20 Ton Electric Chain Hoists with Motorized Trolley for Sale UAE

Electric chain hoist 20 T 10 m lifting height for sale UAE, 415V electric hoist with remote control trolley & hoisting, good price 20 ton electric hoist.

| Hoist type | Motorized trolley travelling electric chain hoist |

| Hoist specification | 20 ton, 10 m lifting height |

| Power supply | 415V50HZ3P |

| Hoist control | Remote control hoist |

| Quantity | 4 units |

| Project location | UAE |

Category: Electric Chain Hoist Crane

Your Trusted Electric Chain Hoist Crane Manufacturer & Supplier

20 Ton Electric Chain Hoists with Motorized Trolley for Sale UAE

Electric chain hoist 20 T 10 m lifting height for sale UAE, 415V electric hoist with remote control trolley & hoisting, good price 20 ton electric hoist.

Electric chain hoists are essential tools in various industries, providing a safe and efficient way to lift and move heavy loads. This blog will delve into the specifics of a 20-ton electric chain hoist with a 10-meter lift height, powered at 415V, and the benefits of customized hoists available for sale in the UAE, including the advantages of remote control functionality.

20 Ton Electric Chain Hoists with Motorized Trolley

Electric chain hoists are mechanical devices designed to lift and lower heavy loads with the aid of a motor. They use a chain as the lifting medium and are commonly powered by electricity. The primary purpose of these hoists is to make lifting heavy objects easier, safer, and more efficient. They are a critical component in many industrial and commercial settings, where manual lifting would be impractical or unsafe.

Common Applications in Various Industries

Electric chain hoists are used across a wide range of industries due to their versatility and efficiency. Some common applications include:

- Manufacturing: Moving raw materials, assembling parts, and handling finished products.

- Construction: Lifting building materials and heavy equipment.

- Warehousing: Loading and unloading goods, stacking products, and managing inventory.

- Automotive: Handling car parts, engines, and assembling vehicles.

- Mining: Transporting minerals, equipment, and machinery.

- Shipyards: Managing heavy components and loading cargo onto ships.

In each of these industries, electric chain hoists help streamline operations, reduce manual labor, and enhance safety.

Not all lifting tasks are the same, and standard hoists may not always meet specific requirements. Customization allows businesses to tailor hoists to their exact needs, ensuring optimal performance and safety. This can include modifications in lifting capacity, lift height, speed, control systems, and more. By customizing hoists, companies can address unique challenges in their operations, leading to more efficient workflows.

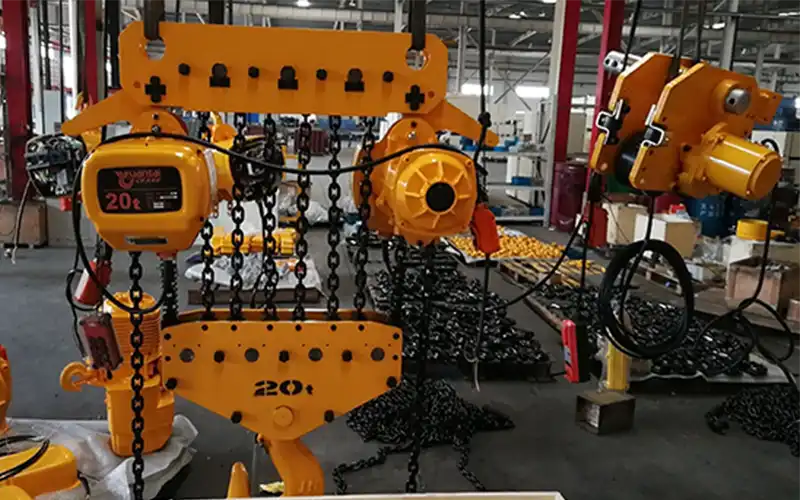

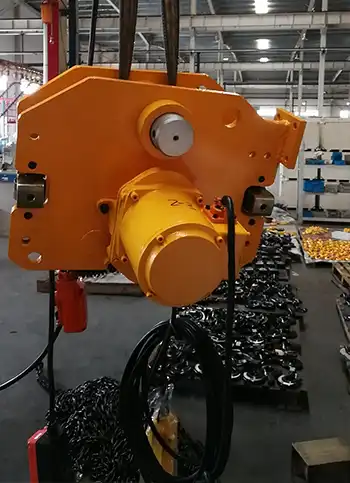

20 ton electric chain hoist

motorized travelling trolley for electric chain hoist

Chain fall bags for 4 sets of electric chain hoist 20 ton 10 m lifting height

Benefits of Customized Solutions

Customized electric chain hoists offer several benefits:

- Enhanced Efficiency: Tailored hoists can be optimized for specific tasks, reducing the time and effort required for lifting operations.

- Increased Safety: Custom features like overload protection, emergency stops, and specific control mechanisms can enhance operator safety.

- Cost Savings: By selecting features that match exact needs, companies can avoid overpaying for unnecessary capabilities while ensuring they have the right tools for the jo

- Adaptability: Custom hoists can be designed to fit into existing systems and processes, minimizing the need for significant operational changes.

The UAE has seen significant industrial growth over the past few decades, driven by investments in construction, manufacturing, oil and gas, and logistics. This growth has created a strong demand for reliable and efficient lifting solutions. Electric chain hoists, with their ability to handle heavy loads safely and efficiently, are in high demand across various sectors in the UAE.

In a fast-growing industrial environment like the UAE, the reliability of lifting equipment is paramount. Downtime due to equipment failure can lead to significant losses. Therefore, businesses in the UAE prioritize high-quality, durable, and efficient lifting solutions. Electric chain hoists that are robust, easy to maintain, and capable of handling heavy loads consistently are essential for maintaining productivity and safety in these industries.

Specifications of the 20 Ton Electric Chain Hoist with Motorized Trolley for Sale UAE

The specifications of a 20-ton electric chain hoist is crucial for making an informed purchase decision. This section will delve into the key aspects of load capacity, lift height, and voltage requirements, explaining their importance and relevance to various industrial applications.

Load Capacity

Definition and Significance of 20-Ton Capacity

- The load capacity of a hoist refers to the maximum weight it can safely lift. A 20-ton capacity means the hoist can handle loads up to 20,000 kilograms (44,092 pounds). This capacity is significant for industries where extremely heavy items need to be moved regularly.

- Heavy Machinery: In manufacturing plants and construction sites, heavy machinery components often weigh several tons. A 20-ton hoist can efficiently handle these loads.

- Bulk Materials: In sectors like mining and metal fabrication, materials such as ore and large metal sheets can be very heavy. A hoist with this capacity ensures smooth handling and transportation.

Typical Applications for Heavy Lifting

A 20-ton electric chain hoist is ideal for:

- Construction: Lifting and placing large structural elements like steel beams and precast concrete.

- Manufacturing: Moving heavy parts during the assembly of large machinery or vehicles.

- Shipbuilding: Handling large ship components, including engines and sections of hulls.

- Mining: Transporting heavy mining equipment and extracted minerals.

Lift Height

Importance of a 10-Meter Lift Height : The lift height indicates how high the hoist can raise a load. A 10-meter lift height (approximately 33 feet) is substantial, allowing the hoist to be used in environments with significant vertical space requirements.

- Vertical Construction: In tall buildings or structures under construction, materials need to be lifted to considerable heights. A 10-meter lift ensures that materials can be transported to higher floors efficiently.

- Warehousing: In large warehouses with high shelving systems, a hoist with a 10-meter lift height is essential for accessing materials stored at elevated levels.

Situations Requiring Extended Lift Heights

- High-rise Buildings: Construction and maintenance of skyscrapers require hoists that can reach significant heights.

- Industrial Plants: In facilities with multi-level production lines, materials often need to be moved vertically over substantial distances.

- Storage Facilities: In large storage facilities, accessing top-tier storage racks demands a high lift capacity to ensure efficient space utilization.

Voltage Requirements

Significance of 415V Power Supply: The voltage requirement indicates the electrical power needed to operate the hoist. A 415V power supply is a standard for heavy-duty industrial equipment, providing sufficient power to handle large loads efficiently.

- Efficiency: Higher voltage means more efficient power usage, enabling the hoist to lift heavier loads with less strain on the motor.

- Compatibility: Many industrial settings are already equipped with 415V power systems, making it easier to integrate the hoist into existing infrastructure.

Compatibility with Industrial Power Systems

Ensuring compatibility with industrial power systems is crucial for seamless operation:

- Standardization: In many regions, including the UAE, 415V is a common standard for industrial equipment. This ensures that the hoist can be easily installed without the need for extensive electrical modifications.

- Safety: Proper voltage matching reduces the risk of electrical issues, ensuring safer operation of the hoist. Industrial-grade power systems are designed to handle the demands of heavy machinery, providing a stable and reliable power source.

In conclusion, understanding these key specifications—load capacity, lift height, and voltage requirements—helps in selecting the right electric chain hoist for your needs. A 20-ton hoist with a 10-meter lift height and 415V power supply is a powerful tool for various industrial applications, ensuring efficiency, safety, and compatibility with existing systems.

Features of Custom 20 Ton Electric Hoists

Custom 20-ton electric hoists offer a range of features designed to meet specific operational needs, enhance performance, and ensure safety. This section will explore the various customization options, build quality, durability, and essential safety features that make these hoists a reliable choice for heavy lifting tasks.

Customization Options

Tailoring to Specific Operational Needs

Customization allows businesses to adapt hoists to their unique requirements, ensuring optimal performance for their specific applications. Key customization options include:

- Lift Speed: Adjusting the hoist's lifting speed to match the pace of operations can improve efficiency and precision.

- Control Systems: Customized control systems, such as pendant controls, wireless remote controls, or automated systems, can be selected based on operator preferences and workflow requirements.

- Chain Length: The length of the lifting chain can be modified to suit the height requirements of the operational environment, whether it's for high-rise construction or ground-level operations.

- Mounting Options: Hoists can be tailored to fit different mounting setups, such as trolley-mounted for horizontal movement along beams, or fixed-mounted for stationary lifting tasks.

Enhancements in Performance and Safety

Customized hoists can include features that enhance both performance and safety:

- Variable Frequency Drives (VFD): VFDs allow for smooth acceleration and deceleration, reducing wear and tear on the hoist and providing more precise control over lifting operations.

- Load Sensors: Integrating load sensors ensures that the hoist operates within safe load limits, preventing overloading and potential equipment failure.

- Environment-specific Coatings: For hoists used in harsh environments, such as outdoors or in corrosive industrial settings, special coatings can protect against rust and corrosion.

Build Quality and Durability

Materials Used in Construction : The materials used in constructing a hoist significantly impact its durability and reliability. High-quality materials ensure the hoist can withstand the rigors of heavy-duty use:

- High-Grade Steel: The use of high-strength steel for the hoist frame and lifting components ensures robustness and longevity.

- Corrosion-Resistant Components: Stainless steel and other corrosion-resistant materials are essential for hoists used in challenging environments, preventing degradation over time.

- Heat-Treated Chains: Chains that are heat-treated for strength and durability can handle the stresses of lifting heavy loads without stretching or breaking.

Longevity and Maintenance Considerations : Durable construction and thoughtful design contribute to the long-term reliability of the hoist:

- Sealed Bearings and Gearboxes: These components are protected from dust and moisture, reducing the need for frequent maintenance and extending the lifespan of the hoist.

- Easy Access for Maintenance: Design features that allow for easy access to critical parts make routine maintenance simpler and quicker, minimizing downtime.

- High-Quality Motor and Electrical Components: Using top-tier electrical components ensures reliable performance and reduces the risk of electrical failures.

Safety Features

Overload Protection: Overload protection is a crucial safety feature that prevents the hoist from lifting loads beyond its capacity, which can cause mechanical failure and pose significant risks to operators and equipment. Key aspects include:

- Load Limiters: These devices automatically stop the hoist if the load exceeds the maximum rated capacity, ensuring safe operation.

- Warning Indicators: Visual and audible alarms alert operators if an overload condition is detected, allowing for immediate corrective action.

Emergency Stop Functions : Emergency stop functions are vital for quickly halting the hoist in case of an emergency, preventing accidents and damage:

- E-stop Buttons: Easily accessible emergency stop buttons on the control units allow operators to quickly shut down the hoist if necessary.

- Automated Emergency Stop Systems: Advanced hoists may include automated systems that detect hazardous conditions and stop the hoist without requiring operator intervention.

In summary, the features of custom 20-ton electric hoists make them a versatile and reliable choice for heavy lifting tasks. Customization options ensure the hoist meets specific operational needs, while robust construction materials and thoughtful design contribute to durability and ease of maintenance. Essential safety features like overload protection and emergency stop functions provide additional layers of security, ensuring safe and efficient operation in various industrial settings.

Remote Control Functionality

Remote control functionality is a critical feature for modern electric chain hoists, enhancing safety, precision, and convenience. This section will explore the advantages of remote control, the types of systems available, and how they integrate with existing systems.

Advantages of Remote Control

Improved Safety and Operator Distance

- One of the primary benefits of remote control functionality is the significant improvement in operator safety. By allowing operators to control the hoist from a distance, the risk of injury from load shifts or mechanical failures is greatly reduced.

- Safe Distance: Operators can position themselves in safe locations, away from the immediate vicinity of the lifting operation. This minimizes exposure to potential hazards such as falling objects or collisions.

- Clear Visibility: Remote control allows operators to choose vantage points with the best visibility of the load and its surroundings, improving the accuracy of movements and reducing the risk of accidents.

Enhanced Precision in Operations

- Remote control systems offer enhanced precision, allowing operators to execute complex lifting tasks with greater accuracy.

- Fine-Tuned Movements: Remote controls often provide more precise control over the hoist's movements, enabling fine adjustments that are crucial for delicate operations.

- Reduced Operator Fatigue: With remote control, operators can manage the hoist from comfortable positions, reducing physical strain and fatigue, which in turn improves concentration and operational precision.

Wired vs. Wireless Options

Remote control systems for electric chain hoists come in both wired and wireless configurations, each with its own set of advantages.

- Reliability: Wired systems are less prone to interference and connection issues, ensuring consistent control.

- Cost-Effective: Typically, wired controls are more affordable and simpler to maintain.

- Limited Mobility: The range is restricted by the length of the cable, which can limit the operator's movement.

- Increased Mobility: Wireless systems offer operators the freedom to move around and choose the best vantage point for lifting operations.

- Ease of Use: Wireless controls eliminate the clutter of cables, reducing trip hazards and simplifying setup.

- Interference Concerns: Wireless systems may face interference from other electronic devices, which can affect performance. However, modern systems often include features to minimize this risk.

Range and Interference Considerations

The effective range and potential for interference are important factors when choosing a remote control system.

Range: The operational range of wireless remote controls varies. It's essential to select a system with sufficient range to cover the entire working area of the hoist. For large facilities, extended-range models are available.

Interference: Wireless remote controls can be susceptible to interference from other wireless devices. Systems with frequency-hopping spread spectrum (FHSS) technology or similar features can help mitigate this issue, ensuring reliable communication between the remote and the hoist.

Integration with Existing Systems

Compatibility and Ease of Installation

- Integrating remote control functionality with existing hoist systems should be seamless and straightforward.

- Compatibility: Most modern electric chain hoists are designed to be compatible with remote control systems. It's crucial to verify compatibility with the specific model and manufacturer.

- Installation: Installation should be simple, ideally involving plug-and-play systems that do not require extensive modifications to the hoist or existing infrastructure. Manufacturers often provide detailed instructions and support for the integration process.

Training Requirements for Operators

- Effective use of remote control systems requires proper training to ensure operators can safely and efficiently manage the hoist.

- Comprehensive Training: Training programs should cover the operation of the remote control, safety protocols, and troubleshooting common issues. This ensures operators are confident and competent in using the new system.

- Ongoing Support: Manufacturers and suppliers should offer ongoing support and refresher training sessions to keep operators up to date with the latest features and best practices.

In conclusion, remote control functionality significantly enhances the safety, precision, and convenience of operating electric chain hoists. Whether opting for wired or wireless systems, understanding the benefits and considerations of each type is crucial for making an informed decision. Ensuring compatibility with existing systems and providing adequate training for operators will maximize the benefits of this advanced feature, leading to safer and more efficient lifting operations.

Benefits of Using Electric Chain Hoists in the UAE

Electric chain hoists offer numerous advantages for businesses operating in the UAE, contributing to efficiency, cost-effectiveness, and regulatory compliance. This section will explore these benefits in detail, highlighting why electric chain hoists are an excellent investment for various industries in the region.

Efficiency and Productivity

Speed and Reliability in Lifting Operations

- Electric chain hoists significantly enhance the speed and reliability of lifting operations, which is crucial for maintaining high productivity levels.

- Rapid Lifting: Electric chain hoists can lift heavy loads quickly and consistently, reducing the time required for each lifting cycle compared to manual or less advanced hoisting methods.

- Consistent Performance: These hoists provide reliable operation with precise control, ensuring that loads are lifted and positioned accurately every time. This consistency minimizes delays and errors, streamlining workflows.

Reduction in Manual Labor

- By automating lifting tasks, electric chain hoists reduce the need for manual labor, which offers several advantages:

- Labor Efficiency: Fewer workers are needed to perform lifting tasks, allowing labor resources to be allocated to other essential activities, improving overall operational efficiency.

- Reduced Physical Strain: Automating heavy lifting tasks decreases the physical strain on workers, reducing the risk of injuries and enhancing workplace safety. This leads to a healthier, more productive workforce.

Cost-Effectiveness

Long-term Savings on Maintenance and Repairs

- Electric chain hoists are designed for durability and require less maintenance compared to manual lifting equipment, leading to significant cost savings over time.

- Robust Design: High-quality materials and engineering reduce the frequency of breakdowns and the need for repairs, lowering maintenance costs.

- Predictable Maintenance: Regular, scheduled maintenance is easier to manage and less costly than emergency repairs, ensuring that the hoists remain operational with minimal downtime.

Increased Lifespan of Hoisting Equipment

- Investing in electric chain hoists can extend the lifespan of lifting equipment, providing better returns on investment.

- Durable Construction: Built to withstand heavy use in industrial environments, electric chain hoists have a longer operational life, reducing the need for frequent replacements.

- Efficient Use of Resources: By maintaining their performance over longer periods, these hoists ensure that businesses get maximum value from their investment, contributing to overall cost savings.

Compliance with Regional Standards

Meeting UAE Safety and Industrial Regulations

- Electric chain hoists are designed to comply with stringent safety and industrial regulations, ensuring safe and legal operation in the UAE.

- Regulatory Compliance: Using equipment that meets UAE standards helps businesses avoid legal issues and potential fines, ensuring smooth and uninterrupted operations.

- Safety Standards: Compliant hoists are equipped with necessary safety features, such as overload protection and emergency stop functions, which protect both operators and the equipment.

Certifications and Quality Assurance

- Certified electric chain hoists provide an additional layer of quality assurance, giving businesses confidence in their investment.

- Industry Certifications: Hoists that carry industry-standard certifications (e.g., ISO, CE) have been tested and verified to meet high standards of quality and safety.

- Quality Assurance Programs: Manufacturers often have rigorous quality assurance programs to ensure their products consistently meet or exceed regulatory and performance standards. This reliability is crucial for maintaining efficient and safe operations.

In conclusion, electric chain hoists offer numerous benefits for businesses in the UAE, enhancing efficiency, reducing costs, and ensuring compliance with regional standards. By improving the speed and reliability of lifting operations, reducing the need for manual labor, and providing long-term savings on maintenance and repairs, these hoists are a valuable addition to any industrial setup. Furthermore, their compliance with safety and industrial regulations ensures safe and legal operations, providing peace of mind for business owners and operators.

Market for 20 Ton Electric Hoists in the UAE

The market for 20-ton electric hoists in the UAE is robust, driven by the country's industrial growth and the demand for efficient lifting solutions. This section provides a detailed analysis of the demand, key suppliers, and customer considerations in this market.

Demand Analysis

Key Industries Utilizing Hoists

Several key industries in the UAE heavily rely on electric chain hoists for their operations:

- Construction: The booming construction industry in the UAE, characterized by numerous high-rise buildings and infrastructure projects, demands powerful hoists for lifting heavy materials and equipment.

- Oil and Gas: The oil and gas sector requires robust hoisting equipment to handle heavy machinery and materials used in extraction and processing.

- Manufacturing: Factories and production facilities use electric hoists for moving heavy components and finished products efficiently.

- Shipbuilding and Maritime: The shipbuilding industry needs high-capacity hoists for assembling large ship sections and handling heavy cargo.

- Mining: The mining sector uses hoists for transporting heavy minerals and mining equipment.

Growth Trends in Industrial Sectors

- The industrial sectors in the UAE are experiencing significant growth, which directly impacts the demand for heavy lifting equipment:

- Construction Boom: The UAE's continuous urban development and infrastructural expansion projects, such as the Expo 2020 site and various smart city initiatives, drive demand for construction-related lifting equipment.

- Energy Sector Expansion: Investments in oil and gas as well as renewable energy projects increase the need for reliable and efficient hoisting solutions.

- Manufacturing Growth: The government's focus on diversifying the economy away from oil has led to the growth of the manufacturing sector, further boosting the demand for industrial equipment, including hoists.

Key Suppliers and Manufacturers

Leading Brands and Their Offerings

- Several leading brands provide high-quality 20-ton electric chain hoists in the UAE market:

- Konecranes: Known for their durable and technologically advanced hoists, Konecranes offers models with enhanced safety features and remote control options.

- Demag: A prominent name in the hoisting industry, Demag provides robust hoists designed for various industrial applications, with a focus on precision and efficiency.

- Yale (Columbus McKinnon): Yale hoists are recognized for their reliability and versatility, offering a range of customization options to meet specific needs.

- Hitachi: Hitachi's hoists are known for their high performance and durability, making them suitable for heavy-duty industrial use.

Comparison of Product Features and Prices

When comparing hoists, it's important to consider key features and pricing:

- Performance: Factors like lifting speed, load capacity, and power efficiency.

- Safety Features: Overload protection, emergency stop functions, and advanced control systems.

- Durability: Construction materials, corrosion resistance, and maintenance requirements.

- Pricing: While premium brands may have higher upfront costs, their long-term reliability and lower maintenance needs can offer better value.

Customer Considerations

Factors Influencing Purchase Decisions

- Several factors influence the purchase decisions of businesses looking to invest in 20-ton electric hoists:

- Operational Needs: The specific requirements of the lifting tasks, such as load capacity, lift height, and speed.

- Quality and Reliability: The reputation of the manufacturer and the reliability of the hoist in demanding industrial environments.

- Safety Standards: Compliance with regional and international safety regulations.

- Cost: Initial investment versus long-term cost savings in maintenance and operational efficiency.

- Ease of Integration: Compatibility with existing systems and ease of installation.

Case Studies of Successful Implementations

Real-world examples of successful implementations can provide valuable insights:

- Construction Site in Dubai: A leading construction company in Dubai implemented Konecranes' 20-ton electric hoists for a high-rise project, significantly improving lifting efficiency and reducing project timelines.

- Oil Refinery in Abu Dhabi: An oil refinery utilized Demag hoists for handling heavy machinery parts, enhancing operational safety and efficiency.

- Manufacturing Plant in Sharjah: A manufacturing plant integrated Yale hoists into their assembly line, resulting in streamlined operations and reduced labor costs.

In conclusion, the market for 20-ton electric hoists in the UAE is thriving, driven by industrial growth and the need for efficient lifting solutions. Key suppliers offer a range of high-quality products that cater to various industries, and customer considerations such as operational needs, quality, and cost play a crucial role in purchase decisions. Successful implementations across different sectors highlight the value of investing in reliable and advanced hoisting equipment.

Conclusion

In wrapping up our comprehensive look at 20-ton electric chain hoists, we reflect on the critical aspects covered, the future outlook for hoist technology, and practical recommendations for businesses in the UAE.

Understanding the specifications of a 20-ton electric chain hoist is crucial for ensuring it meets the specific needs of different industries. Key specifications such as load capacity, lift height, and voltage requirements are fundamental to selecting the right hoist. Customization options allow businesses to tailor hoists to their operational requirements, enhancing performance and safety. The ability to customize aspects like lift speed, control systems, and chain length ensures that the hoist integrates seamlessly into existing workflows and meets specific operational demands.

Remote control functionality stands out as a significant advantage, improving safety and operational efficiency. By allowing operators to manage hoisting tasks from a safe distance, remote controls reduce the risk of accidents and enhance precision. Whether using wired or wireless options, remote controls facilitate fine-tuned movements and reduce operator fatigue, leading to more efficient and accurate lifting operations.

Final Recommendations

Choosing the Right Hoist for Specific Needs

Selecting the right 20-ton electric chain hoist involves careful consideration of operational requirements, industry standards, and specific project needs. Businesses should:

- Assess the load capacity and lift height needed for their operations.

- Consider the benefits of customization to meet unique operational demands.

- Evaluate the reliability and reputation of different manufacturers.

- Ensure compatibility with existing systems and ease of integration.

Ensuring Proper Maintenance and Safety Practices

Maintaining the longevity and safety of hoisting equipment is paramount. Businesses should:

- Implement regular maintenance schedules to keep hoists in optimal condition.

- Train operators thoroughly in the safe use and maintenance of hoisting equipment.

- Adhere to manufacturer guidelines for maintenance and operational practices.

- Invest in hoists that come with comprehensive safety features and certifications.

In conclusion, 20-ton electric chain hoists are indispensable tools for a variety of industries in the UAE. By understanding the importance of specifications, leveraging the benefits of remote control functionality, and staying abreast of technological advancements, businesses can make informed decisions that enhance productivity and safety. As the market continues to grow and evolve, choosing the right hoist and maintaining it properly will ensure long-term operational success and safety compliance.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch