300kg Jib Crane for Sale Indonesia, Cheap Pillar Jib Crane 300KG

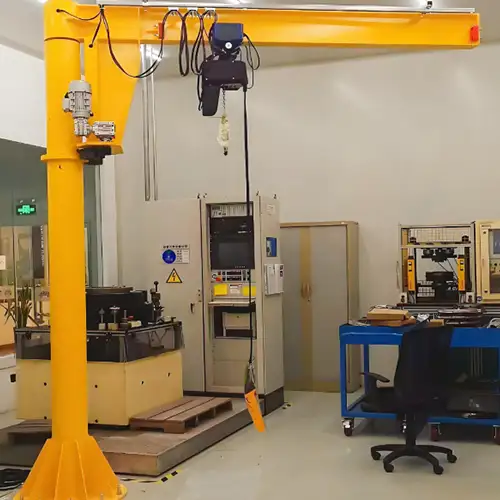

300kg jib crane for sale Indonesia, custom pillar jib crane 300kg, 11 m height pillar jib crane design, :415V50HZ3P for manufacturing factory in Indonesia.

| Crane type | Pillar jib crane |

| Crane capacity | 300kg |

| Lifting Height | 11 m |

| Crane Span | 2 m |

| Crane power | 415V50HZ3P |

| Project locations | Indonesia |

Category: Indonesia

Your Trusted Jib Crane Manufacturer & Supplier

300kg Jib Crane for Sale Indonesia, Cheap Pillar Jib Crane 300KG

300kg jib crane for sale Indonesia, custom pillar jib crane 300kg, 11 m height pillar jib crane design, :415V50HZ3P for manufacturing factory in Indonesia.

300kg jib crane for sale Indonesia, Economical Pillar jib crane 300kg

- Crane type: pillar jib crane

- Crane capacity: 300kg

- Cane arm length: 2m

- Crane lifting height: 11.m

- Crane power supply:415V50HZ3P

- Crane application: Manufacturing industry

- Crane project location: Indonesia

A Cost-Effective Lifting Solution for a Manufacturing Factory in Indonesia

In this case study, we will explore the implementation of a 300kg jib crane in a manufacturing factory in Indonesia. The primary objective is to meet the factory's material handling requirements efficiently and safely. The customdesigned pillar jib crane with a lifting capacity of 300kg and an 11m height plays a vital role in streamlining the production process while adhering to costeffectiveness.

Customer Requirements of small jib crane 300kg

The manufacturing factory in Indonesia faced challenges in handling heavy materials during the production process. They sought a lifting solution that would increase efficiency and reduce manual labor efforts. The client had specific requirements for the crane's capacity, height, and power supply to ensure it met their operational needs.

A pillar jib crane was selected for its simplicity and versatility. It consists of a vertical pillar securely installed on the factory floor, with a horizontal jib arm extending from it. The jib arm allows the crane's lifting mechanism to move materials horizontally, covering a specific area within the factory.

Solution of 300kg Pillar Jib Crane

The solution provided was a tailormade 300kg pillar jib crane. Its features are as follows:

- Crane type: pillar jib crane

- Crane capacity: 300kg

- Cane arm length: 2m

- Crane lifting height: 11.m

- Crane power supply:415V50HZ3P

- Crane application: Manufacturing industry

- Crane project location: Indonesia

Jib Crane Capacity: 300kg

The 300kg lifting capacity of the jib crane perfectly matched the client's material handling requirements. It ensures the crane can handle various loads within the factory, facilitating smooth and efficient operations.

column of 300 kg pillar jib crane with length of 11 meters

1 section of 11 m length column of 300kg jib crane

Crane Lifting Height: 11m

The 11meter height of the jib crane enabled the client to lift materials to different levels, such as stacking raw materials or finished products on higher shelves or platforms. This aspect further enhanced the factory's production capabilities and storage capacity.

The features of an 11m lifting height crane column (pillar jib crane) include:

- Height: The crane column is designed to have a maximum lifting height of 11 meters, providing significant vertical reach for lifting materials to elevated platforms or levels within the workspace.

- Load Capacity: The crane column is engineered to support a specific load capacity, which may vary based on the crane's design and construction. The load capacity determines the maximum weight the crane can lift safely.

- Construction Material: Typically, crane columns are constructed from sturdy and durable materials such as steel or highstrength alloys to ensure structural integrity and longevity.

- Base Plate: The crane column is anchored to a heavyduty base plate that is securely fixed to the floor or foundation. This base plate provides stability and support for the entire crane structure.

- Column fabrications into 2 sections: Due to the length of 300kg jib crane is 11 meters, which is processed into 2 sections of 5 meters and 5 meters, which can be assembled at customer's sites which makes the transportation of jib columns easy and much cheaper.

pillar jib crane arm cantilever 2 meter i beam cantilever

300kg slewing jib crane cantilever with tie rod design

Crane Arm Length: 2m

With a 2meterlong jib arm, the crane could cover a considerable working area. This provided the necessary flexibility to reach different workstations within the manufacturing facility.

An Ibeam jib cantilever, also known as an Ibeam jib crane or Ibeam cantilever crane, is a type of lifting equipment that consists of a horizontal Ibeam supported by a vertical column or mast. It is designed for lifting and moving heavy loads in industrial settings. Here are the key features of an Ibeam jib cantilever:

- IBeam Construction: The main horizontal beam, often referred to as the Ibeam, is a strong and rigid structural member that forms the primary loadbearing component of the crane. Ibeams are known for their high strengthtoweight ratio, making them ideal for handling heavy loads.

- Cantilever Design: The Ibeam jib cantilever is designed with a cantilevered structure, which means the beam is supported by a single vertical column rather than a supporting structure on both ends. This configuration allows the crane to extend over an area without the need for support underneath the load, maximizing the workspace.

- Rotation: Many Ibeam jib cantilevers are designed to rotate, allowing the horizontal beam to swivel horizontally, providing versatility and coverage over a larger working area. The rotation may be manual or powered, depending on the crane's design.

- SpaceSaving Design: The cantilever design of the crane allows for efficient use of floor space, making it suitable for applications where floor space is limited or needs to be maximized.

Overall, the Ibeam jib cantilever is a versatile and robust lifting solution that finds applications in various industries, including manufacturing, warehouses, workshops, and assembly lines, where heavy lifting and precise material handling are required.

415V electric chain hoist for 300 kg jib crane

300kg jib crane hoist, small jib hoist

300kg small jib crane hoist

A 415V electric chain hoist designed for a 300kg jib crane is a specialized lifting device used to handle loads weighing up to 300 kilograms in a manufacturing, industrial, or construction setting. It is an essential component of the jib crane system, providing efficient and controlled lifting and lowering of loads within the crane's specified capacity. Here are the key features and specifications of the electric chain hoist:

- Electric Power Supply: The hoist operates on a 415V electrical power supply, which is commonly used in industrial and commercial settings. This voltage ensures the hoist can deliver sufficient power to lift the designated loads effectively.The crane's power supply was optimized to match the factory's existing electrical infrastructure, eliminating the need for significant modifications and ensuring seamless integration.

- Compact and Lightweight Design: Electric chain hoists are designed to be compact and lightweight, making them easy to install and maneuver within the jib crane's structure.

- Durability and Reliability: The 300kg electric chain hoist and travelling trolley is constructed from highquality materials to ensure durability and longterm reliability in demanding industrial environments.

- Compliance with Standards: The electric chain hoist is designed and manufactured to meet industry safety standards and regulations, ensuring safe and reliable lifting operations.

In summary, the 415V electric chain hoist for the 300kg jib crane is a crucial component that enables efficient and safe material handling in various industrial applications. Its robust design, combined with the jib crane's capabilities, allows for seamless lifting and lowering of loads, contributing to increased productivity and improved workplace safety.

Packages and delivery

300kg pillar jib crane packed for delivery

300kg slewing cantilever crane packed into wooden box for delivery

|

| Unit L(m) | Unit W(m) | Unit H(m) | Pacakges | Volume m³ | Unit weight kg | Total weight kg |

1 | Jib crane | 66 | 1.67 | 1.17 | 1 | 11.059074 | 1920 | 1920 |

2 | Hoist box | 0.56 | 0.34 | 0.5 | 1 | 0.0952 | 53 | 53 |

3 | Trolley box | 0.53 | 0.36 | 0.36 | 1 | 0.068688 | 43 | 43 |

Total |

|

|

|

| 3 | 11.222962 |

| 2016 |

Advantages and CostEffectiveness solution for Indonesia

The deployment of the 300kg jib crane offered several advantages to the manufacturing factory:

- Enhanced Efficiency: The jib crane significantly reduced manual handling efforts, increasing the speed and efficiency of material transportation within the factory premises.

- Improved Safety: By automating the lifting process, the risk of worker injuries due to heavy lifting and strain was minimized.

- SpaceSaving Design: The compact and ergonomic design of the pillar jib crane allowed for effective utilization of the factory's floor space.

- Customization: The crane was customized to match the client's specific requirements, ensuring optimal performance and satisfaction.

- CostEffectiveness: The economical nature of the 300kg pillar jib crane made it a practical investment for the client, offering a good return on investment.

The 300kg jib crane for sale used in the manufacturing factory in Indonesia proved to be a successful endeavor. The costeffective lifting solution streamlined their material handling processes, improved productivity, and enhanced workplace safety. The customdesigned pillar jib crane demonstrated its versatility and efficiency, showcasing how the right lifting equipment can significantly impact the performance of industrial operations.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch