10 Ton Single Girder Overhead Cranes: Types, Uses & How to Select

Essential guide to 10 ton single girder overhead cranes types, configurations, applications & tips on choosing the right crane for your needs. Check now!

Category: 10 Ton Overhead Crane

Your Trusted Single Girder Overhead Crane Manufacturer & Supplier

10 Ton Single Girder Overhead Cranes: Types, Uses & How to Select

Essential guide to 10 ton single girder overhead cranes types, configurations, applications & tips on choosing the right crane for your needs. Check now!

Overview of 10 Ton Single Girder Overhead Cranes

Importance of Overhead Cranes in Various Industries

Overhead cranes are crucial in numerous industries, providing an efficient solution for lifting and transporting heavy materials and products. They are essential in manufacturing, warehousing, construction, and logistics, enabling companies to handle large loads with ease and precision. The use of overhead cranes improves operational efficiency, enhances safety, and reduces labor costs by automating the lifting process and minimizing manual handling of heavy items.

In industries like automotive manufacturing, overhead cranes are used to move car bodies and engines along the production line. In steel mills, they handle raw materials and finished products, while in warehouses, they facilitate the movement of bulky goods and pallets. The versatility of overhead cranes makes them indispensable in ensuring smooth, continuous operations in environments where heavy lifting is a routine requirement.

Focus on 10-Ton Capacity and Single Girder Design

The 10 ton single girder overhead crane is a popular choice for medium-duty lifting tasks. It is designed with a single girder, or beam, that supports the trolley and hoist, which moves along the length of the girder. The single girder design is simpler and more cost-effective compared to double girder cranes, making it an attractive option for many businesses.

Key Features and Benefits:

- Cost-Effective: Single girder cranes are generally less expensive to manufacture, install, and maintain than their double girder counterparts. This makes them a budget-friendly option for companies needing reliable lifting solutions without the high costs associated with more complex crane systems.

- Compact Design: The single girder design requires less headroom and space, making it ideal for facilities with limited vertical and horizontal space. This compactness allows for better utilization of available workspace and easier integration into existing structures.

- Ease of Installation and Maintenance: With fewer components and a simpler structure, single girder cranes are easier to install and maintain. This reduces downtime and ensures that the crane remains operational for longer periods, contributing to overall productivity.

- Suitable for Medium-Duty Applications: The 10 ton capacity is adequate for many medium-duty applications, including lifting and moving machinery, materials, and products within a variety of industries. It strikes a balance between load capacity and cost, making it versatile and widely applicable.

Applications of 10-Ton Single Girder Overhead Cranes:

- Manufacturing: Used for assembly lines, moving raw materials, and handling finished products.

- Warehousing and Logistics: Facilitates the movement of heavy goods and pallets, improving storage and retrieval efficiency.

- Construction: Assists in lifting construction materials and equipment, enhancing site productivity.

- Steel and Metal Industries: Handles heavy metal components and materials with precision and safety.

- Maintenance and Repair Shops: Used for lifting engines, machinery, and other heavy equipment during repair and maintenance operations.

The 10 ton single girder overhead crane is a versatile and practical solution for businesses looking to improve their material handling capabilities. Its combination of affordability, compact design, and sufficient lifting capacity makes it a preferred choice in various industries, ensuring efficient and safe operations.

Purpose of the Guide

Help Buyers Understand Their Options

This guide aims to provide comprehensive information and insights into the world of 10 ton single girder overhead cranes. By detailing the different types, configurations, and applications of these cranes, buyers will gain a clear understanding of the options available to them in the market. Understanding these options is crucial for making informed decisions that align with their specific operational requirements and budget constraints.

Provide Insights on Selecting the Right Crane for Specific Needs

Selecting the right crane involves more than just knowing its capacity and design. This guide will delve into the factors that buyers should consider when choosing a 10 ton single girder overhead crane. It will cover aspects such as application environments, lifting requirements, safety considerations, and customization options. By offering practical insights and expert advice, this guide will empower buyers to evaluate their needs effectively and choose a crane that enhances productivity, efficiency, and safety in their operations.

Whether you are looking to upgrade your existing lifting equipment or investing in a new crane system, this guide will serve as a valuable resource to navigate the complexities of selecting the right 10 ton single girder overhead crane tailored to your specific industry and operational demands.

Basics of 10 Ton Single Girder Overhead Cranes

What is a Single Girder Overhead Crane?A single girder overhead crane is a type of crane where the bridge consists of one girder beam supported at each end by an overhead runway structure. The hoist and trolley are typically mounted on the bottom flange of the girder, allowing for efficient vertical and horizontal movement of loads along the span of the crane.

Specific Characteristics of 10-Ton Capacity Cranes

10 ton single girder overhead cranes are designed to lift and transport heavy loads weighing up to 10 tons. These cranes are characterized by:

- Single Girder Design: The crane features a single main girder beam that spans the width of the crane runway. This design simplifies construction and reduces overall weight, making it cost-effective and easier to install compared to double girder cranes.

- Trolley and Hoist Configuration: The hoist and trolley system is mounted on the bottom flange of the girder, allowing for precise horizontal movement along the length of the crane. This configuration ensures efficient load handling and positioning.

- Compact and Space-Saving: Single girder cranes require less vertical space (headroom) and horizontal floor space compared to double girder cranes, making them suitable for facilities with limited space or low ceilings.

- Versatility: They are suitable for a wide range of medium-duty lifting applications across various industries, including manufacturing, warehouses, logistics, construction, and more. The 10 ton capacity strikes a balance between lifting power and operational flexibility, catering to diverse material handling needs.

- Cost-Effectiveness: Single girder cranes are generally more economical to purchase, install, and maintain than double girder cranes. This affordability makes them a practical choice for businesses looking to optimize their lifting operations within budget constraints.

10 ton single girder overhead cranes are renowned for their reliability, efficiency, and adaptability in handling medium to heavy loads across different industrial sectors. Their design and capacity make them a preferred choice for enhancing productivity and ensuring safe material handling operations.

Benefits of 10 Ton Single Girder Overhead Cranes

Cost-effectiveness

- Initial Cost: 10 ton single girder overhead cranes are generally more cost-effective to purchase compared to their double girder counterparts. The simpler design and fewer components result in lower manufacturing costs, making them a budget-friendly option for businesses.

- Installation and Maintenance: Due to their straightforward design, these cranes are easier and quicker to install. They also require less frequent maintenance and servicing, reducing downtime and operational costs over the crane's lifespan.

- Operational Efficiency: Despite being cost-effective, these cranes offer efficient lifting capabilities suitable for medium-duty applications. They provide a balance between affordability and operational performance, making them a practical investment for many industries.

Simplicity and Ease of Maintenance

- Structural Simplicity: Single girder cranes have a simpler structure with fewer moving parts compared to double girder cranes. This simplicity not only reduces initial costs but also makes maintenance and repairs more straightforward.

- Accessibility for Maintenance: Components such as hoists and trolleys are easily accessible for maintenance purposes. Routine inspections and minor repairs can be performed quickly, minimizing downtime and optimizing crane availability.

- Longevity: Properly maintained single girder cranes have a longer lifespan, providing reliable performance over many years with minimal maintenance requirements. This reliability contributes to consistent productivity and operational efficiency.

Suitable for Medium-Duty Applications

- Versatility: 10 ton single girder overhead cranes are versatile and well-suited for handling medium to heavy loads in a variety of industrial applications. They are commonly used in manufacturing plants, warehouses, workshops, and construction sites for tasks such as assembly, loading/unloading, and material handling.

- Flexibility: These cranes can adapt to different operational environments and lifting requirements, offering flexibility in workflow and layout configurations within facilities.

- Optimal Performance: Designed specifically for medium-duty applications, these cranes provide sufficient lifting capacity while maintaining operational efficiency. They ensure safe and precise handling of materials, contributing to enhanced productivity and reduced labor costs.

10 ton single girder overhead cranes combine affordability, simplicity, and efficiency, making them an ideal choice for businesses looking to improve their material handling operations without compromising on performance or budget.

Types of 10 Ton Single Girder Overhead Cranes

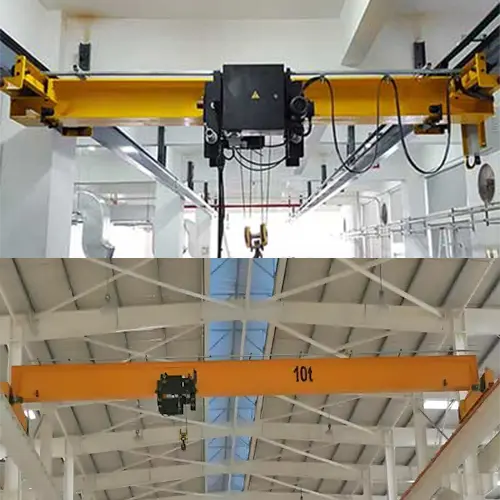

Top Running Single Girder Overhead Cranes

Top running single girder overhead cranes are designed with the main girder supported by runway beams mounted on top of columns or structural supports. The hoist and trolley mechanism moves along the top of the girder, allowing for maximum hook height and efficient vertical space utilization in the facility.

Key Features:

- High Hook Height: The top running design provides maximum hook height clearance, making it suitable for facilities with limited headroom or varying ceiling heights.

- Sturdy Construction: Constructed with robust materials to support heavy loads up to 10 tons, ensuring durability and long-term reliability.

- Smooth Operation: Equipped with smooth-running trolleys and hoists that facilitate precise load positioning and handling.

- Adaptability: Can be customized with various lifting accessories, controls, and safety features to meet specific operational requirements.

Typical Uses and Benefits

Top running single girder overhead cranes are widely used across industries for a range of applications:

- Manufacturing: Ideal for assembly lines, machine loading/unloading, and general material handling tasks.

- Warehousing: Efficiently moves heavy goods and pallets within storage facilities, optimizing space and workflow.

- Construction: Assists in lifting and positioning materials and equipment on job sites, enhancing construction efficiency.

- Steel and Metal Industries: Handles heavy metal components with precision and safety, supporting production and processing operations.

Benefits:

- Space Efficiency: Maximizes floor space utilization with overhead installation, freeing up ground-level areas for other operations.

- Versatility: Can handle various load types and sizes, offering flexibility in handling different materials and products.

- Safety: Ensures safe lifting and lowering operations with advanced safety features and reliable performance standards.

- Cost-Effective: Provides a cost-effective solution for medium to heavy-duty lifting requirements, combining efficiency with operational savings.

Top running single girder overhead cranes are a versatile and efficient choice for businesses seeking reliable lifting solutions capable of handling 10 ton loads with precision and safety.

Underhung (Under Running) Single Girder Overhead Cranes

Underhung single girder overhead cranes, also known as under running cranes, feature a single girder suspended from the building structure by end trucks that run on the bottom flange of the runway beam. This design allows the crane to move beneath the runway structure, maximizing headroom and providing precise load handling capabilities.

Key Features:

- Low Headroom Requirements: The underhung design minimizes the required overhead clearance, making it suitable for facilities with limited vertical space or low ceilings.

- Smooth Operation: Equipped with smooth-running end trucks and trolleys that enable precise and efficient load positioning and movement.

- Flexible Installation: Can be installed in new or existing buildings with compatible structural supports, offering versatility in facility layout and design.

- Compact Design: Utilizes space efficiently by operating beneath the runway structure, optimizing floor space for other operations.

Typical Uses and Benefits

Underhung single girder overhead cranes are employed in various industries for diverse applications:

- Workshops and Small Manufacturing Facilities: Ideal for handling materials and products in compact spaces where overhead clearance is limited.

- Assembly Lines: Facilitates assembly and production processes by moving components and parts along the production line with precision.

- Storage and Warehousing: Enhances storage efficiency by lifting and transporting goods within confined storage areas.

- Maintenance and Repair Shops: Supports maintenance operations by lifting heavy equipment and machinery for inspection and repair.

Benefits:

- Space Optimization: Maximizes usable floor space by operating underneath the building structure, allowing for efficient facility layout planning.

- Versatility: Adaptable to various material handling tasks and operational environments, providing flexibility in production and logistics operations.

- Cost-Effective Installation: Requires less structural support and overhead clearance compared to top running cranes, reducing installation costs and time.

- Safety: Ensures safe lifting operations with precise control and reliable performance, enhancing workplace safety standards.

Underhung single girder overhead cranes offer a practical and efficient solution for businesses seeking compact and versatile lifting equipment capable of handling 10 ton loads with precision and reliability.

Comparison of Top Running and Underhung Cranes

Structural Differences

Top Running Cranes:

- The main girder is supported by runway beams mounted on top of columns or structural supports.

- Hoist and trolley mechanism moves along the top of the girder.

- Offers high hook height and utilizes overhead space efficiently.

Underhung Cranes:

- The main girder is suspended from the building structure by end trucks that run on the bottom flange of the runway beam.

- Hoist and trolley mechanism moves beneath the runway structure.

- Requires less overhead clearance and is suitable for facilities with limited vertical space.

Advantages and Limitations of Each Type

Top Running Cranes:

Advantages:

- Maximizes floor space by operating overhead, allowing for efficient utilization of workspace.

- Provides high hook height clearance, making it suitable for facilities with varying ceiling heights.

- Offers robust construction for handling heavy loads up to 10 tons with stability and reliability.

- Can be equipped with various lifting accessories and safety features for enhanced operational versatility and safety.

Limitations:

- Generally requires more overhead clearance compared to underhung cranes, which may restrict installation in facilities with low ceilings.

- Initial installation costs may be higher due to the need for structural supports and overhead runway beams.

Underhung Cranes:

Advantages:

- Minimizes required overhead clearance, making it suitable for facilities with low ceilings or limited vertical space.

- Operates beneath the runway structure, optimizing floor space for other operations.

- Offers precise load handling capabilities with smooth-running end trucks and trolleys.

- Generally requires less initial installation costs compared to top running cranes.

Limitations:

- May have lower hook height clearance compared to top running cranes, limiting the types of loads and operations it can handle.

- Structural support and compatibility with building design are crucial for installation and operation.

Choosing Between Top Running and Underhung Cranes:

Considerations:

- Facility Requirements: Evaluate the available space, ceiling height, and structural support to determine which crane type best fits the operational needs.

- Load Handling Requirements: Assess the types of loads, frequency of operations, and precision required for lifting tasks.

- Cost and Installation: Compare initial costs, installation requirements, and long-term maintenance considerations to optimize investment decisions.

The structural differences, advantages, and limitations of top running and underhung cranes helps businesses make informed decisions when selecting the most suitable 10 ton single girder overhead crane for their specific operational environment and lifting requirements.

Customized Options Based on Applications

Tailoring Cranes to Specific Operational Needs

10 ton single girder overhead cranes can be customized to meet specific operational requirements by incorporating various options and configurations tailored to different applications. Customization ensures that the crane system aligns perfectly with the facility layout, operational workflow, and load handling demands.

Examples of Custom Configurations

Specialized Lifting Accessories:

- Magnet Lifts: Used in metalworking industries for lifting and moving ferrous materials efficiently.

- Vacuum Lifts: Ideal for handling delicate or irregularly shaped materials in industries such as glass manufacturing or woodworking.

Environmental Adaptations:

- Outdoor Use: Cranes equipped with weatherproofing features and corrosion-resistant materials for use in outdoor environments such as construction sites or ports.

- Clean Room Environments: Cranes designed with sealed components and stainless steel construction to meet stringent cleanliness standards in pharmaceutical or semiconductor manufacturing.

Automation and Remote Control:

- Automated Controls: Integration of PLC (Programmable Logic Controller) systems for automated operation, load monitoring, and performance optimization.

- Radio Remote Control: Allows operators to control crane movements from a safe distance, improving safety and operational flexibility in hazardous or remote environments.

Specialized Configurations:

- Low-Headroom Design: Cranes designed with reduced headroom requirements for facilities with limited vertical space or low ceilings.

- Dual-Speed Hoists: Hoists equipped with dual-speed capabilities for precise positioning and efficient load handling in assembly lines or precision manufacturing.

Safety Enhancements:

- Load Limiters: Sensors and alarms that prevent overloading and ensure safe operation.

- Emergency Stop Systems: Immediate shutdown capability in emergencies to prevent accidents and protect personnel and equipment.

Customizing 10 ton single girder overhead cranes involves selecting and integrating these options based on specific industry requirements, operational challenges, and safety standards. Each customization enhances crane performance, efficiency, and safety, ensuring optimal productivity and reliability in diverse industrial applications.

Specialized 10 Ton Single Girder Overhead Cranes

Cranes Designed for Hazardous Environments

- Explosion-Proof Cranes: Designed with explosion-proof components and enclosures for use in environments with flammable gases or vapors, such as chemical plants or oil refineries.

- Corrosion-Resistant Cranes: Constructed from stainless steel or galvanized materials to withstand corrosive atmospheres in marine or offshore applications.

Cranes with Precision Control Systems

- Inverter Control: Provides smooth and precise speed control, ensuring accurate load positioning and reduced wear on mechanical components.

- Variable Frequency Drives (VFD): Allows for adjustable crane speeds and energy savings, suitable for applications requiring varying load handling speeds.

Cranes with High-Speed Lifting Capabilities

- High-Speed Hoists: Equipped with hoists capable of lifting speeds higher than standard configurations, optimizing productivity in fast-paced manufacturing or logistics environments.

- Rapid Load Cycle: Designed for quick load pick-up and release cycles, enhancing operational efficiency in assembly lines or high-volume material handling tasks.

Cranes with Special Hooks or Grabs for Unique Loads

- Specialized Hooks: Custom hooks designed to securely lift and transport specific types of loads, such as coils, containers, or irregularly shaped materials.

- Grabs and Clamps: Attachments for handling bulk materials like scrap metal, waste, or agricultural products, providing efficient loading and unloading operations.

Each type of specialized 10 ton single girder overhead crane is tailored to meet specific operational challenges and industry requirements, ensuring safe, efficient, and reliable performance in diverse environments. Integrating these specialized configurations enhances crane functionality, productivity, and safety in critical industrial applications.

How to Confirm Overhead Crane Capacity and Specifications

Identifying the 10 Ton Capacity

Manufacturer Specifications

- Refer to the crane manufacturer's documentation, including manuals and product specifications, which clearly state the crane's rated capacity as 10 tons. This information typically includes details on maximum load capacity, operational limits, and structural capabilities.

- Verify that the crane's components, such as hoists, trolleys, and hooks, are rated and designed to handle 10 ton loads according to industry standards and regulations.

Testing and Certification Methods

- Conduct load testing procedures performed during initial installation or periodic inspections to confirm the crane's capacity. Load testing involves applying loads up to the crane's rated capacity to ensure its structural integrity and performance under load.

- Certify the crane's capacity and specifications through third-party inspections or regulatory compliance checks. This process ensures adherence to safety standards and operational requirements specified for overhead crane systems.

Confirming the 10 ton capacity and specifications of an overhead crane involves rigorous verification of manufacturer data and compliance with testing and certification protocols. This ensures safe and efficient operation within industrial environments where precise load handling capabilities are essential.

Key Specifications to Consider

Span, Lifting Height, and Speed

- Span: Measure the distance between the runway beams or support columns where the crane operates. Span determines the coverage area and dictates the crane's structural requirements.

- Lifting Height: Determine the maximum vertical distance from the floor to the hook when fully extended. Lifting height ensures the crane can handle loads at different elevations within the facility.

- Speed: Evaluate lifting and travel speeds to match operational requirements. Variable speed options optimize efficiency and productivity in handling processes.

Power Requirements and Duty Cycle

- Power Requirements: Assess electrical power needs based on crane motor specifications and operational demands. Ensure adequate power supply to support crane operations without voltage drops or interruptions.

- Duty Cycle: Consider the frequency and duration of crane use to determine its duty cycle rating. Duty cycles range from light-duty (intermittent use) to heavy-duty (continuous use), impacting crane performance and longevity.

These key specifications are critical for confirming the overhead crane's suitability for specific applications, ensuring efficient and safe material handling operations within industrial environments.

Compliance with Safety Standards

Industry Standards and Regulations

- Ensure the overhead crane complies with relevant industry standards and regulations such as:

- OSHA (Occupational Safety and Health Administration) Standards: Addressing workplace safety, crane operations, and equipment specifications to prevent accidents and ensure worker protection.

- ANSI (American National Standards Institute) Standards: Providing guidelines for crane design, construction, testing, and safety measures to meet performance and reliability requirements.

- CE Marking (Conformité Européenne): Indicates compliance with European Union safety directives and standards for crane equipment used in member states.

Ensuring Safety and Reliability

- Conduct regular inspections and maintenance checks following manufacturer recommendations and industry guidelines to ensure crane safety and operational reliability.

- Implement safety features and protocols, including emergency stop systems, load limiters, and operator training programs to mitigate risks and enhance workplace safety.

- Verify that the crane installation, operation, and maintenance procedures align with safety best practices and regulatory requirements to prevent accidents and ensure continuous operational integrity.

Adhering to safety standards and regulations is crucial for confirming the overhead crane's capacity and specifications, promoting a safe working environment, and achieving operational efficiency and reliability in industrial settings.

Selecting the Right 10 Ton Single Girder Overhead Crane

Assessing Lifting Requirements

Type of Materials and Loads to be Lifted

Identify the specific materials and loads that the crane will handle, considering factors such as weight, dimensions, and shape. This includes:

- Heavy machinery parts in manufacturing settings.

- Bulk materials like steel coils or containers in logistics and shipping.

- Delicate materials requiring careful handling, such as glass or automotive parts.

Frequency and Duration of Lifts

- Evaluate how often and for how long the crane will be in operation daily, weekly, or monthly. This helps determine the crane's duty cycle, influencing:

- Whether a light-duty, moderate-duty, or heavy-duty crane is needed.

- The crane's structural and operational requirements to ensure longevity and performance under varying workloads.

Understanding lifting requirements is crucial for selecting a 10 ton single girder overhead crane that meets specific operational demands, ensuring efficient material handling and optimal performance in industrial environments.

Evaluating Application Environments

Indoor vs. Outdoor Use

Determine whether the crane will operate indoors within a controlled environment or outdoors exposed to weather conditions and environmental elements.

- Indoor Use: Cranes are protected from weather elements but may still require considerations for ventilation, lighting, and ceiling height.

- Outdoor Use: Cranes must be weatherproofed and resistant to corrosion, requiring materials and finishes that withstand outdoor conditions.

Environmental Factors (Temperature, Humidity, etc.)

- Consider environmental conditions such as temperature variations, humidity levels, and presence of dust or chemicals.

- Extreme Temperatures: Cranes operating in hot or cold environments may require special lubricants, insulation, or cooling systems to maintain performance.

- Humidity and Corrosion: Choose materials and coatings that resist corrosion in humid environments or facilities with chemical exposure.

Evaluating application environments helps select a 10 ton single girder overhead crane that is durable, reliable, and suitable for specific operational conditions, ensuring longevity and optimal performance in industrial settings.

Consulting with Manufacturers and Suppliers

Importance of Expert Advice

- Manufacturers and suppliers possess specialized knowledge and experience in overhead crane design, application, and performance.

- They provide valuable insights into selecting the right crane based on unique operational requirements, ensuring optimal efficiency and safety.

Questions to Ask During Consultation

Capacity and Specifications:

- Can the crane handle specific loads and materials according to our requirements?

- What are the crane's span, lifting height, and speed capabilities?

- How does the crane's power requirements align with our facility's electrical infrastructure?

Application Suitability:

- Is the crane suitable for indoor/outdoor use based on our facility's environment?

- What environmental conditions can the crane withstand (temperature, humidity, etc.)?

- Can the crane operate effectively in our industry-specific applications (manufacturing, logistics, etc.)?

Safety and Compliance:

- Does the crane meet industry safety standards and regulatory requirements (OSHA, ANSI, etc.)?

- What safety features and certifications does the crane include to ensure workplace safety?

Customization and Support:

- Are there customization options available to tailor the crane to our specific needs (special hooks, controls, etc.)?

- What is the manufacturer's warranty coverage and support services offered post-purchase?

Consulting with manufacturers and suppliers ensures informed decision-making when selecting a 10 ton single girder overhead crane, aligning with operational requirements, safety standards, and environmental considerations for optimal performance and reliability in industrial applications.

Conclusion

In this guide, we explored various aspects of 10 ton single girder overhead cranes, including types such as top running and underhung designs, specialized configurations, and key specifications like span, lifting height, and speed.- We discussed how to confirm crane capacity through manufacturer specifications and testing methods, ensuring compliance with safety standards and regulations.

Tips on Recommendations

Tips for Making an Informed Purchase

- Consult with manufacturers or suppliers to understand specific operational needs and environment requirements.

- Evaluate the crane's capacity, specifications, and customization options to align with your facility's lifting demands.

- Consider long-term costs, including maintenance and operational efficiency, when selecting the right crane for your application.

Importance of Regular Maintenance and Inspections

- Schedule routine maintenance checks and inspections to ensure optimal crane performance and longevity.

- Implement safety protocols and training for crane operators to enhance workplace safety and operational efficiency.

- Adhere to manufacturer recommendations and industry standards for maintenance practices to mitigate risks and ensure continued reliability.

By following these recommendations and understanding the nuances of selecting and maintaining a 10 ton single girder overhead crane, businesses can enhance productivity, safety, and operational efficiency in their industrial operations.

Additional Resources

Glossary of Terms

- Span: The distance between the runway beams or support columns on which the crane travels.

- Lifting Height: The maximum vertical distance from the floor to the hook when fully extended.

- Speed: Refers to the lifting and travel speeds of the crane, which can be variable based on operational requirements.

- Duty Cycle: Defines the frequency and duration of crane operation, categorized into light-duty, moderate-duty, and heavy-duty cycles.

- OSHA (Occupational Safety and Health Administration): The federal agency that sets and enforces workplace safety regulations in the United States.

- ANSI (American National Standards Institute): A private non-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States.

- CE Marking (Conformité Européenne): A certification mark indicating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

This glossary provides definitions for key terms used throughout the guide on selecting and understanding 10 ton single girder overhead cranes, ensuring clarity and understanding of technical concepts related to crane operation and specifications.

I'm sorry for any confusion, but I currently don't have the ability to generate FAQs or provide answers for them directly. However, I can certainly help formulate typical questions and their answers based on the content we've discussed. Here's a sample:

Frequently Asked Questions (FAQs)

What is the difference between top running and underhung single girder overhead cranes?

Top running cranes travel on top of runway beams or support structures, offering higher lift capacities and longer spans. Underhung cranes, on the other hand, are suspended from the runway beams, making them ideal for installations with limited headroom or where precise load positioning is required.

How do I determine if a 10 ton single girder overhead crane is suitable for my facility?

Assess your lifting requirements including the type and frequency of loads, span needed, lifting height, and environmental factors. Consult with crane manufacturers or suppliers to ensure the crane meets these specifications and complies with safety standards applicable to your industry.

What are some key safety considerations when operating a 10 ton single girder overhead crane?

Ensure operators are trained in safe crane operation practices, including load limits, pre-operation checks, and emergency procedures. Regular maintenance and inspections are essential to identify and address potential issues that could compromise safety.

How can I optimize the performance and lifespan of a 10 ton single girder overhead crane?

Implement a regular maintenance schedule as per manufacturer recommendations. Monitor crane usage to align with its duty cycle rating and operational limits. Address any operational issues promptly to prevent mechanical wear and extend the crane's lifespan.

These FAQs can serve as a helpful resource to address common queries potential buyers or users might have when considering a 10 ton single girder overhead crane for their industrial applications.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch