Selecting the Ideal Crane Hoist: Manual vs. Electric Hoist Options

This guide compares manual and electric hoists, helping you choose the right option for your small crane based on specific needs.

Overview of Hoists and Cranes

Hoists are mechanical devices designed to lift and lower heavy loads, typically using a rope, chain, or cable. They play a crucial role in crane operations, allowing for the efficient handling of materials in various settings, from construction sites to warehouses. When integrated into small crane systems, hoists enable operators to move items quickly and safely, improving workflow and productivity.

Selecting the right hoist for small cranes is vital for several reasons. First and foremost, the correct hoist ensures safe operations. An unsuitable hoist can lead to accidents, injuries, or equipment damage. Moreover, the efficiency of your operations greatly depends on the hoist type. A well-chosen hoist can streamline tasks, reduce downtime, and minimize physical strain on operators. Thus, The options available is key to making an informed decision that meets the specific needs of your operations.

Purpose of the Guide

This guide aims to provide a clear and detailed comparative analysis of manual and electric hoists, helping readers understand the strengths and weaknesses of each type. By examining various aspects such as performance, cost, ease of use, and maintenance, the guide will empower readers to make a well-informed choice based on their unique requirements.

Additionally, the guide will highlight key factors that influence hoist selection. These include load capacity, frequency of use, environmental conditions, and budget considerations. By considering these factors, users can ensure that their selected hoist not only meets operational demands but also contributes to a safe and efficient work environment.

Importance of Crane Hoist Selection

Safety Considerations

Selecting the appropriate overhead crane hoist is crucial for maintaining the safety of both operators and the work environment. An unsuitable choice can introduce several serious risks, including:

Load Failure

- Choosing a hoist that is not rated to handle the weight of the load can lead to dangerous drops, resulting in severe injuries or property damage.

- It is essential to accurately calculate the total weight of the load, factoring in any attachments or rigging used to secure it.

Equipment Malfunction

- Hoists that are not designed for specific environments, such as corrosive or outdoor settings, may deteriorate more quickly, increasing the risk of malfunction.

- Implementing regular inspections and maintenance schedules is critical to ensure that the equipment remains in safe working condition.

Operator Injury

- The use of manual hoists often requires considerable physical effort, raising the risk of strain injuries over time.

- Providing proper training in hoist operation and load handling is essential to minimize the potential for accidents.

Regulatory Compliance

Adhering to regulatory standards is also a vital aspect of hoist safety. Different industries have specific safety guidelines, including:

Occupational Safety and Health Administration (OSHA) Regulations

- It is important to ensure that all lifting equipment complies with safety standards established by OSH

- Operators should receive training to fully understand these regulations and consistently apply them during operations.

ANSI Standards

- Familiarize yourself with the standards set forth by the American National Standards Institute (ANSI) concerning hoists and cranes, which provide guidelines for safety practices and equipment specifications.

By recognizing and adhering to these safety considerations, organizations can significantly mitigate risks and foster a safer working environment.

Operational Efficiency

Choosing the right hoist is essential not only for safety but also for enhancing operational efficiency. A hoist that is well-suited to specific tasks can lead to significant improvements in various areas:

Improved Workflow and Productivity

- A suitable hoist facilitates seamless lifting and transportation of materials, which helps to minimize delays and ensures that tasks are completed on time.

- For instance, an electric hoist can lift loads much faster than a manual hoist, making it particularly advantageous in high-demand environments where speed is critical.

Reduced Downtime

- Selecting reliable equipment can decrease the frequency of repairs and maintenance, which in turn keeps operations running smoothly.

- Implementing a preventive maintenance program is crucial; it allows teams to identify potential issues before they result in costly breakdowns or interruptions to the workflow.

Lower Maintenance Costs

- Hoists designed for specific applications often require less maintenance, leading to long-term savings.

- Regular inspections and proper handling of the equipment can extend its lifespan and reduce overall operational costs, making it a more economical choice in the long run.

By prioritizing operational efficiency in hoist selection, businesses can significantly maximize productivity and minimize interruptions, ultimately enhancing overall performance.

Suitability for Specific Jobs

Selecting the appropriate hoist type for specific applications and load requirements is crucial for achieving optimal performance. Here are the key considerations that should guide this decision:

Load Weight

- Exact Weight Assessment: Start by determining the exact weight of the loads you will be lifting, including any accessories, attachments, or rigging used. Accurate weight measurements are essential for ensuring safety.

- Lifting Capacity Selection: Choose a hoist with a lifting capacity that exceeds the maximum weight of the load. A general rule of thumb is to select a hoist with at least a 20% safety margin above the load's weight to account for any fluctuations or unexpected conditions during lifting. This precaution helps prevent accidents and ensures reliable performance under varying circumstances.

Lifting Height

- Required Lifting Height: Assess the lifting height required for each specific task. Different hoists have varying limitations in terms of how high they can lift. The operational height needed is essential for effective planning.

- Safety and Comfort: Ensure that the selected hoist can comfortably accommodate the necessary lifting height without compromising safety. This involves checking the hoist's specifications and confirming that it can achieve the desired height consistently. Using a hoist that operates within its designed height range reduces the risk of malfunction and increases operational efficiency.

Frequency of Use

- Usage Evaluation: Evaluate how often the hoist will be used. For tasks requiring frequent lifting, an electric hoist is often the most efficient option due to its speed and reduced operator fatigue.

- Occasional Use Considerations: In contrast, manual hoists may be more suitable for infrequent lifting tasks. They typically have lower initial costs and are easier to operate without the need for electrical power, making them ideal for occasional use scenarios where budget and simplicity are key factors.

By carefully considering these factors, organizations can make informed decisions that align hoist capabilities with specific job demands. This tailored approach not only enhances safety but also improves efficiency in lifting operations, ensuring that tasks are completed effectively and reliably.

Types of Hoists

Manual Hoists

Manual hoists are mechanical devices that enable operators to lift and lower loads using a hand-operated mechanism, typically consisting of a chain or rope. These hoists depend on the physical effort of the operator to generate the necessary force for lifting.

types of manual hoist for sale

Definition and Operation Principles

- Mechanical Operation: Manual hoists operate based on straightforward mechanical principles. They utilize a system of pulleys, gears, and chains designed to amplify the force applied by the operator. This mechanical advantage allows users to lift heavier loads than they could with their bare hands.

- Lifting Mechanism: To lift a load, the operator pulls on the chain or rope, which engages the lifting mechanism. This action raises the load, which is then securely held in place by a ratchet or locking mechanism when the operator stops pulling. This safety feature prevents the load from falling, ensuring a secure lifting operation.

Common Applications in Small Crane Systems

Manual hoists are particularly useful in settings where loads are relatively light and lifting tasks occur infrequently. They are well-suited for a variety of applications, including:

- Small Workshops: Ideal for lifting tools and equipment, manual hoists can help organize workspaces and facilitate easier access to heavy items.

- Garage Settings: In automotive environments, manual hoists are commonly used to hoist parts like engines or transmissions, making repairs more manageable and efficient.

- Construction Sites: For occasional lifting of materials such as lumber or drywall, manual hoists offer a cost-effective solution without the need for electric power.

- Warehouses: Manual hoists can be employed for moving items to elevated storage areas, helping maximize vertical space and improve inventory organization.

Overall, manual hoists are versatile tools that provide reliable lifting capabilities in various environments, particularly where budget constraints or infrequent use make them a practical choice.

Advantages and Disadvantages

Pros

- Cost-Effectiveness:

Manual hoists generally come with a lower purchase price compared to their electric counterparts, making them an accessible option for smaller operations or businesses with limited budgets. This lower initial investment is particularly beneficial for startups or companies that have sporadic lifting needs, allowing them to allocate funds to other essential areas of their operations. - Simplicity and Reliability:

The mechanical design of manual hoists is straightforward, featuring fewer components that can potentially fail. This simplicity contributes to their high reliability and reduced maintenance requirements. Furthermore, since manual hoists do not rely on electricity, they are an ideal choice in environments where power sources are limited or unavailable. This makes them suitable for outdoor work or in remote locations where electrical infrastructure may not be feasible.

Cons

- Physical Exertion Required:

Using manual hoists necessitates physical effort from the operator, which can lead to fatigue, especially during extended use or when lifting heavy loads. This reliance on manual labor increases the risk of safety concerns, including the potential for strains or injuries over time. Employers should consider providing training on proper lifting techniques and ergonomics to mitigate these risks. - Limited Lifting Speed and Capacity:

Compared to electric hoists, manual hoists typically operate at a slower lifting speed, which can hinder productivity in high-demand environments. This slower pace may not meet the needs of operations that require quick turnaround times. Additionally, manual hoists often have a maximum lifting capacity that may be insufficient for heavier loads, necessitating careful consideration of the tasks at hand to avoid overloading the equipment.

In summary, manual hoists can be an excellent choice for specific applications where cost, simplicity, and reliability are prioritized. However, potential users should carefully evaluate the physical demands and limitations regarding lifting capacity and speed to ensure that these hoists effectively meet their operational needs.

Electric Hoists

Electric hoists are advanced lifting devices powered by electric motors, designed to raise and lower loads with significant efficiency. These hoists represent a notable evolution in lifting technology, enabling operators to handle heavier loads more easily and effectively than manual hoists.

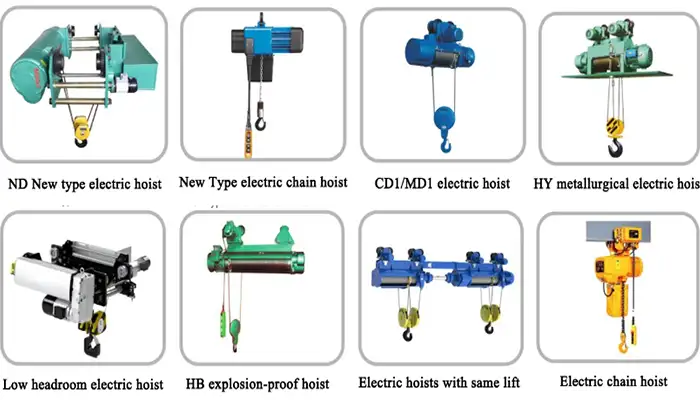

types of electric hoists for sale

Definition and Operation Principles

Electric hoists operate by converting electrical energy into mechanical energy. When activated, an electric motor drives a system of gears and pulleys to lift the load. Operators typically control electric hoists via a pendant or remote control, allowing for precise movement and positioning of loads with minimal physical effort. This feature not only enhances operational efficiency but also allows for greater control, especially when handling delicate or oversized items.

Common Applications in Small Crane Systems

Electric hoists are widely utilized in various settings where efficiency and power are paramount. Common applications include:

- Manufacturing Plants: Used for assembling and moving heavy components, electric hoists help streamline production processes.

- Warehouses: These hoists facilitate the efficient lifting and stacking of products, enhancing storage capabilities and logistics.

- Construction Sites: Electric hoists are essential for hoisting heavy building materials and equipment, improving workflow on-site.

- Automotive Shops: Ideal for lifting engines and other substantial parts, electric hoists ensure safe handling in busy automotive environments.

Advantages and Disadvantages

Pros

- Increased Lifting Speed and Capacity:

Electric hoists can lift loads significantly faster than manual hoists, enhancing productivity, especially in high-volume operations. They typically have a higher lifting capacity, allowing for the safe handling of heavier materials without the risk of equipment failure. - Reduced Operator Fatigue:

With minimal physical effort required from the operator, electric hoists help reduce fatigue and the risk of strain injuries. This ease of operation enables workers to perform lifting tasks more consistently and efficiently over extended periods, contributing to a more productive work environment.

Cons

- Higher Initial Cost:

The upfront cost of electric hoists is typically higher than that of manual hoists, which may pose a barrier for smaller businesses or those operating on limited budgets. Furthermore, installation and setup may require professional assistance, further increasing the initial investment. - Dependence on Electrical Power:

Electric hoists require a reliable power source for operation, which can be a limitation in remote locations or situations where the electrical supply is inconsistent. In the event of a power outage, operations relying on electric hoists may be halted, leading to potential downtime and lost productivity.

In summary, electric hoists provide significant advantages in speed, capacity, and user-friendliness, making them well-suited for a variety of industrial applications. However, potential buyers should carefully consider the higher initial investment and the reliance on electrical power when selecting the appropriate hoist for their specific tasks.

Comparative Analysis of Manual vs. Electric Hoists

Performance Metrics

When evaluating manual and electric hoists, various performance metrics are crucial in determining which option best suits specific applications. Below is a detailed comparison based on key criteria:

Lifting Speed:

- Electric Hoists:

Electric hoists are engineered for high-speed operation, enabling them to lift loads in seconds. This rapid lifting capability is particularly beneficial in fast-paced environments, such as manufacturing plants or construction sites, where time efficiency is paramount. - Manual Hoists:

Manual hoists generally operate at a slower pace since the lifting speed is directly proportional to the operator’s physical effort. This inherent limitation can hinder efficiency in high-demand scenarios, making manual hoists less ideal for tasks requiring quick load handling.

Capacity:

- Electric Hoists:

Electric hoists are designed to accommodate significantly heavier loads, making them suitable for industries where frequent lifting of substantial materials is necessary. Their lifting capacities can range from several hundred pounds to several tons, allowing them to handle a wide variety of applications. - Manual Hoists:

While manual hoists can lift a range of loads, their capacity is typically lower than that of electric hoists, often capping around 2 tons. This limitation may restrict their use in applications requiring the lifting of heavier or bulkier materials, necessitating careful consideration of load requirements.

Range of Motion:

- Electric Hoists:

Both manual and electric hoists can offer similar ranges of motion, depending on the specific crane system they are integrated with. However, electric hoists tend to provide superior control and precision during operation. This enhanced maneuverability is crucial in complex tasks that require accurate positioning of loads. - Manual Hoists:

Manual hoists also offer a flexible range of motion but may lack the precision of their electric counterparts. Operators might find it more challenging to achieve the same level of accuracy when manually controlling load movements, especially in intricate applications.

Comparison of Efficiency in Various Scenarios:

In scenarios that demand frequent lifting and rapid operation, electric hoists demonstrate significantly higher efficiency. Their speed and capacity allow for seamless workflows, minimizing downtime and maximizing productivity.

Conversely, in less demanding environments or situations where cost is a primary concern, manual hoists may be sufficient. Their lower initial investment and simplicity can make them an attractive option for businesses with sporadic lifting needs or limited budgets.

The choice between manual and electric hoists ultimately depends on specific operational requirements. Electric hoists offer advantages in speed and capacity, making them ideal for high-demand environments, while manual hoists can serve as a cost-effective solution for lighter, less frequent lifting tasks. By considering the performance metrics outlined above, organizations can make informed decisions that align with their unique lifting needs.

Cost Considerations

The financial implications of choosing between manual and electric hoists is crucial for making an informed decision. Here’s an in-depth analysis of the various cost factors involved:

Initial Purchase Cost:

- Electric Hoists:

Electric hoists generally come with a higher initial purchase price compared to manual hoists. This higher cost can be a deterrent for small businesses or startups that operate with tight budgets. However, it’s essential to consider that electric hoists often deliver superior performance and efficiency, which can justify the investment. Their ability to handle heavier loads and perform faster may lead to significant time savings and increased productivity in frequent or heavy-duty applications, making them a worthwhile investment in the long run. - Manual Hoists:

Manual hoists typically have a lower purchase price, making them a cost-effective choice for businesses with limited budgets or those that engage in infrequent lifting tasks. The lower initial investment allows smaller operations or projects to afford reliable lifting solutions without the financial strain associated with electric models. This affordability is particularly beneficial for workshops or environments where lifting needs are sporadic and do not warrant the expense of more advanced equipment.

Long-Term Operational Costs:

- Electric Hoists:

While electric hoists have a higher upfront cost, their operational efficiency can lead to lower long-term costs. Electric hoists require less physical labor from operators, which can reduce the risk of injuries and associated costs related to worker fatigue and healthcare. Moreover, their speed and capacity can lead to quicker turnaround times, enhancing overall operational efficiency and potentially increasing profit margins. - Manual Hoists:

Although manual hoists are less expensive upfront, they may incur higher long-term operational costs due to the physical effort required from operators. This reliance on manual labor can lead to operator fatigue, resulting in decreased productivity over time. Additionally, if employees experience strain injuries or fatigue-related incidents, businesses may face increased costs associated with medical expenses and potential workers' compensation claims. Therefore, the overall cost-effectiveness of manual hoists may diminish over time, particularly in environments with frequent lifting tasks.

Maintenance and Repair Expenses:

- Electric Hoists:

Electric hoists necessitate regular electrical maintenance, including inspections of wiring, motor functionality, and electrical components. While these maintenance requirements can contribute to operational costs, proper maintenance can significantly reduce the likelihood of major repairs, leading to lower overall repair expenses over the hoist's lifespan. In general, electric hoists tend to be more durable and reliable if maintained correctly, thereby reducing unexpected costs due to breakdowns. - Manual Hoists:

Manual hoists usually have lower maintenance requirements due to their simpler mechanical design. The absence of complex electrical components means fewer parts that can malfunction, leading to lower ongoing maintenance costs. However, the physical operation of manual hoists can result in wear and tear on components such as chains, gears, and ratchets. Over time, this wear may necessitate repairs or part replacements, which can accumulate costs. Additionally, if operators experience fatigue, it may lead to improper handling, increasing the likelihood of accidents that could necessitate further repairs or equipment replacement.

When considering cost implications, businesses must weigh the initial purchase price, long-term operational costs, and maintenance and repair expenses associated with manual and electric hoists. Electric hoists, despite their higher upfront investment, often provide better efficiency and safety, making them ideal for heavy-duty or frequent applications. In contrast, manual hoists may be better suited for smaller operations with occasional lifting needs, but potential long-term costs should be carefully evaluated. By analyzing these financial factors, organizations can make informed decisions that align with their operational requirements and budgetary constraints.

Ease of Use

The user experience can significantly influence the choice between manual and electric hoists. The ease of use for both types is essential for optimizing operational efficiency and ensuring safety.

User-Friendliness and Training Requirements:

- Electric Hoists:

Electric hoists are generally easier to operate, requiring minimal physical effort from the user. The operation typically involves pressing buttons or using a pendant control, which allows for smooth and precise movements. Training for electric hoists primarily focuses on familiarizing operators with the controls and safety features, rather than on physical lifting techniques. This user-friendly design makes electric hoists suitable for a broader range of operators, including those who may not have extensive physical strength or experience. - Manual Hoists:

Manual hoists necessitate more extensive training regarding safe lifting techniques and proper operation. Operators must understand the mechanical aspects of the hoist and be physically capable of handling the load. The reliance on manual effort means that operators need to be trained not only in how to operate the hoist but also in techniques to lift safely and effectively to prevent injury. This requirement can limit the pool of potential operators, especially in settings where physical capability is varied.

Ergonomics and Operator Comfort:

- Electric Hoists:

Electric hoists are designed with ergonomics in mind, significantly reducing operator fatigue. The minimal physical strain allows for prolonged use without causing discomfort or excessive tiredness. This ergonomic advantage is particularly beneficial in high-use environments, where operators might be required to lift loads multiple times throughout the day. By reducing fatigue, electric hoists can contribute to higher productivity levels and improved operator satisfaction. - Manual Hoists:

The operation of manual hoists often leads to operator fatigue due to the physical exertion required, especially during heavy or repetitive lifting tasks. This can affect overall productivity and lead to decreased operator satisfaction, particularly in environments where lifting tasks are frequent. Prolonged use can also increase the risk of strain injuries, further impacting worker morale and efficiency.

Maintenance and Reliability

The maintenance needs and reliability of both types of hoists is crucial for operational planning and minimizing downtime.

Frequency and Complexity of Maintenance Tasks:

- Electric Hoists:

Electric hoists require regular inspections and maintenance of electrical components, including motors, gears, and wiring. While this maintenance may be more complex than that of manual hoists, it is vital for ensuring safe operation and preventing electrical failures. Operators or maintenance personnel need to be trained in electrical safety and maintenance protocols. Regular checks on these components help extend the lifespan of the hoist and ensure reliability in operations. - Manual Hoists:

Manual hoists typically require less frequent maintenance due to their simpler mechanical design. Routine maintenance mainly involves checks on chains, hooks, and gears for wear and tear. While the maintenance tasks are straightforward, it is still essential to perform them regularly to ensure the hoist operates safely and effectively. The simplicity of manual hoists often allows operators to conduct basic maintenance tasks themselves, reducing reliance on specialized maintenance personnel.

Lifespan and Reliability:

- Electric Hoists:

Electric hoists generally have a longer lifespan if properly maintained, thanks to their robust design and fewer moving parts that are subject to wear and tear. When maintained correctly, the reliability of electric hoists is high, which is critical in environments requiring consistent and safe lifting operations. Their durability makes them a reliable choice for heavy-duty applications, where operational continuity is essential. - Manual Hoists:

While manual hoists are reliable and durable, their lifespan can be shorter when frequently used at or near their maximum capacity. The mechanical components, including chains and gears, may experience more strain, leading to increased wear and potential failures over time. Businesses need to carefully evaluate the expected usage patterns to ensure that manual hoists remain a viable option for their lifting needs.

In conclusion, the choice between manual and electric hoists involves careful consideration of performance metrics, costs, ease of use, and maintenance needs. Electric hoists offer advantages in user-friendliness, ergonomic design, and long-term reliability, making them ideal for environments requiring frequent lifting of heavy loads. Conversely, manual hoists may be suitable for less demanding applications where budget constraints are significant. Evaluating these factors in the context of specific operational requirements will help businesses select the most appropriate hoist for their small crane systems.

Factors to Consider When Choosing a Hoist

When selecting the right hoist for your operational needs, several key factors must be evaluated to ensure that you choose the most suitable option. These factors include load requirements, frequency of use, working environment, and budget constraints. Here’s a detailed breakdown of each consideration:

Load Requirements

The load requirements is critical to selecting the appropriate hoist for your needs.

Assessing the Weight and Type of Loads to Be Lifted:

- Weight Evaluation:

Begin by evaluating the maximum weight of the loads you will regularly lift. This assessment should consider not only the heaviest item but also the average weight of items to ensure the hoist can handle typical operations without strain. - Material Type Identification:

Identify the types of materials to be lifted, such as metal, wood, or machinery. Different materials may require different handling approaches, which can influence the design and capabilities of the hoist you choose.

Safety Margins and Load Limits:

- Choosing Appropriate Capacity:

Always opt for a hoist with a load capacity that exceeds your maximum weight requirements. This safety margin helps prevent accidents and equipment failure during operations. - Manufacturer Guidelines and Industry Standards:

Refer to manufacturer guidelines and industry standards for recommended load limits. Ensuring compliance with these standards is vital for maintaining safety during operation and reducing liability risks.

Frequency of Use

The frequency with which a hoist will be used significantly impacts the choice between manual and electric options.

Determining Usage Frequency:

- Operational Frequency:

Consider whether the hoist will be employed in occasional tasks or if it will be part of daily operations. High-frequency use may necessitate an electric hoist for efficiency, as these systems are designed to handle repetitive tasks without fatigue.

Cost-Effectiveness and Wear and Tear:

- Impact on Longevity:

Frequent use of a manual hoist can lead to more wear and tear, resulting in increased maintenance and potentially shortening its lifespan. - Long-Term Savings with Electric Hoists:

Although electric hoists come with a higher initial investment, they may be more cost-effective in the long run due to their durability and lower physical strain on operators. Over time, the savings in labor costs and maintenance can offset the higher purchase price.

Working Environment

The working environment plays a significant role in determining the suitability of a hoist.

Indoor vs. Outdoor Use:

- Environment Considerations:

Identify whether the hoist will be used indoors or outdoors. This distinction affects the choice of materials and design features. For instance, outdoor hoists need to be designed to withstand weather elements such as rain, wind, and UV exposure.

Environmental Factors:

- Temperature and Humidity:

Evaluate specific environmental conditions. Extreme temperatures may adversely affect electric components, while high humidity can lead to corrosion in both manual and electric systems. - Dust and Contamination:

If operating in dusty or dirty environments, consider hoists with protective features, such as sealed motors or protective coatings, to prevent dust accumulation and ensure smooth operation.

Budget Constraints

Budget considerations are essential when selecting a hoist, impacting both initial costs and long-term expenses.

Initial Investment vs. Long-Term Savings:

- Cost Analysis:

Weigh the initial purchase price against the potential long-term savings associated with reduced maintenance and improved operational efficiency. - Electric Hoists as a Long-Term Investment:

While electric hoists might have a higher upfront cost, they can lead to savings through reduced labor costs and fewer downtime incidents due to their efficient operation.

Financing Options and Total Cost of Ownership:

- Exploring Financial Options:

Explore various financing options that can make the purchase more manageable, such as leasing or installment plans. This approach can help spread out the cost over time. - Total Cost of Ownership Consideration:

Consider the total cost of ownership, which includes not only the purchase price but also maintenance, energy costs, and potential repair expenses over the lifespan of the hoist. A comprehensive analysis can provide insights into the best financial decision.

By carefully evaluating these factors—load requirements, frequency of use, working environment, and budget constraints—you can make a well-informed decision when choosing a hoist that meets your specific needs. This thoughtful approach ensures safe and efficient operation, ultimately enhancing productivity in your operations.

Case Studies and Real-World Examples

This section explores successful implementations of both manual and electric hoists across various industries, showcasing their effectiveness, efficiency, and practical applications.

Successful Implementations of Manual Hoists

Manual hoists have been proven effective in various industries, providing cost-effective lifting solutions where heavy loads are not frequently moved.

Examples from Different Industries:

Construction Industry:

In a small construction firm, manual chain hoists were employed to lift roofing materials to upper floors. The lightweight design allowed workers to transport the hoists easily and set them up quickly, significantly speeding up roof installation times. The ability to operate these hoists manually also provided flexibility in adjusting the lifting height as needed throughout the installation process.

Manufacturing Sector:

A small manufacturing company used manual hoists for assembling components on the production line. Workers appreciated the simplicity and reliability of the manual hoists, which required minimal maintenance and provided a straightforward solution for lifting parts during assembly. The manual hoists enabled operators to position heavy components accurately without the need for additional lifting devices.

Lessons Learned and Key Takeaways:

- Simplicity Matters:

The straightforward operation of manual hoists was a crucial factor in training workers and reducing downtime. Providing clear training and operation manuals contributed to smooth implementation, ensuring that all operators could quickly become proficient in using the equipment. - Cost-Effectiveness:

Many companies reported significant savings by choosing manual hoists over electric options, especially when lifting needs were sporadic. Budget-conscious firms found manual hoists to be a practical choice that did not compromise safety or efficiency, allowing them to allocate resources elsewhere. - Safety Practices:

Regular safety checks and adherence to weight limits were essential for preventing accidents. These practices highlighted the importance of operator training in effective hoist management, ensuring that all staff were aware of safety protocols and operational guidelines.

Successful Implementations of Electric Hoists

Electric hoists have been utilized effectively in numerous applications, showcasing their advantages in speed, efficiency, and safety.

Case Studies Showcasing Efficiency Gains and Safety Improvements:

Automotive Assembly Line:

An automotive manufacturer upgraded from manual hoists to electric hoists on their assembly line. This change led to a 30% increase in production speed, allowing workers to handle heavier components with ease. The electric hoists were equipped with advanced features such as load limiters and automatic braking systems, which significantly enhanced safety measures during operations.

Warehouse Operations:

A distribution center implemented electric hoists for handling heavy pallets. The ability to lift loads rapidly reduced worker fatigue and improved workflow efficiency. Additionally, the electric hoists were integrated with an automated inventory system, which streamlined operations and minimized errors in order fulfillment. This integration enhanced the overall productivity of the warehouse, enabling quicker response times to customer orders.

Key Factors Leading to Successful Outcomes:

- Investment in Training:

Comprehensive training programs for operators were crucial in realizing the benefits of electric hoists. Employees learned to maximize the capabilities of the hoists while adhering to safety protocols, ensuring efficient and safe operations. - Maintenance Plans:

Establishing routine maintenance schedules helped ensure that the electric hoists operated efficiently and safely over time. Regular maintenance contributed to the longevity and reliability of the equipment, minimizing the likelihood of unexpected downtimes. - Customization and Adaptability:

The ability to customize electric hoists to fit specific operational needs, such as varying lifting speeds or specialized attachments, played a significant role in enhancing their effectiveness across different applications. This adaptability allowed businesses to tailor their hoist systems to meet unique requirements.

In summary, both manual and electric hoists have proven their value across industries through real-world implementations. The successful cases highlight the importance of careful planning, training, and ongoing maintenance to achieve optimal results. By focusing on these areas, businesses can enhance safety, efficiency, and productivity in their operations, ultimately leading to a more streamlined workflow and improved outcomes.

Conclusion

In this guide, we explored the essential factors involved in choosing the right hoist for small crane systems, comparing manual and electric options.

Main Differences Between Manual and Electric Hoists:

- Manual Hoists: Known for their cost-effectiveness, simplicity, and reliability, manual hoists require physical effort to operate, which may limit lifting speed and capacity. They are particularly suited for intermittent use and less demanding lifting tasks.

- Electric Hoists: These systems offer increased lifting speed and capacity, reducing operator fatigue and enhancing overall efficiency. However, they come with a higher initial cost and depend on electrical power, making them more appropriate for frequent and heavy lifting applications.

Importance of Careful Selection Based on Specific Needs:Choosing the right hoist is crucial to ensuring safe operations, maximizing productivity, and aligning with specific job requirements. A thorough assessment of load requirements, frequency of use, working environment, and budget constraints will lead to a more effective decision.

Final Recommendations

To aid in making an informed decision regarding hoist selection, consider the following guidelines:

- Evaluate Your Specific Needs: Take the time to assess the type and weight of the loads you will be lifting, along with how often these tasks will be performed. This evaluation is vital to determining whether a manual or electric hoist is the best fit for your operations.

- Prioritize Safety and Compliance: Ensure that the hoist you select meets industry safety standards and is appropriate for the working environment. Training for operators is equally important to maintain a safe worksite.

- Consider Efficiency and Cost-Effectiveness: Balance the initial investment with long-term operational costs. While electric hoists may have higher upfront costs, they often provide greater efficiency and lower labor costs in high-frequency lifting scenarios.

- Test Before You Invest: Whenever possible, try out different hoist systems to see how they perform in your specific environment. This practical approach can provide insights into usability, comfort, and functionality.

In conclusion, both manual and electric hoists have their strengths and weaknesses, making it essential to match the chosen hoist with the specific requirements of your tasks. By carefully considering safety, efficiency, and job suitability, you can make a well-informed decision that enhances your operational capabilities and contributes to a safer working environment.