Gantry Hoist & Gantry Crane, Custom Gantry and Hoist 500kg -10 Ton

Gantry hoist and gantry crane for sale, All types of gantry hoists and cranes for various applications. Light portable gantry hoist & heavy duty industrial gantry hoists.

| Custom Gantry Hoist | Custom gantry hoist for various industrial use. |

| Small gantry hoist | 0.5 ton, 1 ton, 3 ton, 5 ton,10 ton |

| Heavy duty gantry hoist | 1 ton -100 ton |

Category: Overhead Hoist

Your Trusted Overhead Gantry Crane and Hoist Manufacturer & Supplier

Gantry Hoist for Gantry Crane, Custom Gantry and Hoist 500kg -10 Ton

Gantry hoists are powerful and flexible lifting solutions that find applications in various industries and settings. In this comprehensive guide, we will explore the world of gantry hoists, their types, applications, key features, and factors to consider when choosing the right gantry hoist for your needs. Whether you're a garage enthusiast, a construction professional, or a warehouse manager, this guide will provide you with valuable insights into the world of gantry hoists.

Gantry Hoists: Unlocking Versatile Lifting Solutions

A gantry hoist consists of a horizontal beam or framework, supported by sturdy legs or columns, creating an elevated structure that can be easily moved to the desired location. What distinguishes gantry hoists is their remarkable versatility, making them indispensable tools in settings as diverse as garages, construction sites, manufacturing plants, and warehouses.

A gantry hoist is a type of lifting device that is used to move heavy objects vertically and horizontally. It consists of a horizontal beam or girder that is supported by two or more vertical legs. The hoisting mechanism, which can be a winch or electric hoist, is typically mounted on the horizontal beam and is used to lift and lower objects. Gantry hoists are commonly used in industrial settings, construction sites, and workshops for tasks such as loading and unloading heavy equipment, positioning large machinery, and transporting materials.

Key features and characteristics of gantry hoists include:

- 1. Portability: Gantry hoists are often designed to be mobile, allowing them to be moved to different locations as needed. They are mounted on wheels or casters, making it easier to transport them within a facility or from one job site to another.

- 2. Versatility: Gantry hoists are versatile and can be used for a wide range of lifting applications. They can handle heavy loads and come in various sizes and weight capacities to accommodate different requirements.

- 3. Stability: The vertical legs of a gantry hoist provide stability and support for lifting operations. The legs are typically positioned on either side of the load to ensure balance and prevent tipping.

- 4. Adjustable Height: Many gantry hoists feature adjustable heights, allowing the user to raise or lower the horizontal beam to the desired level for lifting or positioning objects.

- 5. Safety Features: Gantry hoists are equipped with safety features such as locking mechanisms to secure the load in place and prevent accidental drops.

- 6. Ease of Assembly: They are designed for ease of assembly and disassembly, making them suitable for temporary lifting tasks or for use in locations where a permanent overhead crane system is not practical.

Gantry hoists are commonly used in conjunction with slings, hooks, or other lifting attachments to securely hold and transport loads. They are an essential tool in various industries where heavy lifting is required, including manufacturing, construction, shipyards, and warehouses.

Exploring the Diverse Types of Gantry Hoists

Gantry hoists come in various types, each designed to cater to specific lifting needs across a wide range of industries and applications. In this section, we'll delve into the different types of gantry hoists and their unique features and advantages.

Gantry Hoists Classified Based on Power Source:

- Overview: Manual gantry hoists are operated by hand and rely on manual force, such as hand-cranked winches or chain blocks, to lift and lower loads.

- Features of gantry and hoist: : Simple and straightforward operation. No reliance on external power sources, making them suitable for remote or off-grid locations. Cost-effective and easy to maintain.

- Benefits of gantry crane hoist: Versatile and can be used in various settings. Suitable for lighter lifting tasks. No need for electrical power or compressed air.

- Applications of Gantry Crane and Hoist: Maintenance and repair work. Smaller workshops or garages. Occasional or infrequent lifting needs.

Electric Gantry Hoists:

- Overview: Electric gantry hoists are powered by electricity and use an electric motor for lifting and lowering operations. They are suitable for handling heavier loads and offer greater control and efficiency.

- Features of gantry and hoist: Precise and controlled lifting. Higher lifting capacities compared to manual hoists. Variable speed and direction control.

- Benefits of gantry crane hoist: Suitable for a wide range of load sizes and weights. Enhanced operator comfort and reduced physical effort. Ideal for repetitive and continuous lifting tasks.

- Applications of Gantry Crane and Hoist: Manufacturing and production lines. Warehouses and distribution centers. Construction sites with electrical power access.

Gantry Hoists Classified Based on Design and Structure:

Adjustable Height Gantry Hoists:

- Overview: Adjustable height gantry hoists feature a horizontal beam with adjustable height, allowing them to accommodate various load sizes and lifting heights.

- Features of gantry and hoist: Telescopic legs or adjustable vertical beams. Versatile and adaptable to different load requirements. Often equipped with locking mechanisms for height adjustment.

- Benefits of gantry crane hoist: Suitable for lifting loads of varying sizes. Provides flexibility in adjusting the lifting height. Can be used in situations where the ground is uneven.

- Applications of Gantry Crane and Hoist: Warehouses with changing storage configurations. Maintenance and repair tasks with different load sizes. Construction sites with varying terrain.

Fixed Height Gantry Hoists:

- Overview: Fixed height gantry hoists have a stationary horizontal beam, and the lifting height is not adjustable.

- Features of gantry and hoist: Simple and robust design. Lower maintenance requirements. Stable and secure load lifting.

- Benefits of gantry crane hoist: Cost-effective and easy to operate. Ideal for consistent lifting heights. Well-suited for long-term installations.

- Applications of Gantry Crane and Hoist: Manufacturing processes with standardized load sizes. Permanent material handling setups. Maintenance tasks with consistent lifting requirements.

- Overview: Single-leg gantry hoists have only one vertical leg and are typically used in tight spaces or against walls.

- Features of gantry and hoist: Space-saving design. Easy access to one side of the load. Suitable for confined work areas.

- Benefits of gantry crane hoist: Maximizes floor space in crowded environments. Ideal for loading/unloading against walls or machinery. Provides a clear path for material flow.

- Applications of Gantry Crane and Hoist: Narrow aisles in warehouses. Machine maintenance and repair in tight spaces. Positioning equipment next to walls.

- Overview: A-Frame gantry hoists have a distinctive A-shaped frame structure with two legs and a horizontal beam connecting them.

- Features of gantry and hoist: Provides excellent stability and load support. Easy to assemble and disassemble. Suitable for medium to heavy loads.

- Benefits of gantry crane hoist: Offers a clear span for moving loads between the legs. Balanced weight distribution for secure lifting. Quick setup and relocation.

- Applications of Gantry Crane and Hoist: Manufacturing and assembly lines. Loading and unloading goods in workshops. Materials handling in construction sites.

Overhead Gantry Hoists:

- Overview: Overhead gantry hoists are designed to be mounted on overhead structures, such as single girder gantry hoists used in factories or warehouses.

- Features of gantry and hoist: Utilizes overhead space efficiently. Provides a large working area on the ground. Can be equipped with trolleys for lateral movement.

- Benefits of gantry crane hoist: Maximizes floor space for other activities. Ideal for moving heavy loads within a facility. Reduces the risk of floor obstacles.

- Applications of Gantry Crane and Hoist: Material handling in manufacturing plants. Warehouses with high ceilings. Automotive assembly lines.

Each type of gantry hoist design and structure offers unique advantages, so selecting the right one depends on the specific lifting needs and space constraints of your application.

- Overview: Aluminum gantry hoists are constructed from lightweight aluminum, making them easy to move and transport. They are ideal for applications where portability is a priority and are often used in cleanroom environments.

- Features:Lightweight and corrosion-resistant aluminum construction. Portable design with easy setup and disassembly. Available in various sizes and weight capacities.

- Benefits:High mobility for use in different locations. Non-corrosive material suitable for cleanroom and corrosive environments. Reduced risk of contamination in sensitive applications.

- Applications:Cleanroom facilities in pharmaceutical, semiconductor, and electronics industries. Laboratories and research environments. Temporary lifting needs in various industries.

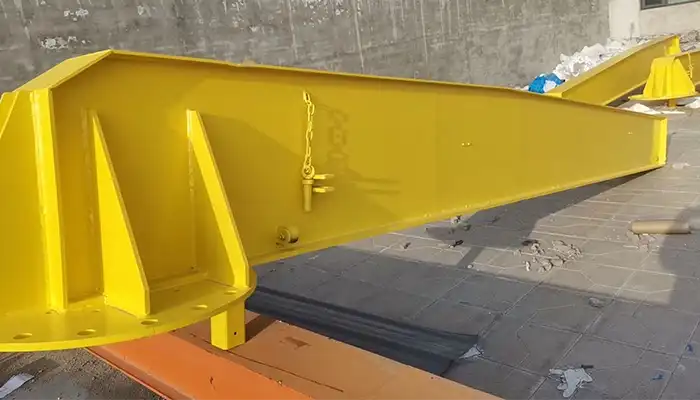

- Overview: Steel gantry hoists are robust and durable, suitable for heavy-duty lifting tasks. They are commonly used in industrial and construction settings where strength and stability are crucial.

- Features:Heavy-duty steel construction for strength and durability. High load capacities to handle heavy materials and equipment. Stable and secure lifting with minimal flexing.

- Benefits:Reliable and long-lasting performance in demanding environments. Suitable for lifting heavy machinery, materials, and structures. Excellent stability and load support.

- Applications:Manufacturing plants with heavy equipment and machinery. Construction sites for lifting steel beams, concrete forms, and equipment. Shipyards and dockyards for ship maintenance and repair.

The choice between aluminum and steel gantry hoists depends on factors such as the required load capacity, environmental conditions, and the need for portability. Aluminum gantry hoists excel in clean and portable applications, while steel gantry hoists are the go-to choice for heavy-duty lifting tasks and rugged industrial environments.

Gantry Hoists Classified Based on Mobility:

- Overview: Portable gantry hoists are designed for easy mobility and can be moved around a workspace or from one location to another.

- Features of gantry and hoist: Equipped with wheels or casters for easy transportation. Quick setup and disassembly without the need for special tools. Compact and space-saving when not in use.

- Benefits of gantry crane hoist: Provides flexibility in choosing work locations. Ideal for temporary or changing job sites. Reduces the need for multiple fixed installations.

- Applications of Gantry Crane and Hoist: Construction sites with varying lifting needs. Maintenance tasks in different areas of a facility. Workshops with limited space for equipment storage.

Stationary Gantry Hoists:

- Overview: Stationary gantry hoists are permanently installed in a specific location and are not meant to be moved.

- Features of gantry and hoist: Bolted or welded to the ground for stability. Fixed position provides a consistent lifting point. Designed for long-term use.

- Benefits of gantry crane hoist: Ensures safety and stability for continuous operations. Ideal for dedicated lifting applications. Eliminates the need for frequent setup and repositioning.

- Applications of Gantry Crane and Hoist: Manufacturing lines with constant lifting tasks. Warehouses with designated loading/unloading areas. Facilities with specialized processes requiring a fixed lifting point.

The choice between portable and stationary gantry hoists depends on the nature of the lifting tasks, workspace dynamics, and the need for flexibility in moving the equipment. Portable gantry hoists offer versatility and adaptability for changing work environments, while stationary gantry hoists provide a stable and reliable lifting solution for dedicated applications.

Gantry Hoists Classified Based on Application:

- Overview: Industrial gantry hoists are designed for heavy-duty industrial applications, such as manufacturing, construction, and shipyards.

- Features of gantry and hoist: High load capacities to handle heavy industrial machinery and equipment. Durability and rugged construction for demanding environments. Various power source options to suit specific needs (electric, hydraulic, pneumatic).

- Benefits of gantry crane hoist: Efficient and safe handling of heavy loads in industrial settings. Versatility to adapt to various manufacturing processes. Enhanced productivity and reduced downtime.

- Applications of Gantry Crane and Hoist: Lifting and positioning heavy machinery. Moving raw materials and finished products in manufacturing plants. Shipbuilding and repair tasks in shipyards.

- Overview: Warehouse gantry hoists are used for material handling and storage in warehouse environments.

- Features of gantry and hoist: Medium to high load capacities suitable for pallets and containers. Mobility for flexible placement within the warehouse. Efficient load stacking and retrieval capabilities.

- Benefits of gantry crane hoist: Streamlined logistics and inventory management. Improved workflow and reduced manual handling. Space optimization and organized storage.

- Applications of Gantry Crane and Hoist: Loading and unloading goods from storage racks. Transporting palletized products within a warehouse. Supporting order fulfillment processes.

- Overview: Cleanroom gantry hoists are designed for use in cleanroom facilities, where hygiene and contamination control are essential.

- Features of gantry and hoist: Stainless steel or non-corrosive materials for easy cleaning. Sealed components to prevent particle generation. Compliance with cleanroom standards and certifications.

- Benefits of gantry crane hoist: Maintains strict cleanliness and contamination control. Prevents the introduction of particles or contaminants. Ideal for critical applications in pharmaceuticals, electronics, and healthcare.

- Applications of Gantry Crane and Hoist: Handling sensitive electronic components. Pharmaceutical manufacturing in cleanroom environments. Aerospace and semiconductor industries.

- Overview: Gantry hoists used in construction sites for tasks like lifting and positioning heavy construction materials and equipment.

- Features of gantry and hoist: Robust construction to withstand construction site conditions. High load capacities for heavy building materials. Portability for use at various locations within a construction site.

- Benefits of gantry crane hoist: Speeds up construction processes and reduces manual labor. Facilitates safe and precise placement of construction materials. Adaptable to different phases of construction projects.

- Applications of Gantry Crane and Hoist: Lifting steel beams and concrete forms. Positioning precast elements in building construction. Assisting in bridge and infrastructure projects.

- Overview: Automotive gantry hoists are commonly used in the automotive industry for tasks such as engine removal and installation.

- Features of gantry and hoist: Specialized attachments for automotive applications. High lifting capacities for vehicle components. Precise control for engine positioning.

- Benefits of gantry crane hoist: Efficient maintenance and repair of vehicles. Safety during engine or transmission handling. Reduction in manual effort and labor costs.

- Applications of Gantry Crane and Hoist: Automotive repair shops and service centers. Vehicle assembly lines. Engine and transmission manufacturing.

The choice of gantry hoist for a specific application is crucial to ensure safe and efficient lifting operations tailored to the needs of the industry or task at hand.

Other Types of Gantry Crane Hoists

Garage Gantry Hoist: A Space-Saving Lifting Solution

Garage gantry hoists are tailored for automotive enthusiasts and professionals working in confined spaces like home garages or small auto repair shops. These hoists offer a compact and space-saving design, making them a practical choice for lifting engines, transmissions, or heavy vehicle components. With their ability to fit seamlessly into garage setups, they maximize workspace efficiency while providing essential lifting capabilities.

Manual Gantry with Hoist: A Powerful Lifting Combo

The combination of a gantry structure with an integrated hoist creates a formidable lifting duo. Gantry hoists with integrated hoists are renowned for their efficiency and versatility. These systems excel in scenarios where both vertical and horizontal lifting and positioning are essential. They offer the strength to hoist heavy loads with precision, making them indispensable in tasks requiring meticulous placement.

Gantry with Electric Hoist: Efficiency Meets Precision

In the world of gantry hoists, electric hoists have ushered in a new era of efficiency and precision. These hoists are powered by electricity, offering enhanced lifting capacity and fine-tuned control. Electric gantry hoists are particularly valuable in industrial settings where accuracy and efficiency are paramount. They allow for precise load positioning and are instrumental in optimizing material handling processes in factories and warehouses.

Gantry Winch: Simplifying Load Management

Gantry winches are engineered to simplify load management tasks, especially those involving controlled horizontal movement. These winches are designed for scenarios where cargo needs to be loaded or unloaded onto trucks or transported within a confined workspace. Gantry winches provide a straightforward yet effective solution for handling heavy loads with ease and ensuring seamless movement.

Gantry Trolley Hoist: Enhancing Mobility

When mobility is a crucial requirement, gantry trolley hoists step into the spotlight. These systems combine the mobility of a trolley with the lifting power of a hoist, offering a winning combination of versatility and convenience. Gantry trolley hoists are ideal for situations where loads must be positioned precisely along a horizontal axis. The integrated trolley system facilitates smooth movement, allowing for efficient load placement with ease.

In conclusion, the world of gantry hoists is marked by diversity and adaptability. Each type of gantry hoist is tailored to address specific lifting challenges and environments, ensuring that you have the right tool for the job. As we continue our exploration of gantry hoists, we'll delve deeper into their applications, key features, and essential factors to consider when selecting the ideal gantry hoist for your unique needs. Whether you're in the automotive industry, construction, manufacturing, or any other sector that demands reliable lifting solutions, there's a gantry hoist type perfectly suited to elevate your operations.

Harnessing the Power of Gantry Hoists: Exploring Diverse Applications

Gantry hoists are versatile lifting solutions that find applications in a wide range of industries and scenarios. In this section, we'll dive into the various applications of gantry hoists, from industrial settings to DIY enthusiasts seeking affordable solutions.

Gantry Lift System: Where and How They Are Used

Gantry lift systems are a cornerstone of material handling and lifting operations across industries. Here are some key areas where they shine:

- Manufacturing Facilities: Gantry hoists play a pivotal role in manufacturing processes, where the precise positioning of heavy machinery and components is critical. They facilitate the assembly and maintenance of equipment with ease and accuracy.

- Construction Sites: Construction professionals rely on gantry hoists to hoist and position building materials, structural components, and heavy machinery. Their mobility and lifting power make them indispensable in erecting structures efficiently and safely.

- Warehouses and Distribution Centers: Gantry hoists streamline the movement of goods within warehouses and distribution centers. They excel in loading and unloading heavy cargo, optimizing storage space, and ensuring efficient logistics.

- Shipping and Transportation: In shipping and transportation industries, gantry lift systems are used to load and unload cargo onto ships and trucks. They ensure the smooth and secure handling of goods in ports and logistics hubs.

Gantry Lift Harbor Freight: Affordable Solutions for DIY Enthusiasts

For DIY enthusiasts and hobbyists, affordability is a key consideration. Gantry lift systems available at Harbor Freight provide accessible solutions for those seeking to lift engines, heavy equipment, or perform other tasks at home or in small-scale workshops. These budget-friendly options offer a practical entry point into the world of gantry hoists.

Gantry Lift for Sale: Finding the Right Fit

When seeking a gantry hoist for your specific needs, you'll often encounter gantry lifts for sale. Finding the right fit involves considering factors such as load capacity, lift height, and mobility. Gantry lifts for sale come in various configurations, ensuring that you can choose the one that aligns perfectly with your lifting requirements.

In conclusion, gantry hoists are indispensable tools in diverse applications, ranging from large-scale industrial operations to DIY projects. Their adaptability, precision, and efficiency make them invaluable for lifting and positioning heavy loads with ease and safety. Whether you're optimizing manufacturing processes, managing construction projects, or embarking on DIY endeavors, gantry hoists are ready to elevate your material handling tasks. As we continue our journey through the world of gantry hoists, we'll explore their key features and essential factors to consider when selecting the ideal gantry hoist for your specific needs.

Unveiling the Key Features of Gantry Hoists: Efficiency and Power Combined

Gantry hoists are renowned for their versatility and ability to handle diverse lifting tasks. In this section, we'll explore the key features of gantry hoists, ranging from manual handling to electric power and their capability to lift heavy loads with precision.

- Manual Handling with Gantry Hoists :Manual gantry hoists are a dependable choice for lifting and positioning tasks that require human control. These hoists are operated by hand, making them highly versatile and suitable for scenarios where precise control is essential. Manual gantry hoists are often preferred for lighter loads and tasks that demand a human touch. Their simplicity and ease of use make them a valuable tool for various applications, from workshops to small-scale manufacturing.

- Gantry Hoist Harbor Freight: Affordable Solutions for DIY Enthusiasts :For DIY enthusiasts and small-scale operators, affordability is a paramount consideration. Gantry hoists available at Harbor Freight provide an accessible entry point into the world of lifting solutions. These budget-friendly options cater to the needs of DIYers and hobbyists seeking cost-effective ways to lift engines, heavy equipment, or other loads. Gantry hoists from Harbor Freight offer quality and functionality without breaking the bank, making them a practical choice for those on a budget.

- Gantry Hoist Electric Power: Enhancing Efficiency :Electric gantry hoists represent a significant advancement in lifting technology. These hoists are powered by electricity, offering enhanced lifting capacity and precise control. Electric gantry hoists are particularly beneficial in industrial settings, where efficiency and accuracy are paramount. They allow for the effortless lifting and positioning of heavy materials and equipment, significantly streamlining material handling processes. The electric power source ensures consistent and reliable performance, making them a preferred choice for demanding applications.

- Gantry Engine Hoist: Power for Heavy Loads :Gantry engine hoists are specialized gantry hoists designed to tackle the weighty task of lifting engines. These hoists are engineered to provide the power and stability needed to safely and efficiently hoist engines out of vehicles or onto workbenches. Gantry engine hoists are equipped with features such as adjustable booms and lifting hooks, ensuring secure and precise engine handling. Their robust construction and lifting power make them an indispensable tool for automotive professionals and enthusiasts.

In summary, gantry hoists offer a spectrum of features tailored to diverse lifting needs. From manual handling for versatility to electric power for enhanced efficiency, gantry hoists provide solutions for a wide range of applications. Whether you require precise control for delicate tasks or the muscle to lift heavy loads, gantry hoists are equipped to meet your lifting requirements. As we continue our exploration of gantry hoists, we'll delve deeper into essential factors to consider when selecting the right gantry hoist for your specific needs.

Selecting the Perfect Gantry Hoist: Factors to Consider

Choosing the right gantry hoist involves careful consideration of several key factors. In this section, we'll explore the essential aspects you should take into account when selecting a gantry hoist for your specific lifting needs.

Load Capacity and Lifting Height

Load capacity is a paramount consideration when choosing a gantry hoist. You must determine the maximum weight you'll need to lift regularly. It's crucial to select a gantry hoist with a load capacity that comfortably exceeds your heaviest load. This ensures not only the safety of your lifting operations but also the longevity of the hoist.

Additionally, consider the lifting height required for your tasks. Some gantry hoists are designed for lower vertical lifts, while others offer extended reach. Ensure that the hoist you choose can reach the desired height while maintaining stability and safety.

Type of Gantry Hoist and Application

Understanding the specific requirements of your application is essential. Different types of gantry hoists excel in various scenarios:

- Garage gantry hoists are ideal for automotive enthusiasts and small-scale workshops, offering a space-saving solution for lifting engines and vehicle components.

- Gantry hoists with integrated hoists provide both vertical and horizontal lifting capabilities, making them versatile for a wide range of tasks.

- Electric gantry hoists are suited for industrial settings where efficiency and precision are crucial.

- Manual gantry hoists are versatile and cost-effective, making them suitable for a variety of applications.

Identifying the most suitable type of gantry hoist for your specific tasks ensures optimal performance and efficiency.

Electric vs. Manual Gantry Hoists

Deciding between an electric gantry hoist and a manual gantry hoist depends on your lifting needs and preferences:

- Electric gantry hoists offer efficient, precise, and consistent performance. They are well-suited for heavy and repetitive lifting tasks, especially in industrial settings. Electric hoists reduce operator fatigue and enhance productivity.

- Manual gantry hoists are versatile and require less maintenance. They are excellent for tasks that demand manual control and precision. They are also more budget-friendly and may be preferable for lighter loads and DIY applications.

Safety Features and Compliance

Safety should be a top priority when selecting a gantry hoist. Look for hoists that come equipped with safety features such as:

- Overload protection: This feature prevents the hoist from lifting loads exceeding its capacity, reducing the risk of accidents.

- Emergency stop: An emergency stop button allows for immediate halting of hoist operations in case of unforeseen circumstances.

- Limit switches: Limit switches can be set to stop the hoist at specified upper and lower travel positions, preventing overtravel.

- Compliance with safety standards: Ensure that the gantry hoist complies with relevant safety standards and regulations in your region or industry.

In conclusion, choosing the right gantry hoist requires a thoughtful assessment of your lifting needs, the type of hoist that suits your application, the power source (electric or manual) that aligns with your tasks, and a strong focus on safety features. By considering these factors, you can select a gantry hoist that not only meets your immediate lifting requirements but also contributes to efficient, safe, and reliable material handling operations.

Gantry Hoist Maintenance and Safety: Keeping Operations Smooth and Secure

Ensuring the safe and efficient operation of gantry hoists is essential to maintain productivity and prevent accidents. In this section, we'll explore how to promote safe usage, extend the lifespan of your hoist, and troubleshoot common issues that may arise during operation.

Ensuring Safe Operation

Safety should always be the top priority when operating gantry hoists. To ensure safe usage:

- Operator Training: Properly train operators to use the gantry hoist, including understanding load capacities, control mechanisms, and safety features.

- Regular Inspections: Conduct routine inspections to check for any signs of wear and tear, damage, or malfunction. Address any issues promptly.

- Load Calculation: Always calculate and ensure that the load being lifted falls within the hoist's rated capacity. Overloading can lead to accidents.

- Use Safety Gear: Operators should wear appropriate safety gear, including helmets, gloves, and safety shoes, when operating the hoist.

- Clear Work Area: Ensure that the work area is clear of obstacles and personnel to prevent accidents during hoisting.

- Emergency Procedures: Have clear emergency procedures in place and train operators on what to do in case of an emergency, such as power failures or equipment malfunctions.

Maintenance Tips for Prolonging Lifespan

Proper maintenance can significantly extend the lifespan of your gantry hoist. Here are some maintenance tips to consider:

- Regular Lubrication: Keep all moving parts well-lubricated to reduce friction and wear. Follow the manufacturer's recommendations for lubrication intervals and types of lubricants to use.

- Inspect Wire Ropes or Chains: Check the condition of wire ropes or chains regularly. Look for signs of wear, corrosion, or damage, and replace them as needed.

- Inspect Electrical Components: For electric gantry hoists, inspect electrical components, including cables and connectors, for signs of wear, damage, or loose connections.

- Check Controls: Ensure that all controls and safety features are functioning correctly. Test emergency stop buttons and limit switches regularly.

- Clean and Protect: Keep the hoist clean from dirt, dust, and debris. Protect it from exposure to harsh environmental conditions that may cause corrosion.

- Document Maintenance: Maintain a maintenance log that records inspection dates, repairs, and any replacement parts used. This documentation helps track the hoist's history and aids in identifying potential issues.

Troubleshooting Common Gantry Hoist Issues

Despite proper maintenance, occasional issues may arise during gantry hoist operation. Here are some common issues and possible solutions:

- Hoist Overheating: If the hoist motor overheats, it may shut down. Allow it to cool before resuming operation. Ensure proper ventilation around the motor.

- Lifting Irregularities: If the hoist doesn't lift or lower smoothly, inspect the wire ropes or chains for tangles or knots. Also, check for any obstructions in the path of the hoist.

- Electrical Problems: If the hoist doesn't respond to controls, check the power source, connections, and fuses. In the case of electric hoists, ensure that the power supply is stable.

- Unusual Noises: Unusual noises may indicate issues with the hoist's components. Inspect the source of the noise, and if necessary, consult a technician for further diagnosis and repair.

By following these maintenance tips and promptly addressing any issues that arise, you can ensure the safe and reliable operation of your gantry hoist, prolong its lifespan, and minimize downtime due to unexpected problems. A well-maintained gantry hoist is not only a safer tool but also a more cost-effective one, as it reduces the risk of accidents and the need for frequent repairs or replacements.

Conclusion: Elevate Your Lifting Operations with Gantry Hoists

In our journey through the world of gantry hoists, we've explored the diverse types, applications, key features, and factors to consider when selecting the perfect hoist for your needs. We've also delved into the critical aspects of safety, maintenance, and troubleshooting. As we conclude, let's recap the key points and take a glimpse into the future trends of gantry hoists.

Key Points

- Versatile Lifting Solutions: Gantry hoists offer versatility across various industries and applications, from manufacturing to construction and DIY projects.

- Types of Gantry Hoists: Different types, including garage gantry hoists, those with integrated hoists, electric hoists, and manual hoists, cater to specific lifting needs.

- Applications: Gantry hoists find applications in manufacturing, construction, warehouses, and transportation, providing essential lifting and positioning capabilities.

- Key Features: Whether you choose manual or electric hoists, gantry hoists offer features tailored to diverse tasks, including precise control, affordability, and the power to handle heavy loads.

- Choosing the Right Hoist: Consider load capacity, lifting height, the type of hoist, and safety features when selecting a gantry hoist.

- Safety and Maintenance: Prioritize safety through proper training, inspections, and adherence to safety procedures. Regular maintenance ensures longevity and reliability.

Future Trends in Gantry Hoists

As technology advances and industry demands evolve, the future of gantry hoists holds exciting possibilities:

- Smart Hoists: Integration of smart technology and automation is likely to enhance hoists' capabilities, offering remote monitoring, diagnostics, and predictive maintenance.

- Energy Efficiency: Gantry hoists are likely to become more energy-efficient, reducing operational costs and environmental impact.

- Improved Safety Features: Continued innovation in safety features, such as advanced overload protection and collision avoidance systems, will further enhance user safety.

- Customization: The trend of customizable hoists to suit specific industry needs will continue, providing tailored solutions for various applications.

- Enhanced Durability: Hoists will be built with improved materials and designs to withstand harsh environments and heavy use.

In conclusion, gantry hoists are indispensable tools for a wide range of lifting tasks, offering versatility, efficiency, and safety. By understanding their types, applications, features, and maintenance requirements, you can harness the full potential of gantry hoists to elevate your material handling operations. As technology continues to advance, embracing future trends in gantry hoists will ensure that your lifting operations remain efficient, cost-effective, and safe in the years to come.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch