Gantry Crane for Precast Concertet Block Manufacturing Plant

Gantry Crane for Block-Making Machinery, Concrete Blocks (Hollow, Solid, Interlocking) Handling , Moving and Stacking in Manufacturing Plants. Get your cusotm gantry crane design!

Category: Construction

Your Trusted Gantry Cranes Manufacturer & Supplier

Gantry Crane for Precast Concertet Block Manufacturing Plant

Gantry Crane for Block-Making Machinery, Concrete Blocks (Hollow, Solid, Interlocking) Handling & Moving and Stacking in Manufacturing Plants.

Typical types of gantry cranes for precast-concetee blocks handling in various types of applications in manfuactruing plants, and in construction site accross various industrial sectors. Gantry Crane for Handling Typical Loads: Concrete Blocks (Hollow, Solid, Interlocking), Crane Applications: Moving and Stacking Blocks, Facilitating Block-Making Machinery.

The production of precast concrete blocks demands a seamless integration of efficiency, precision, and adaptability. In this intricate dance of manufacturing, the role of gantry cranes emerges as a pivotal force, ensuring the smooth orchestration of various production phases.

Gantry cranes stand as stalwart guardians in the realm of concrete block manufacturing. Their significance lies in their ability to facilitate the movement of raw materials, molds, and finished blocks with unparalleled precision. These cranes become the backbone of the manufacturing process, embodying reliability and efficiency.

The diversity in concrete block manufacturing requires a spectrum of gantry crane types, each tailored to specific tasks. From the imposing Full Gantry Cranes to the nimble Straddle Carriers, the array ensures that every facet of the production process is catered to with finesse. Understanding these crane types is akin to mastering the tools of an artisan, each designed for a unique purpose.

Efficient handling within a concrete block manufacturing plant is not merely a convenience; it is a necessity. The timely and precise movement of materials and blocks significantly impacts overall productivity. Gantry cranes, with their versatility and capability, play a pivotal role in streamlining these processes, contributing to the overall efficiency of the manufacturing plant.

Types of Gantry Cranes in Concrete Blocks Manufacturing Plant

Concrete block manufacturing is a nuanced process, demanding a versatile fleet of gantry cranes to execute various tasks with precision. Let's delve into the typical design features, benefits, and applications of the various gantry cranes that bring efficiency and precision to every stage of the concrete block manufacturing process.

Full Gantry Cranes

The Full Gantry Crane, standing as a stalwart sentinel, is characterized by its bridge that spans the entire width of the working area. These cranes are adept at handling heavy loads and provide unobstructed coverage, making them ideal for expansive manufacturing plants. Full Gantry Cranes excel in tasks such as transporting raw materials, moving molds, and stacking finished concrete blocks.

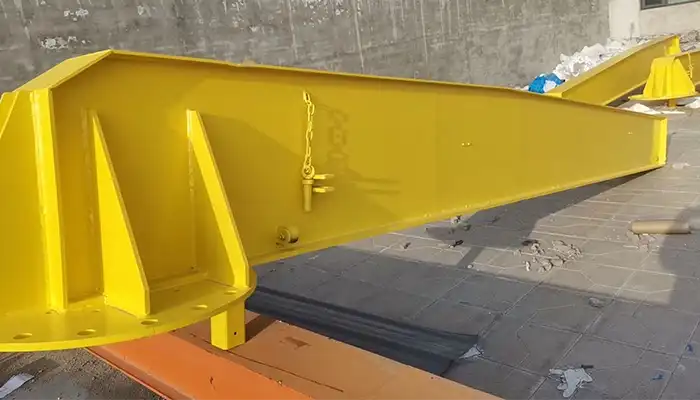

Full Gantry Cranes with Truss Girder Design for Outdoor Precast Block Handling

- Design: Robust steel structure with a bridge spanning the entire working area. Equipped with a hoist trolley for vertical movement. Control cabin for operators overseeing the entire manufacturing floor.

- Features: High lifting capacity, suitable for handling heavy loads such as molds and finished blocks. Unobstructed coverage ensures efficient material movement across the entire plant. Precise control for accurate positioning during critical phases.

- Benefits: Versatile handling capabilities for diverse tasks in concrete block production. Optimal for expansive manufacturing plants with ample space. Enhanced operator visibility and control from the cabin.

- Applications:Transporting raw materials like aggregates, cement, and reinforcement. Moving molds to precise positions for the molding phase. Stacking finished concrete blocks in an organized manner.

Semi-Gantry Cranes

Offering a harmonious blend of flexibility and robustness, Semi-Gantry Cranes are designed with one end supported on a runway, while the other travels on wheels along the ground. This design allows them to efficiently navigate through manufacturing plant layouts with varying spatial constraints. Semi-Gantry Cranes are particularly valuable in optimizing handling processes in areas where a full gantry may be impractical.

- Design: One end supported on a runway or support structure, while the other travels on wheels along the ground. Hoist trolley for vertical movement and a runway for lateral movement. Compact design suitable for areas with spatial constraints.

- Features: Flexibility in navigating through manufacturing plant layouts. Robust structure for reliable and efficient handling.

- Benefits: Well-suited for manufacturing plants with limited space. Adaptability in handling various tasks with precision.

- Applications:Efficient material handling in confined areas. Handling molds and transporting materials within the plant.

RTG Cranes (Rubber-Tired Gantry Cranes)

Embodying agility and adaptability, RTG Cranes are equipped with rubber tires, enabling them to traverse diverse terrains within the manufacturing plant. Their mobility is especially advantageous in swiftly transporting finished concrete blocks to different workstations or storage areas. RTG Cranes are known for their speed, making them a valuable asset in time-sensitive production scenarios.

RTG Cranes (Rubber-Tired Gantry Cranes)

- Design: Equipped with rubber tires for mobility. Hoist trolley for vertical movement. Operator cabin for control and monitoring.

- Features: High mobility for swift transportation of finished concrete blocks. Versatile design for easy navigation across different terrains.

- Benefits: Rapid and efficient movement of finished blocks to various workstations. Ideal for time-sensitive production scenarios.

- Applications:Transporting finished concrete blocks to different areas of the plant. Loading and unloading materials in outdoor or varied terrains.

RMG Cranes (Rail-Mounted Gantry Cranes)

Precision and stability converge in RMG Cranes, which are mounted on rails for controlled movements. Their fixed track design enhances accuracy in handling tasks, particularly in scenarios where meticulous positioning is crucial. RMG Cranes shine in applications such as mold positioning and the organized stacking of finished blocks, ensuring every element is precisely placed.

RMG Cranes (Rail-Mounted Gantry Cranes)

- Design: Mounted on rails for controlled horizontal movements. Hoist trolley for vertical lifting. Precise control for accurate positioning.

- Features: Fixed track design enhances stability and accuracy. Suitable for applications where meticulous positioning is crucial.

- Benefits: Ensures precise handling in critical phases of concrete block production. Stability in movements for enhanced safety.

- Applications:Mold positioning with precision. Organized stacking of finished concrete blocks.

Container Gantry Cranes

In the realm of concrete block manufacturing, where standardized containers play a pivotal role, Container Gantry Cranes take center stage. These cranes are tailored to efficiently handle containers carrying raw materials or finished products. Their specialized design streamlines the loading and unloading of containers, contributing to the overall efficiency of the manufacturing process.

Container Gantry Cranes

- Design: Tailored for handling containers with raw materials or finished products. Hoist trolley and control cabin for efficient operation.

- Features: Specialized design for loading and unloading standardized containers. Adaptability to various container sizes.

- Benefits: Streamlines the handling of raw materials and finished products in containers. Efficient container management for improved logistics.

- Applications:Loading and unloading containers carrying raw materials. Handling finished concrete blocks stored in containers.

Typical Gantry Cranes for Precast Concrete Blocks Handling

In the realm of precast concrete block manufacturing, the role of gantry cranes extends beyond mere material handling. These versatile machines are tailored for specific tasks, each contributing to the seamless progression of the production line. Let's explore the design intricacies, features, benefits, and practical applications of gantry cranes in the key areas of mold positioning, raw material transportation, finished block stacking, and palletizing operations.

Gantry Cranes for Mold Positioning

These gantry cranes are meticulously crafted with a specialized hoist trolley, offering precision controls and adjustable features to accommodate varying mold sizes. Their design ensures high precision in both horizontal and vertical movements, with robust hoisting mechanisms for controlled mold handling. The benefits of these cranes lie in their ability to ensure accurate placement of molds during the molding phase, minimizing errors and contributing to the consistency of the final product.

Applications involve the transportation of molds to designated positions on the production floor and the facilitation of precise alignment for the concrete block molding process.

Gantry Cranes for Mold Positioning

- Design: Specialized hoist trolley with precision controls. Adjustable features for accurate mold positioning. Structural design to accommodate varying mold sizes.

- Features: High precision in horizontal and vertical movements. Robust hoisting mechanisms for controlled mold handling.

- Benefits: Ensures accurate placement of molds during the molding phase. Minimizes errors in mold positioning, contributing to product consistency.

- Applications:Transporting molds to designated positions on the production floor. Facilitating the precise alignment of molds for concrete block molding.

Gantry Cranes for Raw Material Transportation

Crafted with a sturdy hoist trolley for vertical movement, these gantry cranes are equipped with cargo hooks or containers for efficient material transport. Their versatile cargo handling mechanisms adapt to various materials, offering enhanced load capacity suitable for heavy raw materials. The cranes streamline the material handling workflow, efficiently transporting bulk raw materials such as aggregates, cement, and reinforcement to different workstations within the plant.

Applications include the transportation of raw materials to designated areas and the loading and unloading of materials at various points within the manufacturing plant.

Gantry Cranes for Raw Material Transportation

- Design: Sturdy hoist trolley for vertical movement. Cargo hooks or containers for material transport. Enhanced load capacity suitable for heavy raw materials.

- Features: Versatile cargo handling mechanisms for various materials. Adaptability to handle different types of raw materials.

- Benefits: Efficient transportation of raw materials such as aggregates, cement, and reinforcement. Streamlines the material handling workflow, reducing downtime.

- Applications:Transporting bulk raw materials to different workstations. Loading and unloading materials at designated areas within the plant.

Gantry Cranes for Finished Block Stacking

Designed with a robust hoist trolley featuring high lifting capacity, these gantry cranes excel in stacking multiple finished blocks. Precision controls ensure controlled movements for precise placement during stacking, contributing to organized storage and optimized space utilization. The benefits lie in their ability to facilitate the organized stacking of finished concrete blocks for storage or further processing.

Applications involve stacking finished blocks on pallets for storage and creating organized configurations for easy retrieval.

Gantry Cranes for Finished Block Stacking

- Design: Robust hoist trolley with load-bearing capabilities. Precision controls for stacking blocks in organized formations. Structural design to accommodate different block sizes and weights.

- Features: High lifting capacity for stacking multiple finished blocks. Controlled movements for precise placement during stacking.

- Benefits: Organized stacking of finished concrete blocks for storage or further processing. Optimizes space utilization in storage areas.

- Applications:Stacking finished blocks on pallets for storage. Creating organized and easily retrievable block configurations.

Gantry Cranes for Palletizing Operations

Equipped with a hoist trolley featuring palletizing mechanisms, these gantry cranes are designed for swift and accurate palletization of finished concrete blocks. Customizable settings accommodate different pallet sizes and configurations, and their automated or semi-automated palletizing capabilities reduce manual labor in the palletization phase. The benefits encompass efficient palletization and the creation of palletized configurations suitable for storage or transportation.

Applications include transferring finished blocks onto pallets for storage or transportation and creating palletized configurations suitable for shipment to construction sites.

Gantry Cranes for Palletizing Operations

- Design: Hoist trolley equipped with palletizing mechanisms. Control features for precise placement of blocks on pallets. Structural design to handle varying pallet sizes and configurations.

- Features: Automated or semi-automated palletizing capabilities. Customizable settings for different palletization requirements.

- Benefits: Swift and accurate palletization of finished concrete blocks. Reduces manual labor in the palletizing phase.

- Applications:Transferring finished blocks onto pallets for storage or transportation. Creating palletized configurations suitable for shipment to construction sites.

In the dynamic landscape of precast concrete block manufacturing, these gantry cranes act as choreographers, orchestrating movements with precision and finesse. Their specialized applications contribute to the overall efficiency, consistency, and safety of the production process. As we move forward, we'll explore real-world applications and case studies, unveiling the practical success stories of gantry cranes in the concrete block manufacturing realm.

Gantry Crane for Handling Concrete Blocks (Hollow, Solid, Interlocking)

In the intricate tapestry of precast concrete block manufacturing, the role of gantry cranes becomes even more nuanced when it comes to handling different block types. Let's delve into the details of their design, features, and adaptability in the context of hollow blocks, solid blocks, and interlocking blocks.

- Hollow Blocks:Gantry cranes designed for handling hollow blocks exhibit features tailored to the unique characteristics of these blocks. The hoist trolley, equipped with precision controls, ensures gentle handling of the delicate voids within hollow blocks during transportation and stacking. The structural design is optimized to accommodate the often larger dimensions of hollow blocks, offering stability and control.

- Solid Blocks:For solid blocks, gantry cranes are engineered with robustness in mind. The hoist trolley features high lifting capacity to handle the density and weight of solid blocks effectively. The controlled movements of the crane ensure precise placement during stacking operations. The structural design accounts for the compact and uniform nature of solid blocks, contributing to the efficiency of the handling process.

- Interlocking Blocks:Gantry cranes adapted for interlocking blocks showcase a marriage of precision and adaptability. The hoist trolley, with its adjustable features, is adept at accommodating the intricate shapes and connecting mechanisms of interlocking blocks. This design ensures that the interlocking features are preserved during handling, contributing to the integrity of the final product.

Concrete blocks come in a spectrum of weights and sizes, and gantry cranes are engineered to adapt seamlessly to this diversity. The hoist trolley is equipped with features for adjusting to different block weights, ensuring controlled and balanced lifting. The structural design accounts for variations in block sizes, offering stability and efficiency in handling blocks of different dimensions.

The hallmark of an effective gantry crane in precast concrete block manufacturing is its adaptability. Gantry cranes are designed to seamlessly transition between handling hollow, solid, and interlocking blocks. This adaptability is reflected in their control mechanisms, allowing operators to tailor the crane's movements to the specific requirements of each block type. The ability to handle a variety of block types within the same manufacturing plant enhances overall flexibility and productivity.

In essence, the gantry crane becomes a versatile partner in the intricate dance of concrete block production, adapting its movements to the unique characteristics of each block type. As we continue our exploration, we'll unfold the practical applications of these cranes in moving, stacking, and facilitating the production of concrete blocks across the manufacturing plant.

Crane Applications: Moving and Stacking Blocks, Facilitating Machinery

The practical applications of gantry cranes in precast concrete block manufacturing extend far beyond mere material handling. These versatile machines play a pivotal role in orchestrating the movement of blocks, ensuring precise stacking, and facilitating the seamless operation of block-making machinery within the plant.

Moving Blocks within the Plant

- Safe Transportation:Gantry cranes excel in the safe transportation of concrete blocks within the manufacturing plant. Equipped with robust hoist trolleys and advanced control systems, these cranes ensure the secure movement of blocks from one workstation to another. Safety features such as load monitoring contribute to accident prevention, creating a secure working environment.

- Precision Movements in Production Phases:During critical production phases, precision is paramount. Gantry cranes offer controlled and precise movements, aligning with the specific requirements of each phase. Whether it's the transport of molds, positioning during molding, or moving finished blocks to storage, the crane's precision ensures that each step of the production process is executed with accuracy.

Stacking Finished Blocks

- Organized Pallet Stacking:Gantry cranes shine in the organized stacking of finished concrete blocks. The hoist trolley's capabilities for controlled lifting and placement contribute to the creation of neatly stacked configurations. This organized pallet stacking not only optimizes storage space but also facilitates efficient retrieval when blocks are needed for further processing or transportation.

- Adaptability to Pallet Sizes:The adaptability of gantry cranes extends to the varied sizes of pallets used in precast concrete block manufacturing. The hoist trolley is designed to handle different pallet dimensions, ensuring flexibility in stacking configurations. This adaptability enhances the efficiency of storage operations, accommodating the diverse needs of the production line.

Facilitating Block-Making Machinery

- Coordinating with Equipment:Gantry cranes seamlessly coordinate with block-making machinery, enhancing the overall efficiency of the production process. The hoist trolley's precise movements align with the operational requirements of the machinery, ensuring a smooth flow of materials. This coordination minimizes downtime, optimizing the utilization of both the cranes and the block-making equipment.

- Enhancing Overall Production EfficiencyThe synergy between gantry cranes and block-making machinery results in enhanced overall production efficiency. Gantry cranes contribute to a continuous and uninterrupted workflow, from the arrival of raw materials to the stacking of finished blocks. Their adaptability, precision, and coordination with machinery create a harmonious production environment, fostering increased efficiency and productivity.

In the dance of concrete block manufacturing, gantry cranes take on the role of choreographers, ensuring that each movement is executed with precision, safety, and efficiency. As we delve into real-world applications and case studies, we'll witness firsthand how these cranes contribute to the success stories of precast concrete block manufacturing plants.

Selection of Concrete Block Handling Cranes

In the intricate process of selecting gantry cranes for handling concrete blocks in manufacturing plants, several factors come into play. This pivotal decision requires a comprehensive understanding of the diverse block types and sizes, ensuring that the chosen gantry crane is equipped to meet the unique demands of the production environment.

Factors Influencing Crane Selection

Block Types and Sizes

Consideration:The variety and characteristics of concrete blocks being produced are fundamental considerations in the selection process.

Application:Different block types, such as hollow, solid, or interlocking, possess distinct features and requirements. Gantry cranes must be equipped with specific features tailored to handle the nuances of each block type.

- Hollow Blocks:The crane should have a gentle handling mechanism to protect the delicate voids within hollow blocks. This consideration ensures that the crane's movements are precise and do not compromise the structural integrity of the blocks.

- Solid Blocks:Robustness and high lifting capacity are crucial for efficiently handling the density and weight of solid blocks. Gantry cranes selected for this application should demonstrate strength and stability during lifting and transporting operations.

- Interlocking Blocks:Adjustable features are essential to accommodate the intricate shapes and connecting mechanisms of interlocking blocks. Gantry cranes with customizable settings ensure that the handling process is tailored to the specific configurations of interlocking blocks, contributing to seamless operations.

The consideration of block types and sizes goes beyond a generic approach, emphasizing the need for specialized features that align with the unique characteristics of each block type. By tailoring gantry cranes to the specific requirements of hollow, solid, and interlocking blocks, manufacturers ensure precision, efficiency, and the preservation of block integrity throughout the handling process.

Production Layout and Space Constraints

Consideration:The layout of the manufacturing plant and the available space are critical considerations in selecting gantry cranes.

Application:The chosen gantry crane should provide optimal coverage within the plant layout while minimizing disruptions to the production flow. Different types of gantry cranes, such as full gantry cranes, semi-gantry cranes, and straddle carriers, offer varying degrees of adaptability to different spatial configurations.

- Full Gantry Cranes:Ideal for expansive spaces, full gantry cranes offer extensive coverage and are suitable for plants with a layout that allows for unrestricted movement.

- Semi-Gantry Cranes:Designed for more compact layouts, semi-gantry cranes are a practical choice when space constraints limit the installation of full gantry cranes. Their asymmetric configuration allows them to navigate efficiently within confined areas.

- Straddle Carriers:Particularly beneficial in plants with limited space, straddle carriers operate on rails and have a narrow footprint, making them suitable for congested production environments.

The production layout and space constraints is crucial for selecting a gantry crane that not only fits within the available area but also ensures efficient coverage and maneuverability. This consideration directly influences the flow of materials, minimizing disruptions and contributing to the overall productivity of the concrete block manufacturing plant.

As our exploration continues, we will delve into additional factors influencing gantry crane selection, including the material handling workflow, adaptability to changing production requirements, integration with block-making machinery, safety considerations, and economic factors. The intricate interplay of these considerations ensures that the selected gantry crane aligns seamlessly with the dynamic requirements of the precast concrete block manufacturing process.

Material Handling Workflow

In the intricate process of choosing gantry cranes for handling concrete blocks in manufacturing plants, a thorough understanding of the material handling workflow is essential. This consideration is crucial for aligning the capabilities of the gantry crane with the various phases of the production process.

Consideration:Comprehensive insight into the material handling workflow, from the arrival of raw materials to the stacking of finished blocks.

Application:Ensuring that the gantry crane is strategically placed to facilitate smooth transitions between different phases of the material handling workflow, minimizing downtime and optimizing overall efficiency.

- Raw Material Transportation:Gantry cranes play a vital role in efficiently transporting raw materials such as aggregates, cement, and reinforcement to designated areas within the plant. The crane's design should support the swift and secure movement of these materials to ensure a continuous supply for production.

- Mold Positioning and Handling:Specific gantry cranes are utilized for the precise positioning of molds during the molding phase. These cranes contribute to the accuracy of the molding process, ensuring that molds are placed with precision for optimal block formation.

- Finished Block Stacking and Palletizing:Gantry cranes are instrumental in stacking finished blocks onto pallets with organized precision, ready for storage or transportation. The crane's adaptability to different block sizes and weights is crucial in creating stable and organized pallet configurations.

- Transportation to Construction Sites:In some cases, gantry cranes, particularly rubber-tired gantry cranes (RTG cranes), are used for transporting finished concrete blocks to construction sites efficiently. This involves careful handling during loading and unloading operations.

- Pallet Handling:Gantry cranes are equipped to handle pallets, ensuring their swift movement and accurate placement in various areas of the production process. This capability is essential for maintaining a continuous flow of materials within the plant.

The intricacies of the material handling workflow allows for the strategic placement of gantry cranes, ensuring that they play a pivotal role in each phase of the production process. This comprehensive approach contributes to the seamless operation of the concrete block manufacturing plant, minimizing disruptions and maximizing overall efficiency.

As we progress in our exploration, we will continue to unravel additional factors influencing gantry crane selection, including adaptability to changing production requirements, integration with block-making machinery, safety considerations, economic factors, and real-world case studies showcasing successful implementations of gantry cranes in concrete block manufacturing plants.

Adaptability to Changing Production Requirements

Consideration:The ability of the gantry crane to adapt to changing production requirements, including variations in block types, sizes, and weights.

Application:Facilitating seamless adjustments in the handling process to accommodate fluctuations in demand and production needs.

- Block Types and Sizes:Gantry cranes must be adaptable to the diverse range of block types, such as hollow, solid, or interlocking, each with its unique characteristics. Additionally, the crane should handle blocks of varying sizes and weights efficiently.

- Consideration:The variety and characteristics of blocks.Application:The gantry crane should be equipped with specific features to handle different block types. For example, precise handling for delicate hollow blocks or high lifting capacities for dense solid blocks.

- Fluctuating Production Demands:Production demands in a concrete block manufacturing plant can vary based on market trends, project requirements, or seasonal factors. The selected gantry crane should have the flexibility to scale operations up or down as needed.

- Consideration:The ability to adjust to varying production volumes.Application:Flexible gantry crane systems accommodate fluctuations in demand, ensuring that the material handling process can be seamlessly adjusted to meet changing production requirements.

- Integration with Other Equipment:Gantry cranes need to integrate smoothly with other equipment in the production process. Whether it's coordinating with block-making machinery or working in conjunction with conveyors, the crane's adaptability ensures a harmonious workflow.

Integration with Block-Making Machinery

In the complex decision-making process of selecting gantry cranes for handling concrete blocks in manufacturing plants, integration with block-making machinery emerges as a pivotal factor. This consideration ensures that the gantry crane is seamlessly compatible with other machinery in the production process, fostering smooth interactions and optimizing overall efficiency.

Consideration:The compatibility of the gantry crane with block-making machinery.

Application:Facilitating smooth interactions between the gantry crane and machinery, contributing to the optimization of the overall production process.

- Compatibility with Block-Making Machinery:Gantry cranes should be designed to work in harmony with the specific block-making machinery employed within the manufacturing plant. This includes coordinating with conveyors, molds, and other equipment involved in the block formation process.

- Consideration:Compatibility with block-making machinery.Application:The gantry crane's design should allow for seamless interactions with block-making equipment, ensuring that the material handling process aligns effortlessly with the various stages of block production.

- Precise Coordination During Molding:Gantry cranes play a crucial role in the precise positioning of molds during the molding phase. The crane's adaptability and precision movements contribute to the accurate placement of molds, ensuring the creation of high-quality concrete blocks.

- Consideration:Precision coordination during the molding phase.Application:The gantry crane's capabilities should align with the specific requirements of mold positioning, ensuring that the molding process proceeds with accuracy and efficiency.

- Efficient Handling Throughout the Process:From the transportation of raw materials to the stacking of finished blocks, gantry cranes are integral to the entire material handling workflow. Ensuring that the crane integrates seamlessly with other machinery ensures a continuous and uninterrupted flow of materials.

- Consideration:Efficient handling throughout the production process.Application:The gantry crane's adaptability and compatibility with block-making machinery contribute to an optimized material handling workflow, minimizing downtime and maximizing overall efficiency.

The integration of gantry cranes with block-making machinery is akin to a synchronized dance, where each movement is precisely coordinated to create a seamless and efficient production process. As we progress in our exploration, we will delve into additional factors influencing gantry crane selection, including safety considerations, economic factors, and real-world case studies showcasing successful implementations of gantry cranes in concrete block manufacturing plants.

Safety and Environmental Considerations

In the critical process of selecting gantry cranes for handling concrete blocks in manufacturing plants, safety and environmental considerations take center stage. This factor ensures that the chosen gantry crane is equipped with advanced safety features, contributing to a secure and sustainable working environment.

- Advanced Safety Features:Gantry cranes must be equipped with advanced safety features to minimize the risk of accidents during operation. These features may include overload protection, collision avoidance systems, emergency braking mechanisms, and comprehensive operator training programs. Gantry cranes with safety features contribute to accident prevention, safeguarding both personnel and valuable equipment within the manufacturing plant.

- Environmental Responsibility:Considering environmental factors, such as energy-efficient design and sustainable operational practices, is crucial. Gantry cranes designed with environmental responsibility in mind contribute to the overall sustainability of the manufacturing process. Gantry cranes designed with energy-efficient components and sustainable operational practices align with environmental standards, supporting a greener and more responsible manufacturing environment.

- Compliance with Regulations:Gantry cranes must comply with industry regulations and standards related to safety and environmental impact. Ensuring that the selected crane meets or exceeds these requirements is essential for maintaining a safe and compliant working environment. Gantry cranes that adhere to established safety and environmental standards provide assurance that the manufacturing plant operates within regulatory frameworks.

Safety and environmental considerations underscore the commitment to creating a workplace that prioritizes the well-being of personnel, minimizes environmental impact, and aligns with global standards for responsible manufacturing. Advanced safety features and environmentally conscious designs contribute to a secure, sustainable, and compliant working environment.

Safety and environmental considerations go hand in hand, reflecting a commitment to the well-being of personnel, the longevity of equipment, and the broader impact on the surrounding environment. As we navigate through the intricate landscape of gantry crane selection, we will explore additional factors, including economic considerations and real-world case studies that highlight successful implementations of gantry cranes in concrete block manufacturing plants.

General Material Handling Requirements

In the realm of practical details for gantry crane selection in concrete block manufacturing plants, addressing general material handling requirements is pivotal. This involves understanding the specific applications where gantry cranes play a vital role in ensuring efficient and precise operations throughout the production process.

- Raw Material Transportation: Gantry cranes are integral for the efficient transport of raw materials within the manufacturing plant. This includes aggregates, cement, and reinforcement, which need to be transported swiftly and securely to designated areas.

- Mold Positioning and Handling: Specific gantry cranes are employed for the precise positioning of molds during the molding phase. This application ensures the accurate placement of molds, contributing to the creation of high-quality concrete blocks.

- Finished Block Stacking and Palletizing: Gantry cranes play a vital role in stacking finished blocks onto pallets with organized precision. This application is crucial for preparing blocks for storage or transportation, ensuring stability and ease of handling.

- Transportation to Construction Sites: Gantry cranes, particularly rubber-tired gantry cranes (RTG cranes), are utilized for the efficient transport of finished concrete blocks to construction sites. This involves careful handling during loading and unloading operations.

- Pallet Handling: Gantry cranes are equipped to handle pallets efficiently. This includes swift movement and accurate placement of pallets in various areas of the production process, ensuring a continuous and organized flow.

Understanding these practical applications sheds light on the diverse roles gantry cranes play in material handling within concrete block manufacturing plants. Each application is intricately connected to the overall efficiency and productivity of the production process. As we proceed, we will explore additional factors influencing gantry crane selection, including economic considerations and real-world case studies showcasing successful implementations of gantry cranes in concrete block manufacturing plants.

Economic Considerations

Delving into the economic considerations of selecting gantry cranes for concrete block handling in manufacturing plants involves a meticulous evaluation of long-term costs and expected returns on investment (ROI). These considerations are paramount in making financially sound decisions that balance affordability with reliability, ultimately contributing to the overall efficiency and profitability of the manufacturing process.

Lifecycle Costs

- Consideration:Evaluating the total lifecycle costs associated with the gantry crane, encompassing acquisition, maintenance, and operational expenses.

- Application:Balancing affordability with reliability, selecting a gantry crane that offers an optimal combination of initial cost-effectiveness and long-term dependability. This consideration ensures that the crane remains a valuable and cost-efficient asset throughout its operational life.

Return on Investment (ROI)

- Consideration:Assessing the expected ROI based on the increased efficiency, reduced downtime, and improved safety provided by the gantry crane.

- Application:Gantry cranes that demonstrate a positive impact on overall plant productivity and profitability are considered valuable investments. The ROI calculation takes into account the tangible benefits derived from the crane's operational efficiency, including minimized downtime, enhanced safety, and streamlined material handling workflows.

Economic considerations in gantry crane selection are integral to aligning the investment with the long-term goals and financial health of the concrete block manufacturing plant. A well-informed decision in this regard contributes to sustainable and economically sound material handling solutions. As we progress in our exploration, we will further explore real-world case studies showcasing successful implementations of gantry cranes, providing practical insights into their economic impact on concrete block manufacturing plants.

Case Studies and Examples

Embarking on an exploration of real-world applications and success stories in the efficient handling of concrete blocks with gantry cranes provides invaluable insights into the practical impact of these machines in manufacturing plants. Examining case studies unveils the diverse applications, efficiency gains, and lessons learned, offering a wealth of knowledge for those considering or optimizing gantry crane utilization.

In real-world scenarios, gantry cranes have been deployed in diverse concrete block manufacturing plants, showcasing their adaptability to different settings and operational requirements. These applications demonstrate how gantry cranes efficiently handle various tasks, from raw material transportation to finished block stacking and palletizing. The real-world applications underscore the versatility and reliability of gantry cranes in supporting seamless material handling workflows.

Success Stories in Efficient Block Handling

Success stories highlight concrete examples where the implementation of gantry cranes has resulted in substantial efficiency gains and improvements in block handling processes. These stories showcase how the selection of the right gantry crane, tailored to the specific needs of the manufacturing plant, has positively impacted productivity, reduced operational costs, and enhanced overall plant efficiency. Success stories provide tangible evidence of the transformative power of well-chosen gantry cranes in concrete block production.

Lessons Learned and Best Practices

Gathering lessons learned from the implementation of gantry cranes in concrete block manufacturing plants yields valuable insights for industry professionals. Examining challenges faced, innovative solutions devised, and best practices developed provides a roadmap for optimizing gantry crane operations. Lessons learned contribute to a collective knowledge base, allowing manufacturers to make informed decisions, anticipate potential hurdles, and implement efficient material handling strategies.

As we delve into these case studies, success stories, and lessons learned, we'll uncover the intricate details of how gantry cranes have become indispensable assets in the realm of concrete block production. The practical experiences shared in this section will enrich our understanding of gantry crane applications and inspire thoughtful considerations for their optimal utilization in various manufacturing settings.

Conclusion

Gantry cranes, with their versatile design and precision control, have proven indispensable in a variety of applications within concrete block manufacturing plants. From the transportation of raw materials to the precise positioning of molds, stacking of finished blocks, and palletizing operations, gantry cranes form the backbone of efficient and streamlined material handling workflows. The recap of gantry crane applications underscores their adaptability and essential role in ensuring the smooth operation of the entire production process.

In the context of modern block production, gantry cranes stand as technological stalwarts, revolutionizing the way concrete blocks are handled and manufactured. Their ability to navigate large working areas, handle diverse block types, and provide precise movements during critical production phases has elevated them to pivotal roles. Gantry cranes contribute significantly to enhancing efficiency, reducing downtime, and optimizing overall productivity in concrete block manufacturing. Their role extends beyond mere machinery; they are catalysts for progress in the dynamic landscape of modern block production.

In conclusion, gantry cranes represent not just a piece of equipment in concrete block manufacturing but a strategic investment in the future of efficient and sustainable production. Their applications, roles, and the ongoing technological advancements paint a compelling picture of how gantry cranes have become integral to the success of modern block production facilities. As we embrace the ever-changing landscape of manufacturing technology, gantry cranes stand tall, embodying progress, efficiency, and a commitment to excellence in material handling.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch