Overhead Birdge Crane ,Overhead Gantry Cranes, jib Crane ISO

ISO certified crane for sale. Custom overhead bridge crane, overhead gantry crane, overhead jib crane, and overhead hoists with iso certifications for sale.

Category: Featured

Your Trusted ESO Overhead Crane Manufacturer & Supplier

ISO Certifications for Overhead Crane

The International Organization for Standardization (ISO) is a globally recognized body that develops and publishes international standards to ensure the quality, safety, and efficiency of products and services across various industries. ISO standards provide a framework for organizations to establish and maintain robust management systems, fostering excellence and continuous improvement.

In the overhead crane industry, where precision, safety, and reliability are paramount, adherence to ISO certifications is crucial. ISO certifications set the benchmark for quality management, environmental responsibility, occupational health and safety, and other key aspects of manufacturing and supply chain processes. For overhead crane manufacturers and suppliers, obtaining and maintaining these certifications not only enhances their credibility but also demonstrates a commitment to delivering high-quality, safe, and environmentally responsible products and services.

Requirements for Different Types of Overhead Cranes:

Design Considerations

Bridge cranes, also known as overhead traveling cranes, are characterized by their ability to move horizontally along a runway. Specific requirements for bridge cranes include:

- Structural Integrity: Certification processes must evaluate the structural integrity of the bridge, ensuring it can withstand the loads and forces associated with lifting and moving heavy loads.

- End Carriage Design: Attention to the design of end carriages, which support the bridge and house the trolley mechanism, is crucial. Certification ensures that these components meet safety and performance standards.

Safety Features

- Emergency Stop Systems: Bridge cranes must be equipped with reliable emergency stop systems to promptly halt operations in case of emergencies, contributing to overall workplace safety.

- Overload Protection: Certifying bodies assess the incorporation of overload protection mechanisms to prevent the crane from lifting loads beyond its capacity.

Track and Structure

Gantry cranes differ from bridge cranes in that they are supported by legs on either side of the span. Certification requirements for gantry cranes include:

- Track Stability: Certifying bodies evaluate the stability of the track or rail system on which the gantry crane moves, ensuring it can support the crane and its intended loads.

- Leg Design: The design and construction of supporting legs are examined to ensure they provide sufficient stability and durability.

Lifting Mechanism

- Hoisting Systems: Certification processes scrutinize the hoisting systems, including winches and hooks, to guarantee safe and efficient lifting operations.

- Load Distribution: Certifying bodies assess load distribution mechanisms to prevent uneven loading and potential hazards during lifting and movement.

Rotation Mechanism

Jib cranes are characterized by a horizontal jib or boom that supports a moveable hoist. Certification requirements for jib cranes include:

- Rotation Mechanism: Certifying bodies evaluate the rotation mechanism to ensure smooth and controlled movement of the jib, preventing sudden or unexpected rotations.

- Boom Design: The design and construction of the jib or boom are closely examined to ensure stability and resistance to loads.

Operational Safety

- Slew Limiters: Certifying bodies assess the inclusion of slew limiters to prevent excessive rotation of the jib crane, enhancing operational safety.

- Emergency Procedures: Manufacturers must provide clear and comprehensive emergency procedures in the user manual, detailing steps to be taken in case of malfunctions or emergencies.

Manufacturers must tailor their certification processes to address the unique features and functions of each overhead crane type. Whether it's the horizontal movement of bridge cranes, the support structure of gantry cranes, or the rotational aspect of jib cranes, adherence to specific requirements ensures a comprehensive and effective CE certification.

Intelligent Crane with Advanced Crane Design with Smart Features

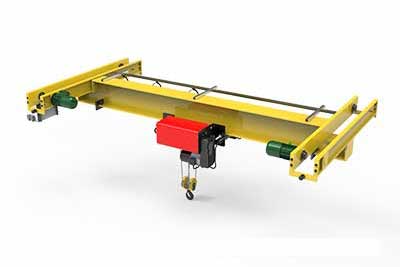

Double girder overhead crane with rotary trolley for sale

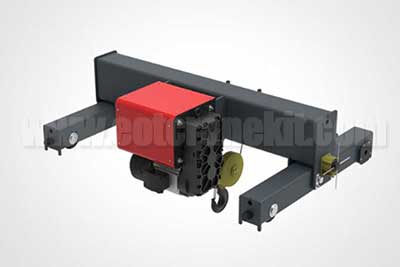

Double girder gantry cranes with intelligent hoists including main hoist and auxialiry

Intelligent Crane and Smart Hoist Parts and Components

NR mode standard headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

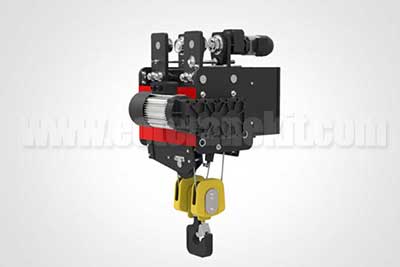

NR mode low headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

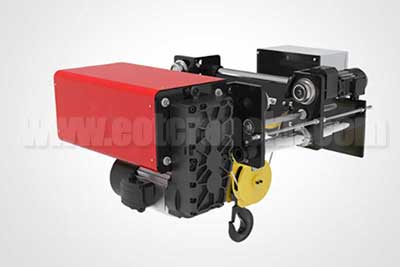

NRT crab electric hoist

Lifting capacity: 3t~80t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Explosion Proof Electric Wire Rope Hoists

BNR explosion-proof electric hoist for LNG

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNR low headroom explosion-proof electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNRT crab model explosion-proof electric hoist

Lifting capacity: 3t~30t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

ISO Certifications for Overhead Crane Manufacturers

ISO 9001: Quality Management System (QMS)

ISO 9001 is a globally recognized standard for Quality Management Systems (QMS). It provides a systematic approach to managing processes, ensuring consistency, efficiency, and continuous improvement. The standard sets out the criteria for a quality management system that can be applied to various industries, including overhead crane manufacturing.

Application in Overhead Crane Manufacturing

In the context of overhead crane manufacturing, ISO 9001 plays a pivotal role in establishing a framework for quality control and assurance. Manufacturers adopting ISO 9001 implement documented processes and procedures to monitor and enhance the quality of their products. This includes criteria for design, production, testing, and customer satisfaction.

Benefits for Manufacturers

- Enhanced Product Quality - ISO 9001 helps manufacturers define and implement stringent quality control measures, leading to the production of high-quality overhead cranes. Consistency in processes ensures that each crane meets or exceeds specified standards.

- Improved Efficiency - The standard encourages the optimization of manufacturing processes. By identifying and eliminating inefficiencies, manufacturers can enhance overall operational efficiency, reduce waste, and improve resource utilization.

- Increased Customer Satisfaction - ISO 9001 emphasizes customer focus. By consistently delivering quality products, manufacturers can boost customer satisfaction and loyalty. Clear communication, accurate documentation, and timely delivery contribute to positive customer experiences.

- Competitive Advantage - Having ISO 9001 certification sets manufacturers apart in the competitive landscape. It serves as a testament to their commitment to quality, instilling confidence in customers, partners, and stakeholders.

- Regulatory Compliance - ISO 9001 compliance often aligns with regulatory requirements in the manufacturing sector. Manufacturers can navigate regulatory frameworks more effectively and ensure adherence to industry standards.

In conclusion, ISO 9001 certification is foundational for overhead crane manufacturers, providing a structured approach to quality management that positively impacts product quality, efficiency, customer satisfaction, and overall competitiveness.

Next, we will explore ISO 14001, focusing on environmental management within the context of overhead crane manufacturing. Stay tuned for insights into how manufacturers can achieve environmental sustainability while producing cutting-edge crane systems.

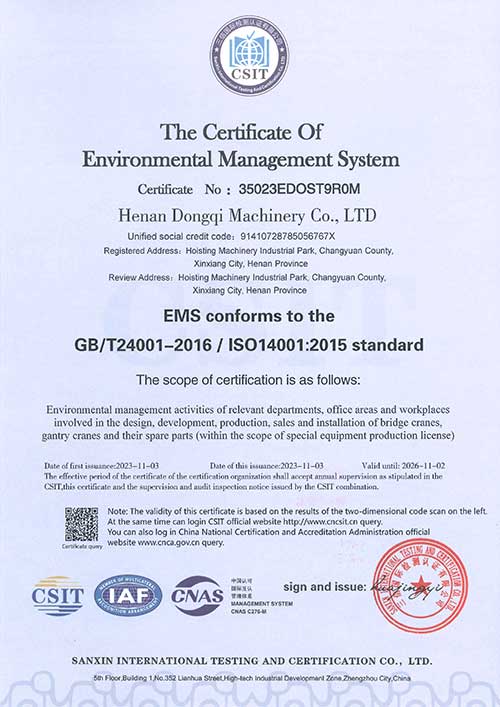

ISO 14001: Environmental Management System (EMS)

ISO 14001 is an international standard that outlines the requirements for an Environmental Management System (EMS). It provides a framework for organizations to identify, monitor, and manage their environmental impact. ISO 14001 is designed to help businesses integrate environmental considerations into their operations and decision-making processes.

Environmental Considerations in Crane Manufacturing

In the realm of overhead crane manufacturing, environmental considerations are paramount. The production processes involved in crafting these heavy-duty machines can have a significant impact on the environment. ISO 14001 encourages manufacturers to assess and mitigate the environmental effects of their activities, products, and services.

Sustainability Practices

- Materials Selection - ISO 14001 prompts manufacturers to evaluate the environmental impact of materials used in crane manufacturing. Opting for sustainable and recyclable materials can reduce the overall ecological footprint of the production process.

- Energy Efficiency - Manufacturers can implement energy-efficient practices, such as optimizing machinery and adopting renewable energy sources. ISO 14001 encourages the reduction of energy consumption, contributing to both environmental sustainability and cost savings.

- Waste Management - Proper waste management is a key aspect of ISO 14001. Manufacturers are encouraged to minimize waste generation, recycle materials, and responsibly dispose of any by-products. This not only benefits the environment but also aligns with global efforts toward circular economies.

- Emissions Reduction - ISO 14001 emphasizes the control and reduction of harmful emissions. In overhead crane manufacturing, this includes addressing emissions from various processes, such as welding and painting. Implementing technologies and practices to minimize emissions is essential.

- Compliance with Environmental Regulations - Adherence to ISO 14001 ensures that manufacturers stay in compliance with environmental regulations. This is critical in the overhead crane industry, where environmental standards are increasingly stringent.

ISO 14001 certification for overhead crane manufacturers demonstrates a commitment to environmental stewardship. It goes beyond legal compliance, fostering a proactive approach to sustainability. Manufacturers who embrace ISO 14001 not only contribute to a healthier planet but also enhance their reputation as socially responsible entities.

Next in our guide, we will explore ISO 45001, focusing on occupational health and safety management in the context of overhead crane manufacturing. Stay tuned for insights into ensuring the well-being of workers involved in the production processes.

ISO 45001: Occupational Health and Safety Management System (OHSMS)

ISO 45001 is an international standard that outlines the requirements for an Occupational Health and Safety Management System (OHSMS). It provides a framework for organizations to proactively manage the health and safety of workers in the workplace. ISO 45001 focuses on identifying and controlling health and safety risks, promoting a safer working environment.

Importance in Crane Manufacturing

The manufacturing of overhead cranes involves intricate processes and heavy machinery, posing inherent risks to workers. ISO 45001 is particularly crucial in this industry to ensure that occupational health and safety are prioritized throughout the manufacturing lifecycle. The standard provides a systematic approach for identifying potential hazards, assessing risks, and implementing measures to protect the well-being of workers.

Ensuring Worker Safety

- Hazard Identification and Risk Assessment - ISO 45001 requires manufacturers to systematically identify workplace hazards and assess associated risks. In the context of overhead crane manufacturing, this involves analyzing potential dangers related to machinery operation, lifting processes, and materials handling.

- Implementation of Controls and Safety Measures - Manufacturers are mandated to implement controls and safety measures to mitigate identified risks. This includes providing adequate training to workers, ensuring the use of personal protective equipment (PPE), and implementing engineering controls to enhance overall safety.

- Emergency Preparedness and Response - ISO 45001 emphasizes the importance of being prepared for emergencies. Manufacturers in the overhead crane industry need to have robust emergency response plans in place, including evacuation procedures, first aid measures, and communication protocols.

- Worker Involvement and Consultation - The standard promotes a culture of worker involvement and consultation. Manufacturers should actively engage workers in health and safety matters, encouraging them to report concerns and providing avenues for their input in decision-making processes.

- Continuous Improvement - ISO 45001 encourages a cycle of continuous improvement in occupational health and safety. Manufacturers are expected to regularly review and enhance their safety management systems, learning from incidents, and implementing corrective actions.

ISO 45001 certification not only safeguards the health and safety of workers but also enhances the overall efficiency and reputation of overhead crane manufacturers. It reflects a commitment to creating a workplace where employees can perform their duties without undue risk.

ISO 3834: Quality Requirements for Fusion Welding of Metallic Materials

ISO 3834 is a standard that outlines comprehensive quality requirements for the fusion welding of metallic materials. In the context of overhead crane manufacturing, where welding is a critical component of construction, ISO 3834 plays a crucial role in ensuring the integrity and quality of welded components.

Welding is a fundamental process in the fabrication of overhead cranes, as it involves joining various metallic materials to create the structural elements of the crane. ISO 3834 provides a framework for manufacturers to establish and maintain a quality management system specific to welding processes.

Quality Assurance in Welding Processes

- Welding Procedure Qualification - ISO 3834 requires manufacturers to qualify welding procedures, ensuring that they are capable of producing welds meeting specified requirements. This involves defining welding parameters, conducting tests, and validating procedures to achieve consistent and reliable results.

- Welder Qualification and Certification - The standard emphasizes the importance of qualifying and certifying welders. Manufacturers must ensure that welders possess the necessary skills and expertise to perform welding tasks to the required standards. This includes training, testing, and documentation of welder qualifications.

- Material Traceability and Control - ISO 3834 mandates material traceability throughout the welding process. Manufacturers must establish procedures to identify and trace materials used in welding, ensuring that only approved materials are utilized. This contributes to the overall quality and reliability of welded components.

- Inspection and Testing - Quality assurance involves rigorous inspection and testing of welded components. ISO 3834 outlines criteria for visual inspection, non-destructive testing (NDT), and destructive testing to verify the integrity of welds and detect any defects.

Welded Components in Overhead Cranes

- Structural Elements - Welded components form the structural backbone of overhead cranes, including beams, columns, and joints. ISO 3834 compliance ensures the structural integrity of these components, preventing failures and ensuring the safety of the crane.

- Load-Bearing Components - Critical load-bearing elements, such as lifting mechanisms and support structures, often involve welding. ISO 3834 ensures that these components are manufactured to the highest welding quality standards, minimizing the risk of structural failure.

- Longevity and Durability - Well-executed welding processes, in line with ISO 3834, contribute to the longevity and durability of overhead cranes. Welded joints that meet quality requirements are less prone to corrosion, fatigue, and other factors that could compromise the crane's performance.

ISO 3834 certification for overhead crane manufacturers is essential for guaranteeing the quality and reliability of welded components. It not only enhances safety but also ensures that overhead cranes meet or exceed industry standards for performance and longevity.

In the upcoming section, we will explore ISO 10218, focusing on safety requirements for industrial robots used in the context of overhead cranes. Stay tuned for insights into ensuring the safe integration of robotic components in crane systems.

E. ISO 10218: Robots and Robotic Devices - Safety Requirements for Industrial Robots

The integration of robotic components in overhead cranes represents a technological advancement that enhances automation, precision, and efficiency. Robots play a crucial role in tasks such as material handling, assembly, and inspection within the crane manufacturing process. ISO 10218 sets safety requirements for industrial robots, ensuring their safe integration and operation.

Ensuring Robotic Safety with ISO 10218

- Risk Assessment and Design Considerations - ISO 10218 mandates a thorough risk assessment before integrating robotic components into overhead cranes. Manufacturers must identify potential hazards, assess risks, and implement design considerations to minimize the likelihood of accidents or injuries.

- Protective Measures and Safeguards - The standard outlines specific requirements for protective measures and safeguards to be implemented in and around robotic workspaces. This includes physical barriers, emergency stop systems, and other safety features to prevent collisions and protect workers.

- Operator Training and Competence - ISO 10218 emphasizes the importance of adequately training operators and ensuring their competence in handling robotic systems. This includes understanding emergency procedures, operating controls, and recognizing potential hazards associated with robotic components.

- Collaborative Robots (Cobots) - In scenarios where robots collaborate with human workers, ISO 10218 provides guidelines for ensuring the safe interaction between robots and humans. This includes defining safe distances, limiting force and speed, and implementing technologies that facilitate safe collaboration.

- Documentation and Compliance - Manufacturers integrating robotic components must maintain comprehensive documentation outlining compliance with ISO 10218 requirements. This documentation serves as evidence of adherence to safety standards and can be crucial for regulatory compliance.

ISO 10218 certification for the integration of robotic components ensures not only the efficiency and precision of overhead cranes but also the safety of workers involved in manufacturing processes. By adhering to these safety standards, manufacturers can confidently embrace the benefits of robotic automation while mitigating potential risks.

In the subsequent section, we will explore ISO certifications for overhead crane suppliers, starting with ISO 9001. Stay tuned for insights into how suppliers can ensure the quality of products and services throughout the supply chain.

ISO 9001: Quality Management System (QMS)

Adapting ISO 9001 for Suppliers

ISO 9001, renowned for its emphasis on Quality Management Systems (QMS), is equally vital for overhead crane suppliers as it is for manufacturers. Suppliers play a pivotal role in the supply chain, ensuring that products and services meet specified quality standards. Adapting ISO 9001 involves tailoring the standard to address the unique challenges and requirements of suppliers.

- Documentation and Record Keeping - Suppliers must establish robust documentation processes to record and track the quality of overhead cranes throughout the supply chain. This includes comprehensive records of procurement, storage, and distribution processes.

- Supplier Relationship Management - ISO 9001 encourages suppliers to develop strong relationships with manufacturers. Effective communication, collaboration, and mutual understanding of quality requirements contribute to a seamless supply chain.

Quality Assurance in Procurement and Distribution

- Procurement Processes - ISO 9001 requires suppliers to implement stringent quality controls during the procurement of overhead cranes. This involves thorough supplier evaluations, quality checks on received products, and adherence to specified standards.

- Storage and Handling - Suppliers must ensure proper storage and handling of overhead cranes to prevent damage or deterioration. ISO 9001 provides guidelines for maintaining the quality of products in storage and during transportation.

- Distribution Practices - ISO 9001 emphasizes the importance of maintaining product quality during distribution. Suppliers must have reliable processes for packaging, shipping, and tracking overhead cranes to guarantee that they reach their destination in optimal condition.

- Continuous Improvement - The standard encourages suppliers to adopt a continuous improvement mindset. Regular reviews of processes, feedback mechanisms, and corrective actions contribute to an evolving and refined Quality Management System.

In conclusion, ISO 9001 certification for overhead crane suppliers ensures that they adhere to globally recognized quality standards, contributing to the overall reliability and performance of the products they supply. Next, we will explore ISO 14001, focusing on environmental management in the context of overhead crane supply. Stay tuned for insights into sustainable practices for suppliers in the crane industry.

ISO 14001: Environmental Management System (EMS)

Environmental Responsibility in Supply Chain

ISO 14001, dedicated to Environmental Management Systems (EMS), extends its significance to overhead crane suppliers by emphasizing environmental responsibility throughout the supply chain. As integral participants in the crane industry, suppliers can contribute to sustainable practices and reduce the environmental impact associated with their operations.

- Supply Chain Assessment - ISO 14001 encourages suppliers to assess their supply chain for environmental impacts. This involves evaluating the environmental practices of manufacturers, transportation providers, and other entities involved in the supply of overhead cranes.

- Eco-Friendly Procurement - Suppliers are encouraged to prioritize eco-friendly procurement practices. This includes sourcing materials and components from manufacturers who adhere to environmental standards, reducing the overall ecological footprint of the supplied products.

Sustainable Practices for Suppliers

- Energy Efficiency - ISO 14001 promotes energy efficiency in all aspects of operations. Suppliers can adopt sustainable practices, such as using energy-efficient equipment, optimizing transportation routes, and implementing energy-saving measures in warehouses.

- Waste Reduction and Recycling - Suppliers must focus on waste reduction and recycling initiatives. ISO 14001 guides suppliers in implementing processes to minimize waste generation, segregate recyclables, and collaborate with recycling facilities.

- Carbon Footprint Reduction - The standard encourages suppliers to actively work towards reducing their carbon footprint. This involves assessing emissions from transportation, energy usage, and other operational activities, followed by implementing strategies to decrease overall emissions.

- Environmental Compliance - Suppliers must stay informed about and comply with environmental regulations. ISO 14001 provides a framework for ensuring that suppliers operate within legal environmental constraints and maintain a commitment to environmental stewardship.

In conclusion, ISO 14001 certification for overhead crane suppliers demonstrates a commitment to environmental sustainability within the supply chain. By integrating eco-friendly practices and reducing environmental impacts, suppliers contribute to a more sustainable crane industry. In the subsequent section, we will explore ISO 45001, focusing on occupational health and safety management for suppliers in the overhead crane supply chain. Stay tuned for insights into ensuring the well-being of workers involved in supply chain operations.

ISO 45001: Occupational Health and Safety Management System (OHSMS)

Safety Considerations for Suppliers

ISO 45001, designed for Occupational Health and Safety Management Systems (OHSMS), holds paramount importance for overhead crane suppliers. The safety of workers involved in handling and distributing overhead cranes is a critical aspect that suppliers must address to ensure a secure and healthy workplace.

- Risk Assessment in Supply Chain Operations - ISO 45001 requires suppliers to conduct comprehensive risk assessments for all aspects of their operations, particularly those related to the handling and distribution of overhead cranes. Identifying potential safety hazards is essential for developing effective preventive measures.

- Training and Competence - Suppliers must prioritize the training and competence of their employees involved in supply chain operations. ISO 45001 emphasizes the importance of ensuring that workers are adequately trained to handle overhead cranes safely.

Employee Safety in Handling and Transportation

- Safe Handling Procedures - ISO 45001 guides suppliers in establishing safe handling procedures for overhead cranes. This includes protocols for loading and unloading, securing loads during transportation, and ensuring that employees are equipped with the necessary protective gear.

- Transportation Safety Measures - Suppliers must implement safety measures during the transportation of overhead cranes. This involves securing loads to prevent shifting, adhering to weight limits, and employing trained drivers who are aware of the unique considerations associated with transporting heavy equipment.

- Emergency Preparedness - ISO 45001 requires suppliers to have robust emergency preparedness plans. This includes procedures for responding to accidents, injuries, or unforeseen events during the handling and transportation of overhead cranes.

- Continuous Improvement in Safety Practices - The standard encourages suppliers to continuously improve their safety practices. Regular reviews of incidents, feedback from workers, and the implementation of corrective actions contribute to an evolving and effective Occupational Health and Safety Management System.

In conclusion, ISO 45001 certification for overhead crane suppliers ensures a commitment to the health and safety of workers throughout the supply chain. By adhering to safety standards, suppliers can create a workplace that prioritizes employee well-being and minimizes risks associated with the handling and transportation of overhead cranes.

In the upcoming section, we will explore ISO 9001 for distributors, focusing on the specific requirements for suppliers involved in the distribution of overhead cranes. Stay tuned for insights into maintaining quality standards throughout the distribution process.

ISO 9001 for Distributors

Specifics of ISO 9001 for Distributors

ISO 9001 for distributors is a tailored application of the Quality Management System (QMS) standard specifically designed for entities involved in the distribution of products, including overhead cranes. Distributors play a crucial role in maintaining the quality of products as they move through the supply chain. ISO 9001 provides specific guidelines for distributors to ensure that the quality standards set by manufacturers are upheld.

- Documentation and Traceability - Distributors must maintain meticulous documentation of incoming and outgoing products, including overhead cranes. ISO 9001 requires traceability to ensure that each crane can be traced back to its origin, providing transparency in the supply chain.

- Handling and Storage Practices - ISO 9001 outlines specific requirements for the handling and storage of products during the distribution process. Distributors must adhere to these guidelines to prevent damage, deterioration, or deviations from quality standards.

Ensuring Quality Throughout the Supply Chain

- Quality Inspections - Distributors are responsible for conducting quality inspections upon receiving overhead cranes. ISO 9001 emphasizes the importance of thorough inspections to verify that the delivered products meet the specified quality criteria.

- Packaging Standards - ISO 9001 for distributors includes guidelines for packaging standards. Proper packaging is essential to protect overhead cranes during transportation and storage, ensuring that they reach their destination in optimal condition.

- Delivery Accuracy - Distributors must focus on maintaining delivery accuracy, ensuring that the right products, including overhead cranes, are delivered to the correct destinations. ISO 9001 outlines procedures for accurate order fulfillment.

- Continuous Monitoring and Improvement - ISO 9001 encourages distributors to establish processes for continuous monitoring and improvement. Regular reviews of distribution practices, feedback from customers, and implementation of corrective actions contribute to an evolving and effective Quality Management System.

In conclusion, ISO 9001 certification for distributors ensures that the quality of overhead cranes is preserved throughout the distribution process. By adhering to the specific requirements outlined in ISO 9001 for distributors, entities in the distribution chain contribute to maintaining the overall quality and reliability of overhead crane systems.

This concludes our exploration of ISO certifications for overhead crane manufacturers and suppliers. For additional resources and references, please refer to the end of this guide. If you have further inquiries or specific topics you'd like more information on, feel free to reach out. Thank you for following our comprehensive guide on ISO certifications in the overhead crane industry.

ISO 31000: Risk Management

Managing Risks in Supply and Distribution

ISO 31000 is a comprehensive standard that outlines principles and guidelines for effective risk management. For overhead crane suppliers involved in supply and distribution, managing risks is essential to ensure the smooth flow of operations and maintain the integrity of the supply chain.

- Risk Identification - ISO 31000 emphasizes the identification of risks associated with supply and distribution processes. Suppliers must conduct thorough risk assessments to identify potential challenges, uncertainties, and disruptions that could impact the timely and secure delivery of overhead cranes.

- Risk Assessment and Evaluation - The standard guides suppliers in assessing and evaluating identified risks. This involves analyzing the potential impact of risks on the supply and distribution chain, considering the likelihood of occurrence, and prioritizing risks for mitigation.

- Mitigation Strategies - ISO 31000 encourages the development of mitigation strategies to address identified risks. Suppliers should implement proactive measures to minimize the impact of potential disruptions, ensuring the continuous and reliable supply of overhead cranes.

Importance of Risk Management in Crane Supply

- Supply Chain Resilience - Risk management, as per ISO 31000, contributes to the resilience of the supply chain. Suppliers in the overhead crane industry must be prepared to navigate various risks, including disruptions in the transportation network, supplier issues, or unexpected events that could impact the timely delivery of cranes.

- Quality Assurance - Effective risk management enhances quality assurance in the supply and distribution of overhead cranes. By addressing potential risks, suppliers can maintain the quality standards set by manufacturers and ensure that cranes reach their destination in optimal condition.

- Timely Delivery - Risks such as delays, uncertainties, or logistical challenges can impact the timely delivery of overhead cranes. ISO 31000 helps suppliers implement strategies to mitigate these risks, ensuring that cranes are delivered according to schedule.

- Customer Satisfaction - Managing risks in supply and distribution contributes to overall customer satisfaction. Suppliers who can reliably deliver overhead cranes, even in the face of challenges, build trust with customers and enhance their reputation in the industry.

In conclusion, ISO 31000 certification supports overhead crane suppliers in effectively managing risks in the supply and distribution chain. By implementing risk management principles, suppliers can enhance their resilience, maintain quality standards, and ensure customer satisfaction in the dynamic and complex landscape of crane supply.

This concludes our exploration of ISO certifications for overhead crane manufacturers and suppliers. If you have any further questions or if there's anything specific you'd like to delve into, feel free to let me know. Thank you for engaging in this comprehensive guide on ISO certifications in the overhead crane industry.

ISO 50001: Energy Management System (EMS) (Optional)

Energy Efficiency in Operations

While ISO 50001 is optional, adopting an Energy Management System (EMS) can bring significant benefits to overhead crane suppliers. Energy efficiency in operations is not only environmentally responsible but also contributes to cost savings and long-term sustainability.

- Energy Consumption Assessment - Suppliers can use ISO 50001 to assess and analyze energy consumption in their operations. This involves identifying areas where energy is used, determining consumption patterns, and understanding opportunities for improvement.

- Optimization of Equipment - ISO 50001 encourages suppliers to optimize equipment for energy efficiency. This includes the use of energy-efficient machinery, implementing technology to reduce energy consumption, and maintaining equipment to ensure optimal performance.

Sustainable Energy Practices

- Renewable Energy Sources - Suppliers can explore the integration of renewable energy sources as part of sustainable practices. ISO 50001 provides a framework for incorporating renewable energy, such as solar or wind power, into operations, contributing to a reduction in carbon footprint.

- Continuous Monitoring and Improvement - ISO 50001 emphasizes continuous monitoring and improvement in energy management. Suppliers can establish protocols for regular energy audits, track performance indicators, and implement measures for ongoing efficiency enhancement.

- Employee Awareness and Engagement - Engaging employees in energy management practices is a key aspect of ISO 50001. Suppliers can foster a culture of energy awareness among staff, encouraging them to contribute ideas, practices, and behaviors that enhance energy efficiency.

- Regulatory Compliance - Adherence to ISO 50001 ensures that suppliers are aligned with energy management regulations. This not only demonstrates a commitment to sustainability but also helps suppliers stay compliant with evolving environmental standards.

In summary, while ISO 50001 is optional, overhead crane suppliers can benefit from adopting an Energy Management System. Enhancing energy efficiency not only aligns with environmental goals but also contributes to operational cost savings and long-term sustainability.

This concludes our exploration of ISO certifications for overhead crane manufacturers and suppliers. If you have any further questions or if there's anything specific you'd like to delve into, feel free to let me know. Thank you for engaging in this comprehensive guide on ISO certifications in the overhead crane industry.

Certification Process

Overview of the Certification Process

- Initial Assessment - The certification process typically begins with an initial assessment of the organization's current practices and systems. This involves identifying areas that align with ISO standards and those that require improvement.

- Gap Analysis - A gap analysis is conducted to identify the differences between current practices and the requirements of the chosen ISO standards. This step provides a roadmap for necessary changes and improvements.

- Implementation of Changes - Organizations implement changes based on the findings of the gap analysis. This involves updating processes, documentation, and practices to align with ISO standards.

- Documentation - Comprehensive documentation of processes, procedures, and policies is crucial for ISO certification. Organizations must create and maintain detailed documentation to demonstrate compliance during audits.

- Internal Audits - Internal audits are conducted to assess the effectiveness of implemented changes. This step ensures that the organization is ready for external certification audits.

- External Certification Audit - A certification body, accredited to perform ISO audits, conducts an external certification audit. This audit assesses the organization's compliance with ISO standards and determines eligibility for certification.

- Certification Decision - Based on the results of the external audit, the certification body makes a decision regarding ISO certification. If the organization meets the required standards, it is awarded the certification.

Collaboration with Certification Bodies

- Selection of Certification Body - Organizations choose a certification body accredited by relevant accreditation bodies. The selected certification body should have expertise in the specific ISO standards the organization is seeking.

- Collaboration and Communication - Effective collaboration and communication between the organization and the certification body are essential. This includes providing necessary documentation, addressing queries, and coordinating audit schedules.

Common Challenges and Solutions

Lack of Awareness and Understanding

Challenge: Organizations may face challenges due to a lack of awareness or understanding of ISO standards.

Solution: Training programs and educational resources can address this challenge, providing employees with the knowledge needed for successful certification.

Resistance to Change

Challenge: Resistance to change within the organization can impede the implementation of new processes.

Solution: Clear communication about the benefits of certification, involvement of employees in the process, and addressing concerns can help overcome resistance.

Documentation Overload

Challenge: Creating and managing extensive documentation can be overwhelming.

Solution: Implementing efficient document control systems and focusing on essential documentation can streamline the process.

Resource Constraints

Challenge: Limited resources, both in terms of personnel and finances, can be a challenge.

Solution: Prioritizing activities, seeking external support if necessary, and phasing the implementation can help manage resource constraints.

Timelines and Costs

- Timelines - The timeline for ISO certification varies based on the complexity of the organization's processes and the chosen ISO standards. It can range from several months to over a year.

- Costs - The costs associated with ISO certification include fees charged by certification bodies, training costs, costs related to process improvements, and ongoing maintenance costs. The investment varies based on the organization's size and complexity.

In conclusion, the certification process involves a structured approach to aligning organizational practices with ISO standards. Collaboration with certification bodies, addressing common challenges, and understanding the timelines and costs are crucial aspects of a successful ISO certification journey. If you have specific questions or need further details on any aspect, feel free to ask.

Conclusion

In this comprehensive guide, we explored key ISO certifications relevant to the overhead crane industry. These certifications include:

ISO 9001: Quality Management System (QMS)

ISO 14001: Environmental Management System (EMS)

ISO 45001: Occupational Health and Safety Management System (OHSMS)

ISO 10218: Robots and Robotic Devices - Safety Requirements for Industrial Robots (for manufacturers)

ISO 9001: Quality Management System (QMS) (for suppliers and distributors)

ISO 14001: Environmental Management System (EMS) (for suppliers and distributors)

ISO 45001: Occupational Health and Safety Management System (OHSMS) (for suppliers and distributors)

ISO 31000: Risk Management

ISO 50001: Energy Management System (EMS) (optional)

Impact on Quality, Safety, and Sustainability

Implementing ISO certifications in the overhead crane industry has a profound impact on quality, safety, and sustainability:

- Quality Assurance - ISO certifications, particularly ISO 9001 and ISO 3834, ensure that overhead crane manufacturers adhere to rigorous quality standards in design, manufacturing, and welding processes. This results in high-quality and reliable crane systems.

- Occupational Health and Safety - ISO 45001 focuses on the well-being of workers in both manufacturing and supply chain operations. Adhering to this standard enhances safety practices, reduces accidents, and creates a secure working environment.

- Environmental Stewardship - ISO 14001 promotes environmental responsibility in manufacturing and supply chain processes. Manufacturers and suppliers adopting this certification contribute to sustainable practices, reduce environmental impact, and meet regulatory requirements.

- Risk Management - ISO 31000 guides organizations in identifying, assessing, and mitigating risks in supply and distribution chains. This proactive approach enhances resilience and ensures the reliability of overhead crane supply.

- Energy Efficiency (Optional) - Organizations opting for ISO 50001 can improve energy efficiency in operations, contributing to cost savings and environmental sustainability.

Encouraging Industry-wide Adherence

Encouraging industry-wide adherence to ISO standards involves collaborative efforts among manufacturers, suppliers, distributors, and industry stakeholders. Key strategies include:

- Knowledge Dissemination - Disseminating knowledge about the benefits and importance of ISO certifications through industry forums, training programs, and collaborative initiatives.

- Collaboration Platforms - Establishing platforms for collaboration among industry players, certification bodies, and regulatory authorities to share best practices and facilitate standardization.

- Incentive Programs - Introducing incentive programs or recognition for organizations that actively pursue and achieve ISO certifications, promoting a culture of continuous improvement.

- Regulatory Support - Seeking support from regulatory bodies to incentivize or require ISO certifications in the industry, aligning with global standards for quality, safety, and sustainability.

- Continuous Improvement - Emphasizing the importance of continuous improvement and the integration of new ISO standards as they evolve, ensuring that the industry stays at the forefront of best practices.

In conclusion, the adoption of ISO certifications in the overhead crane industry is a strategic move towards ensuring quality, safety, and sustainability. As organizations embrace these standards, the industry as a whole can achieve higher levels of performance, reliability, and environmental responsibility. If you have further inquiries or require additional information, feel free to reach out. Thank you for engaging in this comprehensive guide on ISO certifications in the overhead crane industry.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch