What is a Jib Crane – A Complete Guide of Jib Cranes

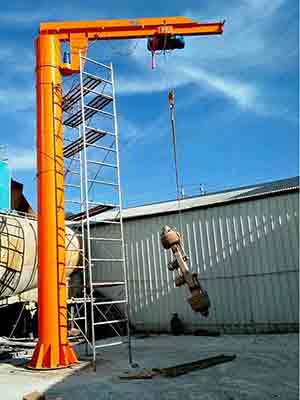

What is a Jib Crane, and what is it used for? It's a light overhead travelling crane with a horizontal cantilever, also called a jib or boom. The cantilever is a crane's horizontally extending operational arm. The jib's job is to support a moveable hoist that is attached to a wall or pillar on the floor. It's primarily employed in industrial settings.

The jib crane usually swings in an arc or is fastened in a fashion that allows for more lateral mobility. The jib is a tilting strut on the crane that supports the fixed pulley lock.

Cranes are sometimes installed on top of warehouse floors to assist in the lifting of products from the floors to higher levels. Cables are joined to the load multiple times around a fixed block and directly to the load. The unconnected end of the cable is either manually pulled or wound with a winding equipment.

The load is given a force via the pulley system. As a result, the force applied is increased by the length of wire flowing between two blocks. The mechanical advantage is the name of the product.

Jib Cranes Designs

Jib cranes include the following features and specifications:

The Reach is a horizontal beam on the trolley that moves back and forth. The boom is another name for it. The boom on freestanding and mast jib cranes can rotate up to 360 degrees. On the other hand, the amount of rotation produced by a wall or column-mounted crane is between 180 and 200 degrees.

- Mast: Also known as the pillar, the mast is a vertical column that provides support for the boom on mast or freestanding systems.

- Hoist: This is a moveable component that lifts, positions, and lowers loads.

- Trolley: The trolley transports the hoist, wires, wire rope, chains, and the boom hook. The trolley can be moved manually, mechanically, or pneumatically.

- Electric Collector Rings, sometimes known as pneumatic airlines, are attached to the mast at either the top or bottom. This component's job is to assist with rotation. It also enables the boom to rotate continuously in a 360-degree circle.

- Control Buttons: Jib systems that are motorized or air-powered use a push-button control mechanism. The button controllers assist in controlling the boom's rotation and the trolley's motion. The hoist's lifting and lowering actions are likewise controlled by this controller. Multi-speed control buttons are also available on the hoist and trolleys.

- Hook Height: This refers to the lift's ability to travel up or down in height. The higher the hook can travel, the lower the overhead impediment must be.

- The Rotation Stop: This is the part of the crane that controls how fast it may move before colliding with neighboring objects.

- Jib cranes are not permitted to be used in hazardous settings, such as those that are flammable, explosive, or corrosive.

Features of jib cranes

The following are typical characteristics of a jib crane:

- Jib cranes are a recently invented material handling device that can operate freely in three dimensions.

- Jib cranes are built with a unique construction that provides great safety, reliability, and efficiency, allowing you to save energy and time.

- Jib cranes have a compact working area, are simple to operate and maintain, and are rotary versatile, cost-effective, and long-lasting.

Applications of Jib crane

- Jib cranes are frequently used in the following applications:

- Jib cranes are commonly employed in workstations, storage, yards, and other fixed or localized locations, among other places.

- Jib cranes are ideal for short-distance or serried material handling, such as transporting items from one work cell to another.

- For material handling, jib cranes can be used to supplement a huge overhead crane.

- Jib cranes can be used as a suspended tools.

- Jib cranes can also be employed for cost-effective outdoor applications.

Free standing jib crane for sale

Free standing jib crane for sale

Free standing jib crane for sale

Free standing jib crane for sale

Considerations for Selecting a Jib Crane:

A comprehensive analysis must be undertaken to identify how the crane will effect the efficiency of the work area and how it will be used in daily operation. The following are the most significant aspects when selecting a crane:

- The kind and extent of available structural support

- Current and future requirements for powered hoist or crane operation

- Each crane type's attributes and design

- The overall height as well as the height under the boom

- The cost of each type of jib crane.

- The total installation cost

Free standing jib crane

Overview of free standing jib cranes:

- Base Plate Mounted, Insert Mounted, and Sleeve Insert Mounted options are all available.

- The mast pipe, head assembly, and I-beam boom are all the same in all three variants.

- The mounting arrangement differs between the versions.

- Allow for continuous rotation of 360 degrees.

- A round mast pipe is present on all versions and remains stationary throughout rotation.

Full cantilever jib crane v.s. Drop cantilever jib crane

Designs for Full Cantilever Jib Cranes

Designs for full cantilever jib cranes include: The complete cantilever jib crane is utilized when there are no above barriers. The boom or jib arms are situated on the top of the mast or pillar, allowing jib cranes to give optimum lifting capacity and clearance beneath them.

Designs for Drop Cantilever Jib Cranes

Designs for Drop Cantilever Jib Cranes: Because of the side plate connection designs, the boom or arm can be "drop installed," providing clearance for overhead impediments right above the top of the mast.

Mast jib cranes are comparable to freestanding jib cranes in that they can be utilized for the same heavy-duty/high-productivity applications. Mast jib cranes, on the other hand, require an overhead beam or support structure in addition to the base to give support.

Types of free standing pillar jib cranes

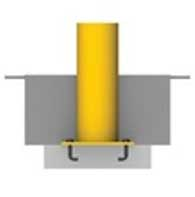

Design of a free standing jib crane with a base plate

The Base-Plate Mounted Jib Crane Design is one of the most common and straightforward methods of installing free-standing jib cranes. The jib crane's pillar or mast is bolted to a base plate secured to the reinforced concrete foundation.

Foundation/Insert mounted free standing jib crane design

The foundation jib crane ideas are to weld a steel plate at the bottom of the pillar or mast, which is anchored during the first-pour concrete footing, while the pillar is supported by a second concrete pour without the requirement for gussets.

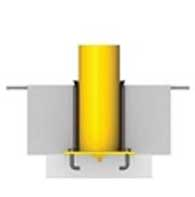

Sleeve-Insert mounted jib crane design

The jib crane sleeves with a welded steel plate are anchored by a first pour concreted footing, while the pillar is put into the sleeve, leveled, and then welded in place during the second pour. The sleeve insert mounted jib crane designs allow for jib crane connection while also preventing damage to the pillar.

- Advantages of pillar jib cranes-When compared to other types of jib crane designs, this one has the highest capacity, longest spans, and biggest rotating angle.

- Disadvantages of pillar jib cranes-When compared to other jib crane designs, these are the most expensive.Due to freestanding jib cranes, permanent mounted solutions are among the most expensive systems and require the most specialized foundation to anchor and secure the crane and maintain the weight during a lift.

Application:

Jib cranes from the Free Standing Jib Cranes series are simple to set up and perform a wide range of tasks within a work environment.

- Even when employing electric or air-powered hoists and trolleys, provide for continuous 360o rotation.

- Maximum hoist lift is possible with the cantilever-style boom.

- Doesn't put any strain on the building's structural structure (all the force of the crane is supported by its foundation). Free standing jib cranes series are perfect for handling and transferring items, and can be used to:

- Provide service in an open area without being tethered to a structure

- Assist a bridge crane

- Provide service in areas where a bridge crane is either unavailable or impractical.

- Replace a wall or column-mounted crane when fewer than 360 degrees of rotation is required but no other support structure is available.

Before choosing a Free Standing Series jib crane, two fundamental characteristics must be met:

- 1.The jib crane must be supported by a physically sound base in all situations.

- 2. Throughout the arc of the boom, there must be enough clearance above it (about 3 inches).

How to Order a Free Standing Jib Crane:

We want to make the ordering procedure as easy and convenient for you as possible. Please include the following details when ordering an FS series jib crane:

- Mounting Design (i.e., base plate: FS300, insert mounted: FS350, or sleeve insert: FS350S)

- Abilities

- Length (pivot point to end of boom)

- HUB (Height Under Boom) or OAH (Overall Height) (OAH)

- Make and Model

- Desired Additions (tagline, anchor bolts, plywood base plate template, bottom or top entry collector, etc.)

- Any other important details (i.e., outdoor application, motorized rotation, etc.)

Wall bracket jib cranes

Wall bracket jib crane or wall mounted jib crane consists of a conventional I-Beam for the boom, a tie rod (right-hand threaded at either end), a top and bottom bracket, a beam bracket, and trolley stops Combines simplicity of design, heavy durability construction, ease of installation, and low cost

Provides a wide range of practical applications within a 200 degrees rotating area

Application:

Ideal for individual use in bays, along shop walls, or as a complement to an overhead traveling crane or monorail.Covers approximately 200 degrees of rotation Is the most cost-effective solution when compared to other jib cranes because the tie rod suspension eliminates the need for a mast member and allows the use of a smaller section boom than other jib cranes with cantilever-style suspensions (learn more).Based on the item on which they are attached, wall jib cranes and column jib cranes can be categorised.

Wall Cantilever Crane Design

Wall Cantilever Crane Design: Wall mounted cantilever cranes provide the most space above and below the pillar, as well as the option of a full-cantilever design.

Tie-Rod Jib Crane Design

Tie-Rod The most cost-effective crane design is the jib crane, which provides hoist coverage along walls or building columns. A wall bracket and a single tie-rod support the crane arm, which allows it to hoist the arm or beam.

The use of a wall mounted jib crane or a column mounted jib crane has the disadvantage of not being able to rotate in a full 360° angle. To support the loads, a column or support is required.

How to buy a wall mounted jib crane for your application

If a Wall Bracket series jib crane is the proper crane for your application, locate the corresponding row and column in the Wall Bracket Jib Pricing area of the product binder to get the model number needed and the list price. For each conventional crane type, these charts also provide the bracket center measurements, the thrust and pull exerted, and the shipping weights. The bracket fitting size, the span, and the depth of the boom are all designated by the model number.

Be sure to include the following information:

- Capacity

- Model number

- Length of span

- The distance between the center of the brackets

- Bracket dimensions

- Accessories that are desired

- Any other pertinent information

Why to buy jib crane

Jib Cranes hoist and move loads in semi-circles and full circles, with the jib rotating between 200 and 360 degrees around the support.Why should you buy a jib crane? Because of the following benefits of a jib crane:

- Jib cranes help you save a lot of room when working.

- The wall-mounted jib crane requires minimal floor space, allowing you to preserve valuable workspace.

- Take advantage of what you already have: When developing your crane, we'll take into account your specific working conditions and lifting needs. We can use your building columns or overhead beams to mount the jib cranes in some designs, minimizing your costs.

- Indoor/outdoor use: A pillar jib cane, also known as a free-standing crane, can be used both indoors and out.

- Cooperate with your existing cranes: Jib cranes and overhead cranes can function together. Jib crane jibs can be folded to keep them out of the way of massive overhead cranes.

How to select the jib crane for your application?

When choosing the correct jib crane for your application, keep the following aspects in mind:

Select the duty cycle or service duty classification for the jib crane, which will ensure that the crane and crane parts will last long enough to meet the requirements.

- Freestanding jib cranes and mast jib cranes can rotate 360 degrees; wall mounted jib cranes and wall travelling jib cranes can only rotate 180 degrees.

- Actual working time required: At each end, the working (or hook) distance is about equal to the length of the boom minus 12 trolley length.

- What kind of power do you need: electric, manual, or air? Other aspects include the application setting, such as whether it is used indoors or outdoors, and so on.

How to buy jib crane

How do you choose the right jib crane for your needs? What impact will the jib crane have on your productivity? What role will it play in day-to-day operations? Purchasing a jib crane for your business necessitates careful thinking and skilled advice.

- 1. What are you looking to move? What types of loads will your jib crane handle? It is one of the first questions to consider while choosing jib crane parameters. The lifting capacity, lifting height, and arm length of a jib crane will be determined by the general conditions of the loads, such as size, weight, and forms.

- 2.Decide on a route to take. Determine the route of travel. How far will the loads be moved? Will there be any roadblocks along the way? Will it be utilized inside or outside? The capacity of the unit and the length of the jib crane span have an impact on the total height of the jib crane. The depth of the support beam and the headroom required for the electric hoist and trolley employed will rise as the jib crane capacity and span increase.

- 3. Include the entire cost rather than simply the unit cost. One portion of the crane price is the cost of the jib crane. The material, transportation, and sales tax for the jib crane and electric hoist are straightforward to calculate, but there are other expenses to consider, such as training, maintenance, and after-sales services, among others.

- 4. Be familiar with the building codes and requirements in your area.

- It's possible that your local construction codes deviate from national norms. To ensure that the jib crane can be placed, you must have a thorough understanding of the circumstances of your building.

All in All

The following variables should be considered when purchasing a jib crane for your application:

- 1.The state of the available structural support in your building.

- 2.The available headroom and overall height.

- 3.Your expected jib crane or electric hoist requirements.

- 4.The characteristics and benefits of each type of jib crane.

- 5.The price of each jib crane type.

- 6.The total cost of installation, training, maintenance, and post-sale services, among other things.

Still haven't figured out how to make a purchase? Send a message to us, your jib crane manufacturer and supplier, to receive free consultations that could help you save money on your jib crane purchase.

Jib cranes for sale

Parameters needed on jib crane buying

- Capacity to lift- Your application's maximum weight must be equal to or less than the crane's maximum weight. When determining the lifting capacity of your jib crane, keep the following in mind:1)Add 15% to the hoist and trolley's combined weight.2)a 15% bonus for hoist and trolley deflection3) A capacity allowance of +25% for impact

- Rotational Degr-The pillar jib crane can rotate 360 degrees.A wall-mounted jib crane may rotate up to 180 degrees.

- Outreach Range-The outreach range of jib crane refers to the distance from the boom tip to the crane hook, which also is the working area needed.

- Crane Height -The height of jib crane has the attachments such as electrical entries included.

- Under Boom Height-The under boom height refers to the distance from the floor to the underside of the boom, which will determine the type of hoist required.

FAQ & Answers on Floor mounted jib crane services

Our factory, which specializes in jib cranes, not only sells cranes but also provides crane services to improve the efficiency of your crane. For your convenience, jib crane manufacturing engineers have provided a list of frequently asked questions and answers on floor mounted jib cranes, pillar jib cranes, and floor jib cranes. Our Crane aspires to be your go-to specialist for floor-mounted jib cranes.

What dimensions are important when purchasing a floor mounted jib crane?

- Lifting capability of a jib crane installed on the floor. One of the most essential dimensions in jib crane design is the weight of the heaviest load to be hoisted, or the lifting capacity of the floor mounted jib crane.

- The length of a jib crane's journey. The jib crane travelling length, which is also an essential parameter, is how far the electric hoist can move along the jib crane arm or cantilever.

- Lifting height of a jib crane: How high must the weight be lifted? The jib crane's lifting height is this.

What Rotation options are available on a Floor mounted jib crane?

- Instead of traveling, a floor-mounted jib crane rotates to cover an area. Most customers desire to have as much area as possible covered by a single jib rotation. Some customers, on the other hand, may wish to limit the rotation of a jib crane positioned on the floor. Rotation brakes can be added on most floor-mounted jib cranes for a minor additional fee.

- For example, in a machine shop with a computerized machining center adjacent to a floor mounted jib crane, the crane buyer does not want the floor mounted jib crane to be able to revolve into the CNC machine next to it. Depending on the rotation kinds, certain crane buyers will require different electrification options, such as a "top entry collector" or "bottom entry collector."

- Because each choice has a more appropriate application, the jib crane engineer will make this decision. These types of collectors aid in the flexibility of jibs by allowing infinite rotation in one direction.

- Finally, the boom can be self-powered. This is a more expensive option that is typically utilized in heavy-duty or high-capacity jib crane applications. Powered rotation jibs are commonly used in pipe pit-casting applications

Why aren't the rotation motion and traverse motion powered usually?

It's typical to see a floor-mounted jib crane with an electric hoist motion. However, powered traverse (trolley) and rotating motions are uncommon. The floor mounted jib crane is frequently acquired as a cost-effective lifting tool to cover a small workstation, where parts are hoisted and put into machines, as well as tacked on to bigger assemblies.

The overhead crane then transports the completed item to the next workstation. That is, the overhead crane is employed for moves of more than five to ten feet. Many crane buyers believe that a floor-mounted jib crane does not need to be motorized in order for the crane operator to gently push the weight to surrounding equipment and workbenches. Both rotation and traverse(trolley) motions are offered as powered motions at an additional expense for crane purchasers who want a motorized floor mounted jib crane.

How Does a Floor mounted jib crane Work?

A jib crane positioned on the floor will always spin and will always lift or support a load. Most floor-mounted jib cranes will also feature a third action, traverse: when the jib rotates, the load will be able to traverse the cantilever from the center to the perimeter of the circle generated by the jib. Hand-powered rotation and traverse motion are prevalent on floor-mounted jib cranes, while electric-powered or hand-powered lift motion is also popular.Push/pull is used to power the rotation and traverse motions, while a chain, similar to a non-powered garage door, is used to power the lifting motion. For individuals looking to buy a floor mounted jib crane, motorized rotation and traverse options are available on almost all of them.

Foundation footing design of floor mounted jib cranes

Jib cranes that are mounted on the floor must be properly installed or the crane would collapse, causing damage to the load as well as human injury or death. A limited number of floor-mounted jib cranes can be installed directly to a 6" reinforced concrete floor, which is the industry standard. The rest of the floor-mounted jib crane range requires tearing up a square of industrial floor and installing a specially-designed concrete base.

How can I tell if my floor-mounted jib crane requires a foundation? Unless your jib crane engineer specifically tells you otherwise, you should plan on needing a foundation. How do I know how big that pillar foundation should be? We will provide you with a drawing that shows the length, depth, and width of the required pillar foundation, as well as any reinforcement and anchor bolt placement. We also provides a kit that includes anchor bolts, an anchor bolt template, and an early kit shipment so that the customer can install the jib crane foundation, including the anchor bolts, before the actual floor mounted jib crane arrives.

What install a floor mounted jib crane to the Floor?

Anchors that can be ordered with the floor mounted jib crane or purchased by the customer at a local bolt or supply house are used to secure the crane to the foundation or wall. The floor mounted jib crane must be properly anchored to a proper concrete footing or a properly engineered wall or building column. Most floor mounted jib cranes cannot be anchored into an industry standard 6" reinforced concrete floor with bolts alone.

The floor will sag, the jib crane will fall, and loads and/or people will be injured. If you have any questions, please contact our office first or consult the owner's manual that comes with every floor mounted jib crane. A floor-mounted jib crane is simple to install if the instructions are carefully followed. Most customers prefer to install their own floor mounted jib cranes, but installation by Floor mounted jib crane Outlet installation field crews is available.

How to install a pillar jib cranes?

- When you begin installing the cantilever crane, double-check the vertical column installation and examine the vertical extent from various angles. The ground must be smooth and free of debris; if the floor tiles are paved, a layer of sufficient padding must be added to maximize friction with the ground.

- When installing the silk cylinder, the nut must be tightened; however, the commonly used hook wrench will not achieve the required force; therefore, it is recommended that when using a hook wrench in front of a longer pipe, you always verify if the nut is loose. In the installation position, the rotary arm in the column cannot be too high or too low; too high will result in a decreased column bearing capacity, resulting in the down bar. The optimal oblique arm and column angle is 45 degrees. As the angle is increased, the arm lengthens and the column load increases. When using a swivel arm in a column, make sure the rotation is flexible and use the proper grease. The pole should be replaced as soon as possible if it deforms.

- When raising the cargo in the air, try to avoid using the power brake; the trembling created by the column is a serious hazard, and if lifting the weight, the column can easily collapse. When products enter and exit the window, they should seize the cargo smoothly rather than pulling it hard, especially when lifting a larger volume or heavier cargo.

- Lifting more than 70% of the nominal weight is not recommended. The weight should be dropped more as you lift higher.

- When inserting the clutch, make sure it is entirely entered into the air to guarantee that the machine is fully closed before starting it. You should always check the clutch when raising the machine.

- After the machine is installed, it should be less hanging at first, to ensure that the equipment is in good working order, and to check if the nut is free, before gradually increasing the weight. The application of motor driven goods decentralization is impossible to open the clutch when loading the items. Pre-feet on the brakes to keep the pulley from spinning.

You should inspect the machine for abnormalities on a regular basis, as well as do routine maintenance on it. If the gears are damaged, the items might easily tumble to the ground; however, if you perform routine maintenance, you can avoid such difficulties.

How to select the best Jib crane manufacturer?

Below some factors mentioned, which will help you to choose the best crane manufacturer in China.

- Reputation-Consider the reputation of an EOT, gantry crane, or Jib crane manufacturer while making your decision. A well-known crane manufacturer offers a diverse choice of high-quality cranes. When you buy jib cranes from a reputable company, you can rest assured that the cranes will work properly. If an issue is discovered, the jib crane manufacturer can replace the crane.

- Experienced crane manufacturer- It's critical to think about a jib crane manufacturer's past experience. A reputable jib crane manufacturer can deliver high-quality jib cranes at a reasonable price. Because professional jib crane manufacturers have good specialized talents, they can create a variety of jib cranes with the most up-to-date and distinguishing features. You will make the appropriate investment if you choose an experienced jib crane manufacturer.

- Cost -For each product, the price is the most important factor. When buying jib cranes from any crane manufacturer, take into account the price that fits your budget. You should look for a crane manufacturer who offers a high-quality product at a reasonable price.

- Provide multiple ranges -You should choose a manufacturer that offers a diverse choice of products of consistent quality. The finest manufacturer will always offer a diverse assortment of items with varying lifting capacity. In the market, there are various varieties of EOT, gantry cranes, and Jib cranes; therefore, it is critical that your chosen manufacturer offers all of these cranes.Safety concern

- When offering these jib cranes, a professional crane manufacturer places a premium on safety. Because these jib cranes can be handled manually or electrically, it's critical to ensure their safety.

Please see Jib crane selection suggestions from jib crane manufacturer for more information on jib crane design and jib crane manufacturer choosing.