Ultimate Guide to 10 Ton Double Girder Overhead Cranes in Construction

Guide on10 ton double girder overhead cranes in construction, highlighting specifications, benefits & application scenarios for enhanced efficiency. Click!

Category: 10 Ton Overhead Crane

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

Ultimate Guide to 10 Ton Double Girder Overhead Cranes in Construction

Guide on10 ton double girder overhead cranes in construction, highlighting specifications, benefits & application scenarios for enhanced efficiency. Click!

Comprehensive Guide to 10 Ton Double Girder Overhead Cranes in Construction

10-ton double girder overhead cranes are robust lifting devices designed for handling heavy loads in construction environments. They feature two beams (girders) atop parallel runways, providing superior strength and stability compared to single girder cranes. This design allows them to lift larger capacities and manage heavier materials with ease.

In the construction sector, these cranes play a pivotal role in facilitating efficient material handling and construction processes. They are essential for lifting and positioning heavy components such as steel beams, concrete panels, machinery parts, and prefabricated structures. Their versatility makes them suitable for a wide range of construction projects, from building skyscrapers and bridges to assembling industrial facilities and handling materials in warehouses.

Advantages over Other Crane Types

- Enhanced Capacity: Capable of lifting heavier loads compared to single girder cranes, making them ideal for large-scale construction projects.

- Improved Stability: Double girder design provides increased stability and reduces sway during lifting operations, ensuring safety and precision.

- Durability: Built to withstand rigorous construction site conditions, offering long-term reliability and minimal downtime.

- Versatility: Suitable for various applications including lifting bulky materials, machinery installation, and structural assembly.

These cranes are valued for their efficiency, safety features, and ability to optimize construction timelines by streamlining material handling tasks. Their robust design and lifting capabilities make them indispensable in modern construction practices.

Types of 10 Ton Double Girder Overhead Cranes

There are several types of 10-ton double girder overhead cranes available, each tailored to specific operational needs and environments in the construction and industrial sectors. Here are some common types:

Each type of 10-ton double girder overhead crane offers distinct advantages depending on the operational needs, facility layout, and load handling requirements of the construction or industrial setting. Choosing the right type involves considering factors such as load capacity, span length, height clearance, and the specific demands of the application to ensure optimal performance and efficiency.

NLH Double Girder Overhead Cranes with Top Running Design:

- General Purpose Usage: These cranes are versatile and robust, suitable for medium to heavy lifting in a wide range of industrial applications.

- Top Running Configuration: Designed with rails mounted on top of the runway beams, allowing for efficient load movement and optimal use of headroom.

- Suitable for Heavy Loads: Ideal for environments requiring frequent and intensive lifting operations, such as steel mills, foundries, and heavy manufacturing facilities. They are capable of handling loads up to 10 tons with reliability and precision.

QDX Box Girder Double Girder Cranes with Open Winch Trolley:

- Enhanced Flexibility: Similar to the hoist trolley variant, these cranes feature an open winch design that offers increased accessibility and ease of maintenance.

- Efficient Maintenance: The open winch design simplifies maintenance tasks, providing quick access to critical components, thereby minimizing downtime and ensuring efficient operations.

- Versatile Applications: Used across diverse applications requiring heavy lifting capabilities combined with operational flexibility. They are commonly found in industries such as automotive manufacturing and power generation, handling components like heavy dies, turbine parts, and generator components.

LH Box Girder Double Girder Cranes with Hoist Trolley:

- Structural Strength: These cranes utilize box-shaped girders that provide exceptional strength and stability, ensuring reliable performance under heavy loads.

- Hoist Trolley Integration: Equipped with a hoist trolley system that enhances flexibility and precision in load handling and positioning. This design allows for smooth movement and precise placement of heavy components.

- Applications: They are well-suited for demanding industrial environments where robust construction and precise load control are crucial, such as shipyards and large-scale construction sites handling components like ship hulls, large beams, and heavy machinery parts.

QD Customized Double Girder Cranes with Builtup Hoist :

- Tailored Solutions: These cranes are specifically engineered to meet unique project requirements and operational challenges, offering bespoke configurations and specialized features.

- Industry-Specific Adaptations: Customized for applications across various industries, including aerospace, nuclear facilities, and specialized manufacturing where standard crane configurations may not suffice.

- Key Features: Customizations can include specialized controls for intricate operations, extended spans to cover larger areas, enhanced safety systems such as anti-collision devices and overload protection, and seamless integration with existing infrastructure to optimize operational efficiency and safety.

Each type of double girder overhead crane offers distinct advantages tailored to specific industrial needs, ensuring reliable performance, safety, and efficiency in handling heavy loads and critical materials across various operational environments.

These descriptions outline the distinct features and applications of each type of 10-ton double girder overhead crane, highlighting their suitability for different industrial environments and specific operational needs.

Design and Components of 10 Ton Double Girder Overhead Cranes

Structural Design Features

10-ton double girder overhead cranes are engineered with a sturdy structure to ensure reliable performance in demanding construction environments. The key structural design features include:

- Double Girder Configuration: Two parallel beams spanning the crane runway, providing increased stability and lifting capacity compared to single girder cranes.

- Box Girder Construction: Utilizes box-shaped girders for added strength and rigidity, capable of supporting heavy loads without deformation.

- End Carriages: Support the bridge and provide smooth movement along the runway through wheels mounted on axles.

Components Overview

These cranes consist of several essential components that work together to facilitate efficient lifting operations:

- Hoist: Mounted on the trolley, the hoist lifts and lowers loads vertically. It incorporates a motor, drum, and braking system for controlled lifting.

- Bridge: The main structure spanning the width between the runways, supporting the hoist, trolley, and load.

- Trolley: Moves horizontally across the bridge, allowing precise positioning of the load within the crane's span.

- Controls: Include pendant controls or radio remote control systems for operating the crane, adjusting speed, and managing load movements.

Safety Features and Compliance

Safety is paramount in crane operations, especially in construction settings. 10-ton double girder overhead cranes are equipped with:

- Limit Switches: Prevent over-travel and ensure safe operation within specified limits.

- Emergency Stop: Allows immediate halting of crane operations in case of emergency.

- Load Limiting Devices: Prevents overloading, ensuring crane and operator safety.

- Safety Audits and Compliance: Regular inspections and adherence to safety standards (such as OSHA, ANSI, or local regulations) ensure safe crane operation and site compliance.

These safety features mitigate risks associated with heavy lifting, enhancing workplace safety and operational efficiency on construction sites.

Applications in Construction Industry

Types of Construction Projects Utilizing 10 Ton Double Girder Cranes

10-ton double girder overhead cranes play a crucial role in several key construction applications, leveraging their robust lifting capabilities and precise material handling features:

Skyscraper Construction

In skyscraper construction projects, these cranes are essential for:

- Lifting Heavy Structural Components: Such as steel beams and concrete panels, facilitating the vertical construction of skyscrapers.

- High Load Capacity: Handling substantial weights required for building tall structures efficiently and safely.

Bridge Construction

For bridge construction, 10-ton double girder overhead cranes are utilized in:

- Handling Large Bridge Sections and Girders: Critical for assembling bridge components such as decks, beams, and supporting structures.

- Precise Placement: Ensuring accurate positioning of heavy materials to achieve structural integrity and alignment.

Industrial Facility Construction

In the construction of industrial facilities like manufacturing plants and warehouses, these cranes excel in:

- Installing Heavy Machinery and Equipment: Such as assembly line components, industrial boilers, and storage systems.

- Construction of Robust Structures: Supporting the erection of large-scale industrial buildings that require durable infrastructure.

Overall, 10-ton double girder overhead cranes are indispensable in construction projects where heavy lifting, precise positioning, and reliable material handling capabilities are essential. They enhance operational efficiency, ensure safety compliance, and contribute to timely project completion in diverse construction environments.

Detailed Applications of 10 Ton Overhead Cranes

Heavy Steel Beam Handling with 10 Ton Double Girder Overhead Cranes

In the realm of structural steel fabrication, the efficient handling of heavy steel beams, girders, and other structural components is paramount to ensuring both precision and productivity. At the heart of this capability lies the versatile 10-ton double girder overhead crane, a stalwart in industrial settings where robust lifting capacities and precise material control are indispensable.

- Typical Loads Handled:These cranes excel in managing substantial loads such as steel beams, girders, and structural components, typically weighing up to 10 tons. This capability makes them indispensable in environments demanding efficient handling of large and bulky materials essential for structural fabrication.

- Typical Crane Application:Found predominantly in structural steel fabrication workshops, 10-ton double girder overhead cranes play a pivotal role in the assembly and movement of steel components. These cranes are tailored to navigate the expansive spaces of workshops, facilitating the seamless transport and positioning of steel beams and girders with exactitude.

- Typical Tonnages Used:The choice of a 10-ton capacity aligns perfectly with the demands of handling heavy steel components efficiently. This tonnage range strikes a balance between robust lifting power and operational agility, allowing for the swift and safe maneuvering of large steel structures within the confines of a fabrication workshop.

In essence, the 10-ton double girder overhead crane stands as a cornerstone in the realm of structural steel fabrication, enabling workshops to achieve optimal efficiency and precision in heavy steel beam handling. Its ability to manage substantial loads with finesse ensures that projects progress smoothly, meeting stringent quality standards and timelines. As industries continue to evolve, these cranes remain indispensable tools, driving the seamless integration of heavy steel components into the built environment.

Precast Concrete Panel Installation with 10 Ton Double Girder Overhead Cranes

In the domain of precast concrete manufacturing and construction, the precise installation of concrete panels, slabs, and elements is critical for ensuring structural integrity and project efficiency. Central to this process are 10-ton double girder overhead cranes, renowned for their robust lifting capabilities and exacting material handling.

- Typical Loads Handled:These cranes excel in managing heavy loads such as precast concrete panels, slabs, and structural elements. With a lifting capacity of up to 10 tons, they are instrumental in safely transporting and positioning large concrete components during installation.

- Typical Crane Application:Found extensively in precast concrete manufacturing plants and construction sites, 10-ton double girder overhead cranes play a pivotal role in the assembly and installation of precast concrete elements. They are designed to maneuver within the confines of manufacturing facilities and construction environments, ensuring precise placement of concrete panels and slabs with efficiency and accuracy.

- Typical Tonnages Used:The 10-ton capacity of these cranes aligns perfectly with the demands of handling precast concrete components. This tonnage range strikes a balance between robust lifting power and maneuverability, enabling the seamless integration of precast concrete elements into construction projects.

In summary, 10-ton double girder overhead cranes are indispensable in the realm of precast concrete panel installation, facilitating the safe and efficient handling of heavy concrete loads. Their ability to lift and position precast elements with precision not only enhances construction site productivity but also ensures adherence to quality standards and project timelines. As the construction industry continues to innovate, these cranes remain integral to the seamless integration of precast concrete solutions, driving efficiency and excellence in building projects worldwide.

Machinery and Equipment Assembly with 10 Ton Double Girder Overhead Cranes

In the realm of industrial machinery assembly, the precise handling and installation of heavy equipment parts are crucial for operational efficiency and safety. At the forefront of this capability are 10-ton double girder overhead cranes, renowned for their robust lifting capacities and precise material handling.

- Typical Loads Handled:These cranes excel in managing heavy loads such as machinery and equipment parts, typically weighing up to 10 tons. Their robust design and precise control mechanisms ensure the safe and efficient transport and positioning of industrial components during assembly.

- Typical Crane Application:Found extensively in machinery assembly workshops and industrial facilities, 10-ton double girder overhead cranes play a pivotal role in the assembly and installation of heavy machinery. They are designed to navigate the expansive spaces of workshops and manufacturing facilities, facilitating the seamless integration of machinery parts with precision and reliability.

- Typical Tonnages Used:The 10-ton capacity of these cranes is perfectly suited for safely installing and positioning industrial machinery. This tonnage range strikes a balance between lifting power and operational flexibility, enabling efficient handling of heavy equipment parts while ensuring adherence to stringent safety standards.

In conclusion, 10-ton double girder overhead cranes are indispensable in the realm of machinery and equipment assembly, facilitating the safe and efficient handling of heavy industrial loads. Their ability to lift and position machinery parts with precision not only enhances assembly line productivity but also ensures the integrity and safety of industrial operations. As industries continue to evolve, these cranes remain integral to the seamless integration of heavy equipment solutions, driving efficiency and excellence in industrial manufacturing worldwide.

Shipyard Construction with 10 Ton Double Girder Overhead Cranes

In the dynamic environment of shipyard construction, the efficient handling and assembly of ship components and heavy materials are crucial for maritime operations. At the forefront of this capability are 10-ton double girder overhead cranes, renowned for their robust lifting capacities and precise material handling.

- Typical Loads Handled:These cranes excel in managing substantial loads such as ship components, large ship parts, and heavy materials. With a lifting capacity of up to 10 tons, they facilitate the safe transport and precise positioning of ship structures during construction and assembly.

- Typical Crane Application:Found prominently in shipbuilding yards and dockyards, 10-ton double girder overhead cranes play a pivotal role in the assembly and construction of maritime vessels. They are designed to operate in maritime environments, navigating large workspaces and ensuring the efficient integration of ship components with accuracy and reliability.

- Typical Tonnages Used:The 10-ton capacity of these cranes is ideally suited for maneuvering and assembling ship structures. This tonnage range provides the necessary lifting power and stability required for handling heavy ship components and structural elements during the construction phase.

In summary, 10-ton double girder overhead cranes are indispensable in shipyard construction, facilitating the safe and efficient handling of ship components and heavy materials. Their ability to lift and position ship structures with precision not only enhances shipbuilding productivity but also ensures adherence to maritime safety standards and project timelines. As shipbuilding continues to advance, these cranes remain integral to the seamless integration of ship structures, driving efficiency and excellence in maritime construction worldwide.

Bridge Construction and Erection with 10 Ton Double Girder Overhead Cranes

Bridge construction demands precision and strength in handling heavy components and construction materials. The 10-ton double girder overhead crane stands out as a reliable solution for these tasks, combining robust lifting capabilities with precise material control.

- Typical Loads Handled:These cranes are adept at managing a variety of heavy loads essential for bridge construction, including bridge sections, beams, and construction materials. Their capacity to lift up to 10 tons ensures the safe and efficient transportation and placement of critical bridge components.

- Typical Crane Application:Primarily employed in bridge construction sites and infrastructure projects, 10-ton double girder overhead cranes play a crucial role in the assembly and erection of bridges. Designed to operate in rugged construction environments, these cranes navigate the complexities of bridge construction sites, facilitating the precise positioning and integration of bridge components with ease.

- Typical Tonnages Used:The 10-ton capacity of these cranes is well-suited for lifting and positioning bridge components. This tonnage range strikes a balance between lifting power and maneuverability, enabling efficient handling of heavy bridge sections and ensuring structural integrity during the erection phase of bridge construction projects.

In conclusion, 10-ton double girder overhead cranes are indispensable in bridge construction and erection, enabling the safe and efficient handling of heavy bridge components and construction materials. Their ability to lift and position bridge structures with precision contributes to the timely completion and quality assurance of bridge infrastructure projects. As bridge construction methods evolve, these cranes continue to play a pivotal role in enhancing construction efficiency and safety, driving progress in infrastructure development worldwide.

Industrial Warehouse Operations with 10 Ton Double Girder Overhead Cranes

Efficient material handling is essential in industrial warehouses and manufacturing plants, where the movement of heavy goods and machinery must be precise and timely. The 10-ton double girder overhead crane plays a pivotal role in these operations, offering robust lifting capabilities and precise control.

- Typical Loads Handled:These cranes are adept at managing a variety of heavy loads commonly found in industrial warehouses, including bulk materials, heavy industrial goods, and machinery components. With a lifting capacity of up to 10 tons, they ensure efficient and safe handling of diverse materials within warehouse facilities.

- Typical Crane Application:Primarily used in manufacturing plants, warehouses, and logistics hubs, 10-ton double girder overhead cranes are instrumental in streamlining warehouse operations. They are designed to operate efficiently in industrial settings, facilitating the movement and placement of materials with accuracy and reliability.

- Typical Tonnages Used:The 10-ton capacity of these cranes is well-suited for handling heavy industrial goods and machinery components. This tonnage range strikes a balance between lifting power and operational flexibility, enabling warehouses to optimize material flow and enhance productivity.

In summary, 10-ton double girder overhead cranes are indispensable in industrial warehouse operations, supporting the efficient handling and management of heavy loads and machinery. Their ability to lift and transport materials with precision not only improves operational efficiency but also ensures the safety and reliability of material handling processes in manufacturing and logistics environments. As industrial practices evolve, these cranes continue to play a crucial role in enhancing warehouse productivity and meeting the demands of modern industrial operations.

Steel Mill Operations with 10 Ton Double Girder Overhead Cranes

Steel mills and foundries require robust equipment for handling heavy steel products efficiently. The 10-ton double girder overhead crane is essential in these operations, offering strong lifting capabilities and precise control for critical tasks.

- Typical Loads Handled:These cranes excel in handling heavy loads typical of steel mill operations, including steel billets, ladles filled with molten metal, and various heavy steel products. With a lifting capacity of up to 10 tons, they ensure the safe and efficient movement of materials within the industrial setting.

- Typical Crane Application:Predominantly used in steel mills and foundries, 10-ton double girder overhead cranes play a crucial role in the production and processing of steel. They are designed to withstand the demanding conditions of these environments, facilitating the precise positioning and handling of heavy steel components with reliability and efficiency.

- Typical Tonnages Used:The 10-ton capacity of these cranes is ideal for efficiently handling steel products in industrial settings. This capacity range supports the rigorous demands of steel mill operations, ensuring seamless material flow and enhancing productivity in the production and processing of steel.

In conclusion, 10-ton double girder overhead cranes are integral to steel mill operations, enabling the safe and efficient handling of heavy steel products such as billets and ladles. Their robust lifting capabilities and precise material control contribute to the reliability and productivity of steel manufacturing processes. As steel production evolves, these cranes continue to be essential tools, supporting the advancement of industrial capabilities in steel mills and foundries worldwide.

These topics highlight the versatility and specific applications of 10-ton double girder overhead cranes across various construction and industrial environments. Each title encapsulates the crane type, typical loads handled, applications, and tonnages used, making them informative and appealing for further exploration.

Load Handling Capabilities

Typical Loads and Objects Handled

10-ton double girder overhead cranes are designed to handle a wide range of heavy loads and materials essential for construction activities. Typical loads and objects include:

- Steel Beams and Columns: Lifting and positioning large steel beams, columns, and structural components used in building construction and industrial facilities.

- Precast Concrete Elements: Maneuvering precast concrete panels, slabs, and elements in precast concrete plants and construction sites.

- Heavy Machinery and Equipment: Installing and relocating heavy machinery and equipment components during construction and industrial assembly processes.

- Bulk Materials: Transporting bulk materials such as aggregates, sand, gravel, and other construction materials within warehouses and construction sites.

Weight Capacities and Range

10-ton double girder cranes typically have lifting capacities ranging from 1 ton to 10 tons, depending on the specific model and configuration. They are capable of handling loads with precision and efficiency within their designated span and height capabilities.

Examples of Load Handling Scenarios

- Steel Fabrication: Lifting and positioning steel beams weighing several tons for welding and assembly in steel fabrication workshops.

- Precast Concrete Handling: Moving precast concrete panels weighing up to 10 tons each for assembly and installation in construction projects.

- Shipbuilding: Handling ship components such as hull sections and heavy machinery during ship construction and assembly in shipbuilding yards.

- Bridge Construction: Erecting bridge segments and steel girders weighing several tons each for bridge construction and infrastructure projects.

- Industrial Warehousing: Transporting heavy machinery and bulk materials within industrial warehouses for storage and distribution purposes.

These examples highlight the versatility and robust load handling capabilities of 10-ton double girder overhead cranes, demonstrating their crucial role in various construction and industrial applications where heavy lifting and precise material handling are essential.

Benefits and Advantages

Operational Efficiency

10-ton double girder overhead cranes offer significant operational efficiency advantages in construction and industrial settings:

- Increased Productivity: Capable of lifting heavy loads with precision and speed, reducing downtime and enhancing workflow efficiency.

- Quick Material Handling: Facilitates rapid movement and positioning of materials, minimizing project timelines and improving project delivery.

- Multi-tasking Capability: Allows simultaneous handling of multiple loads or tasks, optimizing resource utilization and overall operational output.

Safety Enhancements

Safety is paramount in crane operations, and 10-ton double girder cranes are equipped with features that enhance workplace safety:

- Stable Lifting: Double girder design provides enhanced stability and reduces sway during lifting operations, ensuring safer load handling.

- Advanced Control Systems: Incorporates safety features such as limit switches, overload protection, and emergency stop controls to prevent accidents and injuries.

- Operator Comfort and Safety: Ergonomic designs and operator-friendly controls minimize fatigue and improve operator safety during extended crane use.

Versatility in Handling Various Materials

These cranes are versatile in their ability to handle a wide range of materials and applications:

- Heavy Materials: Capable of lifting heavy steel beams, concrete panels, machinery, and other bulky materials used in construction and industrial projects.

- Variable Load Sizes: Adjusts to handle different load sizes and shapes with ease, from large structural components to smaller, more delicate materials.

- Adaptability to Different Environments: Suitable for indoor and outdoor use, accommodating diverse construction and industrial site requirements.

Overall, 10-ton double girder overhead cranes combine operational efficiency, safety enhancements, and versatility to effectively meet the rigorous demands of construction and industrial applications, making them indispensable tools for modern construction projects and industrial operations.

Customization Options and Special Features

Tailoring Cranes to Specific Construction Needs

10-ton double girder overhead cranes can be customized to meet specific requirements and operational challenges in construction:

- Span and Height Adjustments: Tailoring the crane's span and lifting height to accommodate the layout and dimensions of construction sites or specific project requirements.

- Load Capacity Modifications: Adjusting the crane's lifting capacity to handle varying load sizes and weights encountered in different construction phases.

- Environmental Adaptability: Incorporating features for weather resistance, corrosion protection, and operation in extreme temperatures or challenging environmental conditions.

Advanced Features

These cranes offer advanced technological features that enhance operational efficiency and safety:

- Remote Control Systems: Allowing operators to control crane movements from a safe distance, improving visibility and operational control.

- Automation and Programmable Logic Control (PLC): Implementing automation for repetitive tasks, reducing human error and optimizing crane performance.

- Diagnostic and Monitoring Systems: Real-time monitoring of crane performance and condition, enabling predictive maintenance and minimizing downtime.

Integration with Existing Construction Equipment

10-ton double girder cranes can seamlessly integrate with other construction equipment and systems:

- Compatibility with Existing Infrastructure: Ensuring compatibility with existing runway systems, hoisting equipment, and operational workflows in construction sites.

- Collaborative Operation: Coordinating with other machinery and equipment for synchronized material handling and assembly processes.

- Enhanced Efficiency: Streamlining construction operations by integrating cranes with material handling systems, conveyor belts, and assembly lines.

By offering extensive customization options and advanced features, 10-ton double girder overhead cranes are tailored to meet specific construction needs, enhance operational capabilities, and optimize efficiency in diverse construction environments.

Maintenance and Service Considerations

Regular Inspection and Maintenance Practices

Maintaining 10-ton double girder overhead cranes involves comprehensive inspection and upkeep to ensure safe and efficient operation:

- Scheduled Inspections: Conducting regular inspections of critical components such as hoists, trolleys, brakes, and structural elements according to manufacturer guidelines and regulatory requirements.

- Preventive Maintenance: Performing routine maintenance tasks such as lubrication, alignment checks, and wear part replacement to prevent breakdowns and prolong crane lifespan.

- Fault Detection: Using diagnostic tools and technologies to identify potential issues early, allowing for proactive repairs and minimizing downtime.

Service Life Expectancy and Durability

Understanding the service life expectancy and durability of these cranes is crucial for maintenance planning and investment:

- Expected Lifespan: Evaluating the expected lifespan based on usage intensity, operational conditions, and adherence to maintenance schedules.

- Durability Factors: Considering factors such as crane design, materials used, and environmental conditions to assess durability and anticipate maintenance needs.

- Component Replacement: Planning for timely replacement of wear parts and components to maintain optimal performance and safety over the crane's lifecycle.

Importance of Professional Service Providers

Engaging qualified service providers is essential for ensuring the reliability and safety of 10-ton double girder overhead cranes:

- Expertise and Training: Leveraging specialized knowledge and training of certified technicians who understand crane mechanics and safety protocols.

- Compliance and Regulations: Ensuring compliance with industry standards, regulatory requirements, and manufacturer recommendations for crane maintenance and servicing.

- Emergency Response: Accessing prompt technical support and emergency repair services to address unexpected breakdowns and minimize operational disruptions.

Proper maintenance and professional servicing are integral to maximizing the operational uptime, safety, and longevity of 10-ton double girder overhead cranes in construction and industrial applications. Regular upkeep and adherence to maintenance protocols contribute to efficient crane performance and operational continuity on construction sites.

Cost Considerations and Return on Investment (ROI)

Initial Investment Costs

Investing in a 10-ton double girder overhead crane involves upfront expenses that encompass:

- Equipment Purchase: Cost of the crane itself, which varies based on manufacturer, specifications, and customization options.

- Installation: Expenses associated with crane installation, including assembly, wiring, and commissioning to integrate the crane into the construction site or facility.

- Infrastructure Requirements: Additional costs for runway construction, support structures, and electrical infrastructure to support crane operation.

Operational Cost Savings

Despite initial costs, these cranes offer significant operational cost savings over their lifespan:

- Efficient Material Handling: Reduces labor costs associated with manual material handling, streamlining construction processes and improving productivity.

- Maintenance and Downtime Reduction: Preventive maintenance practices reduce repair costs and minimize downtime, enhancing operational efficiency.

- Energy Efficiency: Energy-efficient design and operational practices contribute to lower electricity consumption, reducing long-term operational expenses.

ROI Calculation and Analysis

Calculating the return on investment (ROI) involves assessing both costs and benefits over the crane's operational lifespan:

- Cost-Benefit Analysis: Comparing initial investment costs against anticipated operational savings and productivity gains achieved through crane usage.

- Timeline for ROI: Estimating the timeframe within which the cumulative savings from operational efficiencies offset the initial investment.

- Long-term Financial Impact: Considering factors such as depreciation, maintenance costs, and potential resale value to determine the overall financial impact and ROI.

Overall, while initial investment costs are significant, 10-ton double girder overhead cranes offer substantial long-term cost savings and operational efficiencies in construction and industrial applications. A thorough ROI analysis helps justify investment decisions and optimize crane utilization for maximum economic benefit over its service life.

Case Studies and Success Stories

Real-world Examples of Crane Implementations

10-ton double girder overhead cranes have been successfully implemented in various construction projects, demonstrating their effectiveness and benefits:

- Skyscraper Construction: In the construction of a high-rise building, a 10-ton double girder crane facilitated the efficient lifting and placement of heavy steel beams and concrete panels, accelerating construction timelines.

- Bridge Construction: On a bridge construction site, these cranes were instrumental in lifting and positioning large bridge segments and girders, contributing to the timely completion of bridge infrastructure.

- Industrial Facility Expansion: During the expansion of an industrial facility, these cranes supported the installation of new machinery and equipment, optimizing production capacity and operational efficiency.

Benefits Experienced by Construction Companies

Construction companies have reported numerous benefits from using 10-ton double girder overhead cranes in their operations:

- Improved Efficiency: Streamlined material handling processes, reduced manual labor, and enhanced productivity on construction sites.

- Cost Savings: Lowered operational costs through efficient use of crane capabilities, reduced downtime, and minimized maintenance expenses.

- Enhanced Safety: Mitigated risks associated with heavy lifting operations, ensuring a safer working environment for construction workers.

- Flexibility and Versatility: Adaptability to various construction tasks and environments, accommodating diverse project requirements and timelines.

- Customer Satisfaction: Meeting project deadlines and quality standards, enhancing reputation and client satisfaction.

These case studies and success stories underscore the practical benefits and operational advantages that 10-ton double girder overhead cranes provide to construction companies, highlighting their role in improving project outcomes and achieving business objectives effectively.

Future Trends and Innovations

Emerging Technologies in Crane Design

The future of 10-ton double girder overhead cranes is poised for advancements driven by innovative technologies:

- Automation and Robotics: Integration of automation for autonomous crane operations, including automated load sensing, path planning, and collision avoidance systems.

- IoT and Connectivity: Utilization of Internet of Things (IoT) for real-time monitoring, predictive maintenance, and remote diagnostics to optimize crane performance and efficiency.

- Advanced Materials: Adoption of lightweight and high-strength materials in crane construction to enhance load capacity while reducing structural weight and energy consumption.

- Energy Efficiency: Development of energy-efficient cranes with regenerative braking systems and energy storage solutions to minimize environmental impact and operational costs.

Predictions for Future Applications in Construction

Future applications of 10-ton double girder overhead cranes are expected to expand in scope and versatility within the construction industry:

- Smart Construction Sites: Integration of cranes with smart construction technologies for enhanced project management, real-time data analytics, and resource optimization.

- Modular Construction: Supporting modular and prefabricated construction techniques with cranes tailored for handling standardized components and modules.

- Green Building Initiatives: Cranes designed to support sustainable building practices, including renewable energy integration and environmentally friendly construction materials.

- Urbanization and Infrastructure Development: Contribution to urban development projects and infrastructure initiatives with cranes designed for efficient material handling and construction in densely populated areas.

As technology continues to evolve, 10-ton double girder overhead cranes are expected to play a pivotal role in shaping the future of construction, offering enhanced efficiency, safety, and sustainability to meet the growing demands of modern construction projects and urban development challenges.

Conclusion

In summary, 10-ton double girder overhead cranes represent a crucial asset in the construction industry, offering robust capabilities and numerous benefits:

- Versatile and Reliable: Designed to handle heavy loads and diverse materials, these cranes enhance efficiency across various construction applications.

- Safety and Efficiency: Equipped with advanced safety features and operational controls, they ensure safe and precise material handling operations.

- Cost-Effectiveness: Despite initial investment costs, they deliver significant operational savings through reduced labor costs, minimized downtime, and enhanced productivity.

- Customization and Innovation: Continual advancements in crane design, including automation, IoT integration, and energy efficiency, promise future-ready solutions for evolving construction needs.

Final Thoughts on Choosing the Right Crane for Construction Projects

Selecting the right crane for construction projects requires careful consideration of specific project requirements, operational conditions, and long-term objectives:

- Evaluate Project Needs: Assess load capacities, span requirements, and operational environments to match crane capabilities with project demands.

- Prioritize Safety and Compliance: Ensure cranes meet safety standards and regulatory requirements to safeguard workers and adhere to industry best practices.

- Consider Total Cost of Ownership: Look beyond initial purchase costs to include maintenance, operational efficiency, and potential ROI over the crane's lifespan.

- Future-Proof Investments: Embrace technological advancements and innovations in crane design to anticipate future construction trends and optimize project outcomes.

Ultimately, choosing the right 10-ton double girder overhead crane involves balancing performance, safety, and cost considerations to support efficient construction operations and achieve successful project execution. By leveraging their robust features and ongoing advancements, these cranes play a pivotal role in shaping the future of construction practices, ensuring continued growth and innovation in the industry.

Cases and projects of 10 ton overhead cranes used in Consctruction Secotrs

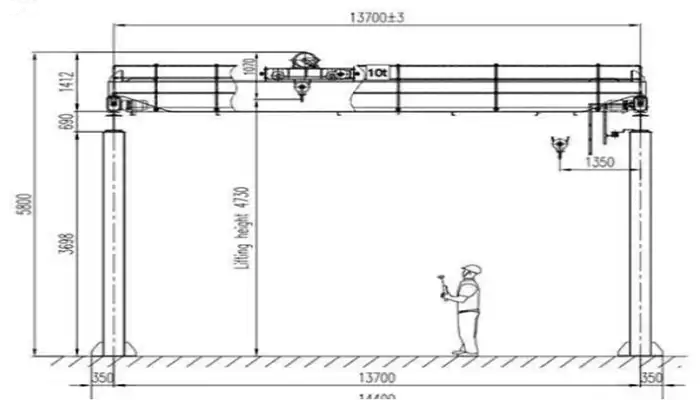

Crane 1:

Capacity: 10 tons

Span: 13.7 meters (45 feet)

Hook Height: 3 meters (9.84 feet)

Power Supply: 480V, 60Hz, 3-phase

Quantity: 1 set

Application industry: Construction

Crane 2:

Capacity: 10 tons

Span: 13.7 meters (45 feet)

Hook Height: 4.7 meters (15.42 feet)

Power Supply: 480V, 60Hz, 3-phase

Quantity: 2 set

Application industry: Construction

These cranes are configured for heavy-duty lifting operations with specific spans and hook heights tailored to your requirements. The 480V power supply ensures compatibility with industrial electrical standards. If you have any further questions or need additional specifications, feel free to ask!

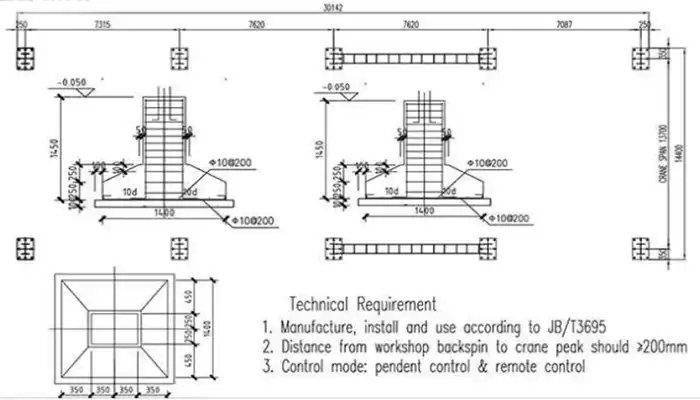

Double girder overhead crane for sale American drawing for your reference

General drawing of double girder bridge crane 10 ton for construction sector

10 ton overhead crane, 13.7 m span girder

10 ton eot crane 13.7 m span

10 ton overhead crane 13.7 m span girder

Electric wire rope hoist 10 ton

End carriages of 10 ton overhead crane kit

Electric hoist trolley frame, custom 10 ton bridge crane kit

Rumway beams of the 10 ton eot crane kit

Supporting columns of 10 ton double girder overhead crane kit

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch