5 Ton Outdoor Crane Installed in Electricity Factory Saudi Arabia

A gantry crane is a type of overhead crane in which the bridge, trolley, and hoist are supported by legs. These legs move along the ground on wheels or on rails embedded in the ground. A gantry crane is commonly used for outdoor applications or to provide lifting capability beneath existing overhead bridge crane systems. Gantry cranes are frequently used in factories, shipyards, scrap yards, railyards, special construction sites, steel mills, and other applications.

A gantry crane, unlike a bridge crane, does not need to be attached to a building's support structure. This design eliminates the need for permanent runway beams and support columns.

Larger gantry systems can travel on embedded rail or track in the ground, usually in a straight line or covering a work area. Smaller gantry systems with wheels or casters can be moved around a facility for light fabrication work or maintenance.

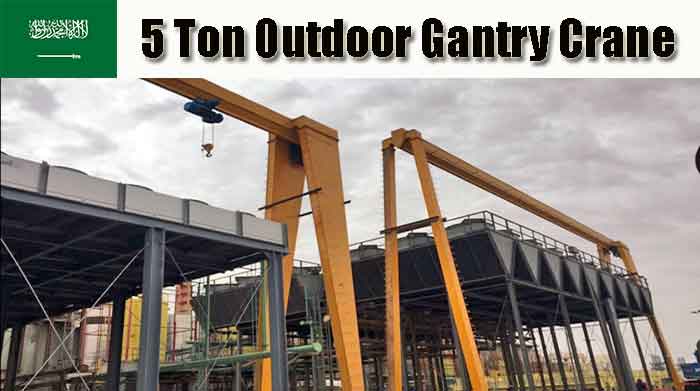

5 ton outdoor gantry crane for sale Saudi Arabia

5 ton gantry crane for sale Saudi Arabia in Electricity Factory for outdoor use. Cost-effective 5 ton outdoor gantry crane for sale Saudi Arabia. If you need any types of outdoor crane or gantry crane, please feel free to contact us.

Outdoor gantry crane main parameters

- Type of outdoor crane: outdoor gantry crane with electric hoist

- Lifting capacity of gantry crane: 5 tons

- Lifting height of gantry crane: 16 meters

- Span of gantry crane: 30 meters

Customer profile

Factory overview of Saudi Arabia's Electricity Company

Saudi Energy Company ("SEC"main )'s principle activity involves the electricity including the generation, transmission, and distribution within Saudi Arabia, the GCC's largest economy. It is the Kingdom's major power producer and the sole owner of the complete transmission and distribution network, which serves all types of consumers. Saudi Arabian Electricity Company is mainly owned by the Saudi government.

Single girder outdoor gantry crane installation procedures

We fly from Beijing to Abu Dhabi before arriving in the Saudi Arabian city of Jeddah.

How is the 5 ton outdoor gantry crane installed? The on-the-spot report will be digested for your reference in this section.

Work out the installation plan for the outdoor gantry crane

When we meet with the customer, we accompany him to the outdoor gantry crane installation site. Then we devised a strategy for how to construct the 5 ton outdoor gantry crane and how long it would take us to complete the operation, and others, etc.

1. The process how to install the outdoor gantry crane:

- Install of gantry crane rail / track

- Connect the end carriages and bottom beam

- Set up the gantry supporting legs

- Lift up the main girder and installed the electric hoist

- Put down the main beam girder on the supporting legs

- Electrical works

2. 15 days estimate time to finish the installation of the outdoor gantry crane.

3. Installations workers and tools

- Personnel required: At least two welders, four mechanical employees, and two electrical workers are required, as well as one driver to operate the 30 ton truck crane and one driver to operate the boom lift/scissor lift.

- Tools required:4 chain blocks with a minimum capacity of 1 ton, Tools box containing wrench, spanner, screw driver, welding machine, and other items

We immediately begin work after confirming the above details.

Installation of 5 ton outdoor gantry crane in Saudi Arabia

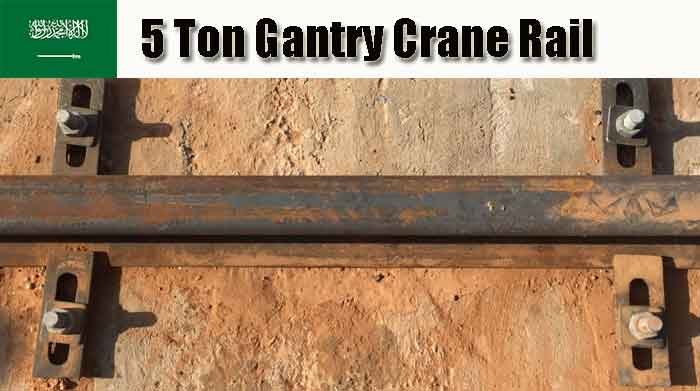

5 ton gantry crane rail installation

Rail installation

The four side rails for the external gantry crane were then installed with the help of workmen.

Because the wheel load on the 5ton, 30m/20m span outdoor gantry crane is heavy, we chose the P38 rail for the customer.

P38 rail is secured to the ground by a platen and bolts.

After this is complete, we may begin connecting the bottom beam and legs.

Bottom beam and legs connections

Bottom beam and leg connection by bolts

- To begin, you must understand that each crane has two bottom beams and four legs. It signifies that two legs will be connected by a single bottom beam.

- Bolt connections are also used.

- Place the bottom beam on the ground with appropriate space between it and the legs, then slowly raise the legs and move them towards the bottom beam directions. When you want to retain the hole between the bottom beam and the legs in the same place, use one steel stick to hold it in place and link all the holes with bolts as quickly as possible. After all of the holes have been bolted together, shake it to see if the connection is stable. If everything seems good, try another leg.

- The engineer must then measure the distance between the two legs with a ruler. This distance must match the saddle of the main girder.

- If the distance is acceptable, locate one box iron and weld it to the legs to ensure that the distance is maintained as it lifts up.

Rail installation. Bolts, clamps, and platen installation secure the gantry rail or track for the 5 ton outdoor gantry crane.

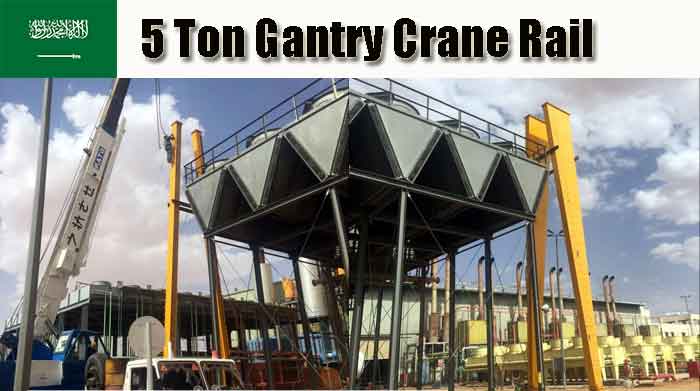

Lifting and setting the legs up on the rail

Supporting legs of outdoor gantry crane installation by truck crane

The girders must be installed on the rail once the two side legs and bottom beams have been connected. It would be ideal to set up legs on one small windy day.

Finding the center of the welded box iron on the two legs and fixing it with the truck chain, then slowly lifting and placing it on the rail.

After lifting the left two legs, we must use the wire rope and chain to secure the middle of the box iron. Two chain blocks are required on either side of one of the left two legs. If this one fails, try another.

Fix the hoist on the bottom of main girder

Allow the truck crane to raise the main girder of the outdoor gantry crane to around 1.5 meters above the ground. Ship the hoist to the main girder's bottom and secure it.

Connect the connections, limit switch, and other components.

Lift and fix the main girder on the top of legs

Main girder installation of the 5 ton outdoor gantry crane

When there is one good position between the legs and the main girder, we must use the truck crane to slowly lift the main girder up and find at least two people to climb to the upside of the legs. Each side's two people must ensure that the main girder edge is in the side of the bolts. Then lower it and allow the welder to weld the girders and legs. Before we can remove the truck crane, we must weld at least two spaces on each connection side.

When all of the welds are completed, the mechanical work is completed.

Electrical works

The engineer will instruct the workers on how to use the boom lift to complete the electrical job.We must test and commission the crane when all mechanical and electrical work is completed.

5 ton gantry crane installations finished successfully for SEC company in September.