Orange Peel Mechanical Grab for Sale Libya for Steel Scrap Crane

Mechanical orange peel grab for steel scrap handling for Libya steel scrap yard. 6 opening 2 cubic meters orange peel mechanical grab bucket 4 ton for sale.

| Grab type | Mechanical orange peel grab |

| Specifications | 2 cubic meters 6 opening orange peel mechanical grab |

| Application | For 9 ton steel scrap crane |

| Project location | Libya |

Category: Grab Crane

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Orange Peel Mechanical Grab for Sale Libya for Steel Scrap Crane

2 Cubic Meters Orange Peel Mechanical Grab Bucket 4 ton 6 Opening

Mechanical orange peel grab for steel scrap handling for Libya steel scrap yard. 6 opening 2 cubic meters orange peel mechanical grab bucket 4 ton for sale.

Orange peel mechanical grab for Steel Scrap Handling for Libya steel scrap yard. 6 opening 2 Cubic Meters orange peel mechanical grab Bucket for steel scrape handling with capacity of 4 ton for steel scrap handling. The orange peel mechanical grab bucket are designed for a crawler crane to handle light steel scrap with 5 ton to 6 ton capacity, volume of 2 cubic meters. The double rope orange peel mechanical grab will be a cost-effective solution for the Libya clients. As for a crane manufacturer and supplier, there are types of cranes and below hook devices for steel scrap handling , such as, overhead cranes, gantry cranes, magnets and type of grabs, etc. If you are in the steel industry or need a proper scrap handling crane and equipment, please feel free to contact us. The customized steel scrap orange peel mechanical grab crane and lifting devices are provided based on your lifting requirements and application conditions.

Double Rope Mechanical Type orange peel mechanical grab for sale Libya

Overview of 2m3 double rope mechanical orange peel mechanical grab

- Grab type: Double Rope Mechanical Type orange peel mechanical grab

- Specifications: Model LS1020, 2 M3, self weight 4 ton.

- Applications: The double rope orange peel mechanical grab is designed for a 9 ton crawler cranes , which is used for handling 4 ton steel scrap at a each grabbing, with 24mm diameter wire rope.

- Delivery of grab: By shipping, containers .

- Project location: Libya

2 cubic meters orange peel mechanical grab bucket for steel scrap handling

On selection of steel scrap grabs

The selection of grab bucket must be confirmed based on the working conditions, the density and weight of the lifting material, the capacity and volume of the grab, the type of the grab, and the lifting capacity of the crane. Only in this way, the the proper grab can be selected , and also, since the grab is generally large in size and difficult to transport, on grab purchasing, the transportation is also very important.

When selecting a grab bucket, it's important to consider the following factors in more detail:

- The type and density of the material to be handled: Different types of materials require different types of grab buckets. For example, for loose bulk materials like sand or gravel, a clamshell grab bucket may be suitable, while for heavier or more compact materials like scrap metal or rocks, a mechanical grab bucket may be more appropriate. The density of the material also affects the size and capacity of the grab bucket needed.

- The maximum weight the grab bucket will need to lift: The maximum weight the grab bucket will need to lift should be considered when selecting a grab bucket. The grab bucket must have a load capacity that is greater than or equal to the maximum weight it will need to lift.

- The type of machinery the grab bucket will be attached to: The type of machinery the grab bucket will be attached to affects the type and size of grab bucket needed. For example, an excavator may require a larger and heavier grab bucket than a overhead crane or gantry crane.

- The environment and working conditions in which the grab bucket will be used: The environment and working conditions in which the grab bucket will be used also affect the type of grab bucket needed. For example, if the grab bucket will be used in a corrosive environment, a stainless steel or anti-corrosion coating may be required. If the grab bucket will be used in a hazardous environment, such as handling radioactive materials, a specialized grab bucket may be required.

In addition to these factors, it's also important to consider the shape and size of the material being handled. If the material is irregularly shaped or difficult to handle, a grab bucket with adjustable tines or claws may be necessary. Furthermore, if the material requires special handling precautions, such as being fragile or hazardous, a specialized grab bucket may be required to ensure safe and efficient handling.

2 M3 steel scrap orange peel mechanical grab selection

Based on particular applications and uses, the proper type of grab will be selected . When selecting an orange peel mechanical grab, consider the size and weight of the material you will be handling, the capacity of the grab, and the type of crane or excavator it will be attached to. It is also important to choose a grab with durable and high-quality materials to ensure longevity.

Initial communication on steel scrap grab selection

On Thu, 16 Feb 2023, 08:10 Mia, <mia@cranedq.com> wrote:

Hi Salah,

Good day to you.

I let the engineer watch your video. Then our engineer feedback that your crawler crane is not suitable for double-rope grab because of its hook, unless you remove the original hook and connect the two wire ropes of the crawler crane to the grab.

If you want to hang the grab directly on the hook of your crawler crane, you need a single-rope grab. However, single-rope mechanical grab is not suitable for your scheme of lifting scrap steel, and its efficiency is not high. We recommend that you also use an electric hydraulic grab to catch scrap steel.

Please kindly check and let me know your reply.

Communications on working condition confirmations

- the machine it which the steel scrap grab will be attached.

The double rope orange peel mechanical grab is designed for a 9 ton crawler cranes , which is used for handling 4 ton steel scrap at a each grabbing, with 24mm diameter wire rope.

The crawler crane drawing for reference. The orange peel mechanical grab will be connected and used for steel scrap handling.

- the steel scarp property

We need to know the proportion of scrap. You confirm this type grab is suitable for your working conditions, right?

It's for scrap. The scrap of different objects has different material proportions. Are you light steel scrap or heavy steel scrap?

Its two drums, one for up and down, and the other for opening and closing

Confirm the connection part of your crawler crane and grab to see whether the hook or wire rope is connected to the grab. This is for the convenience of your later connection.

Finally confirmation on grab specifications

Based on thorough understanding of client's applications, the type of steel scrap grab and its specifications is confirmed, and the specific double rope mechanical orange peel grab drawing and specification are sent to client for confirmation.

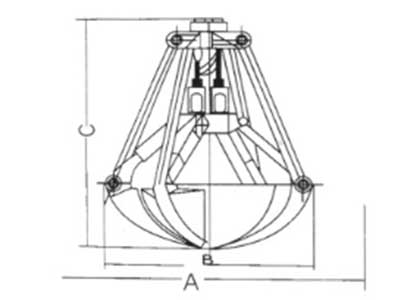

Drawing of 6 opening mechanical orange peel grab

Specifications of orange peel mechanical grab

0n orange peel mechanical grab production

During the production the production pictures of the steel scrap mechanical grabs are updated to clients to keep our client well informed of the processing. The main production pictures of the 2m3 grab are presented for your reference.

6 open orange peel mechanical grab bucket for sale Libya

Production of 6 jaws of mechanical grab bucket for steel scrap handling in scrap yard

Mechanical orange peel grab testing

To ensure safety and quality and save all the troubles before leaving factory, all of our grabs are well inspected and tested.

On transportation of double rope 6 jaws orange peel mechanical grab

The overall dimensions of 6-petal double-rope mechanical grab is 2500 mm *2500mm* 3000mm, which is too large for a container. With carefully calculation and technical communications, the one jaw or petal of the orange peel mechanical grab is removed for the sake a easy transportation, , and then the width is reduced to 2.28 m, which can fit into the container. To ensure safe transportation, the positioning of grab inside of the container is enhanced.

Dimensions of mechanical orange peel grab bucket

fastened grab bucket in continer for delivery to Libya

Scrap crane for delivery to Libya by container

How to ensure your steel scrap safety inside of container?

The safety enhancement measures are used, with the following reinforcement material, such as, trangle wood, steel nails, wire ropes, chuck clips, rubber hose, etc.

triangle wood for mechanical grab fastening

steel nail for mechanical orange peel grab fixing in container

wire rope for scrap crane grab bucket fixing in container for shipping

Chuck clip for safe container shipping

Rubber hose for grab shipping

With all the reinforcement, the steel scrap orange peel mechanical grab will be stay safe in the container during the shipping.

safety delivery of 6 jaw grab bucket

Fastening mechanical orange peel grab

Orange peel grab fastened for delivery

What is a mechanical grab?

A mechanical grab is a type of excavator attachment that is used to grip and lift materials such as rocks, logs, and debris.

1. What are the different types of mechanical grabs?

There are several types of mechanical grabs that are commonly used in industries such as construction, mining, and waste management. Some of the most common types include:

- Clamshell grab: This type of grab has two hinged jaws that can be opened and closed using a hydraulic cylinder. It is commonly used for digging and excavating, as well as for handling bulk materials such as sand, gravel, and coal.

- Orange peel mechanical grab: This type of orange peel grab has multiple jaws that can be opened and closed independently. It is commonly used for handling scrap metal and other irregularly shaped objects.

- Log grab: This type of grab is specifically designed for handling logs and other long, cylindrical objects. It typically has a curved shape that conforms to the shape of the logs.

- Demolition grab: This type of grab is designed for heavy-duty demolition work. It typically has a large, heavy-duty jaw that can crush and break apart concrete and other materials.

- Timber grab: This type of grab is designed for handling timber and other large, bulky objects. It typically has a wide, flat jaw that can grip the object securely.

These are just a few examples of the different types of mechanical grabs that are available. The specific type of grab that is best suited for a particular application will depend on factors such as the size and shape of the objects being handled, the environment in which the grab will be used, and the specific requirements of the job.

2. How does a mechanical grab work?

A mechanical grab, also known as a grapple, is a type of equipment used in material handling to lift and move heavy objects. It typically consists of two or more jaws that are operated by a hydraulic or mechanical system.

When the jaws are opened, they are positioned around the object to be lifted. Once in place, the jaws are closed, gripping onto the object tightly. The hydraulic or mechanical system then lifts the object, allowing it to be moved to a new location.

The design of the mechanical grab can vary depending on its intended use. Some grabs are designed for handling loose materials such as sand or gravel, while others are designed for handling solid objects such as logs or scrap metal.

Overall, the mechanical grab is a versatile piece of equipment that is commonly used in construction, mining, and other industries that require heavy lifting and material handling.

3. What are the advantages of using a mechanical grab?

Mechanical grabs are commonly used in construction and industrial settings to handle heavy loads of materials such as rocks, sand, gravel, and debris. Some advantages of using a mechanical grab include:

- Increased efficiency: Mechanical grabs can handle large quantities of materials in a shorter amount of time, which increases productivity and saves time.

- Versatility: Mechanical grabs come in various sizes and shapes, which makes them suitable for different types of materials and applications.

- Reduced labor costs: Using a mechanical grab eliminates the need for manual labor, which reduces labor costs and minimizes the risk of injury.

- Improved safety: Mechanical grabs are designed to securely hold materials, which reduces the risk of accidents and injuries in the workplace.

- Increased accuracy: Mechanical grabs can be operated with precision, which allows for more accurate placement of materials in desired locations.

- Overall, the use of mechanical grabs can result in increased efficiency, reduced labor costs, improved safety, and greater accuracy in material handling tasks.

4. What materials can be lifted with a mechanical grab?

A mechanical grab, also known as a clamshell grab, is a type of excavator attachment used for lifting and moving materials. It typically consists of two hinged jaws that are operated by hydraulic cylinders or cables.

The type of materials that can be lifted with a mechanical grab depends on the design and capacity of the grab. Generally, mechanical grabs are used for handling bulk materials such as coal, sand, gravel, and rocks. They can also be used for handling scrap metal, waste materials, and other heavy objects.

Some mechanical grabs are designed for specific materials, such as timber or logs. These grabs may have special features such as curved jaws or teeth to grip the material more securely.

It is important to note that the lifting capacity of a mechanical grab is limited by its design and the capacity of the excavator it is attached to. Therefore, it is important to use the appropriate grab for the job to ensure safety and efficiency.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch