Wall Mounted Jib Crane

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes. Wall mounted jib crane for sale.

| Lifting Capacity | 0.25 ton ~5 ton |

| Arm Length | 3~6m |

| Slewing Degree | 180, 220 degree |

| Working class | A3 |

Category: Jib Crane

Your Trusted Overhead Travelling Cranes Manufacturer & Supplier

Cost-effective Slewing Wall Crane Design

Bracket Wall Mounted Jib Crane

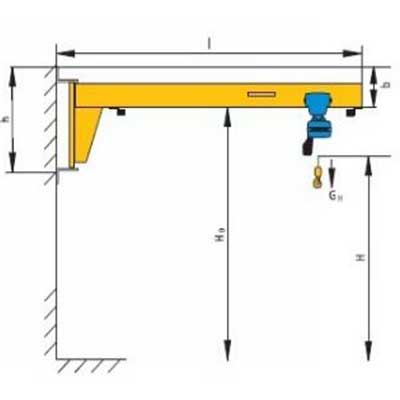

Wall Bracket Crane is a type of wall mounted jib crane which is an economical overhead travelling crane for light duty loads handling in workshops. The wall mounted jib cranes can be mounted on the walls, columns or any other proper supporting structures which exist in the workshop and without change much to your building structures, and eventually save your cost. The wall bracket jib crane does not need to take your floor space or a concrete floor foundation due to the simple structure and light self-weight which is an economical alternative of free standing jib cranes.

Main parameters of wall bracket jib crane

The wall mounted jib crane with wall bracket design is the most economical crane with the main parameters and specifications as following:

General parameters of wall bracket jib crane:

- Jib crane type :BX wall mounted jib crane with i beam or tie rod cantilever

- Lifting capacity of wall mounted jib crane:0.25 ton ~5 ton

- Span length of wall mounted jib crane:3~6m

- Lifting height of wall mounted jib crane:0. 5m-20m

- Rotation of wall mounted jib crane:180, 220 degree

- Working class of wall mounted jib crane:A3

- Ambient temperature of wall mounted jib crane:-25~40℃

- Crane control of wall jib crane : Ground operating control or remote crane control

Fully customized wall bracket jib cranes solutions are available ahead standard configurations.Contact us to free crane drawing of the wall jib crane by leaving a message below.

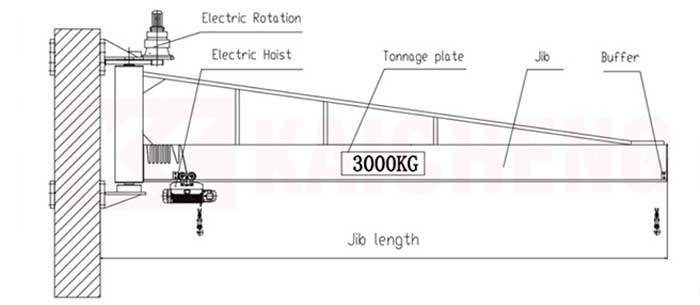

Components & structure

Wall bracket jib crane is one of the most cost-effective overhead travelling crane solution due to the bracket wall mounted jib crane design, simple crane structure and light dead weight. The main crane components and parts of the wall mounted jib crane are consisted of cantilever structure with or without tie rod, rotating cantilever devices, the rotating driven system, ether electrical or manual, the mounting system such as bracket, and fastening devices, wall mounted jib hoist system, including, electric hoist and manual hoist, and other safety devices, etc.Cantilever designs

Usually, the wall bracket jib cranes have the tie rod wall mounted jib crane and full cantilever jib crane configuration with different types of jib cantilevers such as, I beam cantilever, enclose track cantilever, and process designed cantilever, etc. The I beam cantilever wall mounted jib cane is used when the overhead clearance is limited which offers higher clearance than the tie rod type wall jib crane.

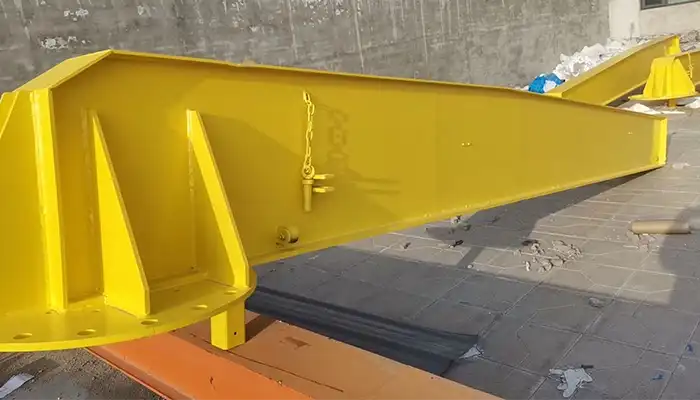

Wall mounted jib crane with full cantilever i beam

The H beam wall mounted crane's design makes the most of the available building dimensions, allowing the load to be transferred at the highest possible lift height.

Specifications of H beam wall mounted jib cranes

- Types: wall mounted jib crane with H beam for low headroom applications

- Crane Rotation: 180°

- Spans: up to 10 m ; longer spans available

- Capacities: up to 5 tons

Features of H beam wall mounted jib cranes

Provides the most clearance, both beneath and above the boom cantilever.

Bronze bushings and grease fittings are used on all swivel connections to facilitate rotation, promoting long life and low maintenance.

Wall mounted jib cranes – overbraced tie-rod jib for long cantilever

When it comes to moving lighter loads by hand, the over braced wall jib crane is an unobtrusive and dependable aid. Because of its lightweight construction, it and its load can be guided quickly and precisely even at longer jib lengths. This is a useful tool for day-to-day operations.

- Crane Rotation: 180°

- Spans: up to 10m ; longer spans available

- Capacities: up to 5 tons

Features of overbraced wall mounted jib cranes

Wall Bracket Jib Cranes are a cost-effective, heavy-duty solution. They have a single tie rod that is right-hand threaded on both ends for simple boom adjustment and installation. These tie rod jibs are great for swinging around or under obstacles.

The wall jib crane with enclosed track cantilever

The enclosed track kbk wall mounted jib crane has been designed to be mounted on a wall or column.

Main specification of enclosed track kbk wall mounted jib cranes

- Wall crane types: wall mounted jib crane with KBK cantilever

- Rotating: a slew range of 180°

- Jib arm lengths: up to 7 m

- Safe Working Loads (SWL): of up to 1.0 t.

Features of wall jib crane

When it comes to moving lighter loads by hand, the wall jib crane is an unobtrusive and reliable support. Because of its lightweight construction, it and its load can be guided quickly and precisely even at longer jib lengths. This is a useful tool for day-to-day operations. The included wall bracket is used to mount the crane, for example, on a steel support within a wall. Other mounting options are available for various building configurations.

Wall mounted jib crane with articulating cantilever design

Articulating wall mounted jib cranes

- Crane Rotation: 180° for inner arm, 360° for outer arm

- Spans: up to 5m

- Capacities: up to 0.5 ton .

Features of wall mounted jib with articulating cantilever

This type of jib crane provides 360-degree rotation for the outer arm and 180-degree rotation for the inner arm, making it ideal for individual workstations where each worker requires complete access to a single jib crane. Outstanding headroom allows for installation in tight spaces and crowded shops. It has a clear work area with no floor obstructions and requires very little overhead clearance to install.

Rotation design of wall mounted jib cranes

And the bracket jib crane can slew or rotate with 180 degree or 220 degree according to requirements of clients and applications, driven by the electric slewing or manual slewing devices. The wall mounted hoist is hung on the jib cantilever moving horizontally for loads and material handling.

Electric Motor Driven Slewing Wall Mounted Jib Crane

- Jib type: electric wall mounted jib crane

- Rotating type: Electric motordriven slewing jib

- Cantilever design: H type beam (1-7 meter )

- Jibhoist: electric traveling and electric lifting chain hoist

- Load capacity : 1 ton - 5 tons

- Lifting height: 3-9 meter

Manual Rotating Wall Mounted Jib Crane

- Jib type: manual rotation wall mounted jib crane

- Cantilever design: KBK type beam (1-7meter )

- Jibhoist: manual traveling + electric lift/down with AC power

- Load capacity: 1-3 tons

- lifting height: 3-5 meter

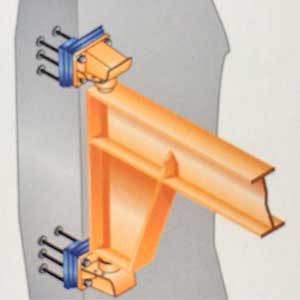

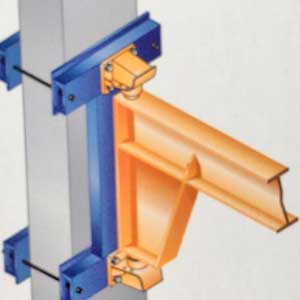

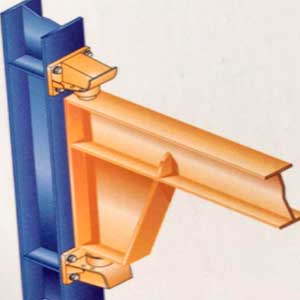

Mounting systems of wall bracket jib crane

Wall bracket crane is the most cost effective overhead crane solution because the installation of wall mounted jib crane is one of the easiest type. The installation of a bracket wall mounted jib crane is quick and simple, which can be relocated at a different place if required. The wall jib crane is mounted on the wall or steel column existing in the workshop with wall brackets and fastening devices. There are various types of mounting systems for your selection:

Wall mounted

Concrete mounted

Steel H beam structure

Wall mounted type- 1) Mounted on strengthened wall- The bracket jib crane can be directly mounted on the wall which has enough strength to support the wall jib crane.The wall jib crane is fastened by adopting threaded rods that go through the wall and bolted to the wall with counter plates and nuts.2) Mounted on the wall with embedded board and anchor bolts - The wall bracket crane can be bolted to the wall after adjusting.

Concrete column mounted type - The wall bracket jib crane can be mounted on the square or rectangular reinforced concrete column which can embrace anchor bolts and wall bracket and support the jib crane.

Steel structure column mounted type - 1) Mounted on the steel structure column strengthened to offer enough strength and contact surface to support the wall jib crane.The rids and connecting bolts used are all with high strength. 2) Mounted on steel structure column welded with steel plate with holes, and connecting the wall jib crane by bolts.

The are various mounting system for you to select and the alternative mounting systems are available based on your request and application conditions. Any problem on the mounting type of wall bracket jib crane, please feel to leave a message below.

Jib hoists & accessories

The lifting hoists are the one of the most important part of the wall mounted jib crane. For different applications and hoisting requirements, there are types of wall mounted hoists options, such as chain hoist, wire rope hoist and hand hoist for you to select. And the featured accessories are presented for you to learn more about the wall mounted jib crane.

- Jib Hoist - For different applications and hoisting requirements, there are types of wall mounted hoists options, such as chain hoist, wire rope hoist and hand hoist.

- Crane buffers or Slew stoppers- It can be fitted in-situ for a pre- determined fixed slewing range.

- Slewing brake - It is used to control the cantilever boom speed during slewing and to prevent uncontrolled movement of the jib arm.

- Locking device- It is adoptedto lock the jib arm in a fixed position.

- Crane control- The wall bracket jib crane can adopt ground operating crane control or remote crane control at your request and no professional driver is required. The crane operator of wall mounted crane is free to walk around on the floor.

Advantages

- Simple structure, low cost -The structure of wall mounted jib crane is simple and the jib crane cost for processing and transportation is low. What's more, the wall mounted crane do not take your floor space which helps to take the best value of the space in your workshops.

- Easy installation, easy relocation - Easy installation is one of the obvious features of wall jib crane. It can be directly mounted on the existing walls or the columns which have enough strength and contact surface for the wall bracket of the jib cranes. And also the wall mounted jib crane can be relocated to a different place if needed due to easy installation.

- Various configurations, wide selections - Rotation of the wall mounted cantilever crane can be powered manually or electrically. The hoisting mechanism are available with wide selection including chain hoist, wire rope hoist, manual hoist, and hazardous hoist for customized configuration.

- Customized design, best value solution - For different occasions, wall bracket cranes can be designed with different features of high-protection, acid-resistant or explosion-proof, etc. Based on the requirements of application conditions and handling tasks, the wall mounted jib crane is worked out to suit your individual application which can fulfill the lifting tasks with high safety but without spending extra money.

- Maximum safety - Various types of security devices are used to ensure all around safety, such as, Overload limiter, voltage lower protection function, emergency stop button, Under-voltage fault phase and phase-deficiency protection, overload protection device, crane travelling limit switch, lifting height limit device, etc.

Application of wall mounted jib crane

- Wall mounted jib crane is usually used for short distance but frequent and intensive material handling and also the bracket jib crane can be used as a complement for overhead travelling bridge crane and gantry crane applications.

- What's more, the wall bracketed jib crane can be used as a alternative when a floor mounted jib crane is impractical where the floor space of workshop is limited. A wall bracket crane can be folded out of the way when operation is completed.

- The wall mounted jib crane is widely used in various applications such as, workshops, warehouses, docks, storage, ports, and assembly line, and other industrial applications, etc.

Wall mounted jib crane withe electric chain hoist - Wall jib crane series

Wall mounted jib crane with electric wire rope hoist- Wall jib crane series

Process wall mounted crane design, economical wall jib crane price

Customized jib cranes with process crane design and particular jib crane specifications for your specific applications are the most cost-effective crane solutions. In order to give your specific quotation quickly, could you please send us the inquiry with the details of the jib crane for us to quote of wall mounted jib crane:

Paremeters needed to give you the specific Wall mounted jib crane price

- 1. Type of the jib crane: Wall mounted jib crane

- 2. Lifting capacity of Wall mounted jib crane : ____?

- 3. Lifting height of Wall mounted jib crane: ____?

- 4. Valid radius (the jib length) of Wall mounted jib crane: ____?

- 5.The power voltage of Wall mounted jib crane: ____(240V 50Hz 3phase)

- 6.Travelling length of Wall mounted jib crane: ____

- 7.Crane control of Wall mounted jib crane: ____ (Pendant control or remote control)

Please confirm the specifications of Wall mounted jib cranes to get lastes crane price.

If you do not know about how to select the jib crane, please feel free to leave us a message or email to us. The reply of our jib crane engineer will be given within 24 hours. Contact us to get the free wall mounted jib crane drawing and specific wall jib crane price now.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch