Full-automated Overhead Crane for Warehouse Crane System Unmanned

Automatic warehouse crane system, a full automated overhead crane, with intelligent crane monitoring, unmanned crane control , high precision positioning & efficient storage to improve your operation efficiency & effective anti collision & anti swing smart crane features to ensure your safety. Customized smart overhead crane system for your warehouses are available.

Automated overhead crane system

Automatic warehouse overhead crane system

A ground central control system and an automatic warehouse crane system are the main components of the full-automatic unmanned warehouse crane system. The ground central control system consists of the ground management server, the ground control system, the remote control system, the HMI, the safety control system, the wired and wireless network, the video monitoring system, and other components. The automatic warehouse crane system includes the crane mounted PLC, automatic warehouse crane positioning device, remote control receiver, wireless network receiving device and automatic warehouse crane electric control PLC.

Hardware requirements of full-automted overhead crane system

The following hardware devices are required for the installation of an unmanned automatic warehouse crane system:

- Position sensors with +/- 1cm accuracy in the three dimensions of X/Y/Z.

- Sensor series mounted on clamps (anti-clamping, anti-collision, opening and closing, aligning, etc.)

- Encoder to control clamp rotation (if required)

- Anti-swing device to prevent steel wire rope from swinging when lifting materials

- Weight sensor

- Inverter-driven drive system

- Independent anti-collision system that is directly linked to the inverter

- Fast and stable data transmission system

Hardware devices to improve system performance (Optional):

- Optical identification system for detecting the size and position of materials.

- Equipment monitoring system.

- Vehicle identification system (incoming/outgoing).

Topological diagram of automatic warehouse crane control system

Safety requirements

The unmanned automatic warehouse crane system must make sure that there are never any incidents involving personal safety or harm to other machinery. To use the unmanned automatic warehouse crane system, we must ensure the following:

- Guard rails are installed in the unmanned automatic warehouse crane's working area, switch devices are installed on the guard rails' doors, and switch signals can be received by the unmanned automatic warehouse crane control system. When someone opens a door of the guard rail , the unmanned automatic warehouse crane will come to a halt and strop running.

- The basement is outfitted with safe and dependable equipment that allows remote control of the automatic warehouse crane. As a result, ground control personnel can stop the automatic warehouse crane at any time for safety or emergency reasons.

- There is a separate anti-collision system as well as a traveling range control system. When the unmanned automatic warehouse crane system detects a dangerous distance, it will execute emergency deceleration or stop, depending on the signal from the anti-collision system.

- The automatic warehouse crane system is directly linked to the overhead crane's driving system.

- The height sensor system makes sure that the automatic warehouse crane is only permitted to move when the clamp is raised to a specific safe height based on the data from the height sensor.

- As much as practical, redundant sensor designs have been used.

- It is advised that a hazard prevention system are installed to detect and assessed the risks

Every possible risk related to the operation safety of the automated warehouse crane can be identified and addressed by the safety risk prevention system in the electromechanical system. Prior to implementing the warehouse crane system, the danger prevention system must be installed.

Automatic Control System

System architecture of warehouse automated overhead crane system

- The automatic control system adopts a three-layer architecture design:

- WMS - Plan management layer

- Incoming and outgoing materials , locations of materials, height of materials, etc.

- ECS - Equipment management layer,

- task assignment, equipment scheduling , equipment failure monitoring, etc.

- Automatic automatic warehouse cranes system - Terminal device

- Automatic warehouse crane driving system, positioning system, detecting system, control system, safety system, etc.

Crane management system of full-automated crane system

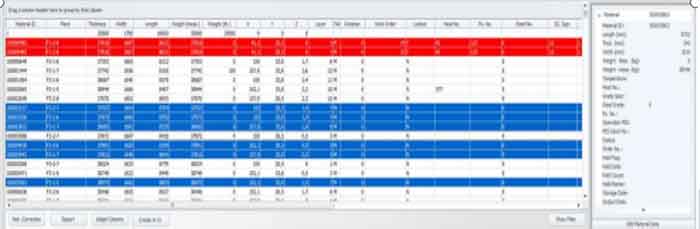

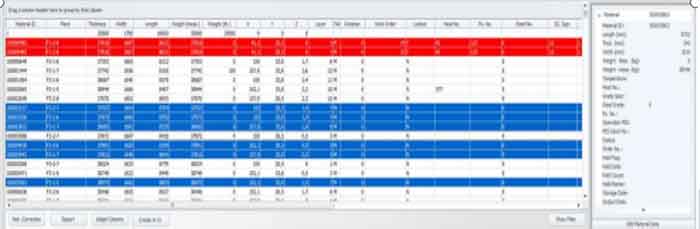

The client software is used to operate and monitor the warehouse management system's daily operations, which include the following functions:

- Graphical display interface

- Displaying details of materials

- Statistical report of stocks

- Storage history of materials

- Registration management of transportation vehicles in the warehouse area

- Management of operation instructions

The toolbar at the top of the interface allows users to easily switch between functions such as vehicle management, operation instruction management, operation mode switching, and so on.

Warehouse crane camera

Overhead crane momitoring

The main window displays the status of the warehouse area, and the user can use it to send operation instructions directly to the designated automatic overhead crane. The window at the bottom of the interface can display detailed information about the selected materials, the production loading plan, customer orders, and so on.

Positioning technology

The following three methods are commonly used for detecting the position of the crane and trolley of an automatic warehouse crane:

- The absolute address information obtained via absolute coded scale position detection is true and reliable, with no error code or accumulation error. The absolute coded scale operates in a non-contact mode.

- It can continuously and accurately detect the absolute address within the traveling range of the automatic warehouse crane using Gray bus position detection with a detection accuracy of 5mm, completely meeting the requirement of accurate positioning of the automatic warehouse crane.

- In laser ranging, the process from the laser transmitter transmitting laser pulses to the reflecting plate to the reflected light being received is timed, and the distance between the laser and the target can then be calculated.

There are several technical methods for detecting the position of an automatic warehouse crane while it is in operation. The positioning technology used for a specific project is determined by the actual situation of the warehouse area, such as the working environment, the size of the warehouse area, the number and layout of automatic warehouse cranes, and so on.

The following methods are commonly used by automatic warehouse cranes to detect Z-direction position:

An encoder can be installed on the hoisting machine to measure vertical distances, and the encoder will send the position to the PLC via communication.

The encoder is used in the unmanned automatic warehouse crane system for more than just vertical data. When the automatic warehouse crane is lifting materials on moving equipment (walking beam, roller table, etc.), the moving equipment can be locked/unlocked based on height data detected by the encoder, preventing accidents caused by sudden movement of the equipment during material lifting. Furthermore, the unmanned automatic warehouse crane system begins traveling in the horizontal direction after determining that the material has been lifted to a certain height based on encoder data.

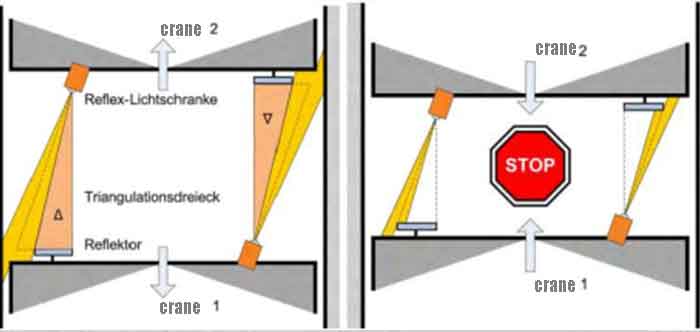

Anti-collision system

The automatic warehouse overhead crane's anti-collision function is critical. The anti-collision system must operate independently of the automatic warehouse crane's other control systems. As a result, even if the PLC system or positioning device fails, the anti-collision system can continue to function normally, preventing collision accidents between automatic warehouse cranes.

Some of the most common anti-collision technologies are as follows:

- Grating

- Laser

- Radar or radio waves (frequency 5.8GHz or 61GHz)

Optical (grating or laser) anti-collision technologies are commonly used in aluminum foil plants for automatic warehouse cranes. For extremely harsh working conditions, radar anti-collision technology can be considered. The specific technical proposal must be meticulously designed to meet the actual needs of the customers.

Grating technology is used in the most common anti-collision system. On one automatic warehouse crane, a grating transmitter is installed, and on an adjacent automatic warehouse crane, a reflecting plate is installed. A specific angle is formed by adjusting the grating transmitter and the traveling track. The light transmitted from the grating will hit the reflecting plate of the adjacent automatic warehouse crane when the distance between the two cranes approaches a certain level. The system will send an alarm signal after receiving the reflected signal. If the safety standard is high, two sets of grating anti-collision systems (using different communication channels) can be installed on each unmanned automatic warehouse crane.

Anti swing for the full automated warehouse crane systems

Mechanical anti-swing

The most effective anti-swing is mechanical, but it must be implemented during the automatic warehouse crane's design and manufacturing phases. The mechanical anti-swing transformation of the delivered automatic warehouse cranes is quite challenging, and a poor transformation could compromise the automatic warehouse cranes' performance in terms of safety.

The mechanical anti-swing mechanism reduces clamp swinging caused by the automatic warehouse crane's acceleration and deceleration through the special design of lifting equipment or steel wire rope, and the design details vary depending on the crane manufacturer.

Electrical anti-swing

Due to the flexibility of the steel wire rope, the lifting appliance will inevitably wing when the crane and trolley come to a stop while operating the automatic warehouse crane. Experienced operators will anticipate swinging direction and adjust the speed of the crane and trolley accordingly to reduce clamp swinging, but swinging cannot be completely avoided.

The anti-swing control system is built into the inverter and is simple to debug. Within two swing cycles, it can eliminate more than 95% of swing and ensure that the swing amplitude is less than 30mm. The anti-swing system is controlled by an electronic switch, and no swing angle detection device is required. To achieve the purpose of anti-swing, the inverter calculates and adjusts the inverter's output speed and acceleration in real time based on the output speed and acceleration, anti-swing pendulum length, and anti-swing mathematical model. The inverter's actual output speed curve is as follows.

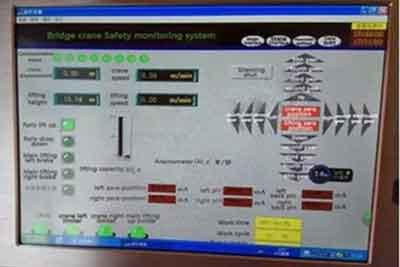

Equipment status monitoring system

The system monitors the status of key devices such as electrical equipment, safety doors, clamps, and other devices of the automatic warehouse crane, receives information from these devices, controls the operation of the devices comprehensively, monitors the status of the devices, understands the running status of the devices through monitoring parameters, and assists operators in device failure judgment, ensuring safe production, avoiding unnecessary shutdown, and reducing costs.

Video monitoring system

The intelligent storage system includes an unmanned automatic warehouse crane monitoring system. The monitoring system focuses on monitoring the operation of the automatic warehouse crane, incoming and outgoing loads, incoming and outgoing personnel and vehicles in the warehouse area based on the warehouse area's current situation. The camera positions will be arranged in the warehouse area according to the stacking area where steel coils are placed and the operating area of the automatic warehouse crane.

The operation of the automatic warehouse crane, the lifting of loads by the lifting appliance, and the walking beam area are designed as the project's monitoring focus. The monitoring scheme is divided into two parts: video monitoring for ground warehouse status and video monitoring for automated overhead crane devices.

Vehicle identification system

The vehicle identification system correctly calculates the coordinates of objects or material loading and unloading positions based on the information of various types of vehicles and sends them to the warehouse management system. The system also allows the operators to select the coil loading and unloading positions.