10 Ton Overhead Crane Kit with No Main Girder for Sale Indonesia

Economical 10 Ton Single Girder Overhead Crane Kit with CD/MD Wire Rope Hoist and No Main Girder for Sale in Indonesia.Get your 10 ton overhead crane kit cost-effectively.

Category: Indonesia

Your Trusted Overhead Crane Kit Manufacturer & Supplier

10 Ton Overhead Crane Kit with No Main Girder for Sale Indonesia

Economical 10 Ton Single Girder Overhead Crane Kit with CD/MD Wire Rope Hoist and No Main Girder for Sale in Indonesia.

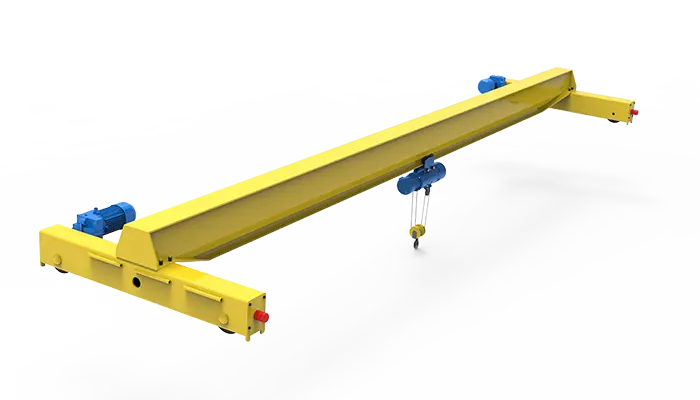

For businesses in Indonesia seeking efficient and cost-effective lifting solutions, the 10-ton single girder overhead crane kit with a CD/MD wire rope hoist offers an excellent option. This crane kit, distinguished by its no main girder design, provides both flexibility and affordability. Here, we delve into the main specifications and benefits of this crane system, focusing on its adaptability and suitability for various industrial applications.

Overview of LD Single Girder Overhead Cranes with CD/MD Suspension Electric Hoists

LD Single Girder Overhead Cranes with CD/MD suspension electric hoists are highly efficient and versatile lifting solutions widely used in various industries. These cranes are designed with a robust single-girder structure, offering cost-effective material handling capabilities for loads ranging from light to medium weight. Equipped with CD (single speed) or MD (dual speed) electric hoists, they provide precise and reliable lifting and movement, making them ideal for workshops, warehouses, and production facilities. Their compact design ensures maximum space utilization, and they are customizable to meet specific operational needs, ensuring safety, efficiency, and long-term durability in diverse applications.

Features and Benefits of LD Single Girder Overhead Cranes with CD/MD Suspension Electric Hoists

Features:

- Single Girder Design: The crane's single girder structure is lightweight, yet strong, reducing material costs and installation effort while offering reliable load-bearing capacity.

- CD/MD Electric Hoists: Equipped with CD (single-speed) or MD (dual-speed) hoists, these cranes allow for flexible operation with smooth and precise load control, catering to different speed and performance requirements.

- Compact Structure: The crane's low headroom and compact design allow for better space utilization in workshops or warehouses with limited space, optimizing the available height for lifting operations.

- Flexible Installation: LD single girder overhead cranes are adaptable to various building structures, with simple installation processes that minimize downtime and disruption during setup.

- Customizable Options: These cranes can be tailored to specific operational requirements, including load capacity, span width, and lifting height, ensuring a perfect fit for diverse applications.

- High-Quality Components: The use of high-grade materials, advanced hoist mechanisms, and precision engineering ensures longevity, reliability, and minimal maintenance requirements.

- Enhanced Safety Features: Built-in safety mechanisms, such as overload protection, limit switches, and emergency stop systems, ensure secure and controlled lifting operations.

Benefits:

- Cost-Efficiency: The single girder design and electric hoists provide an affordable solution for material handling, reducing both initial investment and long-term operational costs.

- Improved Productivity: With their smooth operation and accurate load positioning, LD cranes enhance workflow efficiency, helping businesses handle materials faster and more effectively.

- Space Optimization: The compact, low-headroom design makes these cranes ideal for facilities with limited space, allowing for more operational flexibility without compromising lifting height.

- Versatility: Suitable for a wide range of industries, including manufacturing, warehousing, and assembly lines, these cranes handle a variety of materials and loads, from light to medium weight.

- Reduced Maintenance: The use of high-quality components minimizes the need for frequent repairs and downtime, reducing maintenance costs and ensuring long-lasting performance.

- Enhanced Safety and Reliability: The built-in safety features and precise control provided by the electric hoists contribute to safer working conditions, reducing the risk of accidents and equipment damage.

- Customizable to Application Needs: Tailoring the crane to specific operational requirements ensures that it meets the exact demands of your business, improving overall performance and efficiency.

Case: 10 Ton Single Girder Overhead Crane Kit with CD/MD Wire Rope Hoist and No Main Girder

10 ton and 20 ton crane kit project for your reference

Main Specifications

Electric Single Girder Overhead Crane (Model: LD10T)

- Span: 11.7 meters

- Working Class: A4

- Control Method: Pendant + Remote

Description: The LD10T model with an 11.7meter span is designed to handle heavy loads efficiently within its specified working class of A4. This class indicates a moderate usage level, suitable for standard industrial operations. The crane's control system includes both pendant and remote options, offering flexibility and ease of use in various operational environments.

Electric Single Girder Overhead Crane (Model: LD10T)

- Span: 11.24 meters

- Working Class: A4

- Control Method: Pendant + Remote

Description: Similar to the first model, this LD10T crane features a slightly shorter span of 11.24 meters but maintains the same working class of A4. The control method also includes both pendant and remote options, providing versatility and convenience in controlling the crane.

Benefits of the No Main Girder Design

Cost-Effectiveness

The absence of a main girder in these crane kits reduces material costs and installation complexity. This makes the crane system a cost-effective solution, particularly advantageous for businesses with budget constraints.

Installation Flexibility

The no main girder design allows for easier installation in spaces where traditional cranes might not fit. This design feature simplifies integration into existing structures and reduces installation time.

Load Handling Efficiency

Despite the absence of a main girder, the crane kits are designed to handle loads efficiently. The CD/MD wire rope hoist provides reliable lifting capabilities, ensuring smooth and effective material handling.

Applications in Indonesia

Manufacturing Facilities

The crane kit is ideal for manufacturing environments, where it can handle heavy machinery and components. Its efficient load handling and control options make it suitable for various production processes.

Warehousing and Logistics

In warehousing and logistics operations, the crane kit enhances inventory management by facilitating the lifting and placement of goods. The versatility of the pendant and remote control methods ensures precise and efficient handling.

Construction Sites

For construction projects, the crane kit can assist in lifting and positioning building materials. Its adaptability and reliable performance contribute to smoother construction workflows.

Why Choose This Crane Kit in Indonesia?

Local Availability:

This crane kit is readily available in Indonesia, with local suppliers providing comprehensive support and services. This ensures businesses can access timely assistance and maintenance.

Customization Options:

Suppliers often offer customization options to cater to specific industry needs. Businesses can tailor the crane kit to meet their operational requirements, ensuring optimal performance.

Reliable Performance:

Equipped with the CD/MD wire rope hoist, the crane kit ensures reliable operation and durability under heavy-duty conditions. This reliability contributes to long-term performance and minimal downtime.

The economical 10-ton single girder overhead crane kit with CD/MD wire rope hoist and no main girder offers a cost-effective, flexible, and efficient solution for industrial lifting needs in Indonesia. With its notable specifications, including various spans and working classes, and versatile control options, this crane kit is well-suited for manufacturing, warehousing, and construction applications. The availability of local support and customization options further enhances its value, making it a smart choice for businesses seeking reliable and adaptable lifting solutions.

Main Crane Kits of 10 Ton Single Girder Overhead Crane with No Main Girder

Item: Single girder overhead crane Model: LD10T-11.7 m

No. | Item | Type | Unit | Qty | Packing | Remark | |||

Bolts | |||||||||

1 | GB/T27-88 | M20x65 | set | 20 | Plywood box | Grade 8.8, for connecting main girder and end carriage | |||

2 | GB/5783-86 | M8×50 | set | 4 | Plywood box | For travel limiter | |||

、 Hoist | |||||||||

1 | Hoist assembly | CD10T-6m | set | 1 | Plywood box | Pendant and remote included | |||

2 | Conductive frame |

| pc | 1 | Placed inside the hoist's plywood box | ||||

3 | Hook | 10T | pc | 1 | Installed on hoist | ||||

4 | Wire rope |

| m | 32 | Installed on hoist | ||||

5 | Electric cabinet |

| pc | 1 | Placed inside the hoist's plywood box | ||||

Structure | |||||||||

1 | End beam | 10T | pc | 2 | Rainproof cover | Buffer included | |||

2 | Three-in-one motor | 0.75KW | set | 2 | Plywood box | 380V 50HZ | |||

3 | C-track | C30 | m | 17 | Rainproof cover | ||||

4 | Fixing clamp | C30 | pc | 5 | Plywood box | ||||

5 | Bracket | C30 | pc | 5 | |||||

6 | Trolley | C30 | pc | 7 | Including head and tail trolley | ||||

7 | Joint | C30 | pc | 2 | |||||

Electricals | |||||||||

1 | Electric cabinet | 10T | set | 1 | Plywood box | 380V 50Hz | |||

2 | Crane travel limiter | Rotary limit switch | set | 1 | Mechanic | ||||

3 | Cable | YC3X10MM+1 | m | 3 | For main power | ||||

4 | Cable | YVFB5X6MM | 25 | For lifting motor | |||||

5 | Cable | YC3X5+5X5MM | 25 | For cross travel, overload limiter and secondary limiter | |||||

6 | Cable | YC3X5MM | 23 | Crane motor | |||||

7 | Cable | 4X5MM | 5 | Travel limiter | |||||

Accessories | |||||||||

1 | Bus bar | 200A | m | 220 | Plywood box | Accessories included | |||

2 | Current collector | set | 4 | Plywood box | |||||

3 | Rail | P22 | m | 440 | Nude | Accessories included | |||

Main Crane Kits of 10 Ton Single Girder Overhead Crane with No Main Girder

Item: Single girder overhead crane Model: LD10T-11.24m

No. | Item | Type | Unit | Qty | Packing | Remark | |||

Bolts | |||||||||

1 | GB/T27-88 | M20x65 | set | 20 | Plywood box | Grade 8.8, for connecting main girder and end carriage | |||

2 | GB/5783-86 | M8×50 | set | 4 | Plywood box | For travel limiter | |||

Overhead Crane Hoist | |||||||||

1 | Hoist assembly | CD10T-9m | set | 1 | Plywood box | Pendant and remote included | |||

2 | Conductive frame |

| pc | 1 | Placed inside the hoist's plywood box | ||||

3 | Hook | 10T | pc | 1 | Installed on hoist | ||||

4 | Wire rope |

| m | 44 | Installed on hoist | ||||

5 | Electric cabinet |

| pc | 1 | Placed inside the hoist's plywood box | ||||

Structure | |||||||||

1 | End beam | 10T | pc | 2 | Rainproof cover | Buffer included | |||

2 | Three-in-one motor | 0.75KW | set | 2 | Plywood box | 380V 50HZ | |||

3 | C-track | C30 | m | 11 | Rainproof cover | ||||

4 | Fixing clamp | C30 | pc | 5 | Plywood box | ||||

5 | Bracket | C30 | pc | 5 | |||||

6 | Trolley | C30 | pc | 7 | Including head and tail trolley | ||||

7 | Joint | C30 | pc | 2 | |||||

Electricals | |||||||||

1 | Electric cabinet | 10T | set | 1 | Plywood box | 380V 50Hz | |||

2 | Crane travel limiter | Rotary limit switch | set | 1 | Mechanic | ||||

3 | Cable | YC3X10MM+1 | m | 3 | For main power | ||||

4 | Cable | YVFB5X6MM | 17 | For lifting motor | |||||

5 | Cable | YC3X5+5X5MM | 17 | For cross travel, overload limiter and secondary limiter | |||||

6 | Cable | YC3X5MM | 14 | Crane motor | |||||

7 | Cable | 4X5MM | 4 | Travel limiter | |||||

Accessories | |||||||||

1 | Bus bar | 25mm Four pole 25mm | m | 35 | Plywood box | Accessories included | |||

3 | Rail | P22 | m | 70 | Nude | Accessories included | |||

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch