phases helps buyers anticipate potential challenges, actively participate in quality assurance, and ensure that the crane is delivered and installed successfully.

Final Considerations Before Crane Installation

Reviewing Final Specifications

Before the crane is installed, it's essential to do a final check on the specifications to ensure everything aligns with what was agreed upon during the design and manufacturing stages. This final review confirms that the crane is ready for successful installation and operation.

Key Actions for Buyers:

- Reviewing the Specifications: Double-check the final crane specifications, including dimensions, weight capacity, and any custom features (e.g., anti-corrosion materials, explosion-proof systems).

- Assembly Instructions: Ensure the installation team has received the correct assembly instructions that detail how each component should be assembled and installed.

- Load Charts and Safety Protocols: Confirm that the crane's load charts, operational limits, and safety protocols are included in the documentation for the installation team. This will guide the team in understanding the crane's operational parameters and ensure safe installation.

Site Preparation

Preparing the installation site is a critical step in ensuring that the crane is properly installed and will operate safely and efficiently. The site must meet the specifications outlined in the design and fabrication stages, with all necessary infrastructure in place.

Key Areas to Address:

- Space Requirements: Confirm that the installation site has enough space for the crane and all its components. The site should also allow for sufficient clearance for the crane's movement and operation, including overhead and lateral clearances.

- Foundation: Ensure the crane's foundation is strong enough to support the weight of the crane and the loads it will carry. The foundation must be level and constructed to the specifications provided in the crane's design drawings.

- Electrical and Mechanical Systems: Verify that all electrical connections (power supply, controls, etc.) and mechanical systems (e.g., hoists, motors) are ready for the crane's installation. This includes checking the wiring, grounding, and any system interfaces that the crane will interact with.

- Collaborating with the Installation Team: Work closely with the installation team to ensure that the site is fully prepared. A collaborative approach will help resolve any issues early and make the installation process smoother.

Safety and Compliance Checks

Before proceeding with crane installation, a final safety and compliance review is necessary to ensure the crane meets industry standards and local regulations. This includes checking that all safety features are in place and verifying compliance with the relevant safety standards and certifications.

Key Areas to Review:

- Safety Features: Ensure that the crane includes all necessary safety features, such as emergency stop buttons, overload protection, and proper safeguarding around moving parts. These features must align with the design specifications and industry safety standards.

- Regulatory Compliance: Double-check that the crane complies with all regulations such as OSHA (Occupational Safety and Health Administration) standards, ISO standards, and any other local regulations that govern crane installation and operation. This includes load testing, safety equipment, and structural integrity checks.

- Certifications: Verify that all required certifications are in place, including proof of compliance with relevant safety and quality standards. This may involve checking that the crane manufacturer has provided all necessary documentation proving that the crane meets required certifications, such as CE marks or other regulatory approvals.

Final Checklist for Buyers

- Review final crane specifications and documentation (assembly instructions, load charts, and safety protocols).

- Prepare the installation site: Confirm adequate space, foundation, and electrical/mechanical systems.

- Collaborate with the installation team to ensure site readiness and smooth assembly.

- Conduct a final safety and compliance review, ensuring all features and certifications are in place.

- Ensure the installation team is fully informed and prepared for the task.

By taking these final steps and ensuring the installation site is ready, you'll set the stage for a successful crane installation that meets your expectations and operates safely and efficiently.

Common Buyer Pitfalls to Avoid

Misunderstanding the Design Process

One of the most common mistakes crane buyers make is misunderstanding or rushing through the design process. Every stage of the design—whether it's concept, preliminary, or detailed—has its unique significance and should not be skipped or rushed.

Risks of Skipping Stages or Rushing:

- Unclear Requirements: If you don't spend enough time in the early stages (such as gathering all the requirements), the design might not align with your needs. Rushing through the planning and concept stages could result in a crane that doesn't fit your space, lacks the needed capacity, or doesn't meet safety requirements.

- Operational Inefficiencies: Overlooking design details—such as the crane's dimensions, hoist positioning, or clearance space—can lead to poor operational performance. For example, if the crane's travel path isn't properly accounted for, it could be difficult for operators to maneuver the crane efficiently.

- Safety Issues: Neglecting to follow proper design procedures can lead to safety hazards. For instance, failing to account for appropriate safety features, load-bearing limits, or clearances between the crane and other equipment can put workers at risk and may result in accidents or injuries.

Inadequate Review of Design Drawings

Many crane buyers fail to thoroughly review the design drawings, which can result in costly mistakes or delays later in the project.

Importance of Thorough Review:

- Missed Structural and Safety Specifications: Missing details about structural elements, safety features, or materials in the design drawings can have a significant impact on both the crane's performance and safety. For example, the material specifications (steel grade, corrosion resistance, etc.) might not meet the environmental conditions, affecting the crane's durability and reliability.

- Ignoring Load Capacities and Clearances: Failing to check that the load capacity and clearance requirements match the needs of your operations can lead to underperformance or operational restrictions once the crane is installed.

- Discrepancies in Materials: Material choices outlined in the design drawings—such as the type of steel used for beams or hoists—are critical for the crane's strength and longevity. Overlooking these details could result in a crane that is unable to handle the specified loads, or is at risk of premature wear and tear.

Delays in Manufacturing and Delivery

Another common mistake is delaying or failing to clarify design expectations upfront, which often leads to manufacturing and delivery delays.

Clarifying Design Expectations Upfront:

- Clear Communication is Key: Ensuring that all aspects of the crane's design, functionality, and specifications are clearly defined from the start will prevent confusion later in the process. Lack of clarity during design discussions can lead to misunderstandings that cause design changes, which will delay production.

- Manufacturing Delays: If your expectations aren't clearly communicated and agreed upon, the manufacturer may need to make revisions to the crane's design or materials after production begins. This can slow down the entire manufacturing process, and as a result, the crane may not be delivered on time.

- Setting Realistic Timelines: Establishing realistic timelines for production and delivery is crucial to avoid delays. Make sure you've accounted for factors such as material procurement, fabrication time, and transportation logistics. Additionally, consider any potential challenges that may arise during manufacturing and allow extra time to address them.

How to Avoid These Pitfalls

- Spend time understanding each stage of the design process and don't rush through it. Work with the design team to ensure every requirement is clearly understood.

- Review all design drawings in detail and ensure that all specifications, including materials, dimensions, and safety features, are accurate and aligned with your operational needs.

- Clarify your expectations upfront with the manufacturer and establish a clear, realistic timeline for manufacturing and delivery to avoid unnecessary delays.

By actively avoiding these common pitfalls, crane buyers can reduce risks and ensure that the crane installation process runs smoothly, efficiently, and safely.

How to Ensure a Smooth Crane Buying Experience

Effective Communication with the Manufacturer

Clear and continuous communication with the crane manufacturer and engineering team is key to a successful crane purchasing process. This ensures that your needs are understood at every stage and that any potential issues are addressed promptly.

Keep the Lines of Communication Open:

- Regular Updates: Stay in regular contact with the manufacturer to get updates on the design, manufacturing process, and any potential delays. Establish a point of contact who can provide timely information and answer your questions.

- Feedback and Revisions: Make sure you provide feedback early and often, especially during the design phases. If there are any concerns or adjustments needed, addressing them sooner will prevent delays and miscommunication later.

- Clarify Expectations: Make sure that everyone is on the same page regarding the crane's specifications, timeline, budget, and delivery requirements. This will reduce the risk of misunderstandings that can lead to mistakes or delays.

Key Questions to Ask Throughout the Design Process:

- About Design: "How does the design address our facility's specific needs (space, load capacity, headroom)? Are there any potential limitations?"

- About Materials and Components: "What materials will be used for the crane? Are they suitable for the operating environment?"

- About Timelines: "What is the estimated timeline for design, production, and installation? Are there any potential factors that could delay delivery?"

- About Safety: "Are the crane and its components compliant with relevant safety standards and regulations (e.g., OSHA, ISO)?"

Setting Realistic Expectations

Setting realistic expectations is essential for both managing the project effectively and ensuring the crane meets your operational needs without unnecessary delays or budget overruns.

Understanding the Timeline:

- Realistic Timeframes: Understand that the crane design, production, and installation process can take time. A typical timeline will vary depending on factors like the complexity of the crane, custom features, and potential challenges such as site preparation or shipping logistics.

- Plan for Delays: Always factor in potential delays due to manufacturing, shipping, or unforeseen site challenges. Having some buffer time can help avoid frustration if the schedule shifts slightly.

Understanding the Budget:

- Know Your Budget: Be clear about your budget from the start and make sure the design and specifications align with it. Custom features and specialized cranes can increase the cost, so ensure that your budget accounts for any extras.

- Cost-Benefit Analysis: Weigh the benefits of any extra features (e.g., higher lifting capacity, anti-corrosion materials, automation) against their added costs. Understanding these trade-offs will help you make informed decisions and avoid overspending.

Potential Challenges:

- Manufacturing Constraints: Be aware that certain design elements (e.g., special materials, unique customizations) could affect the production timeline. Discussing these potential challenges early on will help avoid surprises later.

- Installation Site: Understand that the site conditions—such as foundation strength, available space, and accessibility—can also impact the crane installation process. Ensure the installation site is adequately prepared in advance to prevent delays.

Post-Installation Support and Maintenance

The process doesn't end once the crane is installed. Ongoing support and maintenance are crucial for ensuring that the crane operates smoothly over its lifespan.

Ongoing Communication with the Manufacturer:

- Post-Installation Support: Establish a post-installation support plan with the manufacturer to ensure that any issues are resolved quickly. This might include technical support, spare parts availability, and periodic check-ins.

- Troubleshooting: If there are any operational issues during the initial usage period, it's important to have access to quick, responsive support from the manufacturer. Ensure you know who to contact for troubleshooting and repairs.

Proper Maintenance:

- Routine Inspections: Set up a routine maintenance schedule that includes regular inspections, lubrication, and adjustments to keep the crane running at optimal performance. Many crane manufacturers offer maintenance programs to help ensure longevity and safety.

- Training for Operators: Ensure that your crane operators are properly trained on how to use and maintain the crane safely and efficiently. Proper training can reduce wear and tear on the crane and prevent avoidable damage.

- Spare Parts and Repairs: Discuss with the manufacturer the availability of spare parts and how to access them quickly when necessary. Having a plan for parts replacement and repairs will prevent long periods of downtime.

By establishing strong communication, setting realistic expectations, and planning for post-installation support, you can ensure that your crane buying experience goes smoothly, meets your operational needs, and provides long-term value for your business.

Conclusion

Summary of the Design Process for Crane Buyers

The crane buying process involves several critical stages, each playing a key role in ensuring that the crane you receive meets your exact operational requirements. Understanding each stage—from the initial concept to final installation—will help you make informed decisions and avoid costly mistakes.

- Concept Stage: This is where you define the crane's purpose, capacity, and operational environment. It's a collaborative stage, where you work closely with your crane designer to set clear specifications.

- Preliminary Design: In this stage, the design begins to take shape, with a focus on layout, capacity, and space considerations. Preliminary drawings help you visualize how the crane will fit into your facility and provide a baseline for adjustments before final plans are made.

- Construction Drawings: These detailed drawings specify materials, dimensions, and load ratings. They ensure that the crane is designed to the highest standards of safety and durability.

- Fabrication Drawings: Once the construction plans are finalized, fabrication drawings break down the crane into its individual components. These drawings guide the manufacturing process, ensuring each part is made to precise specifications.

- Installation: The final stage involves coordinating the crane's delivery and installation. This is where all the planning comes together, and the crane is set up and tested in your facility.

Final Advice for Buyers

To ensure a smooth and successful crane purchase, stay involved at each stage of the design and manufacturing process. The more informed you are, the better equipped you'll be to spot potential issues early on and address them before they become problems.

- Collaborate Closely with Engineers and Manufacturers: Regular communication with your crane designers and manufacturers is crucial. Make sure they fully understand your operational needs and site conditions. Ask questions, request clarifications, and provide feedback to refine the design and ensure that every detail aligns with your expectations.

- Ensure Proper Documentation: As you move through the design process, make sure all drawings—preliminary, construction, and fabrication—are thoroughly reviewed. Check that they meet the specifications discussed and that the crane's load ratings, materials, and safety features are properly documented.

- Plan for Post-Installation Support: Installation is just the beginning. Set up a maintenance plan with your crane supplier to ensure smooth operations in the long term. This includes operator training, scheduled inspections, and spare parts availability.

By following these steps and staying proactive throughout the crane purchasing process, you'll ensure that the crane not only meets your immediate operational needs but continues to perform reliably over time.

Appendices (Optional)

Glossary of Crane Design Terminology

A clear understanding of the terminology used in crane design can help you navigate the entire process with confidence. Here are some common terms you may encounter:

- Capacity: The maximum weight the crane can lift, usually specified in tons.

- Span: The horizontal distance between the rails or beams that the crane travels on.

- Headroom: The vertical distance from the crane's hook to the overhead structure, such as the ceiling or building beams.

- Lift Height: The maximum height the crane's hook can reach above the ground or work surface.

- Runway System: The tracks or beams on which the crane travels within a facility.

- Trolley: The mechanism that moves the hook along the bridge girder.

- Girder: A major beam of the crane that supports the trolley and hook.

- Clearance: The necessary space between the crane's components (such as the hook and the building structure) to allow for safe operation.

- Fabrication Drawings: Detailed drawings that break down the crane into individual components, including specific materials and assembly instructions.

- Preliminary Drawings: Early-stage design sketches that show the basic layout, dimensions, and key features.

- Construction Drawings: Finalized drawings that specify exact dimensions, materials, and assembly details for the crane.

Checklists for Buyers

This checklist helps ensure that you've covered all key aspects of crane design during the various stages of the purchasing process.

Preliminary Design Stage:

- Confirm crane capacity, span, and lifting height match operational needs.

- Ensure the crane design fits within the available space, considering headroom and clearance.

- Review preliminary drawings for potential space constraints and operational flow.

- Address any environmental considerations (e.g., corrosive environments, extreme temperatures).

Construction Drawings Review:

- Verify that the construction drawings include accurate load ratings and dimensions.

- Confirm that materials specified in the drawings match your requirements (e.g., corrosion-resistant materials).

- Check for the inclusion of safety features and compliance with local regulations.

- Review the load path and structural elements for overall safety and efficiency.

Fabrication Drawings Review:

- Check detailed dimensions and material specifications for all crane components.

- Review welding and assembly instructions to ensure parts are fabricated to the required standards.

- Ensure the drawings match the construction specifications and any previous adjustments made.

- Confirm that the fabrication team understands the installation instructions and site conditions.

Pre-Installation:

- Ensure that the installation site is properly prepared (space, foundation, electrical, and mechanical systems).

- Verify that all parts have been delivered and match the specifications.

- Confirm the installation timeline and ensure all necessary documentation (safety protocols, assembly instructions) is ready.

Post-Installation:

- Set up a maintenance schedule for regular checks and parts replacement.

- Ensure operator training is provided for safe crane operation.

- Review the crane's operational performance after installation and address any issues promptly.

This checklist will help ensure that you don't miss any crucial details during the crane purchasing process, leading to a more successful and efficient crane installation. Click to check more informaiton on crane specificaiton and crane drawing.