Overhead Crane Steel Plate Deformation & Girder Deformations

Overhead Crane Steel Plate Deformation & Girder Deformations

What cause overhead crane steel plate, welding and girder deformations? Check overhead crane deformation reasons & how to prevent & restore it to ensure your overhead crane safety.

Overhead Crane steel plate Deformation

Overhead cranes are overhead material handling cranes that is horizontally installed over workshops, warehouses, and material yards. Because its two ends are supported by tall concrete pillars or metal supports in the shape of a bridge. Overhead travelling cranes are widely used in engineering and manufacturing processing workshops and deformation may occur because malfunction or other reasons. What are the main reasons to overhead crane deformation? Let's check on.

Causes of overhead crane steel plate deformation

After welding, steel plate structures like the beams and columns of overhead cranes and box girder cranes experience localized convex or concave wave deformations on the cover and web in addition to bending deformation. More significantly, the components' strength and stiffness are diminished.

What elements will thus have an impact on the deformation of the steel plate?

The impact of the main beam's pre-bending.

- If the web pre-bending of overhead cranes and box girder cranes is too large or too small during the manufacturing process, it means that excessive welding bending deformation is selected to achieve a regular camber, which increases the welding internal stress of the beam and causes main beam deformation of the beam web.

- When the main beam is horizontally tortuous, tensile stress occurs on one side of the cover plate, uniform tensile stress occurs on the corresponding web plate, and compressive stress occurs on the other side of the cover plate.

The superposition of these compressive stresses will result in higher compressive stresses in some areas of the web, causing deformation of the web of the double girder overhead crane.

Angular deformation caused by fillet welds.

- overhead cranes and box girder cranes have beams and columns made of cover plates, webs, ribs, and other sheet materials that are connected by fillet welds.

- One of the factors causing plate deformation is the welding angle deformation caused by the fillet weld.

- Because the fillet welds between the cover plate and the web, as well as the fillet welds between the cover plate and the ribs, are not uniformly heated along the thickness of the plate, the welds shrink horizontally, resulting in plate deformation.

- When the welding foot size is kept constant, the plate's angular deformation resistance is proportional to the cube of the plate thickness.

Influence of longitudinal welding stress.

- Welding stress occurs in the longitudinal welds of overhead crane and box girder crane beams and columns.

- Between the cover plate and the web, the compressive stress is relatively high. When the compressive stress exceeds the steel plate's critical compressive stress, the cover plate and the middle of the web deform.

- The critical stress is proportional to the plate thickness squared. The greater the plate thickness, the less likely deformation.

The inherent deformation of the material itself.

- Some crane manufacturers lack steel plate straighteners and use unleveled materials.

- Beam, column cover, and web deformation has exceeded the promised beam and column deformation.

Overhead crane welding deformation

The welding deformation of the overhead crane is discovered during the maintenance process, and control of the deformation has become an urgent problem to be solved. Because the overhead crane's cross-sectional shape is a typical box girder structure, it has many welds, a complex structure, and high welding stress and deformation. If a reasonable design and construction process plan is not preceded, deformation will occur during the welding process, affecting welding quality and even preventing the structure from being installed and used correctly.

Types of welding deformation

Welding deformation consists primarily of shrinkage deformation (both longitudinal and transverse), bending deformation, angular deformation, wave deformation, twisting deformation, and other types.

Reasons of steel welding deformation

In most cases, uneven heat input is the root cause of welding deformation in overhead cranes. The size of the heat input is closely related to the welding material and structure. Material and structural factors interact to affect metal movement around the heat source, causing it to be influenced by both internal and external constraints, resulting in welding material stress deformation.

These problems can happen during the welding process for a wide range of reasons, including the following.

- The welding seam is not precisely measured.

- The number of welding seams does not meet the predetermined standard, and there is a significant difference between the welding and design positions.

- The welding substance thermophysical properties are weak.

- The construction process is not conducive to achieving the best welding state, etc.

Control on welding deformation

The most critical part of controlling welding deformation is fully understanding the causes of deformation, which allows for the most appropriate measures to be taken according to the specific situation, reducing the degree of welding deformation to a minimum value, allowing the structure to be used correctly, reasonably, and better. Improve overhead crane performance and provide guarantees for better construction.

Cleaning and grinding before welding

Welding seam grinding before welding

Support to prevent deformation

As one of the leading overhead crane manufacturers in China, we can meet your overhead crane needs and assist you in resolving overhead crane maintenance issues; please do not hesitate to contact us. We can bring out the customized maintenance plan for the overhead crane that we provided.

Main girder deformation of overhead cranes

Overhead crane or bridge crane is usually manufactured of the crane bridge frame and the operating system. The main girder and end girders or end trucks, are the major structural components of the rigid overhead crane bridge frame. Overhead cranes can be categorized into truss overhead cranes, box type overhead cranes, and beam girder overhead cranes based on the bridge frame structures. The bridge frame can be made of general carbon steel, such as Q 235 -B, or general low alloy steel, such as 16 Mn.

Single girder overhead crane main girder- more on crane girder design

Main girder of overhead overhead crane

One of the most essential crane components is the main girder, which supports the travelling trolley or lifting hoist. Main girders of bridge cranes can generally be divided into truss girder, box girder, single girder, double girder, according on the different constructions. Please feel free to contact us if you require crane girder design; we will get back to you quickly.

Overhead crane girder camber

The main girder of overhead crane is the main supporting component of the overhead lifting system, and it must be rigid, strong, and stable to ensure safety. Furthermore, in order to ensure high electric overhead crane usability, crane girders are designed with specific camber to prevent trolley climbing and gliding.

Overhead crane girder camber deformation

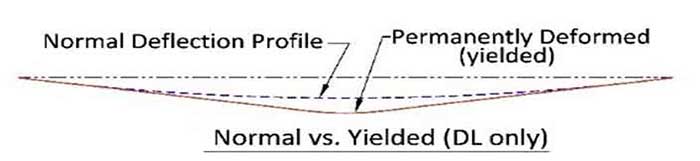

After unloading, the girder will spring back to its original shape if it is less than the yield strength of crane girder steel. The girder camber of an overhead crane is illustrated in the diagram below:

However, girder camber will be lost if the loads exceed the yield strength by more than 10%. When it is loaded again with the rated capacity of the load, it will deflect the normal incremental amount, and the stress will be normal, except that the starting point for the deflection increment will be at a lower elevation due to the lost camber. The girder camber will be lost each time the girder is loaded past its yield strength, resulting in permanent deformation, as shown in the diagram below:

Deflection of normal crane camber vs. permanent deformed crane camber . In severe weather, the overhead crane girder may "kink" around the center of the crane span.

Overhead crane camber deformation causes

Overhead crane camber deformation is caused by a variety of factors, most of which are related to crane design, manufacturing, transportation, installation, and use, and others, etc.

- Impractical design. It is an inherent problem of the electric crane that can be avoided by using professional overhead crane manufacturers.

- Residual Internal Stress. The spot heat produced during crane girder fabrication causes metal shrinkage, and the internal residual stress produced causes deformation of the overhead crane girder.

- The formation of crane girder camber. The formation of the crane girder camber may result in girder camber loss, which can be minimized due to technological advancement.

- Overloading of the bridge crane. Overhead crane loads that exceed the rated capacity will cause girder deformation and potential crane accidents.

- Overhead crane malfunction. Girder camber deformation can also be caused by improper overhead crane operation, such as lifting loads abruptly without straining the wire rope, abrupt braking, vastly braking, abruptly braking heavy loads vertically, and so on.

- Deformation of the web plate. The box crane girder's main supporting component is the web plate. Normally, web plate deformation has little influence on crane girder camber deformation; however, as the web plate deformation increases, the influence on the camber increases, eventually causing the camber to deform.

- High temperature. A large amount of heat radiation causes a temperature difference between the upper and lower plates of the crane girder, causing the lower plate to expand and cause camber loss.

- Improper storage, transportation, lifting, and installation. The overhead crane girder is a long, thin metal part with a high internal Residual Stress that is easily damaged. As a result, improper storage, transportation, lifting, and installation will result in camber deformation of the overhead crane.

- Inferior crane maintenance. During maintenance, the heat generated by cutting and welding on the box girder will cause the girder camber to deform.

The effects of camber deformation on overhead cranes

The deformation of the overhead crane camber will have a negative impact on the entire crane and may result in a crane accident. In general, it will have the following effects on the overhead crane:

- To trolley travelling .The severe deformation of the crane box girder will cause the crane trolley to climb and slide, potentially resulting in a bridge crane accident.

- To the crane's travel mechanism. Severe deformation of crane girder camber will damage the transmission shaft and may even break the coupling tooth or coupling bolt, etc.

- On bridge girder . The camber deformation will cause the crane girder to bend, resulting in trolley track deformation and, eventually, gnawing track.

- To use as a cover plate or web plate. Camber deformation will cause the cover plate or web plate to break, thereby increasing the risk of server crane accidents.

Overhead crane camber restoration

If the overhead crane girder camber is deformed, it must be repaired unless you have a large enough budget to replace the old piece of lifting equipment with a new overhead crane. The traditional Flame Correction Method and the Prestress Correction Method are both used to repair the deformed crane girder.

Method of Flame Correction

The flame correction method works by heating and cooling the three sides of the girder to reform the girder camber. It is difficult to control the heating temperature and time, making it difficult to ensure girder camber reformation.

Prestress Correction Method

The prestressed tensioners are installed on both sides of the flange-slabs of the overhead crane girder and used to produce tensioning forces evenly and simultaneously to restore the crane girder camber. The following are the benefits of this approach:

- The repairing crane girder requires no disassembly and occupies no space.

- In most cases, the repair takes only a few days.

- It not only restores the camber of the overhead crane girder, but it also increases the girder's strength and stiffness, as well as its bearing capacity.

- Repair costs are low.

When overhead crane camber deformation occurs, a professional crane restoration engineer is required to provide advice, technique support, and services from the overhead crane manufacturer. Free consultations are available, feel free to contact us today.