Grab Bucket Goliath Crane Double Girder for Bulk Material Handling

Grab Bucket Goliath Gantry Crane Double Girder offers heavy-duty lifting, customizable specifications, and robust performance for demanding industrial environments.

Category: Double Girder Goliath Crane

Your Trusted Goliath Gantry Crane Manufacturer & Supplier

Grab Bucket Goliath Crane Double Girder: Powerful, Customizable, Reliable for Bulk Material Handling

The Grab Bucket Goliath Crane (Double Girder) offers heavy-duty lifting, customizable specifications, and robust performance for demanding industrial environments.

The Grab Bucket Goliath Crane Double Girder is a heavy-duty, versatile material handling solution designed for large-scale operations. This crane is particularly ideal for environments where high lifting capacity and stability are essential, such as in ports, steel plants, and large construction sites. Its robust design ensures efficient, reliable operation in demanding applications, providing both safety and productivity.

Introduction to Grab Bucket Goliath Crane

The Grab Bucket Goliath Crane is built with a double girder design, offering increased strength, stability, and versatility for lifting and transporting heavy, bulk materials. Unlike traditional single girder cranes, the double girder configuration allows for a higher lifting capacity and greater span, making it perfect for larger operations or areas that require long horizontal movement. This crane features a grab bucket, designed specifically for picking up and transporting loose materials, such as coal, scrap metal, or sand, with ease and precision.

This grab bucket goliath gantry crane with clamshell grab bucket or orange peel grab bucket is engineered for high-efficiency operation with smooth movement, precise control, and a long service life. Its powerful hoisting system, combined with the grab bucket's unique design, provides excellent performance in environments where materials need to be handled quickly and safely. The crane's ability to operate in tough working conditions, such as in wet or dusty environments, further sets it apart from other cranes on the market.

double girder goliath gantry crane with grab bucekt for bulk material handling

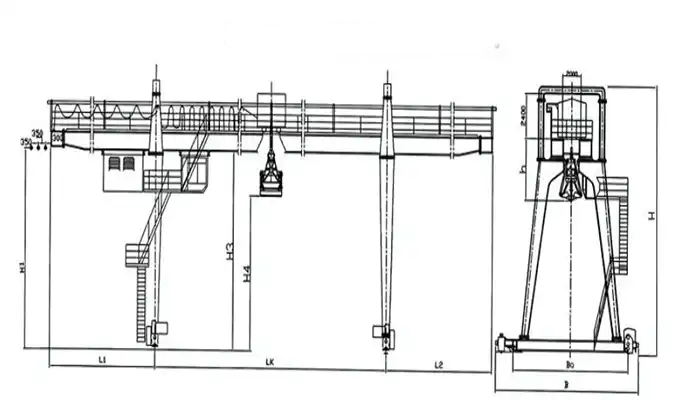

drawing of grab bucket goliath crane double girder design drawing for your reference

Key Features of the Double Girder Configuration

- Increased Load Capacity : The double girder design enhances the crane's ability to carry heavier loads, providing a lifting capacity that can reach up to 200 tons, depending on the model. This configuration allows for the safe handling of large, heavy, and bulky materials, making it suitable for industries such as mining, steel manufacturing, and port operations.

- Superior Stability and Strength : The dual girder setup ensures excellent stability during operation. The evenly distributed load reduces strain on the crane's structure, increasing its lifespan and reliability. This feature is especially beneficial in high-traffic areas where cranes are frequently used for continuous material handling.

- Longer Span and Lifting Height : A double girder crane can span a greater distance than a single girder model, making it ideal for larger work areas. The increased span allows for flexible positioning of the crane to move materials over long distances, while the height of the crane can be customized to meet specific operational needs.

- Enhanced Durability : With a design that includes high-quality materials and reinforced components, the double girder system is built to withstand the rigors of tough industrial environments. This makes the crane an excellent choice for use in harsh outdoor conditions or in facilities with heavy daily workloads.

- Smooth and Precise Operation : The double girder configuration allows for smoother and more controlled movement. This ensures precise positioning of materials and reduces the risk of damage to the crane or materials being handled. Additionally, the crane's low noise and high stability make it ideal for environments where a quiet and controlled operation is necessary.

Overall, the Grab Bucket Goliath Crane Double Girder is designed to offer a combination of strength, versatility, and reliability. Whether you're lifting bulk materials in a steel plant or handling heavy cargo in a port, this crane provides the capability to meet a variety of demanding tasks with ease and efficiency.

Key Features & Specifications

The Grab Bucket Goliath Crane Double Girder is designed to meet the diverse needs of large-scale industrial operations, offering exceptional lifting power, precision, and durability. Below are the key features and specifications that make this crane ideal for heavy-duty material handling in a range of challenging environments.

Grab Bucket Goliath Gantry Crane -Data Sheet

Capacity (t) | 5 Ton | 10 Ton | 16 Ton | 20 Ton | 32 Ton | 50 Ton | 75 Ton | 100 Ton | |

Span (m) | 7.5~31.5 | ||||||||

Operation method | Pendent control,wireless control,cabin control | ||||||||

Speed (m/min) | Lifting | 12.9 | 10.7 | 9.7 | 8.5 | 7.6 | 5.9 | 5.5 | 3.53 |

Cross travel | 35.9 | 36.4 | 36.7 | 37.5 | 38 | 38.5 | 38.4 | 33.86 | |

crane travel | 78.3 | 77.8 | 77.5 | 76 | 75.8 | 74.6 | 65 | 65.6 | |

Working duty | A5,A6,A7 | ||||||||

Power supply (AC) | 220/380/400/415/460V,50/60Hz, 3P | ||||||||

Load Capacity

The Grab Bucket Goliath Crane is built to handle a wide range of loads, making it versatile for different industries and applications. The typical lifting capacities include:

- 10t, 20t, 50t, 100t, and higher, with custom options available for heavier loads.

- Custom lifting capacities can be tailored to meet specific requirements, with options extending up to 200 tons or more, depending on your operational needs.

This flexibility ensures that the crane can meet the demands of various industries, from steel manufacturing to large construction sites and port operations.

Span

The span of the crane refers to the width of the area it can cover. Available spans for the Grab Bucket Goliath Crane Double Girder include:

- Standard spans range from 6 meters to 40 meters.

- Custom spans can be designed for wider coverage, depending on the specific requirements of the workspace and operational needs.

The ability to customize the span allows for optimized space utilization in factories, warehouses, ports, and other large-scale facilities, ensuring that the crane can efficiently handle materials over extended distances.

Lifting Height

The crane's lifting height is customizable to suit the specific height requirements of the work environment:

- Standard lifting heights range from 5 meters to 30 meters.

- Custom lifting heights are available for specialized applications, ensuring the crane can be adjusted to accommodate the varying heights of buildings, workshops, and storage areas.

This flexibility in lifting height enhances the crane's versatility, allowing it to handle materials at different levels with ease and precision.

Working Environment

The Grab Bucket Goliath Crane is designed to operate in a wide range of environmental conditions, offering both outdoor and indoor capabilities:

- Temperature Range: The crane can function within a temperature range of -20°C to +40°C. Customizations for extreme conditions (e.g., higher or lower temperatures) can be made.

- Corrosion Resistance: Ideal for use in coastal, marine, or other harsh environments, the crane can be equipped with corrosion-resistant coatings and materials to withstand high humidity, saltwater exposure, and other corrosive elements.

- High Humidity and Dust Resistance: The crane is built to handle challenging environmental conditions, such as high humidity and dusty environments, ensuring continued reliability and performance.

These features make the crane an excellent choice for use in a variety of industries, including mining, ports, steel plants, and large construction sites.

Control Options

To offer maximum convenience and safety, the Grab Bucket Goliath Crane comes with multiple control options:

- Ground Control: Operate the crane from the ground, using a control panel with easy-to-use buttons or joysticks.

- Remote Control: For greater flexibility and safety, the crane can be operated remotely, allowing the operator to control the crane from a safe distance.

- Operator Cabin: The crane can be equipped with an enclosed or open operator cabin, allowing for a comfortable and secure environment for crane operators, with clear visibility of the work area. The cabin can be customized to be installed on the left or right side of the crane, depending on the layout of the facility.

These diverse control options ensure that the crane can be operated efficiently, safely, and comfortably in various environments.

Power Supply

The Grab Bucket Goliath Crane is designed to accommodate standard and custom power requirements:

- Standard Power Supply: The crane typically operates on 380V/415V, three-phase alternating current (AC) at 50Hz, but it can be customized for different voltages or frequencies to suit your local power supply.

- Custom Voltage and Frequency: If your facility requires specific electrical specifications (e.g., 480V, 60Hz), the crane can be tailored to meet these needs, ensuring compatibility with your facility's power system.

This flexibility in power options makes the crane adaptable to different regions and facilities around the world.

Safety Features

Safety is a top priority in all industrial operations, and the Grab Bucket Goliath Crane is equipped with several key safety features to ensure smooth and safe operation:

- Anti-Collision Systems: The crane comes equipped with sensors and safety features designed to prevent collisions with other structures or equipment in the work area.

- Overload Protection: The crane includes built-in overload protection to prevent damage to the crane and ensure safe operation when handling heavy loads.

- Emergency Stop: In the event of an emergency, an easily accessible emergency stop feature ensures the crane can be halted immediately to protect both operators and equipment.

These safety features help maintain operational efficiency while minimizing the risk of accidents, enhancing the overall safety of the workplace.

The Grab Bucket Goliath Crane Double Girder is a powerful and flexible solution for heavy-duty material handling. With customizable specifications and a range of features designed for safety, durability, and ease of operation, it is an ideal choice for industries that require high-performance lifting capabilities in challenging environments.

Double girder goliath gantry crane with orange peel grab bucket for waste handling or steel scrap handling , customized goliath crane are provided based on your application and requirement.

Applications

The Grab Bucket Goliath Crane Double Girder is an essential tool for industries that require reliable, heavy-duty material handling. Its robust design and versatile capabilities make it suitable for a variety of applications in diverse industrial environments. Below are the key industries, typical loads handled, and environmental conditions where this crane excels.

Industries & Uses

The Grab Bucket Goliath Crane is widely used in industries where heavy lifting and bulk material handling are crucial. Its design allows it to perform in tough conditions, making it a go-to solution for the following sectors:

- Warehouses & Storage Facilities: Used for handling bulk materials, loading and unloading shipments, and moving heavy goods across large warehouse spaces.

- Shipyards & Ports: Essential for loading and unloading cargo, particularly bulk materials like coal, scrap metal, and cement. It's also ideal for managing large containers and heavy loads.

- Manufacturing Plants: Used in factories for lifting raw materials, transporting heavy components, and moving large parts during the production process.

- Construction Sites: Employed for moving heavy materials, such as steel beams, concrete blocks, and construction equipment, across large areas.

- Energy & Mining: In energy production and mining industries, the crane is vital for moving mined materials, such as ores, coal, and other bulk resources.

- Steel scrap yard:Orange peel grab gantry cranes, ranging from 10 to 40 tons, efficiently handle various scrap materials in recycling yards. Click to learn more on Clamshell grab bucket crane vs. Orange peel grab bucket crane to get your suitable goliath crane design.

Typical Loads Handled

The Grab Bucket Goliath Crane is designed for efficient handling of a wide range of bulk materials. Its grab bucket system is particularly suited for lifting and transporting materials that are difficult to handle with traditional lifting equipment. Typical loads include:

- Bulk Material Handling: The crane is highly efficient in managing bulk goods like coal, sand, gravel, and agricultural products. Its grab bucket allows for easy and precise picking of materials, which is particularly useful in environments like ports, cement factories, and warehouses.

- Scrap Metal: Often used in recycling facilities, this crane can handle heavy and irregular scrap metal pieces, ensuring safe and efficient lifting.

- Coal & Cement: Ideal for port operations or mining facilities, where coal and cement are frequently moved in bulk. The crane's large lifting capacity and grab bucket design make it perfect for these materials.

- Other Heavy Loads: The crane can also handle materials like steel coils, construction debris, and machinery parts, which are common in heavy manufacturing plants and construction sites.

clamshell grab bucket goliath crane for bulk material handling in storage yard

double girder goliath crane with grab bucket for truck loading

Environmental Conditions

The Grab Bucket Goliath Crane is built to operate in a variety of harsh environments. Its sturdy construction and customizable features make it an ideal choice for the following challenging conditions:

- Coastal Areas & Marine Environments: The crane can be equipped with corrosion-resistant coatings, making it suitable for use in coastal regions or marine environments, where saltwater can lead to rapid wear and tear. This makes it ideal for use in shipyards and ports.

- High-Humidity Areas: For regions with high humidity, the crane is built to resist rust and deterioration. Anti-corrosion treatments can be applied to ensure durability in such environments, reducing maintenance costs and downtime.

- Extreme Temperature Environments: Designed to operate in temperatures ranging from -20°C to +40°C, the Grab Bucket Goliath Crane can function in freezing cold climates as well as hot and dry conditions. This makes it suitable for use in various geographical locations, including high-altitude mining sites or desert-like environments.

Overall, the Grab Bucket Goliath Crane Double Girder is built to handle the toughest tasks across various industries, lifting heavy materials in a range of environments. Its robust construction and flexibility ensure it performs reliably in any condition, making it an invaluable asset for your material handling operations.

Customization Options

The Grab Bucket Goliath Crane Double Girder is designed with flexibility in mind, offering a range of customization options to meet the specific needs of different industries and operational environments. Below are the key areas where this crane can be tailored to ensure maximum performance, safety, and efficiency:

Custom Load Capacities

The Grab Bucket Goliath Crane can be configured with a wide range of lifting capacities to suit specific requirements. Whether your operation involves light-duty tasks or heavy lifting, this crane offers scalable solutions:

- Standard Capacities: Typically available in 10 tons, 20 tons, 50 tons, etc.

- Custom Load Capacities: Tailored lifting capacities can be provided from as low as 1 ton up to 100 tons or more, depending on your needs. This flexibility ensures the crane is perfectly suited for handling a variety of materials, from lightweight items to extremely heavy bulk materials, ensuring both efficiency and safety.

- Custom configurations allow the crane to accommodate the specific weight of the loads you handle, improving productivity and reducing the risk of overload or strain on the equipment.

Special Features

The Grab Bucket Goliath Crane is designed to meet the demands of various specialized environments, and can be equipped with several custom features to enhance performance and safety:

- Explosion-Proof: For environments where flammable or explosive materials are handled, such as in chemical plants or oil and gas facilities, explosion-proof components can be incorporated into the crane. This ensures the crane meets the safety standards required to operate in hazardous zones.

- Anti-Corrosion Coatings: To increase durability and reduce maintenance in harsh environments (like coastal regions, port operations, or chemical processing plants), the crane can be fitted with advanced anti-corrosion coatings. This feature extends the crane's lifespan and reduces downtime due to rust and wear.

- High-Temperature Resistance: For operations in extreme heat, such as in steel manufacturing plants or foundries, the crane can be fitted with high-temperature resistant materials and components, ensuring smooth performance even in challenging thermal environments.

Control System Options

The Grab Bucket Goliath Crane can be equipped with various control systems to suit the specific needs of your facility and ensure safe, efficient operation:

- Manual Control: For simple operations, the crane can be operated via manual control from a ground-level panel, giving the operator direct access to all essential crane functions.

- Electric Control: For more advanced automation, the crane can be equipped with an electric control system, offering precision and ease of operation for complex tasks.

- Remote Control: This option allows the operator to control the crane from a safe distance, ideal for hazardous environments or situations where the operator needs to maintain a clear line of sight. Remote control enhances flexibility and safety by reducing the need for personnel to be near moving loads.

- Frequency Converters: To ensure smooth, precise operations, the crane can be fitted with frequency converters that control the motor speed. This ensures steady and reliable lifting, reducing jerks and vibrations during material handling and enhancing the crane's overall performance.

Track & Rail Systems

The stability and efficiency of the crane largely depend on the rail and track system it operates on. Customization of the crane's rail and track options ensures optimal movement and reliability:

- Custom Rail Systems: The crane can be paired with customized rails that fit the specific layout of your facility or operational area. Whether your site requires straight or curved tracks, we can design a rail system to optimize crane movement and enhance operational efficiency.

- Track Options for Stability: Different track configurations are available to ensure smooth crane movement. Whether it's to handle heavier loads or operate in tight spaces, we offer custom rail options that support the crane's stability, improve performance, and minimize wear.

- Optimized Crane Travel: Custom track systems can help achieve smoother crane travel, ensuring that the crane moves precisely along its designated path. This reduces energy consumption and enhances the overall lifespan of both the crane and the track system.

These customization options provide the flexibility needed to tailor the Grab Bucket Goliath Crane Double Girder to your specific operational needs. Whether you're handling materials in extreme conditions, require special control features, or need a custom track system, these options ensure the crane will operate at its highest efficiency, improving productivity, safety, and longevity.

Economical Solution: Grab Bucket Goliath Gantry Crane Kit without Girder & Supporting Leg

For businesses looking for a cost-effective and flexible solution, the Grab Bucket Goliath Gantry Crane Kit without the girder and supporting leg provides an excellent option. This kit offers a more affordable entry point for customers who need reliable material handling capabilities but don't require a fully assembled gantry crane structure. Here's how this economical solution can benefit your operation:

What's Included in the Kit

The Grab Bucket Goliath Gantry Crane Kit is designed to be a modular and customizable solution. The kit includes the essential components for the crane, minus the girder and supporting legs, which can be purchased separately based on your specific requirements. The basic kit includes:

- Grab Bucket Assembly: Essential for lifting bulk materials like coal, scrap metal, and cement. The grab bucket system is easy to operate and efficient for handling materials in both indoor and outdoor environments.

- Hoisting Mechanism: A robust hoist mechanism that facilitates smooth lifting and lowering operations, which can be customized for different lifting capacities.

- Electrical System & Control Panel: The kit comes with the necessary electrical systems for controlling the crane's movement, lifting, and other operations. These can be tailored to suit different voltage, frequency, and control needs.

By excluding the girder and supporting legs, this version of the crane kit allows businesses to adjust the crane's framework based on the space available and the specific requirements of their facility.

Benefits of the Economical Solution

- Cost-Effective Entry: Without the girder and supporting legs, the kit comes at a lower upfront cost, making it an excellent option for companies with budget constraints. The flexibility to purchase additional components separately enables businesses to pay for only what they need initially.

- Customizable Setup: Since the girder and supporting legs are not included in the kit, businesses can tailor the crane's structure according to their specific space and load-handling needs. This allows for flexibility in designing the crane to fit within your existing infrastructure or to meet custom height and span requirements.

- Modular Approach: The modular nature of the crane kit means that businesses can gradually expand and enhance their crane setup over time. For example, you can add a larger girder or customized support legs as your operations grow or require more lifting capacity.

- Easy Installation and Integration: The absence of the girder and supporting legs makes this kit easier to transport and install. Once the necessary structural components are added, the crane can be quickly put into operation, minimizing downtime and setup costs.

- Ideal for Smaller Facilities: For businesses with limited space or smaller-scale operations, this crane kit is an ideal solution. It is particularly well-suited for warehouses, small ports, or manufacturing facilities where there are space constraints but reliable material handling is still needed.

Flexible Customization Options

While the kit itself excludes the girder and supporting legs, it still provides ample opportunities for customization in other areas:

- Lifting Capacity Options: The crane kit can be configured to lift a wide range of materials, from lighter loads to more substantial, heavy-duty items. Custom capacities from 1 ton to 50 tons (or higher) are available to meet your specific lifting needs.

- Control Options: You can choose from manual, electric, or remote control systems depending on the complexity and safety requirements of your operation.

- Track & Rail Systems: The rail system can be customized based on the layout of your facility. Whether it's a straight track or a more complex curved design, the crane kit can be adapted for smooth and efficient operation.

Suitable Applications

The Grab Bucket Goliath Gantry Crane Kit without the girder and supporting legs is suitable for a wide range of industries and applications, especially for smaller or more budget-conscious businesses:

- Warehouses: Ideal for handling bulk goods, containers, or materials in a smaller warehouse setting.

- Manufacturing Plants: Perfect for facilities that need to handle heavy components or parts but don't have the space for a larger, fully assembled crane.

- Ports & Stockyards: The crane kit can be used for smaller port operations or inland stockyards that require efficient material handling but on a smaller scale.

- Construction Sites: Excellent for smaller construction sites needing a reliable, flexible lifting solution that doesn't require extensive infrastructure.

The Grab Bucket Goliath Gantry Crane Kit without Girder & Supporting Leg offers a cost-effective, flexible, and customizable solution for businesses that need high-quality material handling equipment but don't want to invest in a fully assembled gantry crane right away. This modular approach gives you the ability to adapt the crane to your specific space, lifting capacity, and operational needs, all while keeping costs lower than a fully integrated system.

Compliance & Standards

The Grab Bucket Goliath Gantry Crane is designed and built with safety, performance, and regulatory compliance at the forefront. To ensure that it meets industry requirements and provides reliable, secure operation in various environments, the crane complies with a range of international safety and design standards.

Safety Standards: Compliance with Global Standards

- CE Certification: The crane meets the European CE safety standards, ensuring that it complies with the strict safety, health, and environmental protection requirements for machinery used in the European market. This certification demonstrates that the crane is safe to operate and is built with advanced safety features to protect workers and enhance operational efficiency.

- ISO Standards: The crane is also designed and manufactured according to ISO 9001 quality management standards, ensuring that the production process is consistently reliable and adheres to high-quality manufacturing principles. This guarantees that every crane, regardless of capacity or configuration, meets the same stringent standards for safety, functionality, and durability.

- Other Regional Certifications: In addition to CE and ISO standards, the crane may also comply with other regional safety standards depending on the location of operation, such as ASME (American Society of Mechanical Engineers) or BS (British Standards). These certifications ensure the crane is compliant with local safety laws and regulations, particularly when being used in regions with specific industrial safety requirements.

Custom Certifications: Explosion-Proof Certification (If Applicable)

For industries operating in hazardous environments—such as chemical plants, oil and gas facilities, or mining operations—the Grab Bucket Goliath Gantry Crane can be customized with explosion-proof features:

- Explosion-Proof Certification (ATEX, IECEx): The crane can be fitted with explosion-proof motors, electrical components, and wiring to meet ATEX (European Union Directive on Explosive Atmospheres) or IECEx (International Electrotechnical Commission for Explosive Atmospheres) standards. These certifications ensure the crane is safe for use in areas with a risk of flammable gases, dust, or vapors.

- Enhanced Safety Features for Hazardous Environments: The explosion-proof certification ensures that the crane will not spark or cause ignition in potentially explosive atmospheres. This feature is essential for industries where combustible materials are handled, providing peace of mind for operators and reducing the risk of accidents or damage.

Design Standards: Built According to GB/T 14406-2011 (or Relevant Local Standards)

- GB/T 14406-2011 Compliance: The Grab Bucket Goliath Gantry Crane is designed and manufactured according to the GB/T 14406-2011 standard, which outlines the specifications for overhead traveling cranes in China. This standard ensures the crane is built with a rigid structure, high load capacity, and operational efficiency for various industrial applications.

- Customization to Local Standards: In addition to adhering to GB/T 14406-2011, the crane is also fully adaptable to other local design standards depending on the operational location. Whether your facility operates under North American, European, or other regional regulations, the crane can be designed to meet these requirements without compromising safety or performance.

- Seismic and Structural Compliance: For areas with specific structural or seismic requirements, such as regions with a history of earthquakes, the crane can be further customized to meet these additional structural compliance standards, ensuring the crane operates safely under varying environmental conditions.

Environmental and Safety Considerations

- Environmental Compliance: The crane's design also takes into account environmental protection standards. Materials used in construction are compliant with international regulations regarding recyclability, low emissions, and eco-friendly operations, ensuring that the crane contributes to a sustainable operation.

- Regular Inspections and Maintenance: The crane is designed with maintenance and safety in mind. Compliance with international safety and design standards ensures that regular inspections, repairs, and maintenance can be performed with ease, enhancing the longevity and operational efficiency of the crane.

The Grab Bucket Goliath Gantry Crane stands out not only for its reliable performance and customizability but also for its rigorous compliance with global safety standards. Whether you're operating in a highly regulated region, an explosive atmosphere, or a challenging environment, the crane ensures safety, efficiency, and reliability across various industrial applications. The inclusion of explosion-proof and eco-friendly features, as well as adherence to GB/T 14406-2011 and other applicable standards, ensures that this crane is a safe, sustainable, and fully compliant solution for your lifting needs.

Warranty & After-Sales Service

At Grab Bucket Goliath Gantry Crane, we are committed to providing not only high-quality equipment but also comprehensive after-sales support to ensure that your crane operates efficiently and safely for years to come. Our warranty and after-sales services are designed to give you peace of mind and extend the life of your crane.

Warranty: One-Year Warranty on All Major Components

- Coverage: The Grab Bucket Goliath Gantry Crane comes with a one-year warranty that covers all major components, including the hoist mechanism, grab bucket, electrical system, and control panels. This warranty ensures that, should any manufacturing defects or faults occur within the first year of operation, they will be promptly addressed at no additional cost.

- Extended Warranty Options: For customers who require additional coverage, we offer extended warranty plans that can be customized based on the specific needs of your operation. This ensures long-term protection and operational continuity.

- Manufacturer's Support: During the warranty period, our manufacturer's support is available to help troubleshoot any issues, whether mechanical or electrical. This ensures that your crane remains in optimal condition and minimizes downtime.

After-Sales Support: Installation, Training, Repair Services, and Regular Maintenance Contracts

- Professional Installation: We provide installation services to ensure the crane is properly set up, with all components installed correctly and safely. Our team of experts will supervise the installation process, ensuring compliance with local safety regulations and operational requirements.

- Operator Training: Proper training is crucial to the efficient and safe operation of the crane. Our operator training program is designed to provide your staff with the necessary knowledge to operate the crane safely and efficiently. This includes instructions on load handling, safety protocols, and daily maintenance tasks.

- Repair Services: In the event of breakdowns or component failure, our repair service is available to ensure that the crane is back up and running as quickly as possible. We have a network of service technicians available to assist with repairs, either onsite or in our workshops.

- Maintenance Contracts: We offer regular maintenance contracts to ensure your crane stays in top condition throughout its operational life. These contracts can be tailored to your needs, with options for scheduled checks, preventive maintenance, and immediate repair services. Regular maintenance helps minimize unexpected breakdowns and extends the service life of the crane.

Spare Parts: Availability of OEM and Aftermarket Parts for Extended Crane Life

- OEM Spare Parts: We stock a wide range of Original Equipment Manufacturer (OEM) parts for the Grab Bucket Goliath Gantry Crane. These parts are made to the same high standards as the original components and are designed to ensure the optimal performance and longevity of the crane.

- Aftermarket Parts: In addition to OEM parts, we also offer aftermarket spare parts that provide a cost-effective alternative without compromising quality. These parts are sourced from reputable manufacturers and are tested to ensure they meet the necessary performance standards.

- Parts Availability: Whether it's a hoist motor, grab bucket, electrical components, or control systems, spare parts are readily available, and we strive to provide fast delivery to minimize downtime. We maintain a comprehensive inventory and work with reliable suppliers to ensure that you get the parts you need without delay.

- Custom Parts: In the event of unique specifications or modifications, we also offer custom-made parts to fit your specific crane configuration. Our engineering team works closely with clients to develop and supply parts that meet precise needs, ensuring seamless operation.

Ordering & Delivery Information

Ordering a Grab Bucket Goliath Gantry Crane is a straightforward process, designed to ensure that you receive the right equipment for your specific needs. From customization inquiries to final delivery and installation, we guide you every step of the way to ensure smooth, efficient service.

Ordering Process: Steps for Purchasing, Including Customization Inquiries

- Initial Inquiry: Begin by reaching out to our sales team through our website or customer service line. You can inquire about standard models or discuss customization options for load capacity, span, lifting height, and other specifications.

- Consultation & Customization Requirements: Our technical experts will assist in understanding your operational needs, such as the working environment (coastal, high-humidity, etc.), specific features (anti-corrosion, explosion-proof), and any space limitations. This helps us determine the best crane configuration for your facility.

- Quotation & Proposal: Based on your requirements, we will provide a detailed quote that outlines the cost, delivery timeline, and any additional features or options you may have requested. The quote will also include information on the warranty, after-sales support, and customization options.

- Order Confirmation & Agreement: Once the quote is approved, a formal order confirmation will be issued. This will include the final specifications, terms of delivery, and any additional services, such as installation and training.

- Payment & Production: A deposit or full payment is required depending on your order terms. After receiving payment, we will initiate production, which typically takes 60 to 100 days for customized units.

Delivery & Lead Time: Production Timelines (60-100 Days)

- Standard Lead Time: The typical production timeline for a Grab Bucket Goliath Gantry Crane is 60 to 100 days, depending on the complexity of your customization requests and the size of the crane.

- Delivery Logistics: Once your crane is manufactured, our logistics team will arrange for safe and timely delivery to your location. We ensure that all components are properly packed and shipped to prevent any damage during transport.

- Installation Services: Our professional installation team will oversee the setup of your crane at your site. They will ensure everything is installed according to safety regulations, and provide initial testing to verify operational efficiency.

- International Delivery: We offer international shipping to various locations worldwide. The delivery times may vary depending on your location, and we will provide you with an estimated arrival date prior to shipment.

Contact Information & Request a Quote

We are here to assist you with all your inquiries and ensure that you have all the information you need to make an informed purchasing decision. Whether you need a custom quote, more technical details, or have questions about the product, our team is ready to help.

Request a Quote: Detailed Information on How Customers Can Request Pricing Based on Their Specifications

- Online Quote Request: Visit our website and complete the online form with details about your required specifications, including load capacity, span, lifting height, and other custom features. Our team will respond with a detailed quote, typically within 24-48 hours.

- Direct Inquiry: You can also contact us directly via phone or email to request a quote. We'll be happy to walk you through the options, explain the features, and provide a tailored price based on your needs.

- Customization Details: To ensure the quote reflects your exact requirements, please provide as much detail as possible about the working environment, expected load handling, and any special features like anti-corrosion coatings or remote control systems. This will help us provide an accurate pricing estimate. Contact us by leaving a message down below or by WhatsApp: +86 151 3871 1597. Contact us to today to check what we can do to save your grab bucket goliath gantry crane cost.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch