How Small Portable Gantry Cranes Roll Smoothly in Tight Spaces

Small portable cranes roll smoothly in tight spaces using swivel casters, precision bearings & compact designs for effortless maneuverability.Check how!

Category: Featured

Your Trusted Small Gantry Crane Manufacturer & Supplier

How Small Portable Gantry Cranes Roll Smoothly in Tight Spaces

Portble Small Gantry Crane for Tight Spaces

Importance of Space Efficiency in Workshops

In many workshops, space is limited. A lot of times, workers are faced with narrow aisles, cluttered corners, and packed floors. This can make it hard to move equipment and materials around. The challenge becomes finding equipment that fits and works well without crowding the space.

This is where small portable gantry cranes come into play. Their design helps save space while still getting the job done efficiently. They are perfect for moving loads in tight, confined areas where bigger cranes just won't fit.

Why Small Portable Gantry Cranes Are Ideal for These Environments

- Compact size – These cranes are built for tight spots.

- Portability – Easy to move around, even in cramped workshops.

- Adjustability – Many can be customized to fit the exact needs of your workspace.

Small portable gantry cranes offer the perfect balance of size, strength, and maneuverability for busy workshops. They allow workers to use the space they have, without needing more room for larger equipment.

Overview of How These Cranes Navigate Tight Spaces

Small portable gantry cranes are specifically designed to handle challenges in tight spaces. Their ability to move smoothly through narrow areas is what sets them apart.

Key Features That Make Them Suitable for Confined Areas

- Omnidirectional Wheels – These wheels can move in any direction. They allow the crane to change direction without needing to make a large turn. This is a huge advantage in tight aisles or corners.

- Low Profile Design – Their low height and compact frame fit under overhead obstacles like beams or pipes, making them ideal for confined spaces.

- Easy Maneuvering – With lightweight frames and smooth rolling wheels, these cranes can be easily pushed or pulled into position, even in crowded environments.

These features make small portable gantry cranes perfect for environments where every inch of space counts. They offer flexibility and ease of movement, ensuring tasks are done quickly and efficiently without taking up unnecessary room.

Key Features of Small Portable Gantry Cranes

Compact Design for Limited Space

One of the main advantages of small portable gantry cranes is their compact size. They are specifically designed to fit into narrow aisles and tight corners where larger cranes would be too bulky. The smaller frame allows the crane to be placed close to walls, equipment, and other obstacles without taking up too much space.

This space-saving design ensures that the crane can move loads in cramped workshops or small factories without blocking important areas or restricting workflow. Whether you're working with limited floor space or need to navigate around tight spots, the compact design makes it easy to get the job done.

Omnidirectional Wheels

The omnidirectional wheels are one of the standout features of small portable gantry cranes. These wheels can roll in any direction—forward, backward, sideways, and even diagonally. This ability provides exceptional maneuverability in tight spaces.

- Smooth Movement in All Directions – The wheels allow the crane to glide smoothly and precisely, even when navigating obstacles.

- Easy Turning Without Large Arcs – Since the wheels move freely in all directions, the crane doesn't require much space to turn. This makes it possible to reposition the crane quickly and efficiently in narrow aisles or when working around clutter.

These omnidirectional wheels are a game-changer in tight workshops. They make the crane versatile and easy to control, reducing the risk of collisions and enabling better precision during tasks.

Lightweight Build

The lightweight design of small portable gantry cranes also contributes to their ability to fit into tight spaces. With a reduced weight, the crane can be easily pushed, pulled, or repositioned by just one person.

- Ease of Movement and Control – Lighter cranes don't require much force to move, so they can be repositioned quickly without much effort.

- Convenient for Workers – Since the crane is lightweight, it can be easily adjusted, moved between different locations, or stored when not in use. This reduces fatigue for workers and speeds up operations.

The lightweight build makes these cranes user-friendly and perfect for environments where heavy lifting isn't necessary but precision and mobility are key.

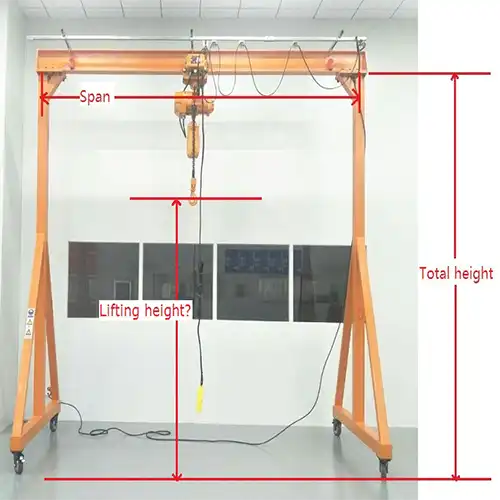

Adjustable Heights and Widths

Small portable gantry cranes offer adjustable heights and widths, giving them the flexibility to work in various environments.

- Adjustable Heights – Many models allow for easy height adjustments to accommodate different load lifting needs, as well as clearance for overhead obstacles.

- Adjustable Widths – The crane can be expanded or contracted to fit different workspace dimensions. This flexibility is crucial when working in areas where space is tight or changing.

This adjustability means the crane can be easily adapted to handle various tasks or fit in environments with unique spatial constraints. Whether the space is narrow or has high overhead clearance, the crane can be customized to fit, making it ideal for tight spots.

Together, these features make small portable gantry cranes the ideal choice for compact, versatile, and efficient handling in limited space environments.

The Role of Steering in Tight Space Movement

Steering Mechanisms for Tight Spaces

In tight spaces, how the crane steers plays a huge role in how easily it can navigate the workspace. The steering systems used in small portable gantry cranes are designed to maximize maneuverability in confined areas.

- 90-Degree Rotating Wheels: Some small portable gantry cranes use wheels that can rotate 90 degrees. This allows the crane to turn on the spot without needing a large turning radius. It's perfect for moving around obstacles or changing direction quickly.

- Omnidirectional Steering: Many cranes feature omnidirectional wheels, which let the crane move in all directions without requiring wide turns. This type of system is especially useful when space is tight and precise movement is necessary.

- Fixed and Swivel Wheels: Some systems combine fixed wheels with swivel wheels that can rotate freely. This helps reduce the amount of space needed to turn, making it easier to handle the crane in tight, crowded areas.

These steering mechanisms help reduce the need for a large turning radius, allowing the crane to change direction smoothly and quickly without requiring extra room. This flexibility is key when working in constrained spaces.

Single-leg Center Rotation of Portable Gantry Cranes for Easy Rolling

1 T, 2 Ton, 3 Ton, 5 Ton Small Gantry Crane on Rollers with Centerline Span Rotation for Tight Space

90-degree Wheel Rotation of Portable Gantry Crane for Sale 1 Ton to 10 Ton

Smooth Rolling and Maneuvering

Along with the steering system, smooth rolling and maneuvering are critical for efficiently operating a small portable gantry crane in a tight workspace. The crane's movement needs to be fluid to avoid scraping or damaging the floor or surrounding equipment.

- Low-Friction Wheels: Cranes with low-friction wheels roll easily, requiring less force to move. These wheels are designed to glide across surfaces without dragging, helping to avoid floor damage and making the crane easier to push or pull.

- Smooth Bearings: The bearings in the wheels ensure that the crane rolls smoothly without any jerky movements. This helps to prevent wear and tear on the crane and minimizes noise.

- Controlled Movement: With a smooth rolling system, operators can control the crane's speed and direction with ease, preventing unwanted accidents or collisions.

The combination of low-friction wheels and smooth bearings provides significant benefits in terms of maneuverability. It makes the crane easier to operate, reduces the risk of accidents, and ensures a clean workspace free from damage. This is especially important in tight, sensitive environments where precision is key.

These steering and movement features make small portable gantry cranes highly effective for maneuvering in narrow, crowded areas, allowing workers to maximize their workspace while maintaining smooth and efficient operations.

Benefits of Small Portable Gantry Cranes in Tight Spaces

Maximizing Available Space

Small portable gantry cranes are perfect for making the most of limited space. Their compact design allows them to fit into narrow aisles, tight corners, and other small spaces where larger equipment just wouldn't work.

- Optimized Movement: These cranes can navigate through crowded workspaces without taking up unnecessary room.

- Better Space Utilization: By moving with ease, they help free up space for other tools, materials, and tasks. Workers can use the entire workshop, without the crane getting in the way.

- Flexible Positioning: Whether in a corner or against a wall, these cranes can be easily moved and positioned where needed, helping to make use of every available inch.

By offering flexibility in placement and movement, small portable gantry cranes ensure that workspaces are fully utilized without sacrificing mobility or functionality.

Efficiency in Operations

When you're working in tight spaces, every minute counts. Small portable gantry cranes help improve operational efficiency by making tasks quicker and smoother.

- Faster Repositioning: Thanks to their maneuverability, cranes can be quickly repositioned to lift or move materials without having to navigate large spaces.

- Less Time Navigating Obstacles: The smooth steering systems reduce the time spent trying to get around obstacles or changing direction. This means less downtime and faster job completion.

- Streamlined Workflows: The ease of movement leads to faster task execution, allowing workers to focus on their main job rather than getting caught up in repositioning equipment.

With these cranes, workers can handle materials in tight spots with speed and precision, resulting in improved overall workflow and time savings.

Enhanced Safety

Working in tight spaces can often increase the risk of accidents, as there's less room to move around. However, small portable gantry cranes reduce this risk by offering better control and flexibility in confined environments.

- Controlled Movement: The lightweight design and smooth steering systems provide precise control, reducing the chance of collisions or accidents.

- Reduced Risk of Damage: With easy movement and no large turns required, there's less chance of the crane scraping walls, floors, or other equipment.

- Improved Stability: These cranes often feature stable wheel bases and low profiles, preventing tipping and ensuring safe lifting and moving.

By allowing operators to have better control over the crane in tight spaces, these cranes reduce the likelihood of workplace accidents, creating a safer environment for everyone.

Overall, the benefits of small portable gantry cranes in tight spaces are clear: they maximize space, improve operational efficiency, and provide a safer work environment—all while maintaining high mobility and flexibility.

Choosing the Right Small Portable Gantry Crane

Considerations for Tight Spaces

When selecting a small portable gantry crane for tight spaces, there are several key factors to consider to ensure it meets the needs of your workshop.

- Space Availability: Before choosing a crane, assess the available space. Measure the width and length of the space where the crane will be used. Consider how much room is needed for the crane to move freely without interfering with other equipment or workers.

- Load Capacity: Choose a crane that can handle the weight of the materials you'll be lifting. Ensure the load capacity is sufficient for the tasks but not unnecessarily large, as this could affect the crane's mobility in tight spaces.

- Steering Mechanism: The type of steering system is critical for maneuvering in confined spaces. Opt for cranes with omnidirectional wheels or 90-degree rotating wheels to ensure smooth movement in narrow aisles and around obstacles.

- Height and Width Adjustability: Consider if the crane needs to fit under overhead obstacles or if it needs to pass through narrow doorways. Cranes with adjustable heights and widths can provide the necessary flexibility to work in various environments.

- Weight: The crane's weight can affect how easily it moves. A lightweight crane will be easier to push and reposition in small spaces, whereas a heavy crane might be harder to maneuver.

These factors will guide you in selecting a crane that is both practical and efficient for your specific workspace needs.

Recommendations Based on Workshop Layouts

Each workshop has its own layout, so choosing the right small portable gantry crane requires assessing how the crane will fit into your unique space constraints.

- Narrow Aisles or Crowded Areas: If your workshop has narrow aisles or is filled with equipment, opt for cranes with omnidirectional wheels that can roll in any direction. This allows the crane to make precise movements and avoid unnecessary turns, saving time and effort.

- Tight Corners: For workshops with many corners or obstacles, a crane with 90-degree rotating wheels is ideal. It allows the crane to change direction quickly without requiring a large turning radius, making it easier to navigate tight corners.

- Overhead Obstructions: If your workshop has overhead beams or structures, choose a crane with adjustable heights. This will allow you to lift materials under low ceilings or adjust the crane's height based on the job requirements.

- Portable Use: If you need to move the crane between different workstations, consider a lightweight model. This will make it easier to carry the crane from one area to another without straining workers or taking up too much time.

Choosing the right small portable gantry crane depends on how your workshop is arranged. By evaluating the layout and understanding the specific requirements for mobility, load capacity, and adjustability, you can find the best crane for your needs.

A well-chosen crane will ensure that your operations are efficient, space is maximized, and workers are able to perform tasks with ease in tight spaces.

Conclusion

Small portable gantry cranes offer incredible benefits when working in tight spaces. Their compact design allows them to fit into narrow aisles, tight corners, and small work areas without obstructing workflow. These cranes are highly maneuverable, with features like omnidirectional wheels and adjustable heights that make it easier to navigate around obstacles and work in confined spaces.

- They help maximize available space by providing flexible positioning without compromising mobility.

- Their lightweight build ensures easy handling, allowing for quick repositioning and improved efficiency in operations.

- Safety is also enhanced, with better control and precision, reducing the risk of accidents in tight areas.

With these features, small portable gantry cranes are essential tools for maximizing both space and productivity in workshops with limited space.

When choosing the right small portable gantry crane, it's important to evaluate your workshop's specific needs. Consider factors such as the available space, load capacity, steering options, and the layout of your workspace. Choose a crane that offers the flexibility to handle a variety of tasks while fitting comfortably into your environment.

- If your workshop has narrow aisles or frequent obstacles, opt for cranes with omnidirectional wheels or 90-degree rotating wheels to ensure easy navigation.

- For environments with low overhead clearance or changing work requirements, look for cranes with adjustable heights and widths.

- Consider the weight of the crane for ease of movement and operation, especially in tight spaces.

By carefully selecting the right crane, you can optimize space, improve efficiency, and create a safer and more productive work environment. Make sure to choose a low built hoist and crane that meets both your operational needs and space constraints for the best results.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch