Truss Gantry Crane with Single Girder & Double Girder Crane Design

Truss crane for sale. 3 ton - 100 tons anti-windy gantry cranes, with single/ double truss gantry girder design, truss leg & complete truss gantry cranes for you!

| Crane Type | Gantry crane with truss design |

| Crane Capacity | 3.2 ton- 100 tons |

| Crane Span | 12 m- 40 m |

| Lifting Height | Customized |

| Working Class | A3-A5 |

Category: Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

Truss Gantry Crane, Anti-windy Gantry Cranes

Single Girder & Double Girder Truss Crane Design

Truss crane mainly refers to truss Gantry Crane, adopting single truss gantry girder or double truss gantry girders, welded from angle - steel or steel bars, for light duty and medium duty general material handling. With the feature of high wind resistance ability , the truss crane is particularly suitable for material handling in the open areas and places with heavy wind or large sandstorm, such as construction and installation sites, lumber yards and other places, etc.

Main parameters of Truss crane

The main parameters of truss gantry cranes are presented for your reference. If custom designed truss gantry cranes are needed, please feel free to contact.

- Lifting capacity of truss gantry crane : 3.2 ton- 100 tons

- Span of truss gantry crane : 12 m- 40 m

- Gantry girder design: Single girder, double girder, with 2 cantilever, 1 cantilever or no cantilever

- Lifting height of truss gantry crane : 6-9m or customized

- Working class of truss gantry crane : A3-A5

- Lifting mechanism of truss gantry crane :CD1,MD1,HC hoist, hoist trolley or open winch

- Crane control of truss gantry crane :Ground controlling and drivers' room controlling.

Structure & Composition

The full gantry truss crane is consisted of the steel structure, the crane traveling system, crane trolley or electric hoist , electric parts and crane control system, and other crane parts and components, etc.The metal structure of Truss Gantry crane mainly consists of the main beam with single girder or double girder design, end beam, supporting legs or out-triggers and end carriages. Truss girder gantry crane has lighter weight than box girder crane. The overall size of truss crane steel structure is determined by the factors,including crane capacity, span length, lifting height, cantilever length, wheelbase of trolley and crane travelling mechanism,etc. .

Steel structure:The steel frame structure of truss crane is welded with Angle steel or Steel bar to make the gantry crane more suitable for windy application with advantages of light dead weight, high rigidity and high wind proof ability. . Connected with unique steel nails, the structure of truss crane is not only strong, but also easy to install, assemble and disassemble when moving to a new site.

Truss girder:Truss gantry girder has two types of designs, the single girder crane design and double girder crane design, which can meet your need for light-duty and heavy-duty material handling. Besides,, the metal structure of the gantry crane girder can be designed with or without cantilevers.

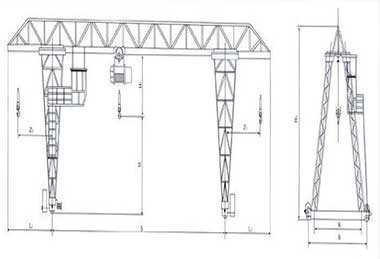

Single girder truss crane drawing

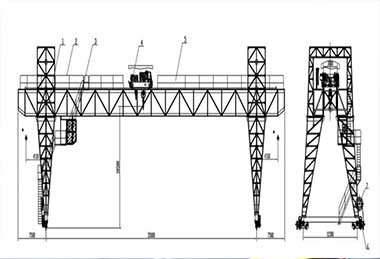

Double girder truss crane drawing

Supporting legs: the truss crane is usually supported on two rigid legs. However, when the length of truss crane span is larger than 35m, the truss gantry crane will be engineered to stand up on one rigid leg and one flexible leg.

Crane frame traveling system: the frame structure of truss crane is travelling on and along the installed track or rail on the ground for the transportation of loads

Lifting system: lifting mechanism of truss gantry crane is an electric winch trolley or electric hoist, equipped with hook and other lifting devices for loads hoisting.

Crane control system: Ground crane control and driver cabinet control, etc.

Single girder & Double girder truss crane

For various material handling needs, the truss gantry cranes of different configurations are available, including single girder truss crane and double girder truss crane, and the both types of truss cranes are available with the designs of semi gantry cranes if needed.

MH Truss Type Single Girder Gantry Crane

Lifting capacity of truss crane: 3.2-32tons

Span of truss crane : 12-30m

Lifting height of truss crane : 6-9m or customized

Working class of truss crane: A3-A5

Lifting mechanism of truss crane: CD1,MD1,HC

MG Truss Type Double Girder Gantry Crane

Lifting capacity of truss crane: 10-100tons

Span of truss crane: 22-40m

Working class of truss crane: A3-A5

Lifting height of truss crane: 6-9m or customized

Lifting mechanism of truss crane: Hoist or trolley or winch

Single girder truss gantry crane

The single girder truss crane is designed for low-speed and light-duty material handling,with single truss gantry girder design, equipped CD, MD, wire rope hoists and other electric hoists as the lifting system with capacity from 3 to 32 tons.With single girder crane design, the single girder truss crane makes the electric hoist trolley moving under along the main beam girder. With cantilevers, the truss crane can delivery the loads through the supporting legs to the crane edge, with convenience and high efficiency.Single girder truss crane is featured as simple structure, light dead weight, easy fabrication and installation.

Double girder truss gantry crane

The double girder truss crane is engineered for high speed and heavy-duty material handling, with double truss gantry girder design, equipped standard hoist trolley or winch trolley as the hoisting system, with capacity from 10 ton to 100 ton. With double girder crane design,the double girder truss crane makes its hoist trolley or winch trolley running along the track on the top of the main beam girder. Double girder truss crane is featured as strong and stable, large lifting capacity, long crane span, and high wind proof ability.

Single cantilever & Double cantilever truss crane

In terms of cantilever design of gantry frame, gantry truss crane can be grouped into

- Double Cantilever truss gantry crane - most frequently used structure, which can take full use of the endurance capacity of crane structure and application space reasonably.

- Single cantilever truss gantry crane - Used when the application space is limited.

- Truss gantry crane with no cantilever - the main girder has no cantilever with the hoisting trolley or winch trolley running within the crane span

Single cantilever

No cantilever

Single cantilever

Double cantilever

Box girder vs. Truss girder

Box gantry girder design:The box shaped gantry girder is welded with steel plates , with features of high safety, stiffness and other, etc. Box gantry girder design is usually used for gantry cranes with large and super large tonnages. .The box gantry girder design also has the drawbacks of high production cost, heavy self weight and poor wind resistance.

Truss gantry girder design: The truss gantry girder is welded with angle steel or I-beam, featured as low manufacturing cost, light self-weight, and good wind resistance. However, due to the large amount of welding points and the inborn defects of the truss structure,the truss gantry girder has the disadvantages of large deflection, low rigidity,low reliability, and frequent welding spots detection. . Truss cranes are suitable for application required not so much on safety and lifting capacity.

Truss gantry crane with single girder crane design & double girder crane design

Truss gantry crane with single girder crane design & double girder crane design

Box girder gantry crane with single beam crane design & double beam crane design

Box girder gantry crane with single beam crane design & double beam crane design

By contrast, truss crane is a more reasonable selection for windy application than box girder gantry crane with the features of light weight, durable performance, and good wind resistance

Benefits of employing truss gantry crane

- With small windward area, the truss crane is inborn with excellent wind resistance, an ideal lifting solution in heavy wind areas

- With truss structure and cantilever design, truss gantry crane offers light dead weight and large hook coverage.

- Truss crane is easy to be operated, installed and maintained with safety and convenience.

- With low noise and power consumption, truss type gantry crane is environment friendly.

Features of truss gantry crane

The truss cranes in general have the features of light weighted main steel structure, small wheel load pressure and reliable performance, developed on the base of Russian gantry crane. Main specification of the gantry crane with truss steel structure includes lifting capacity, lifting height, crane span, operating speed, working duty class, total crane weight and wheel load pressure, and others, etc.The features of truss gantry cranes are detailed as follow:

- The crane truss steel structure is made of strengthened triangular truss, with light weight, and high wind resistance. Wind resistance of truss crane is class 6 with loading and class 11 without loading.

- Stable structure, easy installation and removal.Thermal expansion seamless steel legs or truss legs are connected with the main beam girder and ground girder with the bolts or pin connections. Both main and auxiliary legs of the truss crane can be dismantled easily, making transportation convenient and saving shipping cost.

- Based on the national rules and standards, the design and manufacturing of the truss gantry cranes meet all the requirements of meteorological conditions.

- With environmental friendly designing concept, the truss cranes complies with the relevant environmental laws and regulations.

- Ground control or driver's cab control are available for truss gantry crane.

Application of truss crane

Truss gantry crane has a wide application and are used in various industrial occasions. Typically, truss gantry cranes are widely used for material handling in Concrete beam yard and Bridge Construction site.

- First, truss gantry crane are widely used in Concrete Beam Yard for handling concrete bridge beams, concrete plates and other concrete products, etc. And an electric hoist is equipped on the main crane girder for light and small tools or loads handling.

- Engineered truss gantry crane will be used on bridge construction site for hoisting the concrete beam from ground transporter to bridge transporter, helping launcher crane to build the whole bridge.

- Third, engineer truss gantry crane also can be used for disassembling and re-erection of launcher cranes.

With various designs and configurations, truss cranes can be used in many different other working occasions such as, Port, Shipyard, Railway line, Material yards, etc. And also, truss gantry crane can be widely used for material handling in various industrial factories and plants such as,Steel, Forest Products, Inter-modal, Biomass/Pellet and many other industries,etc.

All in all, the truss crane with single gantry girder design or double gantry girder design are widely used in various application because of the features and advantages of light-weighted, strong and stable performance and high wind resistance, etc. If you need a cut-to-tail truss gantry crane solution, please feel free to contact us. Get free consultation on Truss Cranes and Truss Gantry Crane now.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch