Lifting Electromagnet Specifications, Tailored for Your Steel Hoisting

Crane electromagnet tailored for particualr steel loads handling with special tonnages, dimensions, shapes, & temperatures, i.e,steel scraps, billet, girder, etc.

Category: Hoist and Crane Specifications

Your Trusted Overhead Crane Electromagnet Manufacturer & Supplier

Lifting Electromagnet Specifications, Tailored for Your Steel Hoisting

500kg, 5 ton, 8 ton, 10 ton, 12 ton, 16 ton, up 22 ton

Customized electromagnet cranes with tailored specifications are available to meet particualr loads handling with special tonnages, dimensions, shapes, and temperatures. Generally, our electromagnets are widely used for clients to steel scraps, billet, girder, slab, wire (coiled bar), bundled rebar, round steel pipe, heavy rail, steel plate, coiled steel, and other materials, etc.

What is electromagnets?

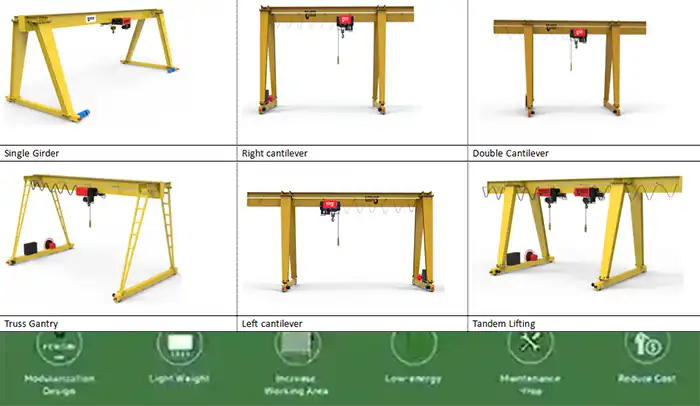

Lifting electromagnet usually be used with eletromagnet overhead cranes and electromagnet gantry crane and applied in steel factory, ship-building company, heavy machine manufacturing, steel storage, port and railway. It is to load ferro magnetic material instead of labour power to improve safety and efficiency.

It is the most ideal electromagnetic manipulator, freeing people from hazardous, abominable, and heavy labor. It also applied to some undesirable conditions, such as high temperatures, being submerged in water, being dusty, highly toxic, chilly, and wild. It is a necessary electronic device in metallurgy, transportation, and machine manufacturing.

The lifting electromagnet control is a complete control system. It has the ability to command the lifting electromagnet to increase its suction by using methods such as electricity excitation, cutting power degauss, or forced excitation. Furthermore, it adjusts the suction to achieve the unloading of the steel plate; even when the power is turned off, the lifting iron's suction can be maintained to prevent the steel object from falling off and injuring people or other equipment.

We also design and manufacture non-standard electromagnets based on the needs of our clients.

How to use electromagnet safely?

How to operate electromagnet safely? The following operation notices for your reference. If you have any need or problem about the electromagnets , please feel free to contact us.

Operating Notice of lifting electromagnet

- Check all welding joints on non-magnetic guard boards or other parts on a regular basis.

- Check the junction box and the cable, and repair or replace it as soon as possible.

- Examine the electromagnet insulation resistance and coil dc resistance on a regular basis.

- Examine the electrical control equipment.

- Examine the working current of an electromagnet in its thermal state. Stop it once over time and find how it happened.

- Maintain stable current and voltage, avoid unnecessary magnetic disturbance, ensure quick unloading, and avoid high and middle voltage impact current coils.

- Use the electromagnet in accordance with the operating rules; do not change the current arbitrarily.

- lIt must be used within the supposed working condition range.

How are the lifting electromagnet are produced?

First and foremost, we guarantee product quality of all our electromagnets. We adopt straightforward procedures, establishing and improving a multi-level quality guarantee system, and rigorous testing procedures. It is strictly banned to use unqualified materials and spare parts in production processes, and all of the electromagnets provided are of 100% qualified rate to achieve high lever of customer satisfactions.

Main production stages of lifting electromagnet

- Purchasing and sorting raw material and parts.

- Parts manufacture and quality inspection.

- Assembly and quality inspection.

- Insulation glue water

- Drying, cooling

- Finished product processing.

- Inspection before delivery.

Welding process of crane electromagnet

Lifting electromagnet welding includes shell structure welding, non-magnetic guard board and shell welding (including cast steel shell),which all adopt arc welding.

- Welding of electromagnet shell structure -Low carbon steel plate is used to weld the structure, with the features of high density , few leftover materials, and short production, making it suitable for simple, small batch, and short production products. However, its integrity and sturdiness are inferior to that of cast steel parts.

- The non-magnetic guard board and shell welding -The non-magnetic guard board is made of non-conduction alloy steel, whose material is 1Cr18Ni19Ti , manganese board is 20Mn23AL. It is dissimilar steel welding with shell, easy to craze. So choosing electrode is very important. Our factory use the Austenite stainless steel electrode with good plasticity and crack resistance. Andmore, the drawing should tell that the welding parts must be heated when in low room temperature in winter.

Preparation before electromagnet welding :

- Preliminary working: the weldable joint is stressed. (For example, up cover board and boundary pole, up cover board and iron core) It must be finished by machine work with a minimum fineness of 6 grade. Straightness and flatness must be at least 9 grades. And the weld groove is created in accordance with the design drawing.

- Choose an electrode: T42 steel electrode is suitable for electromagnets with mild steel shells.

Lifting requirements for electromagnet welding

- Welding request: The welding on the shell must comply with GB986 standards. In accordance with GB3323 standards, lug welding is classified as H class. These requirements must be noted in the drawing and communicated to the welding demanding.

- Welding process requirements: the drawing should emphasize the importance of keeping the connection tight and avoiding being out of shape while working.

How to select electromagnets for your application?

Electromagnets selection Tips

the parameter needed when choosing electromagnets for your applications:

- Crane type: ___? ( What type of cranes will be used? e.g. 10+10T)

- lifting object:___? (e.g. square billet,thin plate,vertical coil, steel rob, rebar, etc. )

- lifting object's size and quality:___? (e.g. Square billet: 150*150*12000mm,lift 6 pieces in normal temperature)

- Controlling cabinet: ___? (e.g.ordinary type, magnetic power type, adjustable magnetic type. )

- whether it needs inverter power supply or not:___?

Main types of electromagnets and specificaitons

Customized electromagnet cranes with tailored specifications are available to meet particualr loads handling with special tonnages, dimensions, shapes, and temperatures. Generally, our electromagnets are widely used for clients to steel scraps, billet, girder, slab, wire (coiled bar), bundled rebar, round steel pipe, heavy rail, steel plate, coiled steel, and other materials, etc.

Hot sales electromagnets for your selections

16 ton

16 ton

8 ton

8 ton

10 ton

12 ton

22 ton

8 ton

5 ton

Laser cutting machine feeding 400kg

Cold rolling plate carry500kg

Laser cutting machine feeding 500kg

MW22 series of electromagnets for ingot & large rolling billet handling

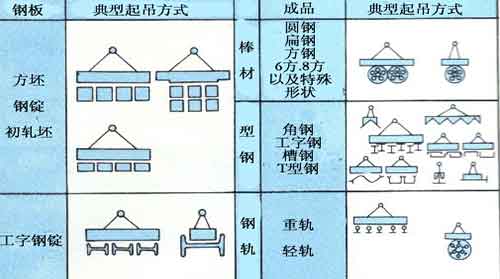

Application:the electricomagents are used for lifting steel ingot, Large rolling billet early and structural steel. Different steel have different Magnetic circuit design. This series have many electromagnets for lifting different object: such as "I" steel, cogged ingot , beam slab and wire coil.

electromagnets for ingot & large rolling billet handling

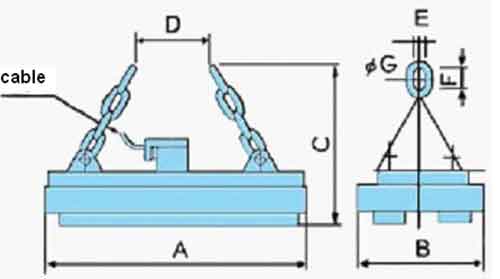

Dimension drawing of large ingot handling electromagnet

Tech. Parameter in Normal Temperature

Type | MW22-8060L | MW22-11060L | MW22-120100L | MW22-140100L | MW22-140150L | |||||||

Dimension (mm) | A | 800 | 1100 | 1200 | 1400 | 1400 | ||||||

B | 600 | 600 | 1000 | 1000 | 1500 | |||||||

C | 900 | 900 | 950 | 1100 | 1100 | |||||||

D | 300 | 300 | 300 | 900 | 900 | |||||||

E | 110 | 110 | 125 | 125 | 125 | |||||||

F | 180 | 180 | 200 | 200 | 200 | |||||||

G | 32 | 32 | 38 | 38 | 38 | |||||||

wight(kg) | 1000 | 1300 | 2400 | 2000 | 3000 | |||||||

Current(A) | 34.1 | 27.3 | 45.5 | 63.6 | 81.9 | |||||||

Power(kw) | 7.5 | 6 | 10 | 14 | 18 | |||||||

Lifting capacity | Min. size | 10 "I" steel | 10 "I" steel | 10 "I" steel | 10 "I" steel | 10 "I" steel | ||||||

Max. size | 20a "I" steel | 30a "I" steel | 63a "I" steel | 50a "I" steel | 50a "I" steel | |||||||

Max. Length (mm) | 2000 | 2000 | 2000 | 2000 | 2000 | |||||||

Bundle width(mm) | 500 | 500 | 1000 | 650 | 650 | |||||||

Single bundle weight(kg) | 5000 | 4000/6000 | 15000 | 3000/5000 | 4500/6000 | |||||||

Bundles | 4pieces in 1 bundle | 4pieces in 2or1 bundles | 4pieces in 1 bundle | 4pieces in 4or2 bundles | 4pieces in 4or2 bundles | |||||||

Electromagnets with beam spreaders for various loads handling

Electromagnet spreader for ingot, billet, round steel, H beam, and steel beam handling

Tech. Parameter in Normal Temperature

Model | MW22-11090L | MW22-12595L | MW22-15075L | MW22-15095L | MW22-17065L | MW22-17080L | |

Dimension (mm) | A | 1150 | 1250 | 1500 | 1500 | 1700 | 1700 |

B | 900 | 950 | 770 | 960 | 650 | 820 | |

C | 740 | 1150 | 685 | 1120 | 770 | 700 | |

D | -- | 300 | -- | 500 | -- | -- | |

E | -- | 125 | -- | 125 | -- | -- | |

F | -- | 200 | -- | 200 | -- | -- | |

G | -- | 38 | -- | 38 | -- | -- | |

Weight (kg) | 2500 | 3000 | 2400 | 3860 | 2720 | 3100 | |

Current (A) | 38 | 39 | 36.9 | 45.8 | 42.6 | 38.5 | |

Power (kw) | 8.6 | 8.6 | 8.12 | 10 | 9.4 | 8.5 | |

Lifting capacity e.g. two electromagnets | cogged ingot (mm) | 200×240×12000 4pieces | 256×295×12000 4pieces | 4electromagnets 130×130×8000 8pieces | 320×420×10000 2pieces | 150×150×10000 8pieces | 240×320×10000 2pieces |

beam slab (mm) | 500×240×10000 2pieces | 570×300×10000 2pieces | 556×300×10000 2pieces | -- | 540×300×10000 2pieces | ||

Model | MW22-16095L | MW22-20090L | MW22-25090L | MW22-7090L | MW22-16090L | MW22-17090L | |

Diemension (mm) | A | 1600 | 2000 | 2500 | 700 | 1600 | 1700 |

B | 960 | 900 | 900 | 900 | 900 | 900 | |

C | 1155 | 1700 | 1700 | 1000 | 1275 | 815 | |

D | 640 | 600 | 600 | 200 | 700 | -- | |

E | 125 | 230 | 230 | 125 | 125 | -- | |

F | 200 | 370 | 370 | 200 | 200 | -- | |

G | 42 | 70 | 70 | 38 | 38 | -- | |

Weight (kg) | 4130 | 5500 | 6000 | 1500 | 3000 | 3300 | |

Current (A) | 39.8 | 68.2 | 68.2 | 34 | 62.7 | 60 | |

Power (kw) | 8.8 | 15 | 15 | 7.5 | 13.8 | 13.2 | |

Lifting capacity e.g. two electromagnets | cogged ingot (mm) | -- | 330×550×10000 2pieces | 330×550×10000 3pieces | 4 electromagnets 115×115×20500 4pieces | 4 electromagnets 115×115×20000 10pieces | 150×150×12000 10pieces |

beam slab (mm) | -- | 1200×400×10000 1pieces | 1200×400×10000 2pieces | ||||

MW5 series electromagnet for steel scrap handling

Application: the mw5 series electromagnets are used to carrying cast iron ingot steel ball and some steel waste, steel scrap handling

Dimension drawing of electromagnet for steel scrap handling

Tech. Parameter in Normal Temperature

Model | Current(A) | Power(KW) | Lifting capacity(KG) | weight(KG) | Dimension(mm) | ||||||

Steel ball | steel ingot | cutting | A | B | C | D | E | ||||

MW5-70L/1 | 15 | 3.3 | 2500 | 380/200 | 120/100 | 490 | 700 | 800 | 160 | 90 | 30 |

MW5-80L/1 | 18 | 3.96 | 3000 | 480/250 | 150/130 | 620 | 800 | 800 | 160 | 90 | 30 |

MW5-90L/1 | 26.6 | 5.85 | 4500 | 600/400 | 250/200 | 800 | 900 | 1090 | 200 | 125 | 40 |

MW5-110L/1 | 35 | 7.7 | 6500 | 1000/800 | 450/400 | 1350 | 1100 | 1140 | 220 | 150 | 45 |

MW5-120L/1 | 45.5 | 10 | 7500 | 1300/1000 | 600/500 | 1700 | 1200 | 1180 | 220 | 150 | 45 |

MW5-130L/1 | 54 | 11.9 | 8500 | 1400/1100 | 700/600 | 2060 | 1300 | 1240 | 250 | 175 | 50 |

MW5-150L/1 | 71.2 | 15.6 | 11000 | 1900/1500 | 1100/900 | 2830 | 1500 | 1250 | 350 | 210 | 60 |

MW5-165L/1 | 75 | 16.5 | 12500 | 2300/1800 | 1300/1100 | 3200 | 1650 | 1590 | 370 | 230 | 75 |

MW5-180L/1 | 102.4 | 22.5 | 14500 | 2750/2100 | 1600/1350 | 4230 | 1800 | 1490 | 370 | 230 | 75 |

MW5-210L/1 | 129 | 28.4 | 21000 | 3500/2800 | 2200/1850 | 7000 | 2100 | 1860 | 400 | 250 | 80 |

MW5-240L/1 | 154 | 33.9 | 26000 | 4800/3800 | 2850/2250 | 9000 | 2400 | 2020 | 450 | 280 | 90 |

Tech. Parameter in High Temperature

Model | current(A) | power(KW) | Lifting capacity(KG) | weight(KG) | Dimension (mm) | ||||||

Steel ball | Steel ingot | cutting | A | B | C | D | E | ||||

MW5-70L/2 | 12.77 | 2.8 | 2500 | 380/200 | 120/100 | 520 | 700 | 820 | 160 | 90 | 30 |

MW5-80L/2 | 16.1 | 3.54 | 3000 | 480/250 | 150/130 | 650 | 800 | 800 | 160 | 90 | 30 |

MW5-90L/2 | 20.5 | 4.51 | 4500 | 600/400 | 250/200 | 900 | 900 | 1090 | 200 | 125 | 40 |

MW5-110L/2 | 27.5 | 6.05 | 6500 | 1000/800 | 450/400 | 1500 | 1100 | 1350 | 220 | 150 | 45 |

MW5-120L/2 | 33.6 | 7.4 | 7500 | 1300/1000 | 600/500 | 1800 | 1200 | 1280 | 220 | 150 | 45 |

MW5-130L/2 | 40.6 | 8.93 | 8500 | 1400/1100 | 700/600 | 2300 | 1300 | 1280 | 250 | 175 | 50 |

MW5-150L/2 | 51.4 | 11.3 | 11000 | 1900/1500 | 1100/900 | 3200 | 1500 | 1620 | 350 | 210 | 60 |

MW5-165L/2 | 60.6 | 13.3 | 12500 | 2300/1800 | 1300/1100 | 3500 | 1650 | 1630 | 370 | 230 | 75 |

MW61 series electromagnet of oval electromagnets

oval electromagnets

Electromagnet equipped on overhead travelling cranes

Model | Voltage (V) | current (A) | Power(KW) | Lifting capacity(KG) | weight(KG) | Dimension(mm) | |||||||

Steel ingot | cutting | A | B | C | D | E | F | ||||||

MW61-200150L/1-75 | DC-290/200 | 109.8/75.7 | 31.9/15.2 | 2200/1900 | 1000/800 | 4200 | 2000 | 1500 | 1300 | 250 | 180 | 70 | |

MW61-300150L/1-75 | 195/135 | 56.6/27 | 3400/2850 | 1500/1250 | 5700 | 3000 | 1500 | 1570 | 310 | 210 | 60 | ||

MW61-180160L/1-75 | 113/78 | 32.7/15.5 | 2550/2000 | 1150/900 | 5000 | 1800 | 1600 | 1500 | 310 | 210 | 60 | ||

MW61-250200L/1-75 | 179/123 | 51.9/24.6 | 5000/4200 | 2300/1800 | 8400 | 2500 | 2000 | 2000 | 390 | 280 | 90 | ||

MW61-450250L/-175 | 267.3/184 | 77.53/36.8 | 12000/10000 | 5800/3500 | 22000 | 4500 | 2500 | 2000 | 390 | 280 | 90 | ||

MW61-150110L/1 | DC-220 | 54 | 11.9 | 1500/1200 | 800/700 | 2500 | 1500 | 1100 | 1240 | 250 | 175 | 50 | |

MW61-250150L/1 | 118.6 | 26 | 2800/2400 | 1300/1000 | 6500 | 2500 | 1500 | 2000 | 310 | 210 | 60 | ||

MW1 series electromagnet

Model | Current (A) | Lifting weight(kg) | Dimension(mm) | weight (kg) | |||

steel plate | cutting | Steel ingot | ФA | H | |||

MW1-6 | 15 | 6000 | 80 | 200 | 700 | 800 | 492 |

MW1-6(cast) | 13.4 | 6000 | 80 | 200 | 776 | 884 | 640 |

MW1-16 | 35 | 16000 | 200 | 600 | 1100 | 1140 | 1350 |

MW1-16A/G | 32.8 | 25000 | -- | -- | 1400 | 1175 | 3400 |

MW1-45 | 75 | 45000 | 600 | 1800 | 1650 | 1530 | 5520 |

MW1-45A | 82 | 35000 | - | 1300 | 1650 | 1210 | 2700 |

MW1-45B | 71 | 35000 | - | 1500 | 1650 | 1210 | 3650 |

MW84 series of medium or thick steel plate handling electromagnet

Application: this series of crane electromagnets is specially designed for lifting middle or thick steel plate. Working is safe and fast. When it lift long steel plate, it is better to use several electromagnets to ensure the safe loading. For some thick plate(6mm-32mm)the space between electromagnets is3-4m, the extra length is half of this space.there are different types for different lifting quality, 350 type and400 type.350 type is applied in thick plate factory, ship-building factory, machine making. It can lift one or several steel plates one time with adjustable magnetic control.400 type lift steel plates as many as possible.if you need, we can design a special electromagnet for loading under high temperature of 700 Celsius.

Medium or thick steel plate handling electromagnet

Medium or thick steel plate handling electromagnet dimension drawing

Model | Dimension (mm) | Weight (kg) | Power (kw) | Target object's width(mm) | ||||||||||

A | B | C | D | E | F | G | δ6 | δ8 | δ10 | δ12 | δ16 | |||

MW84-9030T | 900 | 300 | 185 | 0.41 | 2300 | 2700 | 3000 | 3200 | 3600 | |||||

MW84-10535T | 1050 | 350 | 960 | 400 | 110 | 180 | 32 | 330 | 0.9 | 2650 | 3150 | 3350 | 3550 | 4050 |

MW84-14035T | 1400 | 350 | 940 | 500 | 110 | 180 | 32 | 430 | 1.2 | 3000 | 3500 | 3700 | 3900 | 4400 |

MW84-17535T | 1750 | 350 | 940 | 700 | 110 | 180 | 32 | 510 | 1.5 | 3350 | 3850 | 4050 | 4250 | 4750 |

MW84-21035T | 2100 | 35 | 920 | 800 | 110 | 180 | 32 | 600 | 1.8 | 3850 | 4200 | 4400 | 4600 | 5100 |

MW84-24535T | 2450 | 350 | 980 | 900 | 110 | 180 | 32 | 720 | 2.5 | 4200 | 4550 | 4750 | 4950 | 5450 |

MW84-12040L | 1200 | 400 | 1017 | 400 | 110 | 180 | 32 | 550 | 3.0 | 4550 | 3500 | 3700 | 4000 | 4500 |

MW84-16040L | 1600 | 400 | 996 | 700 | 110 | 180 | 32 | 690 | 3.2 | 3400 | 3900 | 4100 | 4400 | 4900 |

MW84-20040 | 2000 | 400 | 970 | 800 | 110 | 180 | 32 | 840 | 5.0 | 3800 | 4300 | 4500 | 4800 | 5300 |

MW84-24040L | 2400 | 400 | 890 | 700 | 110 | 180 | 32 | 90 | 6.0 | 4200 | 4700 | 4900 | 5200 | 5700 |

MW84-13042L/G | 1260 | 420 | 1040 | 500 | 110 | 180 | 32 | 650 | 2.4 | 3060 | 3560 | 3760 | 4060 | 4560 |

MW84-17042L/G | 1680 | 420 | 1045 | 700 | 110 | 180 | 32 | 850 | 3.7 | 3480 | 3980 | 4180 | 4480 | 4980 |

MW84-21042L/G | 2100 | 420 | 1010 | 800 | 110 | 180 | 32 | 1050 | 4.0 | 3900 | 4400 | 4600 | 4900 | 5400 |

MW84-25042L/G | 2520 | 420 | 1050 | 900 | 110 | 180 | 32 | 1250 | 4.8 | 4320 | 4820 | 5020 | 5320 | 5820 |

MW04 series of small round electromagnet for thin, large & long steel plate handling

Applied: the small round electromagnet is used to lift single steel plate or long steel plate. It also can be regarded as a fixture or hand to grasp some smal object. You should consider the steel plate's width, thickness, weight when choosing electromagnet and its controlling equipment.

Small round electromagnet for thin,large & long steel plate handling

Dimensions of small round electromagnet drawing

Model | MW04-17T | MW04-22T | MW04-32T | MW04-40T | |||||||

Dimension (mm) | A | 165 | 216 | 318 | 406 | ||||||

B | 113 | 147 | 178 | 480 | |||||||

C | 30 | 40 | 60 | 100/55 | |||||||

D | 10 | 16 | 25 | 16 | |||||||

weight(kg) | 7 | 15 | 30 | 75 | |||||||

Power (KW) | 0.10 | 0.20 | 0.25 | 0.40 | |||||||

One electromagnet lifting size(mm)LxW | 1200×1200 | 1400×1400 | 1600×1600 | 2500×2500 | |||||||

(Several electrognets)One electromagnet share size(mm)L×W | 600×1200 | 700×1400 | 800×1600 | 1000×2500 | |||||||

attraction | thickness | δ3.2 | δ5 | δ6 | δ10 | δ10 | δ20 | δ12 | δ32 | ||

fasten around | >100kg | >200kg | >300kg | >600kg | >800kg | >2000kg | >4000kg | ||||

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch