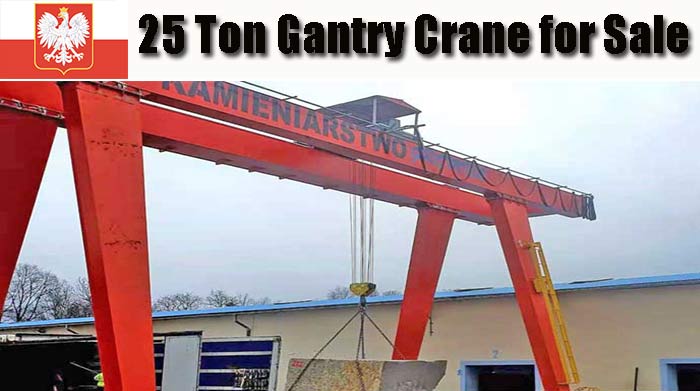

25 Ton Double Girder Gantry Crane for Stone Block Handling Poland

Gantry crane for sale Poland, 25 ton gantry, European standard double girder cranefor outdoor use, cost-effective crane price. Check FEM standard 25 ton double girder gantry crane for sale Poland project now.

Main parameters of gantry crane for sale Poland

- Type of gantry crane: MGO

- Lifting capacity of stone handling gantry crane: 25 ton

- Working class of fem gantry crane: A5,

- Span of European style gantry crane: 12m

- Lifting speed ofheavy dutygantry crane: 0.4-4m/min

- Lifting height of outdoorgantry crane: 9m

- Crane travelling speed of fem gantry crane: 2-20m/m

- Rotate speed of fem gantry crane: 2-20m/m

- Europeanhoist for 25 gantry Poland

Stone block gantry crane

Stone block gantry crane for indoor and outdoor marble handling for sale with high efficiency, precision, safety, low noise, and so on.

The stone handling crane is used to improve production line efficiency and productivity during the stone manufacturing process. These stones, which include marble and granite, are formed from sedimentary carbonate rocks and go through a lengthy fabrication process. The following are the steps that take marble and granite from the quarry or stone pit to the kitchen or other final destination:

- Extraction - Extraction entails removing natural stone from a quarry or stone pit and transporting it to a processing facility. When perpendicular structures are required, marble and granite slabs are assembled, drilled with holes, and set together.

- Gang sawing — Gang sawing is used to cut marble and granite into finer pieces for finishing.

- Polishing and sealing — Artificial diamonds smooth the surface of the stone, revealing its true value and character.

- Waterjet cutting and wet sawing — The stone is cut with a cooling water flow, resulting in minimal heat and friction.

Marble and granite handling cranes are used for efficient and quick handling in large-scale marble and granite restorations, stone repairs, and commercial work.

Stone handling cranes can be equipped with corrosion-resistant, weatherproof controls and enclosures to withstand outdoor environments and manage delicate marble and granite loads, and our precision hoists can be used to carefully turn stones and lay them flat.

Double girder trolley for 25 ton gantry crane

Gantry crane trolley for 25 ton double girder gantry crane

Gantry crane girder for 25 ton double girder gantry crane

Gantry crane girder for 25 ton double girder gantry crane

Gantry parts and components for 25 ton double girder gantry crane

Gantry crane nameplate of 25 ton double girder gantry crane

What are the different types of overhead traveling cranes available for stone handling?

Gantry Crane – Overhead lifting from a wheeled floor structure.

Pros: Low cost, lightweight, and portable, and available in a variety of capacities, spans, and heights.

Cons: Requires floor space and cannot be moved while loaded – it is designed to be placed in position and then loaded to move material side to side or up and down.

Workstation Crane – Fixed-area overhead lifting for up to 2 Tons.

Advantages: Freestanding column options or ceiling support. Capacity ranges from 12 to 2 Tons. With push trolley and bridge, it is designed for powered up and down motion. Designs that can be customized. Installation and relocation are simple.

Cons: The capacity is limited to 2 tons, and options for a powered trolley and bridge are available but expensive.

Vacuum Lifting Attachments – An additional below-the-hook device to make lifting easier.

Pros: Simple operation, self-contained vacuum generator or plant air lift and tilt, movable vacuum cups

Cons: Increases the system's initial cost.

Factors to Consider When Choosing the Right Material Handling Equipment:

Functionality of Workstation

- Consider the type of work environment in which your team operates, as well as the day-to-day operations. Consider the following questions:

- Do you have a large enough facility to support an overhead crane structurally?

- Is it necessary for your team to maximize floor space in order to ensure adequate storage capacity?

- Are your workstations close or far apart, and what other equipment systems do you currently employ?

Can I install a crane system if there are obstructions in the ceiling or floor?

If you're working in an existing building, you're probably dealing with ceiling obstructions like duct work or lighting. Your facility may have oddly shaped rooms or small spaces. Obstructions and/or low headroom requirements can be accommodated in the initial design of the system, which is often done using factory standard equipment.

What if the structure of my building isn't strong enough to support a crane?

While some buildings can accommodate a crane system built into the structural beams, others cannot. We provide freestanding or floor-mounted cranes and collaborate with customers to determine the best system for their workspace.

Material Size, Weight & Shape

The characteristics of the material you'll be handling, such as weight, shape and size, influences the type of equipment you need. Consider the following:

- The capacity of your equipment:How much can your system lift or transport?

- The type of equipment:Will you need an overhead crane to move slabs across your facility, or do you just need a workstation jib?

- The speed needs of your equipment:The heavier the load, the more control you'll need to have over movement.

Size, weight, and shape of the material

The type of equipment you'll need is influenced by the properties of the material you'll be handling, such as weight, shape, and size. Take into account the following:

- Your equipment's capacity:

- How much weight or distance can your system lift or transport?

- The type of equipment: Will you require an overhead crane to move slabs throughout your facility, or will you only require a workstation jib?

- The speed requirements of your equipment:

- The more control you need over movement, the heavier the load.

Costs of Equipment

- Consider your immediate needs and financial capabilities before investing in equipment:

- Long-term investment: Do you require a machine that will last a long time?

- Labor costs: Will this equipment help you save money, or will you need more personnel to assist you during operation?

- Equipment Maintenance: Do you need a machine that operates 24 hours a day, seven days a week and requires constant maintenance, or do you need a "light use" machine that operates a limited number of hours per week?