Waste handling cranes

Solid waste and garbage handling crane is an grab overhead travelling crane with process crane design to meet the particular application in the incineration power plant. The refuse and waste handling grab cranes can be designed automatically for a greater effectiveness and an increase in work cycles, and to reduce the risk of equipment failure. Different process crane configurations from semi-automated waste cranes to fully automated waste cranes are available for the whole processing in the waste management plants. Customized overhead travelling cranes with crane grab are available for wastes, refuse and garbage handling with high efficiency and safety.

Main parameters & specifications

- Crane type : Automatic waste handing overhead travelling cranes with grab

- Lifting capacity of waste handling crane : 3.2t-10t

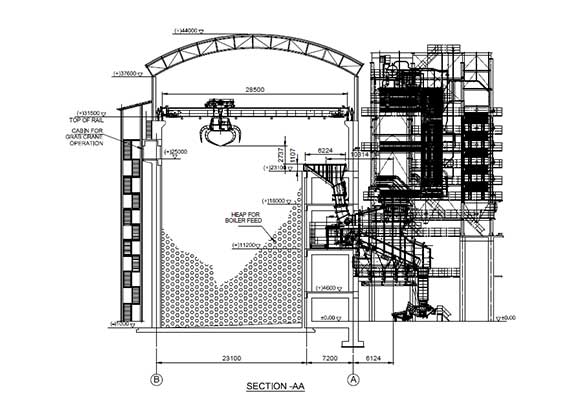

- Span of waste handling crane : 7.5m~25.5m

- Working class of waste handling crane : A7,A8

Waste crane & garbage cranes with process crane designs for your specific waste & recycling centre and incineration plant. Complete waste handling cranes services are available. Contact us to get free crane consultation and waste crane CAD drawing of your process designed industrial cranes.

Advantages of waste handling overhead travelling cranes

- Reasonable crane structure, box-girder crane design, light dead weight

- Favorable performance, accurate and smooth operation, safe and reliable travelling crane

- Low noise, easy operation, high efficiency and safety

- High exchangeability for parts and components , easy and convenient crane maintenance.

Features of garbage disposal overhead travelling crane

- High lifting height: Anti-sway operation, waste cranes with large lifting height.

- Heavy work load: High load rate, high work frequency, heavy duty crane

- Reliable in harsh conditions: Waste cranes with process crane designs to fit the harsh conditions of incineration plant with high temperature, humidity, dusty and gas corrosive,etc.

- Real-time dynamic measurement, to ensure the reliable operation of waste cranes and garbage cranes.

- Grab status monitoring, fault diagnosis alarm and report statistics, effective preventing of crane failure, ensure smooth production.

Automatic & intelligent waste & garbage handling cranes

The process industrial cranes are designed for effective handling of refuse, waste and garbage in the incinerator. The industrial overhead travelling cranes are adopted in the waste processes of mixing, stacking, handling and stirring, to help the waste and garbage sorting and recycling to make sure the uniform of waste composition and calorific value, and keep the stable combustion in the incinerator.

Effective waste & garbage handling: overhead travelling cranes for feeding, fetching, stacking, & mixing

Basic operation of waste & garbage handling overhead travelling cranes in the incinerator:

- Feeding. Grab and feed the garbage & waste into incinerator.

- Lifting and transport. Grab and transport waste & garbage near the discharge door and to prevent waste blocking by serious control of waste quantity in the waste pit to keep the inventory within 3~5d.

- Mixing. Mix and stir the garbage to extract water content, minimize the fermentation time and ensure incineration safety.

- Fetching. Fetch non-flammable substance and objects in the pit.

- Weighing. Weigh the garbage and then dump the wastes into the incinerator.

grab overhead crane for waste handling

Manual, semi-automatic & fully automatic control of wastes crane & garbage cranes

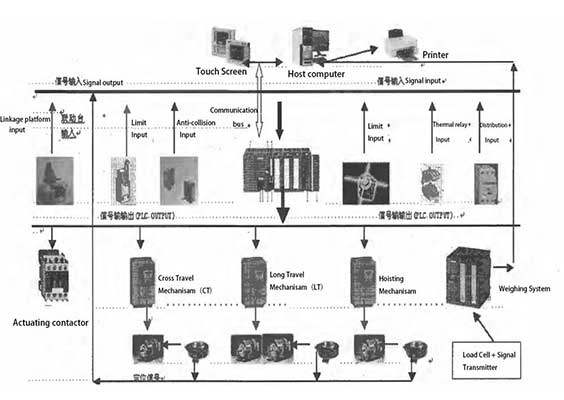

With automatic crane design, the garbage handling cranes can intelligently and automatically to complete the processes of feeding, lifting, transporting, mixing, fetching and weighing, etc. There are three levels of automation for selection including, the manual, semi-automatic, and fully automatic control.

- Manual Type: The garbage handling cranes are controlled by operator with the linkage console.

- Semi-Auto Type:The operation of crane grab is manual control, and the automatic control covers the transporting to charging port, weighing and charging.

- Fully-Auto Type: The waste handling cranes start to work on receiving the charging signal, fully automatic control on grab operation, waste grabbing, lifting, transporting to the charging port, weighing, charging, and returning back to the position, which will be repeated according to your setting automatically.

Waste and garbage handling cranes are dedicated industrial overhead cranes with process crane designs to meet the particular applications of the waste incineration power plant with advanced automatic crane operation technology and intelligent identification technology based on the requirements of customers' needs.

Automatic control for waste handling

Waste cranes, process crane design, maximum efficiency

The overhead travelling crane adopted in the incinerators are required in operation continuously at maximum efficiency to ensure the overall workflow. Usually, there are two garbage cranes and waste cranes installed above the waste pit, with one overhead travelling crane as a backup. The primary waste handling crane conducts the main operating works while the other is being serviced.

- The process crane designs of waste handling cranes are largely defined by the total burning capacity of incinerators, the layout of waste handling area, the type of waste, and the time of waste receiving and processing, and also including the waste mixing which are required to be stirred thoroughly to ensure the processing efficiency, etc.

- What's more importantly, the waste handling cranes can be processed with advanced automatic crane operation technology and intelligent identification technology based on the requirements of customers' needs. The waste handling crane not only can be controlled by the operator console, but also by remote control.

- Complete crane services and turnkey project services are available for waste handling cranes for incineration power plant. Contact us to get free consultation on your incineration plant crane and get your process designed waste crane drawing now.

How to select bridge cranes for waste-to-energy facilities

Waste-to-energy facilities are one of the hardest and most taxing environments for overhead cranes because of their high productivity requirements, constant operation, dirt, and extreme temperatures. Therefore, choosing the appropriate waste cranes is crucial to achieve the highest levels of safety and reliability with overhead cranes:

The first thing you need know is how much feed your hoppers will need overall.

Waste-to-Energy cranes' main job is to transport waste loads to the hoppers that go to the incinerators. More boiler uptime is a common goal for facilities. To feed the incinerators at a specific burn rate, the cranes must be able to transfer enough tonnage per hour.

It is crucial to check cycle timings and establish how many hours per day and how many tons of material will be processed every hour. The entire cycle periods depend on the density of the material being moved as well as the crane's capacity, speed, and grapple size.

Cycle times should be planned based on the busiest crane usage (i.e. peak receiving hours for waste collection trucks). Either overhead crane in a two-crane system ought to be able to handle receiving and feeding throughputs on its own.

Second what is the layout of your handling area?The configuration of your waste-to-energy facility's handling area has a significant impact on the type of overhead cranes used and how well they operate. Wast-to-Energy cranes often work in tight horizontal spaces with lengthy vertical lifts. In this confined area, the bucket must be able to move in three dimensions without colliding with incoming waste being dumped into the pit.

The safety and productivity of the entire facility are impacted by the layout planning of the waste processing area. It is crucial that the receiving area is planned such that there is enough room for trucks and received waste during peak hours, without the cranes having to deliver and dump their loads while operating in the area above the vehicles and employees.

Additionally, the mixing area needs to be planned so that either one or both cranes can mix effectively automatically. Cycle-time calculations highly rely on the placement of your hoppers and the routes your cranes take.

Does the supplier can supply variety of automation modes in waste handling cranes?Cranes for garbage processing would benefit from having a mechanism to choose between full- and semi-automation. Load positioning and collision avoidance are made easier by automation in garbage handling cranes. Additionally, it lessens operator fatigue and may lessen the chance of crane failure.

Automation features sometimes include monitoring devices that let the process be managed from the operator's position or from a centralized control center located far from the garbage pit. Higher productivity, a more reliable and predictable process, and enhanced equipment and worker safety.

Semi-automation, feeding automation, mixing automation, and unmanned complete automation are just a few of the automation modes that are available to best meet the requirements of your operation.

Contact us today to get your customized waste handling crane design tommorrow.