Your Trusted Overhead Crane Manufacturer & Supplier

10 Ton Overhead Crane for Sale: Custom Options and Pricing Insights

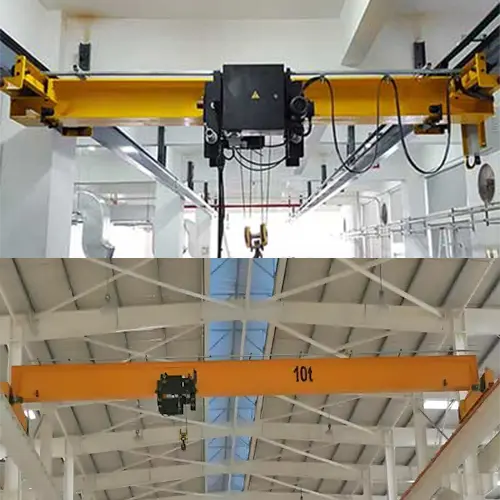

Top Running & Underhung Overhead Crane with Single / Double Girder for Your Needs, Good 10 Ton Bridge Crane Price

Top Running & Underhung Overhead Crane with Sinlge / Double Girder for Your Needs, Good 10 Ton Crane Price

10-ton overhead cranes for sale, featuring competitive pricing and tailored solutions for diverse industrial applications and lifting needs.

10-ton overhead cranes are essential tools in various industries, designed to lift and move heavy loads with ease and precision. These cranes are commonly used in manufacturing, construction, and warehousing, offering a reliable solution for handling materials such as steel beams, heavy machinery, and large components. Their robust construction allows for safe operation in demanding environments, making them a preferred choice for many businesses.

Choosing the right crane for specific applications is crucial for maximizing efficiency and ensuring safety. Different projects may require varying features, such as height, reach, and lifting mechanisms. Selecting a crane that aligns with the unique demands of your operation can lead to improved productivity, reduced downtime, and enhanced safety for workers. Therefore, The specific needs of your application is key to making an informed decision when investing in a 10-ton overhead crane.

Key Features of 10 Ton Overhead Cranes

Load Capacity and Lifting Mechanisms

The primary function of a 10-ton overhead crane is its ability to lift and transport heavy loads efficiently. These cranes are designed to handle loads of up to 10 tons, making them ideal for heavy industrial applications. The lifting mechanisms can vary, typically including electric hoists, manual hoists, or pneumatic systems. Electric hoists are the most common, providing fast and reliable lifting with minimal effort. The design ensures smooth operation and precise control over load positioning, which is crucial in settings where accuracy is paramount.

Safety Features and Compliance Standards

Safety is a top priority in crane operations, and 10-ton overhead cranes come equipped with several safety features to protect both operators and materials. These include overload protection systems that prevent lifting beyond the crane's rated capacity, emergency stop buttons, and limit switches that stop the crane at predetermined points. Additionally, many cranes are designed to meet international safety standards, such as OSHA and ANSI regulations, ensuring that they are built for safe operation in various environments. Regular inspections and maintenance are essential to uphold these safety standards.

Customization Options Available

One of the standout features of 10-ton overhead cranes is the wide range of customization options available. Businesses can tailor cranes to meet specific operational needs, such as adjusting the span, lifting height, and speed of operation. Custom features may include specialized hoists for unique loads, additional safety mechanisms, or enhancements for outdoor use, such as weatherproofing. By investing in a customized solution, companies can ensure that their crane is not only suited for current demands but also adaptable for future needs. This flexibility can lead to long-term savings and improved operational efficiency.

Hot Sale 10 Ton Overhead Cranes

The 10 Ton Overhead Crane is a popular choice for industries requiring robust lifting solutions. Engineered for efficiency and reliability, these cranes are designed to handle heavy loads with ease, making them ideal for manufacturing, warehouses, and construction sites. Their compact design allows for effective use of vertical space, while advanced safety features ensure smooth operation. As demand for high-capacity lifting equipment continues to grow, the 10 Ton Overhead Crane stands out as a versatile and cost-effective solution for businesses looking to enhance their operational capabilities.

HD Single Girder Overhead Crane with Top Running Design

The HD single girder overhead crane with a top-running design is engineered for efficiency and space optimization. This crane utilizes a single beam configuration that runs along elevated rails, allowing it to move loads smoothly and maximize available headroom in the facility.

Key Features:

- Lightweight design for easy maneuverability.

- High-quality materials ensure durability and reliability.

- Adjustable span options to fit various workspace configurations.

Applications:

- Ideal for warehouses, manufacturing plants, and assembly lines.

- Suitable for light to medium-duty lifting tasks.

NLH Double Girder Overhead Crane with Electric Hoist Trolley

The NLH double girder overhead crane is designed for heavy-duty applications, equipped with an electric hoist trolley that provides powerful lifting capabilities and precise load positioning. This crane's robust structure enhances its stability and performance under demanding conditions.

Key Features:

- Electric hoist trolley for efficient lifting and lowering.

- Double girder configuration for superior strength and rigidity.

- Enhanced safety features, including limit switches and overload protection.

Applications:

- Perfect for steel mills, heavy equipment manufacturing, and construction sites.

- Capable of handling large and heavy loads with ease.

QDX Double Girder Overhead Crane with Built-Up Open Winch Trolley

The QDX double girder overhead crane features a built-up open winch trolley, designed for robust lifting tasks in industrial settings. This crane offers exceptional lifting performance and is suitable for continuous operation.

Key Features:

- Open winch design allows for easy maintenance and improved cooling.

- Enhanced lifting height and capacity due to double girder design.

- High lifting speeds for increased productivity.

Applications:

- Ideal for manufacturing, construction, and repair facilities.

- Suitable for handling heavy machinery and materials.

5 Ton + 5 Ton Double Hoists Overhead Cranes for Tandem Lifting Operations

The 5 Ton + 5 Ton Double Hoists Overhead Crane system is designed specifically for tandem lifting operations, providing a powerful solution for moving heavy and oversized loads efficiently. This innovative setup combines two 5-ton hoists, allowing for increased lifting capacity and versatility in various industrial applications.

Key Features

This crane system offers several benefits that enhance its functionality and usability:

- Dual Hoist Configuration: The integration of two hoists allows for simultaneous lifting of larger loads, ensuring efficiency in operations.

- Independent Operation: Each hoist can function independently, enabling customized lifting strategies and improved productivity.

- Compact Design: The crane's design is optimized for limited workspace, making it suitable for environments with space constraints.

Applications

The versatility of the 5 Ton + 5 Ton Double Hoists Overhead Crane makes it ideal for a range of industrial settings:

- Assembly Lines: Facilitates the lifting of components during manufacturing processes.

- Loading Docks: Enhances the efficiency of loading and unloading operations.

- Warehouses: Provides effective lifting solutions for varied storage needs and inventory management.

This crane system is an excellent choice for businesses seeking to optimize their lifting operations while maintaining safety and efficiency.

HD Single Girder 10 Ton Overhead Crane with Double Hoists

The HD single girder crane with double hoists is designed for increased lifting capacity and versatility. This model is particularly useful for operations that require frequent load changes.

Key Features:

- Lightweight yet strong construction ensures stability.

- Double hoists allow for simultaneous lifting and improved efficiency.

- Customizable spans and heights to suit specific operational needs.

Applications:

- Suitable for warehouses, manufacturing, and distribution centers.

- Effective for assembly work and material handling.

NLH Double Girder 10 Ton Overhead Crane with Double Hoist Trolley

The NLH double girder crane with a double hoist trolley is engineered for heavy-duty lifting with precision and safety. This crane is ideal for industries that require robust lifting solutions.

Key Features:

- Double girder design provides enhanced stability and load distribution.

- Dual hoist trolley for versatile operation and increased lifting capabilities.

- Advanced safety features to prevent accidents and ensure operator safety.

Applications:

- Perfect for manufacturing, construction, and shipping facilities.

- Ideal for heavy machinery handling and large-scale operations.

Applications in Various Industries

10-ton overhead cranes are highly versatile and find applications across multiple industries, each leveraging their unique capabilities.

- In manufacturing, these cranes are crucial for assembling heavy machinery and transporting large components during production. They streamline the movement of raw materials and finished products, enhancing overall efficiency.

- In the construction industry, 10-ton overhead cranes are essential for lifting steel beams, concrete panels, and other heavy materials at job sites. This capability improves workflow and safety, as they facilitate organized material handling.

- The automotive sector employs these cranes to move parts along assembly lines, ensuring an efficient production process. They support heavy lifts for engines, chassis, and other critical vehicle components.

- In shipping and logistics, 10-ton overhead cranes are utilized for loading and unloading shipping containers, optimizing warehouse operations and increasing efficiency in port activities.

- In steel fabrication, these cranes play a vital role in handling large steel plates and beams. They enable precise positioning during fabrication, enhancing safety and productivity in steel processing environments.

Custom 10 Ton Overhead Crane Options

Tailored Design Features

Custom 10-ton overhead cranes offer a range of tailored design features to meet specific operational requirements. Businesses can modify various aspects of the crane to enhance functionality and efficiency. Key tailored features may include:

- Span and Lift Height Adjustments: Customizing the span width and lift height allows the crane to fit specific workspace constraints while optimizing load handling.

- Trolley Configuration: Options for fixed or movable trolleys can improve load positioning and maneuverability within the facility.

- Control Systems: Tailored control options, such as remote control or operator cabin designs, enhance user experience and safety during operation.

These tailored features ensure that the crane aligns with the unique demands of the facility and operational workflow.

Specialized Components for Unique Environments

For operations in challenging environments, customized cranes can include specialized components designed to withstand specific conditions. Important components may consist of:

- Weatherproofing: Cranes intended for outdoor use can be equipped with weather-resistant coatings and seals to protect against corrosion and wear.

- Explosion-Proof Options: In industries like oil and gas, cranes can be designed with explosion-proof electrical components to enhance safety in hazardous environments.

- High-Temperature Materials: Custom cranes that operate in extreme heat or cold can utilize materials designed to withstand temperature fluctuations without compromising structural integrity.

These specialized components ensure that cranes function reliably, regardless of environmental challenges.

Case Studies of Customized Solutions

Examining real-world examples highlights the effectiveness of customized 10-ton overhead cranes. Case studies may include:

- Manufacturing Facility Customization: A manufacturer required a crane to navigate tight spaces between machines. The solution involved a single girder design with a compact trolley, enhancing space utilization while maintaining lifting capacity.

- Marine Industry Adaptation: A port operator needed a crane capable of handling heavy loads in a corrosive marine environment. The customized crane featured anti-corrosion coatings and specialized hoisting systems designed for frequent saltwater exposure.

- Automotive Assembly Line Enhancement: An automotive plant sought to improve efficiency in its assembly line. The solution included a double girder crane with advanced control systems, allowing for precise movement of heavy engine components, resulting in reduced cycle times.

These case studies demonstrate how customized 10-ton overhead cranes can solve specific challenges, enhance productivity, and improve operational safety in diverse industries.

10 ton overhead crane with single gider crane design for sale

10 ton overhead crane with double girder crane design for sale

Pricing Factors for Custom 10 Ton Overhead Cranes

Single Girder vs. Double Girder Designs

When selecting a 10-ton overhead crane, it's important to understand the distinctions between single girder and double girder designs.

Single girder cranes consist of a single horizontal beam that supports the hoist and trolley. This design is typically lighter and more cost-effective, making it suitable for a range of applications. Advantages of single girder cranes include:

- They require less headroom, making them ideal for facilities with limited vertical space.

- Their simpler design leads to easier installation and lower maintenance costs.

- They are well-suited for lighter loads, often used in warehouses, assembly lines, and small manufacturing settings.

In contrast, double girder cranes feature two parallel beams that provide increased stability and support for the hoist. This design is better suited for heavy-duty applications. The benefits include:

- Higher load capacities and the ability to handle larger spans, which is essential in demanding environments.

- Greater lifting heights, allowing for more efficient use of vertical space.

- Enhanced durability and rigidity, making them suitable for high-frequency operations in heavy manufacturing and construction.

Top Running vs. Underhung Designs

The choice between top running and underhung crane designs significantly affects performance and installation requirements.

Top running cranes have wheels mounted on top of the girders, running on elevated rails. This design offers maximum lifting height and load capacity, making it ideal for heavy-duty applications. Key benefits include:

- Greater flexibility in layout design and crane movement within large open spaces.

- Suitable for facilities with ample headroom, allowing for the handling of heavy and frequent lifting tasks.

- Often used in large warehouses and manufacturing plants, where operational efficiency is critical.

Underhung cranes, on the other hand, have wheels that run along the bottom flange of the rail. This design allows the crane to hang from the overhead structure, providing a low-profile solution. The advantages include:

- Efficient use of limited vertical space, making them ideal for environments with height restrictions.

- Simple installation, which reduces structural requirements for the building.

- Perfect for applications that require precise movements in confined spaces, such as small workshops and assembly lines.

Material Costs and Design Complexity

The pricing of custom 10-ton overhead cranes is significantly influenced by the materials used and the complexity of the design.

- Material Selection: High-quality materials such as steel or aluminum can drive up costs, especially if specialized materials are needed for specific environments, like corrosion-resistant coatings for marine applications.

- Design Complexity: Custom designs that incorporate unique features or require intricate engineering will typically have higher development and manufacturing costs. For instance, a double girder crane with a specialized hoist system may require more labor and resources compared to a standard single girder design.

- Fabrication Techniques: Advanced fabrication methods, such as precision machining or custom welding, can also increase the overall price due to the added labor and time required for production.

These factors helps businesses budget effectively for their crane investment.

Additional Features and Certifications

Customization often includes additional features and safety certifications, which can impact pricing.

- Safety Features: Cranes equipped with enhanced safety mechanisms, such as overload protection systems, emergency stop buttons, and limit switches, may incur additional costs but significantly improve operational safety.

- Certifications: Compliance with industry standards, such as OSHA or ISO certifications, can require additional testing and documentation, contributing to the overall cost. Companies may choose to invest in these certifications to ensure safety and reliability in their operations.

- Control Systems: Advanced control systems, such as wireless remote operation or automated controls, can add to the price but provide greater operational efficiency and safety.

These additional features not only improve crane functionality but also enhance workplace safety.

Market Trends and Competitive Pricing

Market dynamics and competition play a crucial role in determining the pricing of custom 10-ton overhead cranes.

- Supply and Demand: Fluctuations in the market can affect material availability and pricing, leading to variations in crane costs. For example, increased demand for cranes in booming construction sectors may drive up prices.

- Technological Advances: As new technologies are developed, prices may adjust based on the incorporation of these innovations into crane designs. For instance, cranes with smart technology or IoT capabilities might command higher prices due to their advanced features.

- Competitive Landscape: Companies must also consider the pricing strategies of competitors. Researching multiple suppliers can reveal a range of pricing options and help identify the best value for a custom crane.

By These pricing factors, businesses can make informed decisions when budgeting for a custom 10-ton overhead crane, ensuring that they invest in a solution that meets their operational needs without exceeding their financial constraints.

Comparing Prices: What to Expect

Average Price Range for Standard and Custom Models

When considering the purchase of a 10-ton overhead crane, it's important to understand the price ranges for both standard and custom models.

- Standard Models: Typically, standard 10-ton overhead cranes range from $15,000 to $30,000. This pricing generally covers basic designs with standard features and materials, making them a cost-effective choice for many applications.

- Custom Models: Custom cranes can vary widely in price, often starting around $25,000 and exceeding $50,000 or more, depending on the level of customization and complexity. Factors such as design modifications, specialized components, and enhanced safety features contribute to the higher costs.

Being aware of these ranges helps businesses set realistic budgets for their crane investments.

Cost Breakdown (Materials, Labor, Installation)

The components of crane pricing can provide clarity on where funds are allocated.

- Materials: The choice of materials, such as high-strength steel or corrosion-resistant coatings, significantly affects the overall cost. Quality materials ensure durability and safety but can increase upfront expenses.

- Labor: Labor costs encompass both manufacturing and assembly. Complex designs may require more skilled labor, resulting in higher costs. Installation labor is also a factor, especially if the crane requires specialized setup or integration with existing systems.

- Installation: The cost of installation can vary based on the crane's complexity and the site conditions. Factors such as facility layout, accessibility, and any required modifications to existing structures can influence installation costs.

A detailed cost breakdown allows businesses to understand the value of their investment.

Potential Additional Costs (Maintenance, Spare Parts)

In addition to initial purchase prices, businesses should consider potential ongoing costs associated with owning a 10-ton overhead crane.

- Maintenance: Regular maintenance is essential for safe and efficient crane operation. Companies may incur costs for routine inspections, lubrication, and parts replacement, which can range from a few hundred to several thousand dollars annually, depending on usage and wear.

- Spare Parts: Over time, components may need replacement due to wear and tear. Keeping an inventory of spare parts can minimize downtime but also adds to overall costs. It's advisable to budget for these potential expenses as part of the total cost of ownership.

- Upgrades and Modifications: As operational needs evolve, businesses may find the need to upgrade or modify their cranes. Budgeting for future enhancements ensures that the crane remains effective and meets changing requirements.

By comprehensively evaluating these price comparisons and potential additional costs, businesses can make informed decisions when investing in a 10-ton overhead crane that aligns with their operational needs and budget constraints.

Investing in a 10-ton overhead crane offers numerous benefits that can enhance operational efficiency and safety across various industries. These cranes facilitate the safe and effective movement of heavy loads, streamline workflows, and improve productivity. Custom options allow businesses to tailor the crane to their specific needs, ensuring that it fits seamlessly into existing operations. Additionally, the right crane can reduce labor costs and minimize the risk of workplace injuries.

If you're considering a 10-ton overhead crane for your facility, we encourage you to reach out for inquiries or quotations. Our team is ready to assist you in exploring options that meet your operational requirements and budget. Don't hesitate to contact us for further information or to discuss your specific needs!

FAQs

Common Questions About 10-Ton Overhead Cranes

1. What is the typical lifting height of a 10-ton overhead crane?

The lifting height can vary based on design and specifications, typically ranging from 10 to 30 feet. Custom cranes can be tailored for greater heights depending on operational needs.

2. What types of controls are available for operating a 10-ton overhead crane?

Various control systems are available, including pendant controls, wireless remote controls, and operator cabins. The choice depends on the application and user preferences.

3. How often should a 10-ton overhead crane be inspected?

Regular inspections are vital for safety. It's recommended to inspect cranes at least once a year, with more frequent checks for high-use environments. Daily visual inspections by operators are also essential.

4. Can 10-ton overhead cranes be used outdoors?

Yes, many are designed for outdoor use, especially those with weather-resistant features. Ensure the crane is specified for outdoor applications to withstand environmental conditions.

Clarifications on Customization and Pricing Inquiries

1. What customization options are available for 10-ton overhead cranes?

Customization options include adjustments to span and lift height, specialized hoisting mechanisms, and enhanced safety features. Businesses can also select materials that fit specific environmental conditions, such as anti-corrosion treatments.

2. How does the customization process work?

The process starts with a consultation to assess specific operational needs. After outlining requirements, the manufacturer provides design options and cost estimates. Final specifications are agreed upon before fabrication begins.

3. What factors influence the pricing of custom 10-ton overhead cranes?

Pricing is influenced by material costs, design complexity, additional features, and compliance certifications. The extent of customization also impacts the final price.

4. Are there financing options available for purchasing a crane?

Many manufacturers offer financing options, including leasing arrangements, payment plans, or loans. It's advisable to discuss these options with the supplier for a suitable solution.

5. How can I request a quotation for a custom 10-ton overhead crane?

To request a quotation, contact the manufacturer or supplier via their website or customer service line. Providing detailed information about your requirements will help in getting an accurate quote.

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier