Your Trusted Steel Mill Overhead Crane Manufacturer & Supplier

Light and Heavy Material Handling Overhead Crane in Steel Production

Steel Mill Cranes: Types of Overhead Cranes Used in the Steel Industry from Design to Capacity

Cranes play a crucial role in the steel industry, facilitating the movement and handling of heavy materials and products throughout the production process. Industrial cranes, particularly electric overhead cranes, are essential for lifting and transporting large loads with precision and safety. Their effectiveness is vital in maintaining efficiency within steel mills, where operations involve heavy machinery and raw materials. The right crane can significantly enhance productivity, reduce labor costs, and improve workplace safety.

This article aims to explore the various types of overhead cranes used in the steel industry, focusing on their design and capacity. We will examine single girder and double girder electric cranes, as well as bridge cranes, highlighting how their specific designs cater to different lifting capacities. Additionally, we will discuss the importance of these cranes in various applications, from handling raw materials to performing maintenance tasks. This exploration will provide valuable insights into how the right industrial crane can optimize operations in steel mills.

Steel Mill Cranes Classification Based on Crane Structure Design

Overhead Bridge Cranes Single Girder

Single girder cranes are characterized by their straightforward yet effective design, consisting of a single horizontal beam that supports the hoist and trolley. This lightweight structure makes them particularly versatile and well-suited for various environments, especially in steel mills.

Single girder cranes play a significant role in steel mills, facilitating the handling of lighter steel components and tools efficiently. Their unique features, including space efficiency, adaptability, and cost-effectiveness, make them essential tools for improving workflow and productivity in the demanding environment of steel production.

Characteristics and Features

Lightweight Structure:

- Space Efficiency: The single girder design allows for installation in facilities with limited headroom, making it ideal for environments like steel mills where overhead clearance can be a challenge. This maximizes vertical lifting capabilities while minimizing spatial requirements.

- Durability: Constructed from high-strength materials, single girder cranes are built to withstand the demanding conditions typical of steel mills, including exposure to dust, heat, and heavy loads.

Versatile Use:

- Adaptable Applications: Single girder cranes are often employed in various applications within steel mills, including maintenance, assembly, and storage operations. Their versatility makes them suitable for tasks ranging from moving raw steel materials to assisting in the assembly of equipment and machinery.

- Efficient Load Handling: Designed for frequent repositioning of lighter loads, these cranes can easily lift tools, smaller machinery components, and maintenance equipment, facilitating smooth workflow and quick access to necessary items.

Typical Loads:

- Weight Capacity: Typically capable of handling loads ranging from 1 ton to 5 tons, single girder cranes are ideal for lifting lighter steel components such as brackets, tools, and maintenance parts.

- Specialized Use Cases: In steel mills, they are often utilized to transport smaller steel products, move components for fabrication, or assist in the handling of materials during maintenance operations.

Advantages in Steel Mill Applications

Cost-Effectiveness:

- Material Efficiency: The design requires less material for construction, resulting in lower initial costs, which is especially beneficial for steel mills aiming to optimize their budgets without compromising on operational capabilities.

- Operational Savings: Their efficiency in lifting lighter loads reduces energy consumption, further enhancing their economic appeal in environments where operational costs are critical.

Ease of Installation:

- Quick and Simple Setup: The straightforward design allows for faster installation, which is essential in busy steel mills that prioritize minimal downtime during crane deployment.

- Lower Installation Costs: Fewer components and a simpler structure contribute to reduced installation costs, making single girder cranes an attractive choice for facilities looking to enhance their material handling capabilities without extensive financial investment.

Low Maintenance:

- Fewer Moving Parts: The simplicity of the design leads to fewer moving parts, resulting in lower maintenance needs. This reliability is crucial in steel mills, where equipment uptime is vital for continuous production.

- Long-Term Durability: Their robust construction not only ensures longevity but also minimizes disruptions caused by maintenance issues, allowing for consistent performance in lifting operations.

Double girder bridge cranes are engineered with two parallel beams that provide exceptional strength and stability. This design enables them to support significantly heavier loads and accommodate longer spans between supports, making them particularly well-suited for the rigorous demands of steel mills.

Double girder bridge cranes are indispensable in steel mills, offering the strength, versatility, and precision needed to handle heavy loads efficiently. Their specialized features and applications significantly enhance productivity and safety in the demanding environment of steel production.

Features and Capabilities

High Load Capacity:

- Heavy-Duty Lifting: Double girder bridge cranes can handle loads typically ranging from 10 tons to over 100 tons, making them ideal for heavy-duty tasks within steel production environments. Their robust structure ensures they can safely lift and transport large and cumbersome materials.

- Enhanced Safety: The design allows for greater stability during lifting operations, reducing the risk of accidents and ensuring safe handling of heavy loads.

Advanced Hoisting Systems:

- Electric Hoists: Equipped with powerful electric hoists, these cranes provide smooth and efficient lifting capabilities. The hoists allow for precise control, essential when maneuvering heavy steel products and ensuring accurate placement.

- Flexible Trolley Systems: The advanced trolley mechanisms enhance the crane's maneuverability, allowing for efficient positioning and movement of loads across the workspace. This flexibility is crucial in environments where space may be limited.

Versatility:

- Customizable Attachments: Double girder bridge cranes can be fitted with various lifting attachments, including magnetic systems for handling steel plates and specialized hooks for different load types. This adaptability allows them to meet the diverse lifting requirements of steel mills.

- Multi-Functional Use: Their robust design makes them suitable for a range of applications beyond just lifting, including material handling and assembly tasks, contributing to overall operational efficiency.

Applications in Steel Mills

Transporting Heavy Steel Components:

- Moving Steel Plates and Beams: Double girder bridge cranes are extensively used to transport large steel plates and beams within steel mills. Their high load capacity and stability make them essential for moving these substantial materials safely and efficiently throughout the production process.

- Handling Heavy Machinery: These cranes are also employed to lift and reposition heavy machinery and equipment used in various stages of steel production. Their strength and precision are vital for ensuring smooth operations, especially in critical maintenance and assembly tasks.

Material Handling:

- Storage and Retrieval: In steel mills, double girder bridge cranes facilitate the storage and retrieval of raw materials and finished products. Their ability to span large distances allows for effective organization of materials, maximizing warehouse space and improving workflow.

- Loading and Unloading: They are frequently utilized for loading and unloading operations, ensuring that materials are efficiently moved between different areas of the mill, such as from storage to the production line or from trucks to storage areas.

Assembly and Maintenance Operations:

- Supporting Assembly Lines: Within assembly lines, these cranes play a crucial role in handling large components that require precise positioning. Their versatility allows for seamless integration into production processes where heavy lifting is required.

- Equipment Maintenance: Double girder cranes are essential in maintenance operations, providing the necessary support for lifting and replacing heavy machinery parts, ensuring that equipment remains operational and minimizing downtime.

Gantry Cranes

Gantry cranes are uniquely designed with an A-frame structure that supports the hoist and trolley system above the workspace. This configuration allows for flexible positioning and effective load handling, making them particularly valuable in steel mills, where heavy lifting and material movement are crucial.

Design and Structural Features

Robust Construction:

- High Durability: Gantry cranes are constructed from high-strength materials capable of withstanding the demanding conditions found in steel mills, including exposure to heavy loads, dust, and extreme temperatures. This durability ensures long-term performance and reduces the need for frequent repairs or replacements.

- Enhanced Stability: The A-frame design provides a solid base that distributes weight evenly, enhancing stability during lifting operations. This feature is vital in steel mills, where safety and reliability are paramount when handling heavy materials.

Verstile Configuration:

- Mobile or Fixed Options: Gantry cranes can be designed as mobile units on wheels or fixed installations, depending on the specific application and available space. Mobile gantry cranes can be easily relocated to different areas of the mill, making them versatile tools for various tasks.

- Customizable Height and Span: Many gantry cranes offer adjustable height and span configurations, allowing them to accommodate different load sizes and work environments. This adaptability is particularly useful in steel mills, where the nature of tasks may vary significantly.

Benefits for Steel Mill Applications

Versatility:

- Multi-Functional Use: In steel mills, gantry cranes are employed for a wide range of applications, including lifting and transporting heavy steel plates, coils, and beams. Their design allows for easy integration into existing workflows, enhancing operational efficiency.

- Adaptability to Different Tasks: Whether moving raw materials from storage to production areas or assisting in the assembly of equipment, gantry cranes provide the flexibility needed to meet various operational demands.

Space Efficiency:

- Compact Operation: Gantry cranes can operate effectively in confined areas without requiring extensive overhead support structures. This is particularly advantageous in steel mills where floor space is often at a premium due to large machinery and equipment.

- Optimized Layout: By eliminating the need for fixed overhead tracks, gantry cranes maximize usable floor space, allowing for more efficient material handling and better organization of the production area.

Heavy Lifting Capability:

- Handling Large Loads: Gantry cranes excel in moving substantial weights, often handling loads ranging from several tons to over 50 tons. This makes them ideal for transporting heavy steel components, such as large sheets, heavy machinery, and fabricated parts.

- Improving Productivity: The ability to lift and reposition heavy materials quickly enhances productivity in steel mills. Gantry cranes reduce the time and labor required for material handling, contributing to smoother operations and improved output.

Typical Applications in Steel Mills

- Material Transport: Gantry cranes are commonly used to transport heavy steel products from production lines to storage areas, ensuring efficient flow and reducing bottlenecks in the manufacturing process.

- Loading and Unloading: These cranes are essential for loading and unloading operations, whether transferring materials between trucks and storage or moving products from one area of the mill to another.

- Assembly Operations: In assembly areas, gantry cranes assist in positioning large components, ensuring precise alignment and facilitating the efficient assembly of machinery and equipment.

In conclusion, gantry cranes play a vital role in steel mills, providing a robust and versatile solution for handling heavy loads. Their durable construction, flexible configurations, and adaptability to various tasks make them indispensable tools for enhancing productivity and safety in the steel production process.

Jib Cranes

Jib cranes are defined by their horizontal arm, known as the jib, which extends from a vertical post. This design allows for excellent flexibility in lifting operations and enables precise control when moving materials, making them particularly valuable in steel mills, where efficiency and accuracy are critical.

Arm Configuration and Functionality

Flexible Arm Movement:

- Rotational Capability: The jib can rotate around its vertical post, offering a wide range of motion for lifting and moving loads. This capability is essential in steel mills, where materials may need to be lifted and repositioned from various angles.

- Extendable Reach: Many jib cranes feature adjustable arms that can be extended or retracted, allowing operators to customize the reach based on the specific lifting task. This flexibility is especially beneficial for handling large steel components that require precise placement.

Mounting Options:

- Versatile Installation: Jib cranes can be mounted on walls, floors, or columns, adapting to the layout of the steel mill. This versatility makes them suitable for both new installations and retrofitting existing spaces.

- Space Optimization: Their ability to utilize vertical space while minimizing the footprint helps maximize available floor area, an important consideration in busy industrial environments where space is at a premium.

Use in Steel Mill Operations

Precision Handling:

- Accurate Load Movement: Jib cranes excel in tasks requiring accuracy in lifting and positioning heavy materials. Their design allows for fine control, which is crucial when working with large, heavy steel products that must be placed precisely to avoid damage or misalignment.

- Enhanced Safety: By facilitating precise load handling, jib cranes help reduce the risk of accidents, ensuring that materials are moved safely and efficiently within the steel mill.

Common Applications:

- Assembly Lines: In steel mills, jib cranes are often used on assembly lines to lift and position heavy components such as beams and plates. Their ability to maneuver easily around equipment enhances workflow efficiency and speeds up production processes.

- Maintenance Workshops: Jib cranes are invaluable in maintenance operations, where they allow technicians to lift and reposition tools and heavy machine parts with ease. This flexibility enables quick adjustments and repairs, minimizing downtime and keeping production on schedule.

- Loading and Unloading: Jib cranes are commonly employed for loading and unloading materials from trucks or shipping containers. Their precision allows for careful handling of heavy loads, ensuring that materials are transferred safely without risk of damage.

Space-Saving Design:

- Compact Size: The compact design of jib cranes makes them ideal for confined areas within steel mills, such as tight corners or crowded workspaces. They provide significant lifting capabilities without requiring extensive overhead infrastructure.

- Efficient Localized Operations: Jib cranes enhance efficiency in localized lifting operations by allowing operators to quickly move materials to and from specific locations without the need for large, stationary cranes.

In conclusion, jib cranes are a vital component in steel mills, offering flexible and precise lifting capabilities that improve productivity and safety. Their adaptable design, space-saving features, and effectiveness in various applications make them essential tools for handling heavy loads and optimizing material movement in steel production environments.

Steel Mill Cranes Classification Based on Crane Lifting Capacity

Light-Duty Cranes

Light-duty cranes play a vital role in steel mills, where they are specifically designed to handle lighter weights and support various operational tasks. Their functionality enhances efficiency and safety in environments where heavy lifting is not always necessary.

Specifications and Typical Load Limits

Load Capacity:

- 1 Ton: Ideal for lifting smaller tools, maintenance equipment, and light fixtures within steel mills, making them essential for day-to-day operations.

- 2 Tons: Commonly used for handling lighter steel components, such as brackets and small parts, which are integral to assembly processes in manufacturing lines.

- 3 to 5 Tons: Suitable for moving moderately heavy loads, these cranes can handle tasks such as transferring steel samples or lighter machinery components during maintenance.

Design Features:

- Lightweight Materials: Constructed from durable yet lightweight materials, these cranes facilitate easy maneuverability, which is crucial in a busy steel mill environment where space can be limited.

- Simplified Structures: Their design minimizes complexity, resulting in easier operation and reduced maintenance requirements, essential for maintaining productivity in high-demand settings.

Dimensions:

- Compact Footprint: Light-duty cranes are designed with smaller dimensions, allowing them to fit into tight spaces within steel mills, such as near machinery or in maintenance areas.

- Low Height Requirements: Their ability to operate in low-clearance areas is particularly advantageous in steel mills, where overhead space can be constrained.

Common Applications in Steel Mills

- Maintenance Tasks: Light-duty cranes are frequently employed to lift tools, spare parts, and maintenance equipment essential for the upkeep of machinery in steel mills. Their ease of use allows maintenance teams to work more efficiently, reducing downtime and enhancing overall operational flow.

- Assembly Lines: In steel mills, these cranes support assembly lines where lighter steel components, such as frames and supports, are processed. By facilitating quick and safe lifting, light-duty cranes contribute to streamlined production processes, ensuring that assembly operations run smoothly.

- Warehouse Operations: Light-duty cranes are also used in warehouses associated with steel mills for tasks like stocking lighter inventory and organizing materials. Their maneuverability helps optimize warehouse space and enhances efficiency in material handling.

In conclusion, light-duty cranes are essential tools in steel mills, providing effective solutions for handling lighter loads across various applications. Their specific design features, compact size, and versatility make them indispensable for maintenance, assembly, and warehouse operations within the steel industry.

Medium-Duty Cranes

Medium-duty cranes are essential in steel mills, designed to handle a broader range of loads compared to light-duty models. Their versatility makes them ideal for various applications in the steel production process.

Capacity Ranges and Features

Load Capacity:

- 5 Tons: Commonly used for lifting medium-sized machinery and components, such as motors and smaller structural parts.

- 10 Tons: Frequently employed on production lines for handling larger parts and materials, such as steel plates and beams, that are integral to manufacturing processes.

- 15 Tons: Suitable for more demanding tasks, including lifting structural components during fabrication, which require both strength and stability.

Construction: Medium-duty cranes are built with a robust design, often featuring heavier materials to withstand the increased stress associated with heavier lifting tasks. This construction ensures durability in the harsh environments typical of steel mills.

Operational Flexibility: Equipped with advanced hoisting systems, these cranes provide better control and precision when handling loads. This capability is critical in steel mills where accuracy is necessary to avoid damage to materials.

Applications in Handling Medium-Sized Steel Components

- Steel Fabrication: Medium-duty cranes are commonly utilized in workshops for assembling medium-sized steel components, such as frames, brackets, and other structural elements essential for various applications within the steel industry.

- Manufacturing: These cranes play a crucial role in production lines, where medium-weight materials are frequently moved and positioned. Their ability to handle heavier loads enhances efficiency and productivity in steel processing.

- Installation Tasks: Medium-duty cranes are well-suited for erecting and installing machinery and equipment that falls within the medium load category. Their capacity allows for the safe and effective positioning of equipment, crucial for maintaining operational flow in steel mills.

In summary, medium-duty cranes are vital in steel mills, providing the strength and versatility needed to handle a variety of tasks. Their specific load capacities, robust construction, and operational flexibility make them indispensable tools for steel fabrication, manufacturing, and installation activities.

Heavy-Duty Cranes

Heavy-duty cranes are crucial in steel mills, specifically engineered to meet the intense lifting demands associated with steel production. Their design and capacity make them integral to various operations within the industry.

High Capacity Specifications

Load Capacity:

- 15 Tons: Often utilized in the movement of medium-sized steel components and machinery, these cranes provide reliable support in various manufacturing tasks.

- 30 Tons: Commonly employed for transporting larger steel products, such as heavy plates and beams, which are essential for construction and assembly processes in steel mills.

- 50 Tons: Frequently used for handling substantial machinery and structural elements, facilitating efficient workflow in production lines.

- 100 Tons and Above: Reserved for specialized tasks, such as lifting large modules or heavy machinery during maintenance and upgrades, ensuring that operations run smoothly without compromising safety.

Structural Integrity: Heavy-duty cranes are designed with reinforced materials and advanced engineering, allowing them to safely support significant weights. This durability is critical in steel mills, where the lifting of heavy loads is routine and essential for production efficiency.

Safety Features: These cranes incorporate multiple safety mechanisms, including overload protection and advanced braking systems, to guarantee safe operations under heavy loads. Such features are vital in minimizing risks in high-stakes environments typical of steel production.

Use in Moving Heavy Steel Products and Materials

- Steel Mills: Heavy-duty cranes are essential for the efficient transportation of large steel plates, beams, and rolls of steel. Their high lifting capacities enable the seamless movement of heavy materials between various stages of production, from raw material handling to finished product dispatch. This efficiency reduces downtime and enhances overall productivity within the mill. Material Handling: In addition to lifting finished products, these cranes play a key role in material handling throughout the manufacturing process. They facilitate the loading and unloading of raw steel from trucks and freight cars, ensuring that materials are readily available for production lines. Their capability to handle heavy loads without destabilization is crucial for maintaining a smooth workflow.

- Maintenance Operations: Heavy-duty cranes are also indispensable during maintenance operations within steel mills. They are used to lift and reposition large machinery and equipment for repairs or upgrades, minimizing disruptions to ongoing production. Their robust design and precision controls allow for the safe handling of equipment in confined spaces, making them invaluable in maintaining operational efficiency.

In summary, heavy-duty cranes are vital to steel mills, providing the necessary strength and reliability to handle heavy steel products and materials. Their high capacity, structural integrity, and advanced safety features make them essential tools for material handling and maintenance, ensuring that steel production processes operate smoothly and efficiently.

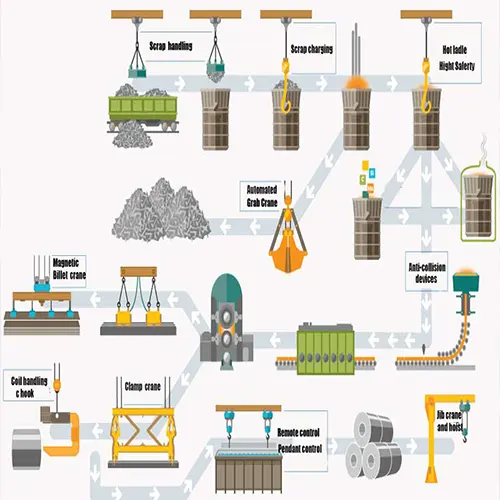

Material Handling Cranes Classified Based on Application in Steel Mill Operations

Steel mills require various specialized cranes to handle raw materials, process heavy steel products, and transport finished goods efficiently and safely. These cranes are engineered to meet the unique demands of steel production, including handling extreme temperatures, heavy loads, and continuous operations. Below is a categorized overview of specialized cranes used in the steel industry:

Raw Material Handling

These cranes are essential for managing the raw materials required for steel production:

- Grab Crane: Equipped with grab buckets, these cranes are used to lift and handle bulk materials like iron ore, limestone, and scrap metal for furnace feeding.

- Electromagnetic Overhead Crane: Ideal for transporting ferrous materials and scrap metal, these cranes use powerful magnets to efficiently grab and release loads, facilitating recycling and material feeding processes.

Molten Metal Handling

Transporting and pouring molten metal is a critical process in steel mills, requiring specialized cranes:

- Ladle Crane: These cranes are specifically designed to handle molten metal in ladles, ensuring precise and safe pouring into molds or casting areas.

Intermediate Product Handling

During various production stages, semi-finished steel products such as slabs, billets, and plates require specialized cranes for movement and processing:

- Slab Tong Crane: Fitted with tong attachments, these cranes securely lift and transport heavy steel slabs, enabling efficient movement between rolling, cutting, and cooling stages.

- Billet Handling Crane: Designed for handling hot or cold billets using hooks, clamps, or magnets, these cranes are crucial for processes like stacking, cooling, and further processing.

- Rotating Crane (Rotary Spreader Crane): These cranes have rotating mechanisms to handle slabs, billets, or plates, allowing for flexible material handling in confined or complex layouts.

- Walking Beam Crane: Ideal for moving heavy steel plates or slabs over long distances, these cranes utilize a segmented "walking" mechanism to transport materials with minimal repeated lifting.

Finished Product Handling

Specialized cranes are also used to handle finished steel products safely and efficiently, minimizing damage:

- Coil Handling Crane: These cranes, fitted with C-hooks or coil tongs, are used to lift and transport large steel coils, ensuring safe handling in storage, shipping, and processing areas.

- C-Hook Crane: Featuring a C-shaped hook, these cranes excel in lifting and turning steel coils, aluminum rolls, or wire spools, especially in tight spaces.

- Clamp Crane: Utilizing mechanical or hydraulic clamps, these cranes maneuver large steel products like coils, pipes, and slabs, providing secure and damage-free transport.

Each specialized crane plays a crucial role in optimizing steel mill operations, whether handling raw materials, transporting molten metal, or managing semi-finished and finished products. By utilizing these purpose-built cranes, steel manufacturers can enhance efficiency, safety, and productivity throughout the production process.

Classification Based on Specific Applications

Material Handling Cranes

Material handling cranes are vital in steel mills, facilitating the efficient transportation of raw materials and finished products throughout the production process.

Role in Transporting Raw Materials

- Streamlined Operations: These cranes enable the quick and safe movement of materials from storage areas to production lines. By minimizing delays in material transfer, they enhance overall workflow efficiency and ensure that production schedules are met without interruptions.

- Integration with Automated Systems: Material handling cranes are often integrated with automated systems to optimize loading and unloading processes. This integration improves productivity by reducing the need for manual labor and increasing the speed at which materials can be moved within the facility.

Examples of Typical Loads Handled

- Raw Steel Ingots: Heavy and bulky, these ingots typically weigh several tons and require robust cranes designed for heavy lifting. Material handling cranes are essential for moving these ingots from storage to processing areas, ensuring they are handled safely and efficiently.

- Steel Coils and Sheets: These products require careful handling to prevent damage during transportation. Specialized hoisting and gripping mechanisms are employed to securely lift and move coils and sheets, minimizing the risk of bending or deformation.

- Bulk Materials: Material handling cranes are also utilized for managing bulk materials, such as scrap metal or ore. These cranes may require specific attachments, like clamshell buckets or magnets, to efficiently handle and transport loose materials while maintaining safety and operational efficiency.

In summary, material handling cranes are integral to the steel mill environment, providing the necessary support for transporting raw materials and finished products. Their ability to streamline operations and integrate with automated systems enhances productivity, while their specialized features ensure the safe handling of heavy and sensitive loads.

Maintenance Cranes

Maintenance cranes are indispensable in steel mills, playing a vital role in the upkeep and repair of heavy machinery and equipment essential for production.

Importance in Equipment Upkeep

- Preventive Maintenance: In the demanding environment of a steel mill, regular use of maintenance cranes is crucial for conducting preventive maintenance on large machinery. By enabling timely inspections and repairs, these cranes help minimize unplanned downtime and extend the operational life of critical equipment, ensuring a smoother production process.

- Accessibility: Maintenance cranes are designed to reach high and difficult-to-access areas of large steel machinery. This capability is essential for safely performing inspections, replacing parts, and conducting repairs, particularly in areas where traditional lifting methods would be inadequate.

Specific Features Designed for Steel Mill Applications

- Compact Design: Many maintenance cranes are engineered with a smaller footprint, allowing them to fit into tight spaces common in steel mills. This design facilitates maneuverability in congested areas, enabling technicians to access various equipment without obstruction.

- Adjustable Height: These cranes often feature adjustable height settings, making them versatile for different maintenance tasks. This flexibility is especially beneficial in steel mills, where machinery sizes and configurations can vary significantly.

- Swivel Hoists: Equipped with swivel hoists, maintenance cranes enhance maneuverability, allowing technicians to precisely position equipment during maintenance. This feature is vital for safely lifting and moving heavy components, ensuring that repairs can be carried out efficiently without risk of damage.

Typical Applications in Steel Mills

- Machinery Inspections: Maintenance cranes are frequently used to lift technicians and tools for conducting inspections on large steel-making equipment, such as furnaces and rolling mills. Their design ensures that workers can safely access high points for thorough examinations.

- Parts Replacement: These cranes are essential for lifting and replacing heavy parts, such as motors and gearboxes, in large machinery. The ability to maneuver and position loads accurately makes them invaluable during maintenance operations.

- Routine Maintenance Tasks: Maintenance cranes support a variety of routine tasks, including lubrication, cleaning, and adjustment of machinery. By providing the necessary reach and lift capabilities, they streamline the maintenance workflow and contribute to overall operational efficiency.

In conclusion, maintenance cranes are critical for ensuring the smooth operation of steel mills. Their specific features and design cater to the unique challenges of the steel industry, enabling effective and safe maintenance of heavy machinery and supporting the continuous productivity of manufacturing processes.

Specialized Cranes for Particular Material Handling

Specialized cranes are designed to meet the unique demands of specific industrial tasks in steel mills and related environments. Their tailored features ensure efficient and safe handling of materials that standard cranes may not be suited for.

Cranes Designed for Unique Tasks

- Scrap Handling Cranes: These cranes are equipped with heavy-duty hooks or grapples specifically designed for the efficient movement and processing of scrap materials. In steel mills, they play a crucial role in collecting and transporting scrap metal to recycling areas or processing plants, ensuring that valuable materials are reclaimed and reused. The robust design and specialized attachments enable them to handle heavy and irregularly shaped loads safely.

- Furnace Charging Cranes: Designed for the critical task of loading materials into furnaces, these cranes often come with specialized attachments, such as ladles or hoppers, for safely handling molten metal and other high-temperature materials. Their precise control and robust construction ensure that heavy loads can be positioned accurately over open furnaces, minimizing the risk of spills and enhancing operational safety.

Customizations Available for Specific Applications

- Material-Specific Attachments: Specialized cranes can be fitted with custom hooks, clamps, or magnets tailored for specific materials. For example, cranes handling ferrous metals might use strong electromagnets to securely lift and transport steel scrap. These attachments increase operational efficiency and reduce the risk of accidents during material handling. Environmental Adaptations: Customizations can also include adaptations for extreme operational conditions. Cranes designed for steel mills might feature heat-resistant components to withstand high temperatures, while those in chemical processing facilities may have corrosion-resistant finishes to protect against harsh environments.

- Advanced Control Systems: Incorporating advanced control systems allows for precise load handling, which is particularly important in specialized tasks where accuracy is crucial. These systems can include features such as programmable logic controllers (PLCs) and remote control capabilities, enabling operators to perform intricate maneuvers safely and efficiently.

In summary, specialized cranes are essential for handling unique tasks in steel mills, such as scrap processing and furnace charging. Their tailored designs and custom features enhance operational efficiency, safety, and effectiveness in managing specific materials and challenging environments.

Your Trusted Steel Industrial Crane Manufacturer & Supplier

Custom Industrial Crane for Your Steel Mill Facility and Steel Products Handling

Overhead cranes are vital to the efficiency and productivity of the steel industry, playing a crucial role in various stages of steel production and handling. Their significance can be summarized as follows:

- Enhanced Material Handling: Different types of overhead cranes—such as single girder, double girder, and bridge cranes—are designed to handle specific loads and tasks, facilitating the smooth transportation of raw materials and finished products within steel mills. This capability minimizes bottlenecks and improves workflow efficiency. Safety and Precision: With the ability to lift heavy loads safely and accurately, overhead cranes reduce the risk of accidents and injuries in high-stress environments. Their design includes safety features like overload protection and precise control mechanisms that ensure safe operations.

- Adaptability: The various classifications of cranes, such as light-duty, medium-duty, and heavy-duty models, allow steel manufacturers to select equipment that best meets their operational needs. This adaptability is crucial for optimizing production processes and maximizing resource utilization.

- Support for Diverse Applications: Whether for material handling, maintenance, or specialized tasks like furnace charging and scrap handling, overhead cranes are versatile tools that contribute to the overall efficiency of steel manufacturing operations.

In summary, overhead cranes are indispensable in the steel industry, providing essential support for material handling and production processes. As technology evolves, the continued development of these cranes will enhance efficiency, safety, and adaptability, ensuring that the steel industry remains competitive in a rapidly changing landscape.