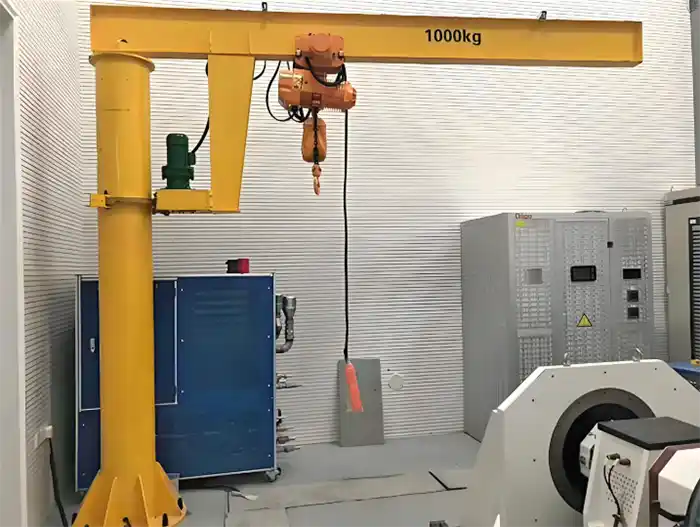

1000kg Jib Crane for Steel Plate Supply to CNC Laser Machines

1000 kg jib crane for sale to handle 1 ton steel plates for fiber laser cutting machines, offering precise material loading and unloading solutions.

Category: Featured

Your Trusted Electric Jib Crane Manufacturer & Supplier

1000kg Jib Crane for Steel Plate Loading Unloading to Fiber Laser Cutting Machines

1000 kg jib crane for sale to handle 1 ton steel plates for fiber laser cutting machines, offering precise material loading and unloading solutions.

Abstract:

This system is designed to efficiently handle 1 ton steel plates for fiber laser cutting machines. It provides precise loading and unloading of plates, improving workflow in CNC workshops. Key features include:

- Vacuum lifter for secure handling of smooth steel plates

- Motorized 360° rotation for accurate plate positioning

- Lifting height of at least 2 meters to fit laser machines

- Safety features to prevent plates from falling during power outages

This solution enhances operational efficiency, reduces manual labor, and ensures safe material handling, making it ideal for industries like metalworking and manufacturing.

Overview of Jib Cranes for CNC Workshops

What is a Jib Crane? A jib crane is a lifting device that uses a horizontal arm (the jib) mounted on a vertical column. The jib can rotate, allowing it to move materials within a designated range. This crane can either be manually operated or motorized for greater precision and efficiency. It is commonly used in industrial environments, particularly in CNC workshops, to lift and move heavy or bulky materials like steel plates, which are essential for machining and cutting processes.

Key Components:

- Horizontal arm (jib)

- Vertical column

- Base for stability

- Rotation mechanism (manual or motorized)

Importance of Jib Cranes for Handling Heavy and Large Materials

In CNC workshops, steel plates are often heavy and cumbersome, with sizes reaching up to 3 meters by 1.2 meters and weights up to 1 ton. Lifting and positioning these materials manually can lead to workplace injuries, inefficiencies, and errors. A jib crane provides a safer, more effective solution.

Benefits:

- Increased Safety: Reduces the risk of injuries from manual handling.

- Improved Efficiency: Speeds up material handling and allows for continuous operation of CNC machines.

- Space Efficiency: Moves materials into tight spaces within the workshop.

The crane's ability to lift heavy loads and move them accurately is critical in a busy CNC workshop, where precision and efficiency are paramount for maintaining high productivity levels.

Applications in CNC Workshops

In CNC workshops, jib cranes are used to move steel plates to various machines, including fiber laser cutting machines, plasma cutters, and milling machines. These machines require precise feeding of materials, which the jib crane facilitates.

Primary Uses:

- Feeding Steel Plates to Laser Cutting Machines: Jib cranes support continuous feeding of steel plates to CNC machines, helping streamline the cutting process.

- Handling Finished Cut Pieces: After laser cutting, jib cranes move the processed materials to assembly areas or conveyors.

- Storage and Organization: Jib cranes are ideal for moving plates into racks or storage spaces, saving valuable floor space.

This handling of steel plates ensures that CNC operations remain efficient, reducing downtime and increasing the overall throughput of the workshop.

Common Industries Using Jib Cranes for Steel Plate Supply

Several industries rely on jib cranes to move steel plates and other heavy materials. These industries include:

- Manufacturing: In sectors like automotive and structural steel fabrication, jib cranes move steel plates to CNC machines for cutting and shaping.

- Metalworking and Fabrication: CNC workshops that specialize in metalworking require jib cranes to handle large sheets of metal.

- Construction: Jib cranes are used on construction sites to move heavy steel components for structural work.

- Shipbuilding: In shipyards, jib cranes are used to handle large steel plates and hull sections.

- Aerospace: The aerospace industry uses jib cranes to move heavy parts during assembly and fabrication.

These industries benefit from jib cranes by enhancing material handling efficiency, reducing labor costs, and improving overall safety in heavy-duty tasks.

This section explains the essential role of jib cranes in CNC workshops, highlighting their ability to safely and efficiently handle large, heavy materials like steel plates. Jib cranes are crucial in improving workflow and productivity in various industries.

1000kg Jib Crane Projects: Customized Solutions from 1 to 16 Tons for Your CNC Workshop

Explore Typical Client Cases: Tailored Solutions for Steel Plate Handling

Discover how our 1000kg Jib Cranes have transformed CNC workshops by providing customized, efficient material handling solutions. Below are real-world examples of how businesses like yours have successfully integrated jib cranes into their operations. These cases highlight the key benefits and applications, ensuring you make the right choice for your workshop's needs.

Key Specifications and Features of the 1000kg Jib CraneProjecs for Client for Your Reference

Crane Capacity

- Maximum Lifting Capacity: The 1000kg jib crane is designed to lift materials with a maximum weight of 1 ton (1000kg). This capacity is ideal for lifting steel plates commonly used in CNC workshops for laser cutting and other machining processes.

- Ideal for Steel Plates: This crane is perfectly suited to handle heavy and large materials like steel plates, which are often used in laser cutting and metal fabrication. With the ability to lift 1 ton plates, the crane ensures that even the heaviest materials can be moved safely and efficiently.

Load Type

Steel Plates as Primary Load: The crane is specifically designed to handle steel plates as its primary load. Steel plates used in CNC workshops for laser cutting typically measure 3m x 1.2m, with thicknesses ranging from 12mm to 30mm.

Smooth Surface Requirement: For compatibility with a vacuum lifter, which is often used for precise lifting, the crane is optimized to handle smooth surface steel plates. A smooth surface ensures a secure grip by the vacuum lifter, preventing any slippage during lifting operations.

Key Load Specifications:

- Plate Size: 3m x 1.2m

- Thickness Range: 12mm to 30mm

- Surface Type: Smooth (for vacuum lifter functionality)

Lifting Height

Minimum Lifting Height: The crane has a minimum lifting height of 2 meters, making it suitable for lifting steel plates from storage areas or moving them to CNC machines such as laser cutters, which may be positioned at a similar height.

Important Consideration:The lifting height is ideal for CNC workshops, where precise control over the material's position is critical during the feeding process to laser cutting machines.

Lifting Height:Minimum: 2 meters

Jib Arm Design

Arm Length: The crane's jib arm is 4 meters long, providing a sufficient reach to handle large steel plates, which may need to be positioned at different angles or moved across longer distances within the workshop.

Slewing Angle: The crane is equipped with 360° motorized rotation, allowing for efficient maneuverability in tight spaces. This feature is particularly beneficial in CNC workshops, where the crane needs to rotate fully to move materials to and from machines, storage areas, and conveyors with precision.

Key Features of the Jib Arm:

- Arm Length: 4 meters

- Slewing Angle: 360° motorized rotation for maximum flexibility

Power and Safety Features

Motorized Rotation: The crane is equipped with motorized rotation to ensure precise positioning of steel plates. This feature allows operators to control the rotation of the jib arm with high accuracy, enabling efficient material handling and reducing the risk of errors.

Vacuum Lifter Safety: One of the key safety features of this crane is the pressure-maintaining function of the vacuum lifter. In the event of a power failure, the lifter will maintain its grip on the steel plate, preventing it from falling. This safety mechanism ensures that materials are not dropped, protecting both the equipment and the operator.

Safety Features:

- Motorized Rotation: For accurate plate positioning

- Pressure-Maintaining Function: Prevents steel plate drops during power outages

This combination of lifting capacity, design, and safety features makes the 1000kg jib crane an excellent choice for CNC workshops, particularly for the handling of steel plates used in laser cutting and other precise machining operations.

Material Handling Considerations for Your CNC Workshop

Types of Materials Handled

- Steel Plates with Varying Thicknesses: The primary material handled by the 1000kg jib crane in CNC workshops is steel plates. These plates typically range from 12mm to 30mm in thickness. This range is common in applications involving laser cutting, bending, and welding, where precise handling is crucial for ensuring accuracy and preventing damage to the material.

- Focus on Smooth Steel Sheets: For optimal operation with the vacuum lifter, the steel plates must have a smooth surface. Smoothness is essential because the vacuum lifter relies on creating a secure grip on the steel sheet to lift and place it without slipping. Any rough or uneven surfaces can compromise the lifting process and safety, making smooth steel sheets the ideal material for use with the crane system.

Key Material Specifications:

- Plate Size: 3m x 1.2m

- Plate Thickness: 12mm to 30mm

- Surface: Smooth (critical for vacuum lifter functionality)

Vacuum Lifter Compatibility

Essential for Handling Smooth-Surfaced Steel Plates: One of the key components in the material handling system is the vacuum lifter. This device uses suction to securely pick up and place smooth-surfaced steel plates without the need for manual handling. The vacuum lifter eliminates the risk of damage to the material during lifting and ensures precision placement, especially when feeding plates into a laser cutting machine.

Need for a Vacuum Lifter: Vacuum lifters are designed to handle smooth materials, like steel plates, by creating a seal that ensures a firm grip. For CNC workshops, where precision is critical, using a vacuum lifter allows for fast and accurate material handling, enhancing overall workflow and reducing downtime.

Key Considerations for Vacuum Lifter Compatibility:

- Plate Surface: Steel plates must have a smooth finish to ensure proper suction by the vacuum lifter.

- Vacuum Lifter Specifications: The vacuum lifter must be matched to the specific thickness of the steel plates, with particular attention to the thinnest plate thickness (e.g., 12.7mm).

- For example, with a typical 12.7mm plate, the vacuum lifter must have the correct suction power to lift securely without causing slippage or damage to the plate's surface.

Machine Feeding and Handling

Understanding the Workflow: In a CNC workshop, steel plates are typically fed into fiber laser cutting machines for precision cutting. This process requires efficient material handling to ensure that the plates are moved from storage areas to the cutting machines seamlessly. The plates must be accurately positioned to align with the machine's cutting area to ensure high-quality cuts and avoid errors.

How the Jib Crane Supports Seamless Steel Plate Feeding: The 1000kg jib crane plays a crucial role in streamlining the material handling process by lifting and positioning steel plates with precision. The crane's motorized rotation and 4-meter arm length provide maximum flexibility in tight spaces, allowing for easy movement and precise placement of steel plates. Once a plate is picked up by the vacuum lifter, the jib crane rotates and positions it accurately above the cutting machine, ensuring a smooth feed into the machine's work area.

Benefits of Jib Crane for Machine Feeding:

- Efficient Material Flow: The crane ensures that plates are fed into the CNC machine without delays, maintaining the efficiency of the entire cutting process.

- Precision Placement: The ability to rotate the crane arm 360° ensures precise positioning of the steel plates for accurate cutting.

- Minimized Human Handling: With the combination of the jib crane and vacuum lifter, the need for manual lifting and placing is reduced, improving both safety and speed.

By considering the material specifications, vacuum lifter compatibility, and machine feeding requirements, your CNC workshop can achieve greater efficiency, accuracy, and safety in material handling. The 1000kg jib crane is designed to meet these needs, ensuring smooth and reliable operation in demanding environments.

Space and Installation Requirements

Indoor Installation and Space Requirements

- Ideal for Industrial Warehouses: The 1000kg jib crane is designed for indoor installation in CNC workshops, metalworking facilities, and industrial warehouses where materials such as steel plates need to be moved efficiently. It's best suited for environments with sufficient ceiling height and workspace to allow for free movement of the crane arm and smooth handling of materials.

- Sufficient Ceiling Height: Before installation, it's crucial to ensure that your workshop or facility has the necessary ceiling height to accommodate the crane. Adequate height is required not only for lifting but also for crane arm rotation and efficient material handling.

Height Considerations

Confirming Ceiling Height Limitations: A key consideration when installing a 1000kg jib crane is the ceiling height. To ensure safe and efficient operation, it's important to confirm that the minimum height from the ceiling to the ground is sufficient to accommodate the minimum 2-meter lifting height.

- Lifting Height: The crane must be able to raise the steel plates to at least 2 meters, and the ceiling height should provide enough space for this lift, plus some clearance for the crane arm's full range of motion.

Ensuring Proper Clearance: The crane's lifting height (minimum 2 meters) must be taken into account when confirming the available headroom. Additionally, you must account for the space required to lift and rotate steel plates safely without obstruction from overhead structures, such as beams or equipment.

Recommended Ceiling Height:

- Minimum 3m Ceiling Height: To comfortably accommodate the 2-meter lifting height of the crane and allow for free rotation and operation.

- Additional Clearance: It's advisable to add extra clearance above the lifting height for crane operation and to account for future adjustments in material handling.

Layout and Configuration

- Efficient Positioning Within the CNC Workshop: The layout of the CNC workshop or industrial space plays a significant role in optimizing crane performance. The 1000kg jib crane should be positioned strategically to allow for efficient material handling between the steel plate storage area and the laser cutting machine.

- Easy Access and Maneuverability: The crane arm's 4-meter length and 360° motorized rotation provide flexibility in positioning steel plates. However, to maximize the crane's effectiveness:The crane should be placed near the laser cutting machine to minimize material handling time.Ensure enough clearance around the crane to allow for easy movement of the plates into the machine's cutting area.

Space Considerations for Layout:Sufficient Floor Space: Ensure enough floor space around the crane's base for safe operation and to avoid congestion in the workspace.Clear Pathways: Create clear paths for the crane arm to travel, with no obstructions blocking its rotation or reach.

By carefully considering space and installation requirements, you can ensure the 1000kg jib crane will operate efficiently in your CNC workshop, enhancing productivity and safety while minimizing downtime and potential operational issues.

Power Outage and Safety Measures

Handling Power Failures

- Ensuring Plate Safety During Power Outages: In the event of a power failure, one of the main concerns for any crane system is ensuring that the steel plates being lifted do not fall or become dislodged. The 1000kg jib crane is equipped with a vacuum lifter that features a pressure-maintaining function. This function ensures that the vacuum lifter retains its suction even if power is lost. As a result, the steel plate will remain securely held in place, preventing any accidental drops or damage.

- Manual Plate Release Procedure: While the vacuum lifter's pressure-maintaining function keeps the plate secure during power loss, the crane and lifter system will be immobilized. Once power is restored, the system can resume operation. However, in the event of a prolonged power outage, operators will need to manually release the plate from the vacuum lifter, ensuring the plate is placed safely before proceeding with any other tasks. This manual release procedure is an important safety step that prevents the plate from falling when the power is off.

Key Power Outage Safety Features:

- Pressure-maintaining vacuum lifter to secure the steel plate during power failure.

- Manual release process for safe detachment of the plate after power loss.

- Immobilization of the crane during power outages to prevent unintended movements.

Safety and Load Security

Built-in Safety Features: The 1000kg jib crane is designed with multiple safety mechanisms to prevent accidents and ensure safe operation. Some of these include:

- Overload protection: The crane system is equipped with sensors that prevent overloading, which could lead to system failure or damage to the crane, vacuum lifter, or steel plates.

- Emergency stop controls: These can be easily accessed during operation in case of any emergency, allowing the crane to halt instantly.

- Pressure-maintaining vacuum lifter: As previously mentioned, this safety feature is especially important in preventing accidents caused by accidental plate drops due to power failure or system malfunction.

Regular Safety Checks and Maintenance: To ensure continuous safe operation, it's crucial to perform regular safety checks and maintenance on the jib crane system. This includes:

- Inspecting the vacuum lifter to confirm that it is functioning correctly and has a firm grip on the steel plates.

- Checking the motorized rotation system to ensure smooth, safe movement.

- Verifying that lifting mechanisms are free from wear or damage and are capable of handling the specified load.

- Ensuring all safety features, including emergency stops and overload protection, are in working order.

Safety and Maintenance Best Practices:

- Daily Inspections: Check the crane and vacuum lifter for any signs of wear or damage.

- Annual Maintenance: Schedule a professional service to assess the crane's lifting capacity, motor functionality, and safety features.

- Training: Ensure all operators are trained in safe operating procedures and emergency protocols, particularly regarding the manual plate release during a power failure.

By implementing these safety measures and understanding the system's response during power outages, your CNC workshop can ensure a safe, secure, and reliable working environment. Regular maintenance and safety checks will further reduce the risk of accidents and maintain the crane's optimal performance.

Summary on the 1000 ton jib crane for Supply Material to the Cutting Table

| Key Factor | What to Consider | Why It Matters |

|---|---|---|

| Lifting Capacity | Crane should lift steel plates up to 1000kg | To safely handle the weight of the plates |

| Plate Size | Plates are usually 3m x 1.2m | Crane must fit the size of the plates |

| Plate Thickness | Plates range from 12mm to 30mm (most common 12.7mm) | Ensure crane can handle different thicknesses |

| Vacuum Lifter | Must be compatible with smooth plates | To safely lift and move plates without damage |

| Lifting Height | Crane should lift at least 2 meters | Ensure enough height to feed plates into the laser machine |

| Crane Arm Length | Typically around 4 meters | To reach all areas of the workshop and laser machine |

| Rotation | 360° motorized rotation | For precise plate positioning and easy maneuverability |

| Ceiling Height | Ensure enough clearance above for crane movement | Prevent any obstructions and allow smooth operation |

| Safety Features | Includes vacuum lifter's pressure-holding function during power cuts | To prevent plates from falling if power goes out |

| Space and Layout | Ensure the crane fits well in your workshop layout | Helps improve workflow and avoid space issues |

Key Questions to Ask When Purchasing a Jib Crane for Material Loading and Unloading for Fiber Laser Cutting Machines

What is the maximum weight of the materials you need to lift?

Consider the weight of your typical materials, such as steel plates, and choose a crane with an appropriate lifting capacity. For example, a 1000kg (1 ton) capacity crane might be sufficient for most fiber laser cutting machine applications.

What are the dimensions of the materials you are handling?

Ensure the crane can accommodate the dimensions of your materials, such as 3m x 1.2m steel plates, or any other size you frequently use.

What is the typical thickness of the materials?

Understanding the thickness range of the materials (e.g., 12mm to 30mm) is crucial for determining compatibility with lifting accessories like vacuum lifters.

Do you need a vacuum lifter to handle smooth-surfaced materials?

If you're handling smooth surface steel plates, a vacuum lifter may be required. It's important to clarify the need for a vacuum lifter and its specifications to ensure secure handling.

What is the minimum lifting height required for your operation?

Ensure that the crane can provide the minimum lifting height necessary to move materials efficiently into the fiber laser cutting machine, typically around 2 meters or more, depending on your machine's requirements.

What is the required rotation or maneuverability for the jib crane?

Do you need manual or motorized rotation? If you're operating in a tight space, consider a crane with motorized rotation and 360° slewing capability for optimal maneuverability.

What is the available ceiling height in your workshop?

Determine the ceiling height of your CNC workshop to ensure the crane can operate without obstruction. Be sure that there's enough clearance for both lifting height and crane operation.

What is the intended environment for crane installation?

Will the crane be installed in an indoor environment? If so, check that it is designed for the specific conditions of your workshop, such as dust, humidity, or temperature fluctuations.

Is power failure protection necessary for your application?

Does your crane need a pressure-maintaining function in the vacuum lifter to prevent the material from falling during a power outage? Clarify the safety features for uninterrupted lifting operations.

What are the specific safety features you require?

Look for safety features such as overload protection, anti-fall devices, and pressure-maintaining functions in the vacuum lifter to ensure safe operation, especially when handling heavy or large materials.

What is the frequency of use?

Will the crane be in use frequently, or only during certain times of the day? This will help determine the durability and the need for more frequent maintenance.

Are there any space constraints or layout requirements?

Ensure the crane's arm length and rotation range fit within your workshop's layout. Consider whether there are any space limitations or specific workflow configurations that need to be accommodated.

Do you need any special customization for your operation?

Do you have any specific requirements for your crane, such as a custom jib arm length, specialized lifting accessories, or special coatings for handling materials in certain conditions (e.g., corrosion resistance)?

What is the budget for the crane and related equipment?

Consider the total cost, including installation, vacuum lifter, and maintenance. Ensure the crane solution fits within your budget while still meeting your material handling needs.

What is the expected maintenance schedule?

Discuss the maintenance requirements, such as lubrication, inspections, and servicing, to ensure your crane operates at peak efficiency over time.

By asking these questions, you can ensure that the jib crane you select will meet your material handling needs for fiber laser cutting machines and optimize the performance of your CNC workshop.

Quick Guide: Key Factors to Consider When Choosing a Jib Crane for Material Handling

Selecting the right jib crane for your workshop or facility involves considering various factors to ensure optimal performance, safety, and efficiency. Whether you're handling steel plates, heavy machinery, or other materials, the crane must meet your specific operational requirements. The following quick guide outlines the key factors you need to consider when choosing a jib crane, from lifting capacity and safety features to installation space and environmental conditions. With these insights, you can make an informed choice that enhances your material handling process and overall productivity.

| Key Factor | What to Consider | Why It Matters |

|---|---|---|

| Lifting Capacity | Crane should match the weight of the materials to be lifted (e.g., up to 1000kg or more) | Ensures safe lifting and handling of various materials |

| Material Type | Determine the materials you'll handle (steel, wood, plastic, etc.) | Crane must be suitable for different material types and weights |

| Lift Height | Consider the required lifting height based on your workflow | Ensures enough clearance for lifting materials to desired height |

| Arm Length | Crane arm length should cover the workspace efficiently | Ensures the crane can reach all areas without obstruction |

| Rotation Range | Choose between manual or motorized rotation, typically up to 360° | For easier maneuverability and precise material positioning |

| Installation Space | Check available space in your workshop, including ceiling height | Ensures the crane fits and operates without interference |

| Power Source | Decide on electric or manual operation depending on workshop needs | Choose based on available power supply and ease of operation |

| Safety Features | Look for overload protection, emergency stop, and fail-safes | Ensures safe operation and reduces risk of accidents |

| Durability | Consider the materials and build quality (e.g., corrosion-resistant) | Ensures long-lasting performance, especially in harsh environments |

| Maintenance Needs | Check for ease of maintenance, availability of spare parts | Simplifies upkeep and extends crane life |

| Environmental Conditions | Consider temperature, humidity, and space conditions | Ensures crane is suitable for operating in your specific environment |

| Load Type Flexibility | Will the crane handle different loads (e.g., bulk, precise loads)? | Choose a crane that adapts to different material shapes and sizes |

This table covers a broader range of factors that influence crane selection for general material handling, ensuring that the crane suits your specific operational needs.

Conclusion: Tailoring Your Jib Crane Solution

When selecting a jib crane for your CNC workshop, it's crucial to base your decision on the specific material handling needs of your operation. Key factors to consider include:

- Lifting Capacity: Ensure the crane can handle the weight of the materials you lift, such as 1 ton steel plates.

- Material Dimensions and Thickness: Choose a crane that can accommodate the dimensions of your plates (e.g., 3m x 1.2m) and the thickness range (from 12mm to 30mm).

- Vacuum Lifter Compatibility: If you are handling smooth-surfaced steel plates, a vacuum lifter will be essential for efficient and safe lifting.

- Workshop Layout: Ensure the crane fits into the space available in your workshop, considering ceiling height, the range of rotation, and the positioning for optimal functionality.

The right crane, tailored to your needs, will improve your workshop's efficiency and reduce downtime, ensuring smooth operations when feeding material into your fiber laser cutting machine.

To ensure the longevity and reliability of your jib crane and vacuum lifter, regular maintenance and attention to safety are critical. Here are some maintenance tips and safety recommendations:

- Regular Inspections: Check the vacuum lifter, crane motor, and other components for wear and tear.

- Lubrication: Keep the crane's moving parts properly lubricated to prevent friction and ensure smooth operation.

- Safety Checks: Test safety features such as overload protection and the pressure-maintaining function of the vacuum lifter.

- Cleanliness: Keep the vacuum lifter pads clean to maintain strong suction, and clear any debris or obstructions that may interfere with crane movement.

- Training: Ensure that all personnel are properly trained on crane operation and safety procedures to minimize risk.

By following these guidelines, your swing jib crane system will remain in top condition, providing consistent performance, improving safety, and extending the lifespan of your equipment. Tailoring your jib crane capacity to your material handling needs and maintaining it well will lead to a more efficient, productive, and safe CNC workshop. Contact us to check what we can do to improve your workflow in CNC workshop.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch