20 Ton Grab Bucket Overhead Crane System for Steel Mills Case

20 ton overhead crane for sale. Custom 20 ton bridge crane with grab bucket, 4 sets for steel mill in India, reliable & cost-effective steel mill solution.

Category: 20 Ton Overhead Crane

Your Trusted Steel Mill Crane Manufacturer & Supplier

20 Ton Grab Bucket Overhead Crane System for Steel Mills Case

4 Sets Bridge Cranes with Grab Bucket, Reliable & Cost-effective Steel mill Crane Solution

20 ton overhead crane for sale. Custom 20 ton bridge crane with grab bucket, 4 sets for steel mill in India, reliable & cost-effective steel mill solution.

Grab Bucket Overhead Crane System to Improve Efficiency in Steel Mill

In the bustling heart of steel mills, where molten metal meets industrial prowess, the efficiency of material handling isn't just a matter of productivity; it's the backbone of operations. Every move counts, every load lifted, and every second saved contributes to the seamless flow of production. That's why, in the pursuit of optimizing steel manufacturing processes, the introduction of the Grab Bucket Overhead Crane System emerges as a game-changer.

Steel mills are dynamic environments where raw materials undergo a transformative journey into the sturdy structures that shape our world. Amidst the clang of machinery and the glow of furnaces, the efficiency of material handling operations is paramount. Every delay, bottleneck, or mishap can ripple through production, causing costly setbacks and jeopardizing deadlines. Efficient material handling isn't just about speed; it's about precision, reliability, and safety. It's about streamlining workflows, minimizing downtime, and maximizing output without compromising quality.

The Purpose of Grab Bucket Overhead Crane System:

Enter the Grab Bucket Overhead Crane System, a sophisticated solution tailored to the unique demands of steel mill environments. Unlike conventional cranes, this system isn't just about lifting; it's about grabbing, scooping, and transporting materials with unparalleled efficiency. With its double girder design and robust grab bucket mechanism, this crane system is engineered to tackle the heavy-duty demands of steel mill operations.

Designed to seamlessly integrate into existing workflows, the Grab Bucket Overhead Crane System revolutionizes material handling processes. Whether it's moving raw materials to the furnace, transferring molten metal to molds, or transporting finished products to storage, this system does it all with precision and speed. By minimizing manual intervention and optimizing load handling, it not only boosts productivity but also enhances workplace safety.

In essence, the Grab Bucket Overhead Crane System isn't just a piece of equipment; it's a catalyst for transformation. It's the bridge between aspiration and achievement, between the vision of efficiency and the reality of seamless operations. In the fast-paced world of steel manufacturing, where every second counts, this system isn't just a luxury; it's a necessity. It's the key to unlocking greater productivity, profitability, and progress in the relentless pursuit of excellence.

Crane Specifications of 20 Ton Overhead Grab Bucket Cranes

Crane Type: Grab Bucket Overhead Crane with Double Girder Design

Crane Capacity: 20 Ton

Crane Span: 23 Meters

Crane Lifting Height: 6 Meters

Quantity: 4 Sets

Target Application: Steel Mill Environment

Details on Grab Bridge Crane Specifications:

Main specifications | |||||||||

Rated capacity | 20t | Span | 23M | ||||||

Working class | A7 | Lifting height | 16m | ||||||

Wheel base | 4.80m | Trolley gauge | 2.50m | ||||||

Max. wheel load | 270KN | The left & right limit end | 1900/1500mm | ||||||

Weight | 52.3t | Total power | 186.5KW | ||||||

Main Structure | |||||||||

Main structure | Box section | Explosion- proof | Not applicable | ||||||

Control method | Cabin control | Lifting tool | Grab bucket | ||||||

Lifting mechanism | |||||||||

Lifting ratio | 1 | Lifting motor | YZR315M-8 | ||||||

Lifting speed | 40.7m/min | Lifting power | 75KW | ||||||

Maximum capacity | 20t | Brake | YWZ4-500/E121-M | ||||||

Working class | M7 | Braking torque | 2500N.M | ||||||

Reducer | ZQ1000-48.57-3CA | Transmission ratio | 48.57 | ||||||

Drum diameter | Φ800mm | Wire rope | 28NAT-6X19W+FC1770 | ||||||

Bridge Crane travelling mechanism | |||||||||

Speed | 89m/min | Power | 13x2KW | ||||||

Working class | M7 | Brake | YWZ4-300/E50 | ||||||

Motor type/Qty | YZR180L-6/2units | Braking torque | 630N.M | ||||||

Reducer | ZQ500-31.5-1/2Z | Transmission ratio | 31.5 | ||||||

Tread diameter of crane wheel | Φ800mm | Recommended rail | QU70 | ||||||

Trolley travelling mechanism | |||||||||

Speed | 45.6m/min | Power | 7.5KW | ||||||

Working class | M7 | Brake | YWZ4-200/E30 | ||||||

Motor type/Qty | YZR160M2-6/1unit | Braking torque | 230N.M | ||||||

Reducer | ZSC600-27.3-1 | Transmission ratio | 27.3 | ||||||

Tread diameter of trolley wheel | Φ400 | Trolley rail | P38 | ||||||

Ambient environment | |||||||||

Power supply | 415V | Frequency | 50Hz | ||||||

Ambient temperature | -10~48℃ | ||||||||

Standard | |||||||||

Design standard | GB/T3811-2008 | Fabrication standard | GB/T14405-2011 | ||||||

Remark: Indoor Use | |||||||||

- Crane Type: Grab Bucket Overhead Crane with Double Girder Design . The Grab Bucket Overhead Crane with Double Girder Design represents a leap forward in material handling technology. Unlike traditional cranes, which rely solely on lifting capabilities, this innovative system combines the power of overhead cranes with the precision of grab buckets. With its robust double girder design, it's engineered to withstand the rigorous demands of heavy-duty operations in steel mills.

- Crane Capacity: 20 Ton. At the heart of this system lies its impressive lifting capacity of 20 tons. This means it can effortlessly handle hefty loads, from raw materials like scrap metal and ore to finished products such as steel beams and coils. With such a high capacity, the crane ensures that no task is too daunting, no load too heavy, enabling seamless workflow and uninterrupted production.

- Crane Span: 23 Meters . Spanning a width of 23 meters, this crane offers extensive coverage across the steel mill floor. Its wide reach ensures that it can access every corner of the production area, facilitating efficient material handling without the need for multiple cranes. This expansive span minimizes downtime associated with repositioning and maximizes productivity by streamlining operations.

- Crane Lifting Height: 6 Meters. With a lifting height of 6 meters, the crane reaches new heights in versatility and adaptability. Whether it's hoisting materials to towering furnaces or loading finished products onto storage racks, this crane excels in reaching elevated destinations with ease. Its impressive lifting height ensures that it can accommodate the vertical demands of steel mill operations without compromising efficiency.

- Quantity: 4 Sets. Recognizing the scale and complexity of steel mill operations, the project calls for the installation of four sets of Grab Bucket Overhead Cranes. This strategic deployment ensures comprehensive coverage across the production facility, minimizing bottlenecks and optimizing material flow. By strategically positioning these cranes, the system maximizes efficiency and throughput, empowering the steel mill to meet the demands of modern industry.

- Target Application: Steel Mill Environment . Tailored specifically for the unique challenges of steel mill environments, these cranes are designed to thrive amidst the heat, dust, and heavy loads characteristic of such settings. From handling molten metal to transporting raw materials, they excel in the rigorous conditions of steel manufacturing. By targeting this niche application, the cranes demonstrate their adaptability and reliability, earning their place as indispensable assets in the steel mill's quest for operational excellence.

Design Considerations:

- Structural Analysis and Engineering . Before the first bolt is tightened, thorough structural analysis and engineering form the foundation of the Grab Bucket Overhead Crane System. Every aspect, from the placement of girders to the configuration of support structures, undergoes meticulous scrutiny to ensure optimal performance and safety. By leveraging advanced modeling techniques and engineering expertise, potential stress points and load-bearing capacities are carefully calculated, guaranteeing structural integrity under the most demanding conditions of steel mill operations.

- Material Selection for Durability and Performance . In the harsh environment of a steel mill, where temperatures soar and debris flies, durability isn't just desirable; it's essential. That's why the selection of materials for the crane's construction is a critical consideration. From high-strength steel for the girders to corrosion-resistant coatings for exposed components, every material is chosen for its ability to withstand the rigors of continuous operation. By prioritizing durability without sacrificing performance, the crane system ensures longevity and reliability in the face of relentless wear and tear.

- Safety Features Implementation . Safety is paramount in any industrial setting, and the Grab Bucket Overhead Crane System leaves no room for compromise. An array of safety features is seamlessly integrated into the design, providing layers of protection for both operators and the surrounding environment. From overload protection systems to emergency stop mechanisms, every precaution is taken to mitigate risks and prevent accidents. Additionally, clear signage, barriers, and warning systems enhance awareness and promote a culture of safety among all personnel.

- Integration of Grab Bucket Mechanism . At the heart of the crane system lies its grab bucket mechanism, a marvel of engineering precision and efficiency. Careful attention is paid to the integration of this crucial component, ensuring seamless operation and optimal performance. Precision-engineered controls allow operators to manipulate the grab bucket with ease, precisely positioning it to grasp and release materials with precision. By seamlessly integrating this mechanism into the crane's design, the system maximizes productivity and minimizes downtime, enhancing overall efficiency in material handling operations.

- Automation and Control Systems. In the age of Industry 4.0, automation is the key to unlocking new levels of efficiency and productivity. The Grab Bucket Overhead Crane System embraces this paradigm shift, incorporating state-of-the-art automation and control systems into its design. From programmable logic controllers (PLCs) to advanced sensor technology, these systems enable precise control and monitoring of crane operations. Automated workflows streamline material handling processes, reducing reliance on manual intervention and minimizing the risk of human error. By harnessing the power of automation, the crane system optimizes throughput and enhances operational efficiency in the steel mill environment.

- Environmental Adaptations for Steel Mill Conditions . Steel mills are notorious for their harsh operating conditions, from extreme temperatures to airborne particulates. Recognizing these challenges, the Grab Bucket Overhead Crane System is equipped with environmental adaptations designed to thrive in such environments. Specialized coatings protect critical components from corrosion, while sealed enclosures shield sensitive electronics from dust and debris. Additionally, cooling systems regulate internal temperatures, ensuring optimal performance even in the sweltering heat of the steel mill floor. By incorporating these environmental adaptations, the crane system demonstrates its resilience and reliability in the face of adverse conditions, guaranteeing uninterrupted operation in the most challenging of environments.

Main Parts and Components of 20 Ton Grab Bucket Overhead Bridge Cranes

A 20-ton grab bucket overhead bridge crane is a complex and robust piece of industrial equipment designed for lifting and transporting heavy loads, particularly in industries such as steel mills, ports, and waste disposal facilities. The main parts and components of such a crane include:

Bridge (Girder)- Main Girder(s): The primary horizontal beam(s) spanning the gap between the runway rails. It supports the hoist and trolley.

- End Trucks: These are located at both ends of the bridge and run on the runway rails, allowing the bridge to move horizontally.

- Runway Rails: Tracks on which the end trucks travel, typically mounted on a building structure or supporting columns.

- Support Columns: Structural elements that support the runway system.

- Trolley: Moves along the bridge girder(s) and carries the hoist. It provides lateral (cross) travel of the load.

- Hoist: The lifting mechanism that raises and lowers the grab bucket. It can be either electric or hydraulic.

- Shells/Jaws: The gripping parts of the bucket that open and close to grab materials.

- Suspension Ropes/Chains: Connect the grab bucket to the hoist.

- Rotating Mechanism (optional): Allows the bucket to rotate, providing better positioning of the load.

- Motors: Provide power for the bridge, trolley, hoist, and grab bucket operations.

- Gearboxes: Reduce motor speed and increase torque for various crane movements.

- Brakes: Ensure the crane stops safely and holds the load in place.

- Control Panel: Houses the electrical components and circuitry for operating the crane.

- Wiring: Electrical cables that connect the control panel to motors, sensors, and other components.

- Pendant Control/Remote Control: Allows the operator to control the crane's movements from a distance.

- Limit Switches: Safety devices to prevent over-travel of the bridge, trolley, or hoist.

- Overload Protection: Prevents the crane from lifting loads beyond its rated capacity.

- Emergency Stop: Allows immediate shutdown of crane operations in case of emergency.

- Anti-Collision Devices: Prevents collisions with other cranes or obstacles on the runway.

- Cabin (optional): Operator's compartment with controls, usually elevated for better visibility.

- Walkways and Railings: Provide safe access for maintenance and inspection.

- Lighting: Illuminates the work area, especially important for night operations or poorly lit environments.

- Lubrication System: Ensures smooth operation and longevity of moving parts.

This configuration allows the crane to perform three-dimensional movements: longitudinal (along the runway), lateral (across the bridge), and vertical (lifting and lowering).

20 Ton Overhead Crane with Grab Bucket for Sale India - Production Pictures for Reference

Main girder of grab bucket 20 ton overhead crane

End carriages and end girder of grab bucket cranes 20 ton for sale

20 ton bridge crane grab bucket

20 ton overhead crane main parts - clamshell grab bucket

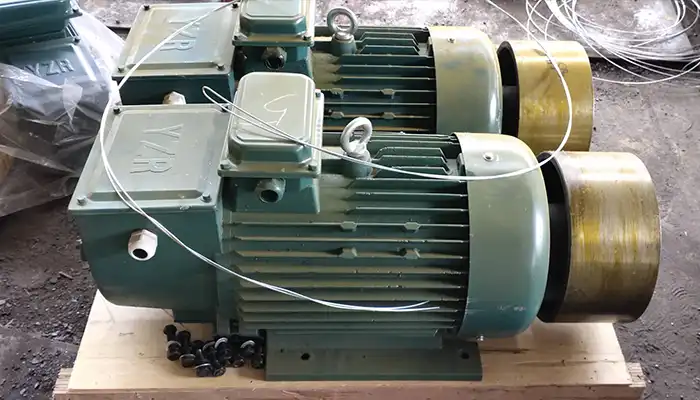

Crane Motor YZR

Reducer of bridge crane, main parts

Conductive frame

Angle iron of walking platform

trolley conductive i beam

Maintenance cage

Ladder

Cable

Hook anti-collision frame

Railing

Electrical cabinet

Driver's cabin

Main supporting structure

No. | Main supporting structure | Material | ||||

Item | | Type | ||||

1 | Main girder | Q235B | Δ16 | |||

2 | Main girder | Q235B | Δ6 | |||

3 | End carriages | Q235B | Δ8 | |||

Main parts

No. | Item | Unit | Item |

1 | Crane wheel | Φ800 | 4 groups |

2 | Trolley wheel | Φ400 | 4 groups |

3 | Crane travelling motor | YZR180L-6/13KW | 2 units |

5 | Trolley travelling motor | YZR160M2-6/7.5KW | 1unit |

6 | Lifting motor | YZR315M-8/75KW | 1unit |

7 | Open and closing motor | YZR315M-8/75KW | 1unit |

8 | Drum group | Φ800x1800 | 2 groups |

Protection devices

No | Item | Type | Quantity |

1 | Crane travelling limiter | YBLX10 | 2 |

2 | Trolley travelling limiter | YBLX10 | 2 |

3 | Crane buffer | JHQ-C-16 | 4 |

4 | Trolley buffer | JHQ-A-4 | 4 |

5 | Load cell | QCX | 1 |

6 | Height limiter | QGX-1:100 | 1 |

7 | Trolley brake | YWZ4-200/E30 | 1 |

8 | Crane brake | YWZ4-300/E50 | 2 |

9 | Opening and closing brake | YWZ200-300 | 1 |

10 | Lifting brake | YWZ200-300 | 1 |

11 | Weight limit | LX-10 | 2 |

Procurement and Fabrication Process of 20 Ton Overhead Crane with Grab Bucket

Procurement:

- Identify reputable suppliers for materials and components: Conduct thorough research to identify reliable suppliers with a proven track record of supplying high-quality materials and components for overhead crane construction. This may involve reaching out to industry contacts, consulting supplier directories, or conducting online research to compile a list of potential suppliers.

- Obtain quotes and negotiate contracts for procurement: Once a list of potential suppliers has been compiled, solicit quotes from each supplier for the required materials and components. Evaluate the quotes carefully, considering factors such as pricing, lead times, quality, and supplier reliability. Engage in negotiations with suppliers to secure favorable terms and pricing, leveraging competitive bids and volume discounts where possible.

- Ensure timely delivery of materials to fabrication facility: Upon finalizing contracts with selected suppliers, coordinate closely with them to ensure timely delivery of materials to the fabrication facility. Establish clear delivery schedules and expectations, communicating any specific requirements or deadlines to the suppliers to prevent delays in the fabrication process. Monitor the progress of material deliveries closely, addressing any issues or discrepancies promptly to maintain project timelines.

- Quality Control: Implement stringent quality control measures to ensure that materials and components meet the specified standards and requirements. Conduct thorough inspections upon receipt of materials at the fabrication facility to verify their quality, dimensions, and compliance with project specifications. Promptly address any discrepancies or defects identified during the inspection process, working closely with suppliers to rectify issues and ensure that only satisfactory materials are used in the fabrication of the overhead crane.

By carefully managing the procurement process and collaborating closely with suppliers, the fabrication facility can ensure the timely and efficient acquisition of materials and components needed for the construction of the 20-ton overhead crane with grab bucket. This proactive approach helps mitigate risks, minimize delays, and maintain the overall project schedule, ultimately contributing to the successful completion of the crane fabrication project.

Fabrication:

- Fabricate crane structures and components according to engineering specifications: Utilizing the engineering specifications provided, the fabrication team commences the manufacturing process of the crane structures and components. This involves cutting, shaping, welding, and assembling steel beams, girders, and other structural elements according to precise measurements and design blueprints. Skilled welders and fabricators meticulously craft each component, ensuring accuracy and adherence to engineering standards.

- Implement quality control measures to ensure compliance with design standards: Throughout the fabrication process, rigorous quality control measures are implemented to uphold the highest standards of craftsmanship and precision. Quality control inspectors conduct thorough inspections at various stages of fabrication to verify dimensional accuracy, weld integrity, and overall structural integrity. Non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, may be employed to detect any defects or imperfections in welds or materials.

- Conduct regular inspections during fabrication process to identify any defects or deviations: Regular inspections are conducted during the fabrication process to identify any defects, deviations, or discrepancies from the engineering specifications. This proactive approach allows for early detection and correction of any issues that may arise, minimizing rework and ensuring that the final product meets or exceeds the required quality standards. Inspectors closely examine welds, joints, and critical components, documenting any findings and taking corrective action as necessary to maintain the integrity of the crane structures.

By adhering to stringent quality control protocols and conducting regular inspections throughout the fabrication process, the fabrication team ensures that the crane structures and components are manufactured to the highest standards of quality and precision. This commitment to excellence contributes to the reliability, durability, and performance of the 20-ton overhead crane with grab bucket, ultimately ensuring its safe and efficient operation within the steel mill environment.

Quality Assurance and Testing Procedures

Quality Assurance:

- Establish quality control protocols for each stage of the project: At the outset of the project, comprehensive quality control protocols are established to govern every aspect of the crane's fabrication, assembly, and installation. These protocols outline specific procedures, standards, and checkpoints to be followed at each stage of the project, from material procurement to final commissioning.

- Conduct inspections and audits to verify compliance with design and safety standards: Throughout the project lifecycle, dedicated quality control inspectors conduct regular inspections and audits to ensure compliance with engineering specifications, design standards, and safety regulations. These inspections encompass all aspects of the crane's construction, including materials, welds, structural integrity, electrical systems, and safety features.

- Document and address any non-conformities or deficiencies identified during quality control checks: In the event that non-conformities or deficiencies are identified during quality control checks, they are promptly documented and addressed according to established procedures. This may involve conducting root cause analyses to determine the underlying cause of the issue, implementing corrective actions to rectify the problem, and verifying the effectiveness of the corrective measures through additional inspections or testing.

- Continuous Improvement: Quality assurance is an ongoing process that emphasizes continuous improvement and refinement of procedures to enhance the overall quality and reliability of the crane system. Lessons learned from quality control checks and audits are documented and used to inform future projects, enabling the organization to continually raise the bar for quality and excellence.

By establishing robust quality control protocols, conducting thorough inspections and audits, and addressing any non-conformities or deficiencies promptly and effectively, the project team ensures that the 20-ton overhead crane with grab bucket meets the highest standards of quality, safety, and performance. This commitment to quality assurance instills confidence in the reliability and integrity of the crane system, ultimately contributing to its successful implementation and operation within the steel mill environment.

Testing Procedures:

- Develop comprehensive testing procedures for crane functionality and safety features: Prior to the crane's installation and commissioning, detailed testing procedures are developed to evaluate its functionality and safety features thoroughly. These procedures are designed to assess various aspects of crane operation, including lifting capacity, hoisting speed, traverse speed, grab bucket functionality, and emergency response mechanisms.

- Conduct performance tests to ensure crane operates within specified parameters: Performance tests are conducted to verify that the crane operates within specified parameters outlined in the engineering specifications. These tests assess the crane's ability to lift and transport loads of varying weights, traverse the designated span, and operate at different lifting heights while maintaining stability, precision, and efficiency.

- Test safety features such as overload protection and emergency stop mechanisms under simulated conditions: Safety features such as overload protection, emergency stop mechanisms, and limit switches are rigorously tested under simulated conditions to ensure their effectiveness in real-world scenarios. Overload tests are conducted to verify that the crane can safely handle loads up to its rated capacity without exceeding permissible limits. Emergency stop tests assess the crane's response to critical safety incidents, such as power failures or equipment malfunctions, ensuring prompt and effective shutdown to prevent accidents or injuries.

- Documentation and Validation: Throughout the testing process, meticulous documentation is maintained to record test results, observations, and any issues encountered. Test data is analyzed to validate the crane's performance against design specifications and regulatory requirements. Any deviations or deficiencies identified during testing are addressed promptly, and corrective actions are implemented as necessary to ensure the crane's compliance with safety standards and operational requirements.

By conducting comprehensive testing procedures for crane functionality and safety features, the project team verifies the reliability, performance, and safety of the 20-ton overhead crane with grab bucket. This rigorous testing process instills confidence in the crane's capabilities and ensures its readiness for deployment in the steel mill environment, where it will play a critical role in enhancing material handling efficiency and productivity.

Test Report of 20 Ton Grab Bucket Overhead Bridge Crane for Reference

Complete Grab Bucket Bridge Crane Inspectation | ||||||||

No | Item and content | Result | Conclusion | Remark | ||||

1 | Label of capacity and safety warning | Eligible | Qualified | |||||

2 | Material | Main supporting structure | Eligible | Qualified | ||||

3 | Welding | Appearance | Eligible | Qualified | ||||

4 | Non-destructive testing | Eligible | Qualified | |||||

5 | Main supporting structural components | Eligible | Qualified | |||||

6 | Working mechanism | Eligible | Qualified | |||||

7 | Control system | Eligible | Qualified | |||||

8 | Main parts | Wire rope and its fixing | Eligible | Qualified | ||||

9 | Lifting tool | Eligible | Qualified | |||||

10 | Pulley | Eligible | Qualified | |||||

11 | High-strength bolts | Eligible | Qualified | |||||

12 | Lubrication device for friction parts | Eligible | Qualified | |||||

13 | Circuit and pipes | Eligible | Qualified | |||||

14 | Walking platform and banisters | Eligible | Qualified | |||||

15 | Cabin | Eligible | Qualified | |||||

16 | Electricals and control system | Protection class | Eligible | Qualified | ||||

17 | Remote | Not applicable | Not applicable | |||||

18 | Cable | Eligible | Qualified | |||||

19 | Electrical protection | Eligible | Qualified | |||||

20 | Main switch, isolating switch | Eligible | Qualified | |||||

21 | Non automatic reset emergency power-off switch | Eligible | Qualified | |||||

22 | Electric cabinet | Eligible | Qualified | |||||

23 | Magnetic system wiring | Not applicable | Not applicable | |||||

24 | Safety protection devices | Brake | Eligible | Qualified | ||||

25 | Load cell | Eligible | Qualified | |||||

26 | Height limiter | Eligible | Qualified | |||||

27 | Crane and trolley travelling limiter, buffer and stop device | Eligible | Qualified | |||||

28 | Interlock protection device | Eligible | Qualified | |||||

29 | Protective measures for moving parts | Eligible | Qualified | |||||

30 | Service cage or platform | Eligible | Qualified | |||||

31 | Force and moment limiting devices of each mechanism | Eligible | Qualified | |||||

Main measurements | ||||||||

No. | Item | Standard | Result | Conclusion | Remark | |||

1 | Basic measurements | Span(m) | 23 | -0.002 | Qualified | |||

2 | Wheel base(m) | 4.8 | +0.002 | Qualified | ||||

3 | Trolley gauge(m) | 2.5 | +0.001 | Qualified | ||||

4 | Main girder | Camber(mm) | (0.9~1.6)s/1000 | 36.8 | Qualified | S, Span | ||

5 | Bending of main beam in horizontal direction (mm) | S/2000 | 6/7 | Qualified | ||||

6 | Diagonal difference at the base point of mounting wheel(mm) | ≤5 | 2 | Qualified | ||||

7 | Height difference of trolley rail joint(mm) | Welding | Eligible | Qualified | ||||

8 | Height difference of the same section of trolley rail (mm) | ≤0.0015Wc | 1 | Qualified | WC | |||

9 | Lateral straightness of trolley rail(mm) | 6+0.2(s-10) | 2 | Qualified | ||||

10 | Horizontal deflection of wheel(tgФ) | ≤0.0015 | 0.0010 | Qualified | ||||

11 | Trolley gauge limit deviation(mm) | ±2~+7 | +1/+2+6 | Qualified | ||||

12 | Local flatness of girder web(mm) | 0.7δ, | 2 | Qualified | ||||

Package and Delivery of 4 Sets of 20 Ton Overhead Grab Bucket Cranes:

Packaging:

- Secure Packaging: Each component of the 20-ton overhead grab bucket cranes is securely packaged to prevent damage during transportation. Heavy-duty crates, pallets, or containers are used to protect the crane structures, grab buckets, electrical components, and other accessories from impacts, vibrations, and environmental elements.

- Customized Packaging: Depending on the size and shape of the components, customized packaging solutions may be utilized to ensure a snug fit and maximum protection. Specialized packaging materials such as foam padding, bubble wrap, and protective coatings are employed to safeguard delicate or sensitive components from scratches, abrasions, and corrosion.

- Labeling and Documentation: Each package is clearly labeled with detailed shipping information, including the destination address, handling instructions, and package contents. Additionally, comprehensive documentation, including packing lists, shipping manifests, and certificates of compliance, is provided to accompany the shipment and facilitate customs clearance and tracking.

Delivery:

- Transportation Logistics: The 4 sets of 20-ton overhead grab bucket cranes are transported via land, sea, or air freight, depending on the destination and urgency of delivery. Transportation logistics are carefully coordinated to optimize efficiency and minimize transit times, ensuring timely delivery of the cranes to the steel mill facility.

- Shipping Coordination: Close coordination is maintained with shipping carriers, freight forwarders, and logistics providers to oversee the entire delivery process. Regular updates and tracking information are communicated to the steel mill's procurement team to keep them informed of the shipment's progress and expected arrival date.

- Customs Clearance: For international shipments, customs clearance procedures are meticulously managed to ensure compliance with import/export regulations and minimize delays at customs checkpoints. All necessary documentation, including commercial invoices, certificates of origin, and import/export licenses, is prepared and submitted in advance to expedite the clearance process.

- On-Site Delivery: Upon arrival at the steel mill facility, the packages containing the 20-ton overhead grab bucket cranes are unloaded and inspected for any signs of damage or discrepancies. A receiving team is on hand to verify the contents of each package against the packing list and ensure that all components have been delivered intact and in accordance with the order specifications.

By meticulously packaging and coordinating the delivery of the 4 sets of 20-ton overhead grab bucket cranes, the procurement and logistics teams ensure that the cranes arrive at the steel mill facility safely, securely, and on schedule. This careful attention to detail minimizes the risk of damage or delays and facilitates the seamless integration of the cranes into the steel mill's operations, enabling enhanced material handling efficiency and productivity.

Benefits and Impacts:

- Enhanced Efficiency in Material Handling Operations . The implementation of the Grab Bucket Overhead Crane System brings a significant enhancement in efficiency to material handling operations within the steel mill. By seamlessly integrating grab bucket technology with overhead crane functionality, the system streamlines the process of loading, transporting, and unloading materials. This results in smoother workflows, reduced idle time, and increased throughput, ultimately boosting overall productivity within the facility.

- Reduction in Downtime and Production Delays. One of the most tangible benefits of the crane system is the reduction in downtime and production delays. With its robust design, precise controls, and high lifting capacity, the system minimizes interruptions to operations caused by equipment failures or inefficiencies. By swiftly and efficiently handling materials, the crane system ensures continuous production, enabling the steel mill to meet deadlines and fulfill orders without costly delays.

- Improved Workplace Safety Standards . Safety is paramount in any industrial environment, and the Grab Bucket Overhead Crane System prioritizes the well-being of workers and the integrity of the facility. Through the implementation of advanced safety features such as overload protection, emergency stop mechanisms, and comprehensive training programs for operators, the system significantly reduces the risk of accidents and injuries. By fostering a culture of safety and compliance, the crane system creates a secure working environment for all personnel.

- Economic and Environmental Sustainability . Beyond its operational benefits, the crane system contributes to economic and environmental sustainability within the steel mill. By optimizing material handling processes and minimizing waste, the system reduces operational costs and resource consumption. Additionally, its efficient operation results in lower energy usage and emissions, supporting the steel mill's commitment to environmental stewardship. Ultimately, the crane system enables the facility to achieve greater efficiency and profitability while minimizing its environmental footprint.

- Competitive Advantage in the Steel Industry . In a competitive market landscape, differentiation is key to success, and the Grab Bucket Overhead Crane System provides the steel mill with a distinct competitive advantage. By enhancing efficiency, reducing downtime, and improving safety standards, the system positions the facility as a leader in operational excellence. Customers value reliability, timeliness, and quality, and the crane system enables the steel mill to consistently deliver on these fronts, solidifying its reputation as a preferred supplier in the steel industry. As a result, the crane system not only drives internal efficiencies but also strengthens the steel mill's position in the marketplace, ensuring long-term success and sustainability.

Overview of Grab Bucket Bridge Crane in Steel Mills:

Grab Bucket Bridge Cranes represent a pivotal innovation in the realm of material handling within steel mills. These cranes, characterized by their unique grab bucket mechanism and overhead bridge design, play a critical role in streamlining the movement of raw materials, semi-finished products, and finished goods throughout the steel manufacturing process.

The primary function of Grab Bucket Bridge Cranes is to efficiently lift, transport, and deposit materials within the steel mill environment. Unlike conventional cranes that rely solely on hooks or magnets for lifting, grab bucket cranes feature a specialized bucket attached to the crane's hoisting mechanism. This bucket is designed to open and close, enabling it to securely grasp and release materials such as scrap metal, slag, or finished products as needed.

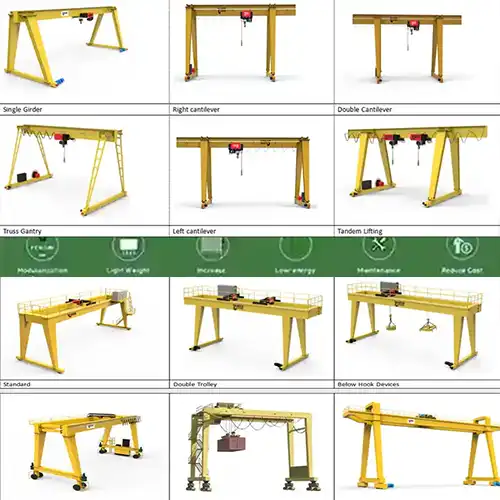

Types of Grab Bucket Overhead Cranes:

Single Girder Grab Bucket Crane:

Features a single girder design, making it lightweight and cost-effective.

Ideal for smaller steel mills or specific applications with lighter material handling requirements.

Offers versatility and maneuverability in confined spaces, allowing for efficient movement of materials across various workstations.

Double Girder Grab Bucket Crane:

Incorporates two girders running parallel to each other, providing increased stability and lifting capacity.

Suited for larger steel mills or heavy-duty applications that demand higher lifting capacities.

Offers enhanced precision and control, enabling the handling of bulkier or irregularly shaped materials with ease.

Four-Rope Grab Bucket Crane:

Utilizes a four-rope grab bucket mechanism for enhanced stability and load control.

Designed for handling loose or granular materials such as ore, coal, or aggregates within the steel mill environment.

Provides efficient loading and unloading of materials from ships, railcars, or storage bins, optimizing logistics and material flow.

Electro-Hydraulic Grab Bucket Crane:

Employs an electro-hydraulic grab bucket system for precise and efficient material handling.

Offers variable control over grab opening and closing, allowing for optimized handling of different material types and sizes.

Equipped with advanced automation and control features for enhanced safety, productivity, and operational flexibility.

These various types of Grab Bucket Overhead Cranes cater to the diverse needs and operational requirements of steel mills, offering tailored solutions to optimize material handling efficiency and streamline production processes. Whether handling raw materials, semi-finished products, or finished goods, these cranes play a vital role in driving productivity, safety, and profitability within the steel manufacturing industry.

Applications of Grab Bucket Bridge Crane in Steel Mills:

- Raw Material Handling: Grab Bucket Bridge Cranes are extensively utilized for handling raw materials within steel mills. This includes the loading and unloading of materials such as scrap metal, iron ore, limestone, and coal. The grab bucket mechanism allows for efficient grabbing and transportation of bulk materials from storage yards, delivery trucks, or railcars to the designated processing areas within the mill.

- Charging Furnaces: In the steelmaking process, Grab Bucket Bridge Cranes play a crucial role in charging materials into the furnace. Whether it's adding scrap metal, alloys, or fluxes, these cranes facilitate precise and controlled placement of materials into the furnace, ensuring optimal melting and alloying conditions for the production of high-quality steel.

- Slag Handling: After the steelmaking process, slag is generated as a byproduct and needs to be efficiently removed from the furnace. Grab Bucket Bridge Cranes are employed to scoop up and transport slag from the furnace to designated slag pits or disposal areas within the mill. The grab bucket mechanism allows for effective handling of hot and abrasive slag materials, minimizing downtime and ensuring smooth operations.

- Intermediate Product Handling: Throughout various stages of steel production, intermediate products such as billets, blooms, and slabs need to be transported between different processing units within the mill. Grab Bucket Bridge Cranes provide a flexible and efficient means of moving these intermediate products, allowing for seamless transfer between rolling mills, cooling beds, and finishing lines.

- Finished Product Handling: Once steel products are processed and finished, Grab Bucket Bridge Cranes are employed to transport them to storage areas or loading docks for shipment. Whether it's steel coils, beams, or plates, these cranes ensure safe and efficient handling of finished products, minimizing damage and maximizing throughput in the shipping and logistics operations of the steel mill.

- Scrap Yard Operations: Steel mills often have dedicated scrap yards where various types of scrap metal are collected and sorted for recycling. Grab Bucket Bridge Cranes are utilized in scrap yard operations to handle and process scrap materials, including sorting, compacting, and loading scrap into melting furnaces for recycling. The grab bucket mechanism enables efficient grabbing and sorting of different types of scrap, optimizing recycling processes and reducing material waste.

In summary, Grab Bucket Bridge Cranes find diverse applications across the entire steelmaking process, from raw material handling to finished product shipping. Their versatility, precision, and efficiency make them indispensable assets in the operations of steel mills, contributing to increased productivity, reduced downtime, and enhanced safety standards within the industry.

Select The Right Grab Overhead Cranes for Steel Mills

Selecting the right Grab Overhead Crane for steel mills involves careful consideration of various factors to ensure optimal performance, efficiency, and safety. Here's a step-by-step guide on how to select the appropriate crane for steel mill applications:

- Assess Material Handling Requirements: Identify the types and quantities of materials to be handled, including raw materials, intermediate products, and finished goods. Determine the weight, size, and shape of the materials to be lifted and transported.

- Evaluate Operational Environment: Consider the operating conditions within the steel mill, including temperature variations, dust levels, and exposure to corrosive substances. Assess the available space and layout of the facility to determine the crane's span, lifting height, and maneuverability requirements.

- Determine Lifting Capacity: Calculate the maximum weight that the crane will need to lift and transport. This should include both individual loads and the cumulative weight of materials handled per day. Ensure that the crane's lifting capacity meets or exceeds the requirements of the steel mill's operations.

- Choose Crane Type and Configuration: Select the appropriate type of Grab Overhead Crane based on the specific material handling tasks and operational needs of the steel mill. Consider factors such as single girder vs. double girder design, grab bucket mechanism, and additional features such as four-rope grabs or electro-hydraulic systems.

- Consider Safety Features: Prioritize safety features such as overload protection, emergency stop mechanisms, and anti-collision systems to mitigate risks and ensure safe operation. Verify compliance with industry standards and regulations governing crane safety and performance.

- Evaluate Automation and Control Systems: Assess the level of automation and control required for crane operations, including manual, semi-automatic, or fully automated systems. Consider features such as programmable logic controllers (PLCs), remote control capabilities, and integrated monitoring and diagnostic systems.

- Review Maintenance and Service Requirements: Evaluate the ease of maintenance and accessibility of critical components for inspection and servicing. Choose a crane manufacturer or supplier with a reputation for reliability, quality, and responsive customer support.

- Consider Long-Term Cost and Value: Evaluate the total cost of ownership, including initial purchase price, installation costs, and ongoing maintenance expenses. Factor in the expected lifespan of the crane, as well as its potential for scalability and adaptability to future changes in production requirements.

By carefully assessing material handling requirements, operational conditions, safety considerations, and long-term value, steel mills can select the most suitable Grab Overhead Crane that meets their specific needs and contributes to enhanced efficiency, productivity, and safety in their operations.

Conclusion:

Throughout the planning, design, and implementation phases, the primary objectives of the project centered on enhancing efficiency, improving safety standards, and optimizing material handling operations within the steel mill environment. By introducing the Grab Bucket Overhead Crane System, the project aimed to revolutionize the way materials are lifted, transported, and processed within the facility. Through meticulous planning and execution, these objectives have been successfully achieved, paving the way for a new era of productivity and excellence in steel mill operations.

As the steel mill continues to evolve and grow, it's essential to consider future upgrades and maintenance strategies to ensure the continued success of the Grab Bucket Overhead Crane System. Regular maintenance schedules, including inspections, lubrication, and component replacements, will help prolong the lifespan of the crane system and minimize downtime. Additionally, exploring opportunities for technology upgrades, such as automation enhancements or sensor integration, can further optimize crane performance and efficiency in the long term.

The introduction of the Grab Bucket Overhead Crane System has had a profound impact on steel mill operations, setting new standards for efficiency, safety, and productivity within the industry. By streamlining material handling processes, reducing downtime, and enhancing workplace safety standards, the crane system has transformed the way materials are managed and processed within the facility. Furthermore, its success serves as a benchmark for other steel mills, inspiring the adoption of innovative solutions to drive operational excellence and competitiveness in the global steel industry. In summary, the Grab Bucket Overhead Crane System has not only revolutionized steel mill operations but also raised the bar for industry standards, demonstrating the transformative power of strategic investments in technology and innovation.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch