Bridge Crane Kit for Sale Pakistan, 3 Ton & 5 Ton Crane Kit Cases

Bridge Crane Kits for Sale Pakistan: 3 Ton & 5 Ton overhead bridge crane kits cases for your reference to get your custom crane kit from 3 ton to 100 ton.

Category: Bridge Crane

Your Trusted Overhead Crane Kit Manufacturer & Supplier

Bridge Crane Kit for Sale Pakistan, 3 Ton & 5 Ton Crane Kit Cases

Bridge Crane Kits for Sale Pakistan: 3 Ton & 5 Ton overhead bridge crane kits cases for your reference to get your custom crane kit from 3 ton to 100 ton.

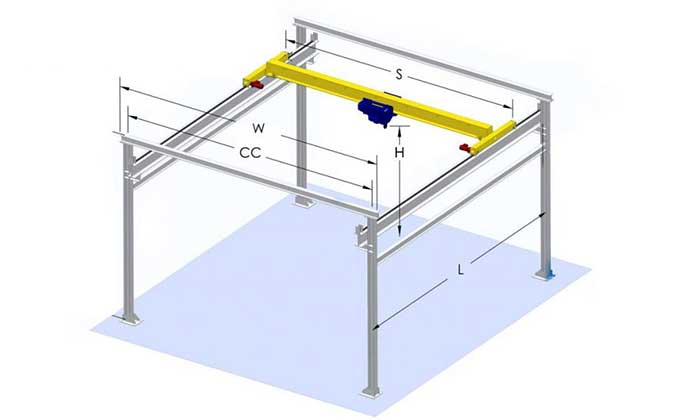

A bridge crane kit is a package of components and materials necessary to assemble a bridge crane, which is a type of overhead crane commonly used in industrial settings for lifting and moving heavy loads horizontally. The kit typically includes essential components such as the bridge beam, end trucks, hoist trolley, electrical components, and necessary hardware for assembly.

There are several reasons why someone might choose to buy a bridge crane kit instead of a complete bridge crane:

- Customization: Bridge crane kits offer the flexibility to customize the crane according to specific requirements, such as lifting capacity, span, and height. This allows businesses to tailor the crane to fit their unique operational needs and workspace constraints.

- Cost Savings: Bridge crane kits are often more cost-effective than purchasing a complete bridge crane. By assembling the crane in-house using a kit, businesses can save on labor costs associated with installation and assembly.

- Ease of Transportation: Complete bridge cranes can be large and heavy, making transportation and delivery challenging, especially to locations with limited access. Bridge crane kits are typically packaged in smaller, more manageable components, making transportation easier and potentially reducing shipping costs.

- Installation Flexibility: With a bridge crane kit, businesses have the flexibility to install the crane themselves or hire a local contractor for installation. This can provide greater control over the installation process and potentially save time and money compared to waiting for a manufacturer's installation team.

- Maintenance and Repairs: In the event of a breakdown or component failure, having a bridge crane kit allows businesses to replace individual components rather than the entire crane. This can reduce downtime and maintenance costs over the crane's lifespan.

Overall, purchasing a bridge crane kit offers businesses greater flexibility, cost savings, and control over the customization, installation, and maintenance of their overhead crane system. However, it's essential to carefully assess the specific needs and requirements of the application before deciding whether a bridge crane kit or complete bridge crane is the right choice.

Bridge Crane Kit for Sale Pakistan, 3 Ton and 5 Ton Projecs for Reference

Bridge crane projects in Pakistan represent a vital component of the country's industrial infrastructure, serving diverse sectors such as manufacturing, construction, and logistics. These projects involve the installation of bridge crane systems for efficient material handling, lifting, and transportation of heavy loads within industrial facilities.

With the growing demand for streamlined operations and increased productivity, bridge crane projects play a pivotal role in enhancing efficiency, reducing manual labor, and ensuring workplace safety. From small-scale workshops to large industrial complexes, bridge crane installations contribute to the optimization of workflows and the smooth functioning of industrial processes across Pakistan.

As businesses strive to modernize their operations and meet the challenges of a competitive market, bridge crane projects continue to be instrumental in facilitating seamless material handling operations, improving productivity, and driving overall growth in the Pakistani industrial landscape.

European Style Overhead Crane3 Ton Bridge Crane Kit with No Girder

Crane Type: HD, European Style Low Headroom Bridge Crane Kits

Capacity: 3 Ton

Crane Span: 18 Meters

Lifting Height: 6 Meters

Voltage: 380V, 50Hz, 3 Phase

The 3 Ton Bridge Crane Kit, particularly the European Style model, is ideal for medium-duty applications. This kit includes advanced control systems and high-quality components designed for durability and precision. It is well-suited for smaller workshops and warehouses where space optimization and efficient load handling are crucial.

Explosion-Proof Overhead Crane Kits without Main Girder : 3 Ton and 5 Ton

In industrial environments where the risk of explosion is present, safety becomes paramount. Explosion-proof overhead crane kits offer a solution tailored to such hazardous conditions, ensuring the safe and efficient movement of materials. Below are specifications for available explosion-proof crane kits:

3 Ton Explosion-Proof Overhead Crane Kit

Crane Type: LB

Capacity: 3 Ton

Crane Span: 15 Meters

Lifting Height: 5 Meters

Voltage: 380V, 50Hz, 3 Phase

5 Ton Explosion-Proof Overhead Crane Kit

Crane Type: LB

Capacity: 5 Ton

Crane Span: 7 Meters

Lifting Height: 9.3 Meters

Voltage: 380V, 50Hz, 3 Phase

3 Ton Explosion-Proof Overhead Crane Kit

Crane Type: LB

Capacity: 3 Ton

Crane Span: 14 Meters

Lifting Height: 5.5 Meters

Voltage: 380V, 50Hz, 3 Phase

These explosion-proof crane kits are designed to meet the stringent safety requirements of hazardous environments while maintaining efficiency and reliability. With their robust construction and specialized components, they ensure safe material handling operations in industries such as chemical plants, oil refineries, and other volatile settings.

Benefits of Bridge Crane Kits

Cost-Effective: Bridge crane kits typically exclude the main steel structure, making them easier and cheaper to transport. Local production of the main girder can reduce overall costs.

Customizable: Kits can be tailored to meet specific operational requirements, allowing for flexibility in installation and use.

Ease of Transport: Lighter components and the exclusion of large steel structures make logistics simpler and more cost-effective.

Bridge crane kits, whether 3 Ton or 5 Ton, provide an adaptable and economical solution for a variety of industrial lifting needs in Pakistan. By understanding the specific benefits and considerations associated with these kits, businesses can make informed decisions that enhance operational efficiency and safety.

European Style Single Girder Top Running Bridge Cranes

Single girder top running bridge cranes with European style are advanced lifting solutions designed to meet the demanding needs of modern industrial applications. These cranes are characterized by their robust design, efficient performance, and adherence to high safety standards. The "European style" refers to a streamlined, efficient design that prioritizes precision, ease of use, and maintenance.

Single girder top running bridge cranes are widely used in various industries, including manufacturing, warehousing, and construction, due to their versatility and reliability. They are installed on elevated runway systems that allow the crane to travel over the entire length of a facility, providing extensive coverage and optimizing space utilization.

The European style single girder cranes are particularly noted for their advanced features such as compact hoist units, optimized lifting mechanisms, and sophisticated control systems. These cranes offer several benefits, including improved load handling, reduced operational costs, and enhanced safety features, making them an ideal choice for businesses looking to boost productivity and ensure workplace safety.

Whether your needs involve routine material handling or more complex lifting tasks, single girder top running bridge cranes with European style deliver exceptional performance and reliability, making them a valuable asset in any industrial setting.

European Style Single Girder Top Running Bridge Cranes Kit with No Main Girder

The Single Girder Top Running Bridge Crane Kit with a capacity of 3 tons offers an efficient solution for material handling requirements in industrial environments. Designed for reliability and precision, this kit includes essential components necessary for the construction of a robust crane system but with out the main steel structure, namly the crane girder to provide a cost-effective solution.

Specifications:

Crane Type: HD

Capacity: 3 Tons

Crane Span: 18 Meters

Lifting Height: 6 Meters

Voltage: 380V, 50Hz, 3 Phase

Components Included:

European-style hoist assembly (NR3T-6M): 1 set (Including electrical equipment 380V 50HZ)

Bridge crane driving wheel (145 integral): 2 sets (Including shaft and shaft sleeve)

Bridge crane driven wheel (145 integral): 2 sets (Including shaft and shaft sleeve)

Bridge crane three-in-one motor (DTE115MLDV-0.4KW): 2 units (Including flange plate 380V 50HZ)

C-channel (30C): 18 meters (4 pieces of 4 meters, 1 piece of 2 meters)

Bracket (30C): 8 pieces (0.4 meters per piece)

Lifting clamp (30C): 8 pieces

Connector (30C): 4 pieces

Host Trolley (30C): 10 pieces (Including ends)

Bridge crane electrical box (3T): 1 set (380V 50HZ)

Various cables for main power supply, hoist control, power lines, motor brake, and limit lines.

Bridge crane limit (Mechanical): 2 pieces

Buffer (A-1): 4 pieces

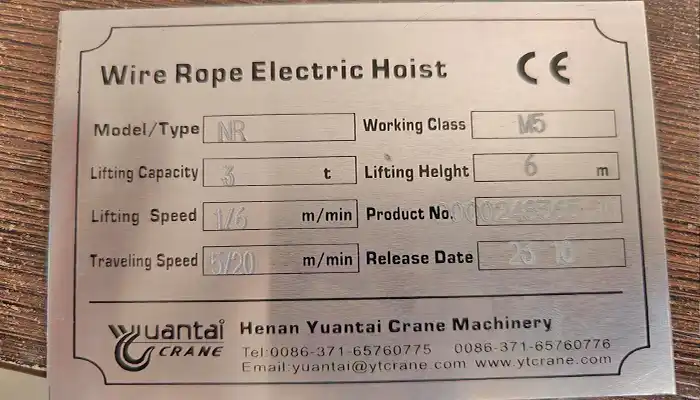

3 Ton electric hoist included in 3 ton bridge crane kit for sale Pakistan

Electrical Box of 3 ton single girder top running overhead bridge crane kit

Nameplate of electric wire rope hoist crane kit

Item No. | Description | Model/Specification | Unit | Quantity | Notes |

1 | European-style hoist assembly | NR3T-6M | Set | 1 | Including electrical equipment 380V 50HZ |

2 | Bridge crane driving wheel | 145 integral | Set | 2 | Including shaft and shaft sleeve |

3 | Bridge crane driven wheel | 145 integral | Set | 2 | Including shaft and shaft sleeve |

4 | Bridge crane three-in-one motor | DTE115MLDV-0.4KW(SZW) | Unit | 2 | Including flange plate 380V 50HZ |

5 | C-channel | 30C | Meter | 18 | 4 pieces of 4 meters, 1 piece of 2 meters |

6 | Bracket | 30C | Piece | 8 | 0.4 meters per piece |

7 | Lifting clamp | 30C | Piece | 8 | |

8 | Connector | 30C | Piece | 4 | |

9 | Host Trolley | 30C | Piece | 10 | Including ends |

10 | Bridge crane electrical box | 3T | Set | 1 | 380V 50HZ |

11 | Cable | YC3X6MM+1 | Meter | 3 | Main power supply |

12 | Cable | YC10X5MM | Meter | 28 | Hoist control line |

13 | Cable | YC3X4MM | Meter | 28 | Hoist power line |

14 | Cable | YC6X5MM | Meter | 26 | Bridge crane motor brake line |

15 | Cable | YC2X5MM | Meter | 8 | Bridge crane limit line |

16 | Bridge crane limit | Mechanical | Piece | 2 | |

17 | Buffer | A-1 | Piece | 4 |

Single Girder Explosion-Proof Bridge Cranes Kits for Sale Pakistan

Single Girder Explosion-Proof Bridge Cranes

Single girder explosion-proof bridge cranes are specialized lifting equipment designed to operate safely in hazardous environments where the risk of explosion is present. These cranes are essential for industries such as chemical plants, oil refineries, gas terminals, and other facilities where flammable gases, vapors, or combustible dust may be present.

Key Features:

Explosion-Proof Components: All electrical components, including motors, controls, and wiring, are specially designed and certified to prevent sparking and minimize the risk of ignition in hazardous atmospheres.

Robust Construction: Single girder explosion-proof bridge cranes are built to withstand the harsh conditions of industrial environments. They are constructed from durable materials and designed for long-term reliability.

Safety Measures: These cranes are equipped with safety features such as overload protection, emergency stop buttons, and limit switches to ensure safe operation at all times.

Customizable Options: Single girder explosion-proof bridge cranes can be customized to meet specific lifting requirements, including lifting capacity, span, and lifting height.

Compliance: These cranes comply with stringent safety standards and regulations for hazardous locations, ensuring compliance with local and international safety requirements.

Applications:

Single girder explosion-proof bridge cranes are used in industries where explosive atmospheres are present, including chemical processing plants, oil and gas refineries, pharmaceutical facilities, and manufacturing plants handling flammable materials.

They are used for lifting and transporting materials safely in hazardous areas, reducing the risk of accidents and ensuring worker safety.

Benefits:

Enhanced Safety: The explosion-proof design minimizes the risk of ignition and ensures safe operation in hazardous environments.

Increased Productivity: These cranes enable efficient material handling in areas where traditional cranes cannot operate due to safety concerns.

Compliance: Single girder explosion-proof bridge cranes comply with industry safety standards and regulations, providing peace of mind to operators and facility managers.

Overall, single girder explosion-proof bridge cranes are essential equipment for industries operating in hazardous environments, providing a safe and efficient solution for material handling needs while ensuring worker safety and regulatory compliance.

Single Girder Explosion-Proof Bridge Crane Kits Without Main Girder

Single girder explosion-proof bridge crane kits without the main girder are specialized lifting systems designed for hazardous environments where explosive gases, vapors, or dust may be present. These crane kits are engineered to ensure safety and reliability in industries such as chemical plants, oil refineries, and other potentially explosive atmospheres. Here's a comprehensive introduction to these crane kits:

Key Features:

Explosion-Proof Design:

Built to comply with stringent safety standards and regulations.

Suitable for environments classified as Zone 1 and Zone 2 hazardous areas.

Ensures safe operation in explosive atmospheres.

Single Girder Structure:

Consists of a single girder beam which supports the trolley and hoist.

Ideal for applications where space is limited and lower headroom is required.

Offers a cost-effective and lightweight solution compared to double girder cranes.

No Main Girder:

The kit is supplied without the main girder, allowing customization and integration with existing structures.

Facilitates ease of transportation and on-site assembly.

Suitable for installations where the existing runway or supporting structure can accommodate the crane components.

Components Included:

Explosion-Proof Hoist:

Designed to lift and lower loads safely within hazardous environments.

Available in various capacities, typically 3 tons and 5 tons.

End Carriages:

Provide support and mobility to the crane across the runway beams.

Equipped with explosion-proof driving and driven wheels.

Control Systems:

Explosion-proof electrical components including motors, control panels, and limit switches.

Remote control or pendant control options for safe and efficient operation.

Trolley and Lifting Mechanism:

Explosion-proof trolley houses the hoist and traverses the length of the girder.

Ensures smooth and precise movement of loads.

Benefits:

Safety:

Mitigates the risk of explosions in hazardous environments, protecting personnel and property.

Compliance with international safety standards ensures a high level of operational security.

Cost-Efficiency:

Modular design allows for flexibility and cost savings in transportation and installation.

Eliminates the need for a complete crane structure, leveraging existing infrastructure.

Versatility:

Suitable for a wide range of industrial applications requiring reliable lifting solutions in explosive atmospheres.

Customizable to meet specific site requirements and operational needs.

Ease of Maintenance:

Explosion-proof components are designed for durability and long service life.

Simplified maintenance procedures reduce downtime and operational costs.

Applications:

Chemical and Petrochemical Industries: Handling of hazardous materials in production and storage areas.

Oil and Gas: Operations in refineries, offshore platforms, and storage facilities.

Pharmaceutical Manufacturing: Safe transport of volatile substances and ingredients.

Mining: Lifting operations in environments with flammable gases or dust.

Single girder explosion-proof bridge crane kits without the main girder offer a robust and flexible solution for hazardous environments. By combining safety, efficiency, and adaptability, these crane kits provide an essential lifting mechanism for industries dealing with explosive materials. Whether for new installations or upgrading existing systems, these crane kits ensure safe and reliable operations in challenging conditions.

Explosion-Proof Overhead Crane Kit 3 Ton with No Girder

Crane Type: LB

Capacity: 3T

Crane Span: 15 meters

Lifting Height: 5 meters

Voltage: 380V 50HZ 3P

Components Included:

Explosion-proof hoist assembly: 1 set (380V 50HZ)

Bridge crane driving wheel (LD300): 2 sets (including shaft and shaft sleeve)

Bridge crane driven wheel (LD300): 2 sets (including shaft and shaft sleeve)

Bridge crane motor (BZDY21-4/0.8KW): 2 units (380V 50HZ)

Bridge crane gearbox (LD20): 2 units

C-channel (30C): 15 meters (3 pieces of 5 meters)

Bracket (30C): 7 pieces (0.4 meters per piece)

Lifting clamp (30C): 7 pieces

Connector (30C): 2 pieces

Host trolley (30C): 7 pieces

Two-in-one electrical box (3T): 1 set (380V 50HZ)

Various cables for power supply, hoist control, motor lines, limit lines, etc.

Bridge crane limit (LX5-5B): 2 pieces

Explosion-proof overload (BQX-3): 1 set (36V)

Explosion-proof counterweight: 1 set

Buffer (A-1): 4 pieces

Item No. | Description | Model/Specification | Unit | Quantity | Notes |

1 | Explosion-proof hoist assembly | 3T | Set | 1 | 380V 50HZ |

2 | Bridge crane driving wheel | LD300 | Set | 2 | Including shaft and shaft sleeve |

3 | Bridge crane driven wheel | LD300 | Set | 2 | Including shaft and shaft sleeve |

4 | Bridge crane motor | BZDY21-4/0.8KW (Yuxing) | Unit | 2 | 380V 50HZ |

5 | Bridge crane gearbox | LD20 | Unit | 2 | |

6 | C-channel | 30C | Meter | 15 | 3 pieces of 5 meters |

7 | Bracket | 30C | Piece | 7 | 0.4 meters per piece |

8 | Lifting clamp | 30C | Piece | 7 | |

9 | Connector | 30C | Piece | 2 | |

10 | Host Trolley | 30C | Piece | 7 | |

11 | Two-in-one electrical box | 3T | Set | 1 | 380V 50HZ |

12 | Cable | YC3X6MM+1 | Meter | 3 | Main power supply |

13 | Cable | YC3X4mm+1 | Meter | 21 | Hoist quick power supply |

14 | Cable | YC3X5MM | Meter | 21 | Hoist slow power supply |

15 | Cable | YC3X5MM | Meter | 21 | Hoist operating power supply |

16 | Cable | YC3X5MM | Meter | 21 | Bridge crane motor line |

17 | Cable | YC6X5MM | Meter | 21 | Hoist limit, overload power supply |

18 | Cable | YC2X5MM | Meter | 8 | Bridge crane limit line |

19 | Bridge crane limit | LX5-5B | Piece | 2 | |

20 | Explosion-proof overload | BQX-3 | Set | 1 | 36V |

21 | Explosion-proof counterweight | Set | 1 | ||

22 | Buffer | A-1 | Piece | 4 |

Explosion-Proof Overhead Crane Kit 3 Ton with No Girder

Crane Type: LB

Capacity: 3T

Crane Span: 14 meters

Lifting Height: 5.5 meters

Voltage: 380V 50HZ 3P

Components Included:

Explosion-proof hoist assembly: 1 set (380V 50HZ)

Bridge crane driving wheel (300): 2 sets (including shaft and shaft sleeve)

Bridge crane driven wheel (300): 2 sets (including shaft and shaft sleeve)

Bridge crane motor (BZDY21-4/0.8KW): 2 units (380V 50HZ)

Bridge crane gearbox (LD20): 2 units

C-channel (30C): 14 meters (3 pieces of 4 meters, 1 piece of 4 meters)

Bracket (30C): 8 pieces (0.4 meters per piece)

Lifting clamp (30C): 8 pieces

Connector (30C): 3 pieces

Host trolley (30C): 8 pieces

1Two-in-one electrical box (3T): 1 set (380V 50HZ)

1 Various cables for power supply, hoist control, motor lines, limit lines, etc.

1 Bridge crane limit (LX5-5B): 2 pieces

1Explosion-proof overload (BQX-3): 1 set (36V)

1Explosion-proof counterweight: 1 set

1Buffer (A-1): 4 pieces

Item No. | Description | Model/Specification | Unit | Quantity | Notes |

1 | Explosion-proof hoist assembly | 3T | Set | 1 | 380V 50HZ |

2 | Bridge crane driving wheel | 300 | Set | 2 | Including shaft and shaft sleeve |

3 | Bridge crane driven wheel | 300 | Set | 2 | Including shaft and shaft sleeve |

4 | Bridge crane motor | BZDY21-4/0.8KW (Yuxing) | Unit | 2 | 380V 50HZ |

5 | Bridge crane gearbox | LD20 | Unit | 2 | |

6 | C-channel | 30C | Meter | 14 | 3 pieces of 4 meters, 1 piece of 4 meters |

7 | Bracket | 30C | Piece | 8 | 0.4 meters per piece |

8 | Lifting clamp | 30C | Piece | 8 | |

9 | Connector | 30C | Piece | 3 | |

10 | Host Trolley | 30C | Piece | 8 | |

11 | Two-in-one electrical box | 3T | Set | 1 | 380V 50HZ |

12 | Cable | YC3X6MM+1 | Meter | 3 | Main power supply |

13 | Cable | YC3X4mm+1 | Meter | 22 | Hoist quick power supply |

14 | Cable | YC3X5MM | Meter | 22 | Hoist slow power supply |

15 | Cable | YC3X5MM | Meter | 22 | Hoist operating power supply |

16 | Cable | YC3X5MM | Meter | 22 | Bridge crane motor line |

17 | Cable | YC6X5MM | Meter | 22 | Hoist limit, overload power supply |

18 | Cable | YC2X5MM | Meter | 8 | Bridge crane limit line |

19 | Bridge crane limit | LX5-5B | Piece | 2 | |

20 | Explosion-proof overload | BQX-3 | Set | 1 | 36V |

21 | Explosion-proof counterweight | Set | 1 | ||

22 | Buffer | A-1 | Piece | 4 |

Explosion-Proof Overhead Crane Kit 5 Ton with No Girder

Crane Type: LB

Capacity: 5T

Crane Span: 7M

Lifting Height: 9.3M

Voltage: 380V 50HZ 3P

Components Included:

Explosion-proof hoist assembly: 1 set (380V 50HZ)

Bridge crane driving wheel (LD300): 2 sets (including shaft and shaft sleeve)

Bridge crane driven wheel (LD300): 2 sets (including shaft and shaft sleeve)

Bridge crane motor (BZDY21-4/0.8KW): 2 units (380V 50HZ)

Bridge crane gearbox (LD20): 2 units

C-channel (30C): 7 meters (2 pieces of 35 meters)

Bracket (30C): 5 pieces (0.4 meters per piece)

Lifting clamp (30C): 5 pieces

Connector (30C): 1 piece

Host trolley (30C): 5 pieces

Two-in-one electrical box (5T): 1 set (380V 50HZ)

Various cables for power supply, hoist control, motor lines, limit lines, etc.

Bridge crane limit (LX5-5B): 2 pieces

Explosion-proof overload (BQX-5): 1 set (36V)

Explosion-proof counterweight: 1 set

Buffer (A-1): 4 pieces

These kits provide all the necessary components for setting up explosion-proof overhead cranes suitable for hazardous environments. Let me know if you need further assistance or details on any specific aspect!

Item No. | Description | Model/Specification | Unit | Quantity | Packaging | Notes |

1 | Explosion-proof hoist assembly | 5T | Set | 1 | Box | 380V 50HZ |

2 | Bridge crane driving wheel | LD300 | Set | 2 | Box | Including shaft and shaft sleeve |

3 | Bridge crane driven wheel | LD300 | Set | 2 | Box | Including shaft and shaft sleeve |

4 | Bridge crane motor | BZDY21-4/0.8KW (Yuxing) | Unit | 2 | Box | 380V 50HZ |

5 | Bridge crane gearbox | LD20 | Unit | 2 | Box | |

6 | C-channel | 30C | Meter | 7 | Bare | 2 pieces of 35 meters |

7 | Bracket | 30C | Piece | 5 | Box | 0.4 meters per piece |

8 | Lifting clamp | 30C | Piece | 5 | Box | |

9 | Connector | 30C | Piece | 1 | Box | |

10 | Host Trolley | 30C | Piece | 5 | Box | |

11 | Two-in-one electrical box | 5T | Set | 1 | Box | 380V 50HZ |

12 | Cable | YC3X10MM+1 | Meter | 3 | Box | Main power supply |

13 | Cable | YC3X6mm+1 | Meter | 14 | Box | Hoist quick power supply |

14 | Cable | YC3X5MM | Meter | 14 | Box | Hoist slow power supply |

15 | Cable | YC3X5MM | Meter | 14 | Box | Hoist operating power supply |

16 | Cable | YC3X5MM | Meter | 14 | Box | Bridge crane motor line |

17 | Cable | YC6X5MM | Meter | 14 | Box | Hoist limit, overload power supply |

18 | Cable | YC2X5MM | Meter | 8 | Box | Bridge crane limit line |

19 | Bridge crane limit | LX5-5B | Piece | 2 | Box | |

20 | Explosion-proof overload | BQX-5 | Set | 1 | Box | 36V |

21 | Explosion-proof counterweight | Set | 1 | Box | ||

22 | Buffer | A-1 | Piece | 4 | Box |

Explosion Proof Bridge Cranes Kits Pictures for Your Reference

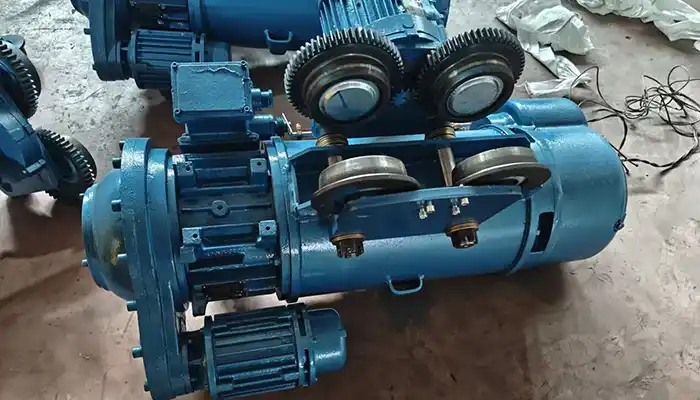

Electric explosion electric hoist, the main parts of explosion proof bridge crane kit

Electric explosion electric hoist, the main parts of explosion proof bridge crane kit

Explosion proof electric hoist trolley with motor , the main parts of explosion proof bridge crane kit

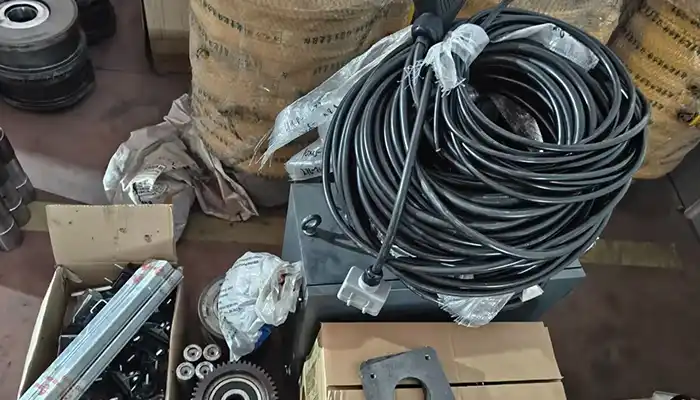

Main parts and components of single girder bridge crane kit with explosion proof crane design

Main parts and components of single girder bridge crane kit with explosion proof crane design

Main parts and components of single girder top running bridge crane kit with explosion proof crane design

Benifits and Considerations of Buying Bridge Crane kits and Complete Bridge Crane

Indeed, one of the primary distinctions between bridge crane kits and complete bridge cranes is the inclusion of the main steel structure, particularly the main girder:

Bridge Crane Kits:

The main steel structure, such as the main girder, is typically not included in bridge crane kits.

Instead, bridge crane kits consist of essential components such as end trucks, hoist trolleys, electrical components, and hardware for assembly.

This absence of the main steel structure makes bridge crane kits easier to transport, as the components are typically smaller and more manageable.

Complete Bridge Cranes:

Complete bridge cranes come with the main steel structure fully assembled and integrated into the crane system.

The main girder, along with other structural components, is included and installed by the manufacturer or certified installer.

This means that complete bridge cranes require local production or fabrication of the main steel structure, adding to the complexity of transportation and installation.

In summary, the key difference lies in the inclusion of the main steel structure. Bridge crane kits omit the main girder, making them easier to transport, while complete bridge cranes come fully assembled with the main steel structure included. This difference impacts transportation logistics, installation requirements, and overall convenience for businesses purchasing overhead crane systems.

Benefits and Considerations of Buying Bridge Crane Kits:

Benefits:

Customization: Bridge crane kits offer greater flexibility in customization, allowing businesses to select specific components based on their unique lifting requirements.

Cost-Effectiveness: Generally more cost-effective than complete bridge cranes due to lower upfront costs and potential savings on labor and customization.

Transportation: Easier to transport as bridge crane kits typically consist of smaller and more manageable components, omitting the main steel structure.

Installation Control: Businesses have greater control over the assembly and installation process, allowing them to schedule and oversee the project according to their timeline and preferences.

Maintenance and Repairs: In the event of maintenance or repairs, businesses can replace individual components as needed, potentially reducing downtime and costs.

Considerations:

Assembly and Installation: Requires self-assembly or installation by a local contractor, which may require time, labor, and technical expertise.

Customization Complexity: While customization offers flexibility, businesses must ensure they select the correct components to meet their specific lifting requirements, which may require technical knowledge and expertise.

Transportation Logistics: While easier to transport compared to complete bridge cranes, businesses must still coordinate transportation logistics for the various components of the bridge crane kit.

Structural Requirements: Businesses must ensure they have the necessary structural support and foundation in place to accommodate the assembled bridge crane kit.

Benefits and Considerations of Buying Complete Bridge Cranes:

Benefits:

Convenience: Complete bridge cranes come fully assembled and ready for installation by the manufacturer's team or a certified installer, offering convenience and peace of mind.

Professional Installation: Ensures proper installation by experienced technicians, reducing the risk of errors and ensuring optimal performance and safety.

Time Savings: Eliminates the need for self-assembly or coordination with a local contractor, saving businesses time and effort.

Comprehensive Solution: Provides a comprehensive solution with the main steel structure included, reducing the need for additional fabrication or sourcing.

Considerations:

Higher Upfront Costs: Complete bridge cranes often come with higher upfront costs due to the inclusion of the main steel structure and professional installation services.

Limited Customization: Offers limited customization compared to bridge crane kits, as businesses may have fewer options to tailor the crane to their specific requirements.

Transportation Complexities: Requires coordination for transportation of the fully assembled crane, which may involve larger and heavier shipments compared to bridge crane kits.

Dependence on Manufacturer: Businesses may depend on the manufacturer or authorized service providers for maintenance, repairs, and technical support.

In summary, the choice between buying bridge crane kits and complete bridge cranes depends on factors such as customization needs, budget constraints, installation preferences, and transportation logistics. Businesses should carefully weigh the benefits and considerations of each option to make an informed decision that best suits their operational requirements and objectives.

Comparisons of Buying Bridge Cranes Kits and Complete Bridge Cranes

When comparing buying a complete bridge crane versus a bridge crane kit, several differences emerge across various aspects:

Cost:

Buying a complete bridge crane often entails higher upfront costs due to the inclusion of all components and assembly.

Bridge crane kits typically offer a more economical option as they exclude certain components like the main steel structure, which lowers shipping and assembly expenses.

Shipping and Transportation:

Complete bridge cranes usually require specialized shipping arrangements due to their size and weight, leading to potentially higher shipping costs.

Bridge crane kits are designed to be more compact and easier to transport since they omit bulky components like the main steel structure, resulting in lower shipping expenses.

Assembly and Installation:

Complete bridge cranes are delivered fully assembled, requiring professional installation services, which can incur additional labor costs.

Bridge crane kits are designed for easier assembly and installation, often requiring less specialized labor and reducing installation time and associated expenses.

Customization and Flexibility:

Complete bridge cranes may offer limited customization options since they come preassembled with standardized components.

Bridge crane kits provide more flexibility for customization, allowing customers to select specific components based on their needs and preferences, potentially resulting in a more tailored solution.

Lead Time:

Complete bridge cranes typically have longer lead times due to the complexity of manufacturing and assembly processes.

Bridge crane kits generally have shorter lead times since they involve fewer components and simpler manufacturing processes, enabling quicker delivery and installation.

Local Manufacturing:

Complete bridge cranes may be manufactured centrally and shipped globally, which can limit options for local manufacturing or customization.

Bridge crane kits may facilitate local manufacturing of certain components like the main steel structure, promoting regional production and potentially reducing shipping distances and costs.

In summary, while buying a complete bridge crane offers convenience and immediate readiness, opting for a bridge crane kit can provide cost savings, customization options, and easier transportation and assembly, making it a preferred choice for certain applications and budgets.

Why to Buy Bridge Cranes Kits Over Complete Bridge Cranes

There are several compelling reasons to consider buying bridge crane kits over complete bridge cranes:

- Cost Savings: Bridge crane kits typically offer significant cost savings compared to complete bridge cranes. By purchasing only the essential components and excluding items like the main steel structure, customers can reduce upfront costs, shipping expenses, and assembly fees.

- Customization: Bridge crane kits provide greater flexibility for customization. Customers can choose specific components based on their unique requirements, such as crane capacity, span length, and lifting height. This customization ensures that the crane system meets the exact needs of the application, potentially improving efficiency and productivity.

- Easier Transportation: Bridge crane kits are designed to be more compact and easier to transport compared to complete bridge cranes. By omitting bulky components, such as the main steel structure, kits can be shipped more efficiently, resulting in lower shipping costs and reduced logistical challenges.

- Simplified Assembly: Bridge crane kits are engineered for easier assembly and installation. With detailed instructions and pre-engineered components, the assembly process is streamlined, requiring less specialized labor and reducing installation time. This simplification can lead to quicker deployment and operational readiness.

- Scalability: Bridge crane kits offer scalability for future expansion or modifications. Customers can easily add or upgrade components as their needs change, allowing for incremental growth without significant disruption to operations. This scalability ensures that the crane system remains adaptable to evolving business requirements.

- Local Manufacturing: Purchasing bridge crane kits may support local manufacturing and economic development. By sourcing components locally, customers can promote regional production and reduce reliance on imported goods. This approach fosters job creation, stimulates local economies, and enhances supply chain resilience.

In summary, buying bridge crane kits offers numerous advantages, including cost savings, customization options, easier transportation and assembly, scalability, and support for local manufacturing. These benefits make bridge crane kits a compelling choice for businesses seeking efficient, adaptable, and cost-effective material handling solutions.

Conclusion

In conclusion, the comparison between 3-ton and 5-ton explosion-proof bridge cranes and crane kits highlights the importance of selecting the right solution to meet specific lifting requirements and operational needs. Businesses must carefully assess their lifting capacity, space constraints, safety considerations, and budget constraints when choosing between the two options.

It's crucial for businesses to consider their specific requirements and industry needs when selecting an overhead crane kit. Factors such as lifting capacity, space availability, safety features, and budget constraints play a significant role in determining the most suitable solution. By understanding these requirements and aligning them with the features and specifications of the crane kit, businesses can optimize their material handling processes and enhance productivity in the workplace.

Making informed decisions when purchasing overhead crane kits is essential to ensure that businesses invest in the right solution for their needs. By conducting thorough research, comparing key features and specifications, and consulting with reputable suppliers, businesses can make educated choices that align with their operational goals and objectives. Additionally, prioritizing safety, reliability, and efficiency in crane operations is crucial for maintaining a safe and productive work environment.

In summary, businesses should prioritize careful consideration of their specific requirements and industry needs when purchasing overhead crane kits. By doing so, they can make informed decisions that optimize their material handling processes, improve efficiency, and enhance workplace safety.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch