Marine Jib Crane for Sale Belgium: 4 Sets of 2-Ton Jib Cranes for Port Operations

Four 2-ton marine jib cranes sold in Belgium, designed for efficient port operations with corrosion-resistant materials and enhanced safety features.

A major Belgian port operator needed a solution to boost their cargo handling capabilities. Their operations involve unloading ships, transferring materials around the dock, and conducting maintenance work on vessels. With the challenges of saltwater, humidity, and constant exposure to harsh marine conditions, they needed cranes that could stand up to the elements while performing reliably.

The client requested 4 customized 2-ton marine jib cranes, designed for flexibility, durability, and high performance in this demanding environment. These cranes would handle medium-weight cargo like containers and ship parts, and also support general dockyard operations. The goal was clear: improve productivity, reduce maintenance downtime, and ensure safety in the busy, often hazardous port setting.

Project Specifications and Key Requirements

The cranes had to meet specific operational and environmental criteria. Here’s a quick look at the key specifications:

Lifting Capacity: Each crane can lift up to 2 tons, perfect for handling containers, machinery, and other heavy items.

Crane Span:

- Two cranes with a 4-meter span for handling larger loads over wide areas.

- Two cranes with a 3-meter span for tighter spaces or smaller loads.

Lifting Height: With a lift of H3+37 meters, these cranes could handle tall cargo stacks and high ship decks.

Power Supply:

- Two cranes were designed for a 400V 50Hz 3-phase power supply.

- The other two cranes used a 440V 60Hz 3-phase power supply, accommodating different sections of the port.

Quantity: 4 cranes, split into two sets for flexibility across various parts of the port.

The cranes were designed to operate seamlessly in different power zones across the dock and could handle various lifting tasks with ease.

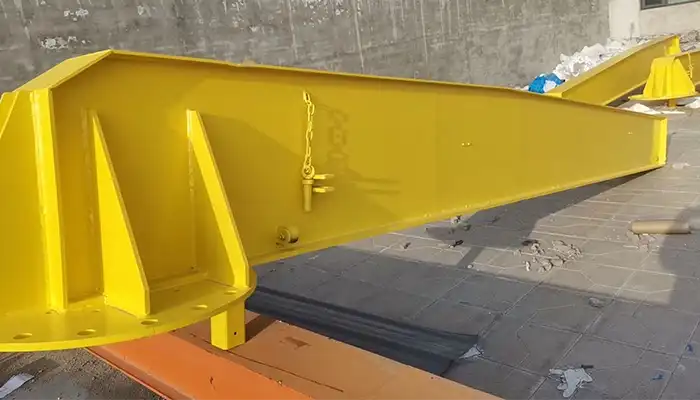

catilever of marine jib crane 2 ton

catilever of marine jib crane 2 ton

4 columns of 2 ton jib crane for sale Belgium

4 columns of 2 ton jib crane for sale Belgium

crane kit of 2 ton pillar mounted jib crane

crane kit of 2 ton pillar mounted jib crane

electric hoist with European style for sale Belgium

electric hoist with European style for sale Belgium

Design Features for Marine Environments

These cranes were built to last in challenging coastal conditions. Here are the standout features that make them ideal for marine operations:

Corrosion-Resistant Materials and Coatings:

- Marine-Grade Steel: The cranes’ frames were constructed from high-strength, marine-grade steel, specifically chosen for its resistance to rust and corrosion. This steel is tough enough to endure the salty air and humid conditions typical of port environments.

- Anti-Corrosion Coating: Every exposed part of the crane was coated with a multi-layer epoxy system that’s resistant to saltwater corrosion. Plus, many components were hot-dip galvanized for added protection, ensuring the cranes stay durable even in the harshest environments.

- Waterproof Electrical Systems: The electrical systems are sealed and weatherproof, preventing water or moisture from damaging the wiring. This ensures that the cranes will function reliably, no matter how wet or salty the conditions get.

Pillar-Mounted Design for Space Efficiency:

- The cranes were designed with a pillar-mounted structure, perfect for tight dock spaces. Instead of needing wide tracks or rails, the pillar allows for 360-degree rotation, maximizing operational flexibility without taking up too much space.

- This configuration is great for ports, where every inch of real estate counts. The crane’s ability to rotate fully means it can cover a large area without needing to move around, making it highly efficient in busy work zones.

Rotating Jib Arm for Versatility:

- The jib arm can rotate 360 degrees, which is a game-changer for port operations. Operators can move heavy loads across the dock without ever needing to reposition the crane itself. This means quicker loading and unloading, less maneuvering, and ultimately faster turnaround times.

- The cranes come in 3-meter and 4-meter spans, giving the client flexibility depending on the size of the cargo and available space.

High Lifting Capacity and Reach:

- With a 2-ton capacity, the cranes can handle a variety of materials, from large containers to machinery and other heavy goods. Their H3+37-meter lifting height ensures they can reach over cargo stacks or up to high vessel decks without any issues.

- Whether it’s unloading from ships or stacking materials in the yard, these cranes offer all the lifting power needed for smooth, efficient operations.

Flexible Power Supply Options:

- The cranes were designed to work with different power supply setups. The two cranes that use 400V 50Hz are perfect for one part of the port, while the 440V 60Hz models are suited for areas with different electrical infrastructure.

- This flexibility means the cranes can be deployed anywhere in the port, without needing to make costly electrical upgrades or adjustments.

Safety Features for Busy Ports:

- Overload Protection: Each crane is equipped with overload limiters, preventing the lifting of more than the rated capacity. This reduces the risk of accidents and ensures safe operation.

- Emergency Stops: In case of a malfunction or emergency, operators can immediately shut down the crane using emergency stop buttons, which are easy to access on both the crane and control panel.

- Anti-Collision Sensors: These sensors detect nearby obstacles, helping to prevent the crane from accidentally hitting surrounding equipment or structures. This is particularly important in busy, congested dock areas.

Installation, Testing, and Launch

After delivery, the cranes were quickly installed and thoroughly tested under load. Installation was efficient, thanks to pre-assembled components that minimized downtime. Testing included running the cranes through real-world scenarios, simulating various loads and operational conditions.

- Operator Training: Port staff were trained on proper crane operation, routine maintenance, and emergency protocols. This training ensured that everyone was prepared for safe and efficient crane use.

- Field Testing: The cranes were subjected to performance testing in different weather conditions, including high winds and rain, to ensure they could handle the extreme conditions typically found in marine environments.

- Operational Launch: Once testing was completed, the cranes were put into full operation. They’ve now been running for several months, improving productivity and streamlining the port's cargo handling.

Challenges and Solutions

- Corrosion Resistance: Saltwater exposure is a major concern in marine environments. To tackle this, we used marine-grade materials, corrosion-resistant coatings, and galvanized components. This approach has ensured the cranes remain strong and reliable, even after months of exposure to harsh coastal conditions.

- Power Supply Variability: Different areas of the port had different power setups, which could have caused integration issues. By designing cranes with dual power options (400V and 440V), we ensured that no matter where the cranes were placed, they could be powered up and put to work without delay.

- Space Constraints: The limited space available in busy port areas required a crane design that could work efficiently in confined spaces. The pillar-mounted rotating jib design solved this by maximizing operational reach while minimizing space use. This flexibility meant the cranes could be used in different parts of the dock without any issues.

Conclusion

The installation of 4 sets of 2-ton marine jib cranes has been a huge success. These cranes are now integral to the port's daily operations, boosting efficiency, safety, and productivity. With their advanced corrosion protection, high lifting capacity, rotating jib arms, and power flexibility, these cranes are designed to last and perform under the toughest conditions.

They’ve already proven to be an invaluable asset, reducing maintenance costs and increasing operational speed. Thanks to their robust design and smart engineering, these cranes will continue to deliver reliable performance for years to come—helping the port operate smoothly and stay competitive in the maritime logistics industry.