How to Select the Right Crane Supplier: Factors to Consider

Select right supplier to get your custom overhead crane, gantry crane, jib crane, electric crane, top running & underhung crane at cost-effective price.

Category: Featured

Your Trusted Electric Overhead Crane Manufacturer & Supplier

How to Select the Right Crane Supplier: Factors to Consider

Select right supplier to get your custom overhead crane, gantry crane, jib crane, electric crane, top running & underhung crane at cost-effective price.

Selecting the Right Crane Supplier: Factors to Consider

Selecting the right crane supplier is a critical decision that can significantly impact your operations. A reliable supplier not only provides high-quality equipment but also ensures timely support and services, which are essential for maintaining smooth and efficient operations. The right supplier can enhance productivity, reduce downtime, and ensure safety, while a poor choice can lead to operational inefficiencies, increased costs, and safety risks.

Overview of Key Factors to Consider

When selecting a crane supplier, several critical factors should be evaluated:

- Supplier Reputation: Look into the supplier's industry experience, customer reviews, and any awards or certifications they have received. A supplier with a solid reputation is more likely to deliver reliable and quality services.

- Product Quality: Assess the range and quality of products offered by the supplier. Ensure that the cranes meet your specific needs in terms of load capacity, durability, and technological advancements.

- After-Sales Service: Evaluate the after-sales support provided by the supplier, including installation, maintenance, and availability of spare parts. Reliable after-sales service is crucial for minimizing downtime and extending the lifespan of your equipment.

- Cost Considerations: Consider the initial purchase price, total cost of ownership, and financing options. A comprehensive cost analysis will help you understand the long-term financial implications of your purchase.

- Additional Factors: Other important aspects include the supplier's responsiveness, the training and support services they offer, and their ability to integrate modern technologies into their products.

By thoroughly evaluating these factors, you can select a crane supplier that not only meets your immediate needs but also supports your long-term operational goals. This guide will delve into each of these factors in detail, providing you with the insights needed to make an informed decision. Check more on How to Select a Chinese Crane Manufactuerer?

Supplier Reputation

Industry Experience and Track Record

When assessing a crane supplier's industry experience and track record, it's essential to delve into specific details to gauge their expertise and reliability effectively.

Years in Business:

Establishment Date: Determine the supplier's founding date to ascertain their longevity in the industry.

Consistency: Evaluate whether the supplier has consistently operated over the years without significant interruptions or changes in ownership.

Evolution: Consider how the supplier has evolved over time, adapting to changes in technology, regulations, and market demands.

Market Presence: Assess the supplier's market presence and reputation relative to their competitors. A long-standing presence indicates trustworthiness and adaptability.

Notable Projects and Clients:

Portfolio Review: Conduct a thorough review of the supplier's portfolio, focusing on the scale, complexity, and diversity of their projects.

Project Scope: Examine the types of projects the supplier has undertaken, including industrial, commercial, and specialized applications.

Success Rate: Evaluate the supplier's success rate in completing projects on time, within budget, and to the satisfaction of their clients.

Client Testimonials: Seek testimonials or references from past clients to gain insights into their experiences working with the supplier.

Industry Recognition: Look for industry awards, accolades, or certifications received by the supplier for their outstanding performance and contributions to the field.

By thoroughly analyzing a crane supplier's industry experience and track record through these detailed perspectives, you can make a more informed decision regarding their suitability for your specific requirements. This meticulous evaluation process ensures that you partner with a supplier who possesses the expertise, reliability, and proven capabilities necessary to meet and exceed your expectations.

Customer Reviews and Testimonials

When considering customer reviews and testimonials in your evaluation of a crane supplier, it's crucial to approach them with a discerning eye to glean actionable insights.

Sources for Reviews:

Supplier's Website: Begin by checking the supplier's website for any testimonials or case studies they may have published. While these are often curated, they can still provide valuable insights into the supplier's strengths and areas of expertise.

Third-Party Review Sites: Explore independent review platforms where customers share their experiences with the supplier. Websites like Trustpilot, Google Reviews, or industry-specific forums can offer unbiased perspectives.

Industry Forums and Social Media: Participate in industry forums or search relevant hashtags on social media platforms to uncover candid discussions and testimonials about the supplier.

References from the Supplier: Request references from the supplier and reach out to their past clients directly. This allows you to ask specific questions tailored to your needs and concerns.

Common Red Flags to Watch For:

Consistent Complaints: Take note of any recurring issues mentioned across multiple reviews, such as consistent complaints about product quality, reliability, or performance.

Poor Customer Service: Pay attention to feedback regarding the supplier's customer service and responsiveness. Instances of unaddressed concerns or difficulty in reaching support staff may indicate potential challenges in your own interactions.

Delayed Deliveries: Reviews mentioning delays in product delivery or installation should raise concerns about the supplier's reliability and ability to meet deadlines.

Unresolved Issues: Be wary of reviews detailing unresolved issues or dissatisfaction with the resolution process. A pattern of unresolved complaints may indicate systemic issues within the supplier's operations.

By leveraging a variety of review sources and critically assessing the feedback provided, you can gain valuable insights into the supplier's performance and customer satisfaction levels. Identifying common red flags allows you to mitigate risks and make informed decisions that align with your procurement objectives.

Awards and Certifications

When assessing a crane supplier's reputation, industry recognitions and compliance with standards are vital indicators of their credibility and commitment to excellence.

Industry Recognitions:

Reputable Awards: Look for awards from esteemed industry organizations or publications that recognize excellence in crane manufacturing and supply. Awards such as "Supplier of the Year" or "Innovation Award" signify the supplier's leadership and innovation within the field.

Innovation and Quality: Industry recognitions often highlight the supplier's innovative solutions, product quality, and overall performance. These accolades affirm the supplier's dedication to delivering cutting-edge technology and superior products.

Compliance with Standards:

ISO Certifications: ISO certifications, such as ISO 9001 (Quality Management) and ISO 45001 (Occupational Health and Safety), demonstrate the supplier's commitment to maintaining high standards of quality and safety in their operations.

Adherence to Regulations: Compliance with industry-specific regulations and standards ensures that the supplier's products meet or exceed safety and performance requirements. This adherence instills confidence in the reliability and durability of their crane equipment.

By considering a supplier's industry recognitions and compliance with standards, you can gauge their reputation for excellence and commitment to meeting your quality and safety expectations. A supplier with a track record of industry recognitions and certifications is more likely to provide high-quality products, excellent customer service, and reliable support, ensuring a beneficial investment in crane equipment for your business.

Product Quality

Range of Products Offered

When assessing a crane supplier's range of products, it's essential to consider both the diversity of crane types available and the extent of customization options offered.

Types of Cranes Available:

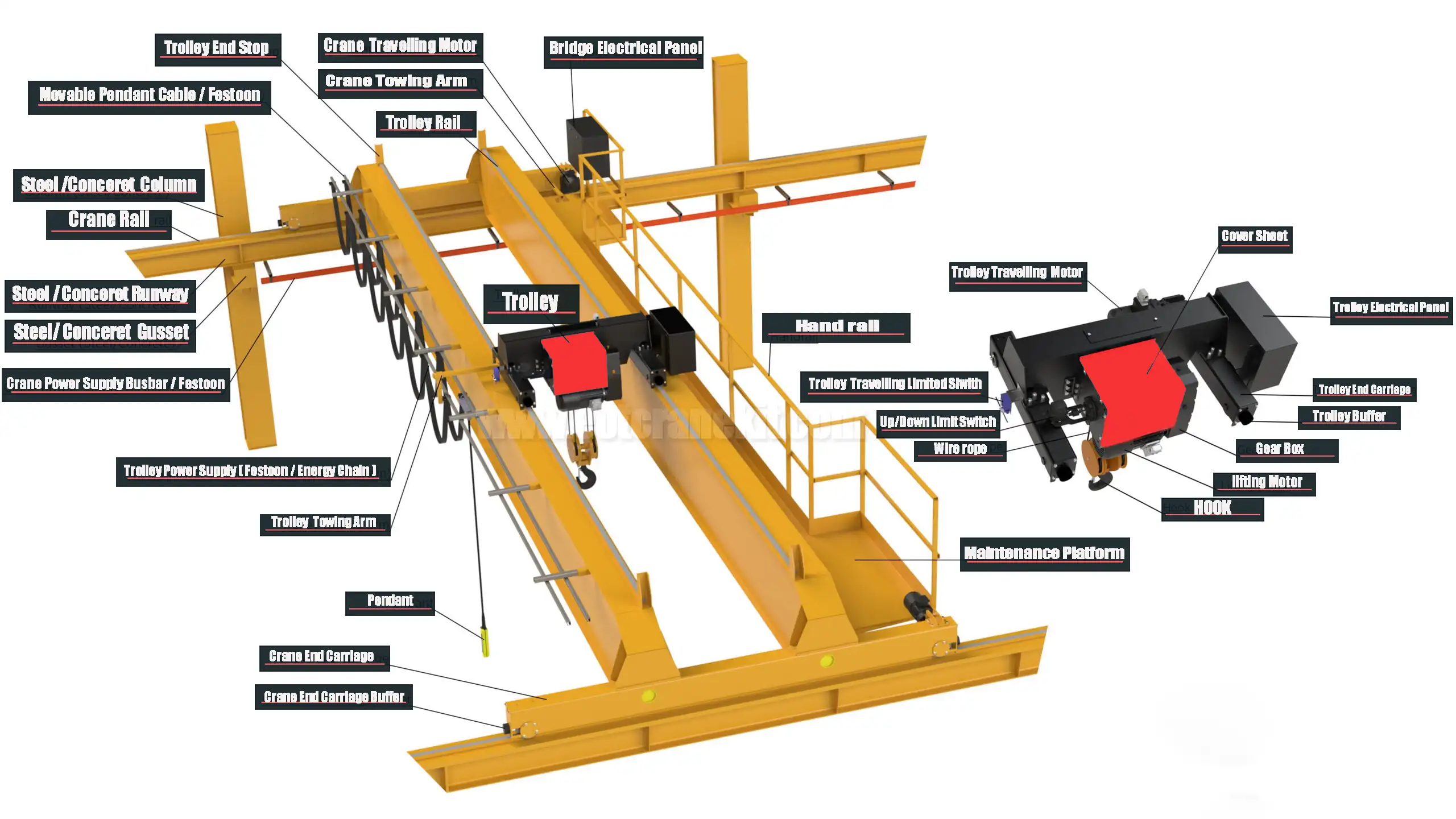

Overhead Cranes: Evaluate whether the supplier offers a range of overhead cranes, including single girder, double girder, and underslung configurations. Each type has distinct advantages and is suitable for different applications, such as heavy lifting in industrial settings or material handling in warehouses.

Gantry Cranes: Determine if the supplier provides gantry cranes, which are ideal for outdoor use or areas where overhead support structures are not available. Gantry cranes offer portability and flexibility, making them suitable for construction sites, shipyards, and storage yards.

Jib Cranes: Assess whether the supplier offers jib cranes, which are versatile lifting solutions for localized tasks. Jib cranes are commonly used for loading and unloading trucks, assembling machinery, and positioning materials in confined spaces.

Specialized Cranes: Investigate if the supplier offers specialized cranes for unique applications, such as explosion-proof cranes for hazardous environments or automated cranes for high-volume production facilities.

Customization Options:

Tailored Specifications: Determine if the supplier can customize crane specifications to meet your specific requirements. This includes adjusting load capacities, lifting heights, span lengths, and operating speeds to optimize performance for your application.

Control Systems: Assess whether the supplier offers customization of control systems, such as pendant controls, radio remote controls, or automated PLC systems. Customized control systems enhance operator efficiency, safety, and productivity.

Safety Features: Consider if the supplier can incorporate additional safety features, such as overload protection devices, anti-collision systems, and emergency stop mechanisms, to enhance workplace safety and regulatory compliance.

By evaluating a crane supplier's range of products and customization options, you can ensure that they can provide tailored solutions to meet your specific lifting and material handling needs. A supplier with a diverse product line and flexibility in customization demonstrates the ability to deliver comprehensive solutions that optimize efficiency, safety, and productivity in your operations.

Material and Manufacturing Standards

When evaluating a crane supplier's material quality and manufacturing standards, it's crucial to delve into the specifics of the materials used and the processes employed in fabrication.

Quality of Materials Used:

Structural Components: Inquire about the materials used for the crane's structural components, such as the main beams, trolley frames, and end carriages. High-strength steel, with properties suited to withstand heavy loads and environmental conditions, is essential for ensuring the crane's reliability and longevity.

Cables and Ropes: Assess the quality of cables and ropes used for lifting and hoisting operations. Durable materials, such as high-tensile steel wire ropes or synthetic fibers with high strength-to-weight ratios, are critical for safe and efficient lifting operations.

Component Sourcing: Verify the sources of the materials used by the supplier. Reputable suppliers procure materials from trusted sources and adhere to industry standards for material specifications and quality assurance.

Manufacturing Processes and Technology:

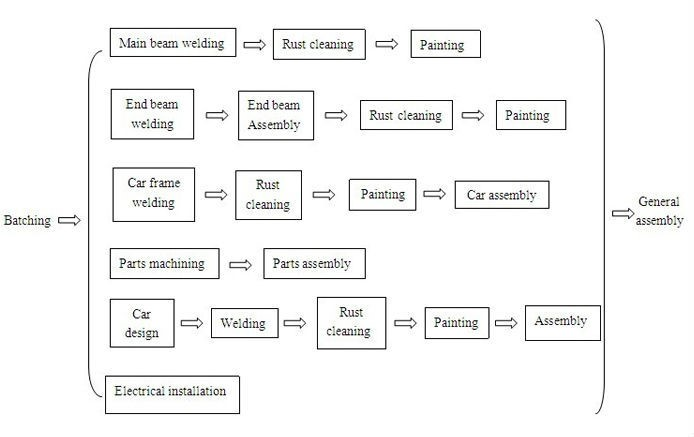

Fabrication Techniques: Evaluate the supplier's manufacturing processes, including welding, machining, and assembly methods. Advanced fabrication techniques, such as robotic welding for precise and consistent welds, contribute to the structural integrity and performance of the crane.

Precision Engineering: Look for suppliers that employ precision engineering methods, such as CNC machining and laser cutting, to ensure accuracy and repeatability in component manufacturing.

Quality Control Measures: Inquire about the supplier's quality control processes and testing protocols. Thorough testing, including load testing, non-destructive testing (NDT), and dimensional inspections, ensures that the crane meets or exceeds industry standards for safety and performance.

By assessing a crane supplier's material quality and manufacturing standards in detail, you can ensure that the crane equipment you invest in meets your expectations for reliability, safety, and performance. A supplier with a commitment to using high-quality materials and employing advanced manufacturing processes demonstrates a dedication to delivering superior products that meet the most stringent industry standards.

Performance and Durability

Ensuring the performance and durability of a crane is paramount to its operational success and long-term value. Here's how you can assess these critical aspects:

Load Capacity and Lifting Height:

Matching Requirements: Confirm that the crane's load capacity and lifting height align with your specific operational needs. It should be capable of safely lifting and maneuvering the maximum weight and reaching the required heights for your applications.

Safety Considerations: Ensure that the crane's load capacity and lifting height are well within its design limits to maintain safety during operations. Overloading or exceeding height limitations can compromise crane performance and pose significant safety risks.

Longevity and Reliability:

Expected Lifespan: Inquire about the crane's expected lifespan and durability. A high-quality crane should have a long operational life, providing reliable performance over many years of use.

Maintenance Requirements: Understand the crane's maintenance requirements, including recommended service intervals and upkeep procedures. Regular maintenance helps prolong the crane's lifespan and ensures optimal performance.

Warranty Coverage: Assess the warranties offered by the supplier, including coverage for parts and labor. A comprehensive warranty provides peace of mind and protection against unexpected repair costs.

Track Record: Research the supplier's track record for delivering durable and reliable cranes. Customer testimonials, case studies, and references can provide insights into the performance and reliability of the supplier's equipment.

By prioritizing these factors, you can invest in a crane that meets your operational requirements and delivers long-term value for your business. A supplier that prioritizes performance, durability, and safety in their crane offerings is more likely to provide equipment that enhances your operational efficiency and contributes to your business's success.

After-Sales Service

Installation and Commissioning Support

When it comes to the installation and commissioning of a crane, thorough support from the supplier is essential to ensure optimal performance and longevity. Here's what to consider:

On-Site Installation Services:

Professional Installation: Confirm whether the supplier offers on-site installation services performed by qualified technicians. Professional installation ensures that the crane is set up correctly, adhering to all safety and operational standards.

Safety Compliance: Verify that the installation process includes adherence to safety regulations and guidelines. Proper installation is crucial for preventing accidents and ensuring the safe operation of the crane.

Operational Efficiency: A properly installed crane operates more efficiently, minimizing downtime and maximizing productivity. Professional installation also reduces the risk of premature wear and tear on components.

Initial Setup and Testing:

Calibration and Testing: Ensure that the supplier conducts thorough calibration and testing of the crane after installation. This includes verifying load capacities, testing control systems, and conducting operational checks to ensure everything functions as intended.

Quality Assurance: Suppliers who prioritize quality assurance during the initial setup and testing phase help identify and address any potential issues early on. This proactive approach minimizes the risk of operational disruptions and ensures that the crane performs reliably from the outset.

Operator Training: Consider whether the supplier offers operator training as part of the commissioning process. Proper training ensures that operators are proficient in using the crane safely and efficiently, reducing the risk of accidents and maximizing productivity.

By partnering with a supplier that offers comprehensive installation and commissioning support, you can ensure that your crane is installed correctly, operates efficiently, and meets your performance expectations. Professional installation and thorough testing help optimize crane performance, minimize downtime, and extend the equipment's lifespan, ultimately providing long-term value for your investment.

Maintenance and Repair Services

When it comes to ensuring the longevity and reliability of your crane, maintenance and repair services play a crucial role. Here's what to consider when evaluating these aspects:

Scheduled Maintenance Plans:

Preventative Maintenance: Look for a supplier that offers scheduled maintenance plans designed to keep your crane in optimal condition. These plans typically include regular inspections, lubrication, adjustments, and the replacement of worn parts.

Compliance and Safety: Scheduled maintenance helps ensure compliance with safety regulations and industry standards. By addressing potential issues proactively, you can minimize the risk of accidents and downtime.

Customization Options: Evaluate whether the supplier can tailor maintenance plans to suit your specific operational needs and usage patterns. A customized maintenance schedule ensures that your crane receives the attention it needs without unnecessary disruptions to your operations.

Emergency Repair Services:

Response Time: Assess the supplier's ability to provide prompt emergency repair services. Look for a supplier that offers 24/7 support and can respond quickly to urgent repair needs.

Technical Expertise: Verify that the supplier's technicians are highly trained and experienced in diagnosing and resolving crane issues efficiently. A knowledgeable repair team can identify problems accurately and implement effective solutions to minimize downtime.

Parts Availability: Ensure that the supplier maintains an inventory of commonly needed parts to facilitate speedy repairs. Access to genuine OEM parts ensures compatibility and reliability in repairs, minimizing the risk of future issues.

By partnering with a supplier that offers comprehensive maintenance and repair services, you can ensure that your crane remains in peak operating condition and experiences minimal downtime. Scheduled maintenance plans help prevent issues before they occur, while emergency repair services provide peace of mind knowing that help is available when you need it most. Together, these services contribute to the long-term reliability and performance of your crane, ultimately maximizing your return on investment.

Spare Parts Availability

Ensuring the availability of spare parts is essential for maintaining the operational efficiency of your crane and minimizing downtime. Here's what to consider when evaluating a supplier's spare parts availability:

Stock of Commonly Needed Parts:

Readily Available Inventory: Verify that the supplier maintains a comprehensive stock of commonly needed spare parts for your crane model. These parts may include components such as motors, brakes, bearings, and electrical components.

Quick Turnaround: A supplier with readily available spare parts can offer quick turnaround times for maintenance and repairs. This minimizes downtime and ensures that your crane can resume operations promptly in the event of a breakdown.

Compatibility and Quality: Ensure that the spare parts offered by the supplier are genuine OEM (Original Equipment Manufacturer) parts. Genuine parts are designed specifically for your crane model, ensuring compatibility, reliability, and optimal performance.

Lead Time for Special Parts:

Special Order Process: Some parts may be less common or require custom manufacturing, resulting in longer lead times. Inquire about the supplier's process for ordering and delivering special parts.

Prompt Delivery: Suppliers who can source and deliver special parts promptly help minimize disruptions to your operations. Clear communication regarding lead times and delivery schedules is essential for effective planning and maintenance scheduling.

By partnering with a supplier that prioritizes spare parts availability, you can ensure that your crane remains operational and productive. A well-stocked inventory of commonly needed parts and efficient processes for sourcing special parts contribute to the overall reliability and performance of your crane. Effective after-sales support, including access to spare parts, is crucial for maximizing the return on your investment and maintaining the long-term success of your crane operations.

Cost Considerations

Initial Purchase Price

When evaluating the initial purchase price of a crane, it's essential to consider various factors beyond just the cost. Here's how to approach this aspect:

Price Comparisons with Competitors:

Competitive Rates: Compare the prices offered by different suppliers to ensure you're getting a competitive rate for the crane you need. However, be cautious of unusually low prices, as they may indicate inferior quality or hidden costs that could arise later.

Value for Money: Consider the overall value proposition rather than solely focusing on the upfront cost. A slightly higher initial investment may be justified if it includes additional features, better quality, or superior after-sales support.

Inclusions and Exclusions in the Quotation:

Transparent Pricing: Scrutinize the quotation provided by the supplier to understand what is included in the price and what additional costs may apply. Ensure that all necessary components, such as installation, training, and warranties, are clearly outlined.

Hidden Costs: Beware of hidden costs that may not be explicitly stated in the quotation. These could include shipping fees, taxes, customs duties, or additional charges for specialized services. Clarify any ambiguities with the supplier to avoid unexpected expenses down the line.

By carefully evaluating the initial purchase price of a crane and considering factors such as competitive rates, value for money, and transparent pricing, you can make an informed decision that aligns with your budget and requirements. A supplier who offers a fair price with clear inclusions and transparent pricing ensures that you get the best value for your investment without compromising on quality or service.

Total Cost of Ownership (TCO)

When assessing the total cost of ownership (TCO) of a crane, it's crucial to consider all expenses associated with owning and operating the equipment over its lifespan. Here's how to evaluate this aspect effectively:

Long-Term Maintenance Costs:

Ongoing Maintenance Expenses: Factor in the anticipated maintenance costs associated with the crane over its lifespan. Consider the frequency of maintenance tasks, the availability and cost of spare parts, and any service contracts or extended warranties offered by the supplier.

Quality and Reliability: While a crane with a lower upfront cost may seem attractive, it's essential to consider its long-term maintenance requirements. A higher-quality crane may have higher initial costs but lower maintenance expenses over time due to its durability and reliability.

Energy Efficiency and Operational Costs:

Energy Consumption: Evaluate the energy efficiency of the crane and its impact on operational costs. Energy-efficient cranes may have higher upfront costs but can result in significant savings in utility bills over the crane's lifespan.

Operational Efficiency: Consider how efficiently the crane operates in terms of productivity and labor costs. A crane that can handle heavier loads or operate more quickly and accurately may offer cost savings through increased productivity and reduced labor expenses.

By considering factors such as long-term maintenance costs, energy efficiency, and operational expenses, you can calculate the total cost of ownership of a crane more accurately. This comprehensive approach ensures that you make an informed decision that aligns with your budget and operational requirements, ultimately maximizing the value and return on investment of your crane purchase.

.

Financing Options

When exploring financing options for purchasing a crane, it's essential to choose a plan that aligns with your financial goals and business needs. Here's how to evaluate financing options effectively:

Payment Plans and Credit Terms:

Flexible Payment Options: Inquire about payment plans and credit terms offered by the supplier. Flexible payment options can help spread out the cost of the crane over time, making it more manageable for your business's cash flow.

Interest Rates and Fees: Consider the interest rates and fees associated with financing arrangements. Compare the terms offered by different suppliers and financial institutions to find the most competitive rates and favorable terms.

Leasing vs. Buying:

Leasing Benefits: Assess the advantages of leasing versus buying the crane outright. Leasing may offer lower initial costs, as well as flexibility in upgrading equipment or returning it at the end of the lease term.

Ownership Considerations: Evaluate the benefits of owning the crane, including potential tax benefits and equity accumulation. Buying the crane outright provides ownership and control over the equipment, which may be advantageous in the long run.

Financial Analysis: Conduct a financial analysis to compare the total costs of leasing versus buying over the crane's expected lifespan. Consider factors such as depreciation, maintenance expenses, and resale value to determine the most cost-effective option for your business.

By carefully evaluating payment plans, credit terms, and the pros and cons of leasing versus buying, you can choose a financing option that suits your budget and operational requirements. Prioritize affordability, flexibility, and long-term value to ensure that your investment in a crane contributes to the success and growth of your business.

Additional Factors

Supplier Responsiveness and Communication

When selecting a crane supplier, their responsiveness and communication skills play a vital role in ensuring a seamless partnership. Here's how to evaluate these aspects effectively:

Response Time to Inquiries:

Promptness: Assess how quickly the supplier responds to your inquiries and requests for information. A supplier who promptly addresses your queries demonstrates attentiveness and a commitment to customer service.

Accessibility: Consider the accessibility of the supplier's communication channels, such as email, phone, or online chat. Ensure that you can easily reach out to them whenever you have questions or concerns.

Quality of Customer Support:

Professionalism: Evaluate the professionalism of the supplier's customer support team. They should be knowledgeable, courteous, and capable of providing accurate and helpful information.

Problem Resolution: Assess the supplier's ability to address your concerns and resolve any issues that may arise during the procurement process or after the sale. A supplier who prioritizes customer satisfaction will work proactively to find solutions to problems.

By prioritizing supplier responsiveness and effective communication, you can establish a productive and collaborative relationship that facilitates the smooth procurement of your crane equipment. Clear and timely communication ensures that your needs are understood and addressed, leading to a successful partnership with your chosen supplier.

Training and Support Services

When investing in a crane, comprehensive training and ongoing support services are essential to ensure safe and efficient operation. Here's how to assess these aspects effectively:

Operator Training Programs:

Availability of Programs: Inquire about the availability of operator training programs offered by the supplier. These programs should cover essential topics such as crane operation, safety procedures, and maintenance practices.

Quality of Training: Evaluate the quality and comprehensiveness of the training programs. Look for programs that are led by qualified instructors and include hands-on practical training to ensure that your operators gain the necessary skills and confidence to operate the crane safely and effectively.

Certifications: Check if the training programs offer certifications or qualifications recognized within the industry. Certified operators demonstrate proficiency and adherence to safety standards, enhancing overall workplace safety.

Ongoing Technical Support:

Availability and Responsiveness: Assess the availability and responsiveness of the supplier's technical support team. They should be easily accessible via multiple communication channels and responsive to your inquiries and requests for assistance.

Troubleshooting Assistance: Evaluate the supplier's capability to provide troubleshooting assistance and guidance for resolving operational issues. Timely and effective technical support ensures that any problems with the crane can be promptly addressed, minimizing downtime and disruptions to your operations.

Remote Monitoring and Diagnostics: Inquire about any remote monitoring and diagnostic capabilities offered by the supplier. Advanced technology solutions can enable remote troubleshooting and proactive maintenance, enhancing the reliability and performance of your crane equipment.

By prioritizing comprehensive training and reliable technical support services, you can ensure that your team is equipped with the knowledge and resources needed to operate the crane safely and efficiently. This investment in training and support ultimately contributes to the overall success and productivity of your crane operations.

Technological Innovations

When selecting a crane supplier, it's essential to consider their commitment to technological innovation and future-proofing capabilities. Here's how to evaluate these aspects effectively:

Integration with Modern Technologies:

Advanced Control Systems: Assess whether the supplier's cranes are equipped with advanced control systems that offer precise and intuitive operation. Features such as variable frequency drives, programmable logic controllers (PLCs), and human-machine interfaces (HMIs) enhance operational efficiency and safety.

Automation Features: Consider whether the cranes offer automation features such as automated load positioning, collision avoidance systems, and predictive maintenance capabilities. Automation streamlines operations, reduces manual intervention, and enhances productivity.

Remote Monitoring and Diagnostics: Evaluate whether the cranes are equipped with remote monitoring and diagnostics capabilities. These features enable real-time monitoring of crane performance, proactive maintenance scheduling, and remote troubleshooting, minimizing downtime and maximizing uptime.

Upgradability and Future-Proofing:

Modular Design: Look for cranes with a modular design that allows for easy upgrades and enhancements. Modular components and plug-and-play functionality facilitate future upgrades with minimal disruption to operations.

Compatibility with Future Technologies: Assess whether the cranes are compatible with emerging technologies and industry standards. Future-proofing ensures that your investment remains relevant and competitive as technology evolves, allowing you to leverage new features and functionalities without the need for costly replacements.

Supplier's Commitment to Innovation: Consider the supplier's track record of innovation and their investment in research and development. A supplier who prioritizes technological advancement and continuous improvement is more likely to offer cutting-edge solutions that meet your evolving needs.

By prioritizing technological innovation and future-proofing capabilities, you can ensure that the crane supplier delivers equipment that not only meets your current requirements but also adapts to future challenges and opportunities. A supplier who embraces modern technologies and invests in innovation can enhance the efficiency, safety, and competitiveness of your crane operations for years to come.

Case Studies and Examples

Successful Partnerships with Reliable Suppliers

Here's how to approach the topic of successful partnerships with reliable suppliers:

Real-World Examples of Effective Supplier Relationships:

Case Study 1: Manufacturing Facility Upgrade

Description: A manufacturing facility sought to upgrade its material handling capabilities to meet growing demand. They partnered with a reliable crane supplier known for their high-quality products and excellent after-sales support.

Impact: The new cranes improved operational efficiency by streamlining production processes and reducing downtime. The supplier's timely maintenance services ensured uninterrupted operations, leading to increased productivity and profitability.

Lessons Learned: Effective communication and collaboration between the business and the supplier were key to the project's success. The supplier's responsiveness to the business's needs and proactive support contributed to a strong and enduring partnership.

Case Study 2: Construction Project Management

Description: A construction company undertaking a large-scale project required a range of cranes for various lifting tasks. They partnered with a reliable crane supplier with a proven track record in the construction industry.

Impact: The supplier's diverse product offerings and customization options allowed the construction company to select cranes tailored to their specific project requirements. The supplier's expertise in project management ensured seamless coordination and timely delivery of equipment, enabling the construction project to stay on schedule and within budget.

Lessons Learned: Choosing a supplier with extensive industry experience and a comprehensive understanding of project requirements is crucial. The ability to provide customized solutions and support throughout the project lifecycle strengthens the partnership and enhances project outcomes.

Lessons Learned from Past Experiences:

Key Factors for Success:

Effective Communication: Open and transparent communication between the business and the supplier is essential for establishing mutual understanding and trust.

Thorough Evaluation: Conducting thorough evaluations of potential suppliers based on factors such as reputation, product quality, and after-sales service helps mitigate risks and ensure compatibility.

Mutual Trust and Collaboration: Building a relationship based on mutual trust and collaboration fosters a supportive partnership where both parties work together to achieve shared goals.

Challenges Overcome:

Supply Chain Disruptions: Businesses and suppliers may face challenges such as supply chain disruptions or unexpected delays. Effective communication and proactive problem-solving strategies are essential for overcoming these challenges and maintaining project momentum.

Changing Requirements: Projects may encounter changing requirements or unforeseen obstacles that require flexibility and adaptability from both the business and the supplier. Flexibility in adjusting plans and solutions is crucial for navigating these changes successfully.

By exploring real-world examples of successful partnerships with reliable suppliers and sharing lessons learned from past experiences, businesses can gain valuable insights into the factors that contribute to successful supplier relationships. These insights can inform their approach to selecting and partnering with suppliers in the future, ultimately leading to more efficient and productive operations.

Negative Experiences with Poor Suppliers

Here's how you can delve into the topic of negative experiences with poor suppliers:

Common Pitfalls and How to Avoid Them:

Overlooking Supplier Reputation: Many businesses make the mistake of overlooking the importance of supplier reputation when selecting a crane supplier. They may prioritize factors like cost or convenience over supplier reliability and track record.

Strategy for Avoidance: Emphasize the importance of conducting thorough research into a supplier's reputation, including reviews, testimonials, and industry recognition. Encourage businesses to prioritize suppliers with a proven track record of reliability and customer satisfaction.

Failing to Conduct Thorough Evaluations: Rushing the supplier selection process or failing to conduct thorough evaluations can lead to choosing a supplier that does not meet the business's needs or standards.

Strategy for Avoidance: Stress the importance of conducting comprehensive evaluations of potential suppliers, considering factors such as product quality, after-sales service, and compatibility with the business's requirements. Encourage businesses to take the time to thoroughly vet potential suppliers before making a decision.

Prioritizing Cost Over Quality: While cost is an important consideration, prioritizing cost savings over quality can lead to choosing a supplier that provides subpar products or services.

Strategy for Avoidance: Encourage businesses to consider the total cost of ownership rather than just the initial purchase price. Emphasize the importance of investing in quality equipment and reliable suppliers to avoid costly repairs, downtime, and safety hazards in the long run.

Impact of Choosing the Wrong Supplier:

Delays in Project Timelines: Choosing a poor supplier can result in delays in project timelines due to issues such as late deliveries, equipment malfunctions, or inadequate support.

Increased Maintenance Costs: Poor-quality equipment may require frequent repairs and maintenance, leading to increased costs over time.

Safety Hazards: Inferior equipment or lack of proper support from the supplier can pose safety hazards to workers and equipment operators.

Damage to Business Reputation: Negative experiences with a poor supplier can damage a business's reputation and credibility, potentially leading to loss of customers and business opportunities.

Highlighting real-world examples of businesses that have experienced these negative outcomes due to poor supplier choices can illustrate the importance of selecting the right crane supplier. By learning from these experiences and avoiding common pitfalls, businesses can mitigate risks and establish successful, long-lasting relationships with reliable suppliers.

Conclusion

In conclusion, selecting the right crane supplier is a crucial decision that can significantly impact your business operations. Throughout this guide, we have discussed several key factors to consider when evaluating crane suppliers, including reputation, product quality, after-sales service, cost considerations, and additional factors.

Based on the factors discussed, it is essential to prioritize reliability, quality, and long-term value when choosing a crane supplier. Look for suppliers with a strong reputation, a diverse range of high-quality products, comprehensive after-sales support, transparent pricing, and a commitment to innovation and customer service.

We encourage businesses to conduct thorough research and evaluation before making a decision. Take the time to assess multiple suppliers, request quotes, review customer testimonials and case studies, and ask questions about their products and services. By investing time and effort into the selection process, you can ensure that you choose a crane supplier that meets your specific needs and contributes to the success of your business.

Choosing the right crane supplier is not just about purchasing equipment—it's about establishing a long-term partnership that supports your business goals and enhances operational efficiency. With careful consideration and informed decision-making, you can find a reliable crane supplier that delivers quality products, excellent service, and ongoing support for your business needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch

Check

Check