Adjustable Gantry Cranes for Sale, All Types of Adjustable Cranes

Adjustable gantry crane for sale - adjustable height & adjustable span gantry crane with portable / fixed gantry design, 1 ton, 2 ton,3 ton, 4 ton,5 ton.

Category: Light Crane & Portable Crane

Your Trusted Adjustable Crane Manufacturer & Supplier

Adjustable Gantry Cranes for Sale, All Types of Adjustable Cranes

Height Adjustable Gantry & Span adjustable Gantry Crane with Portable / Fixed gantry Design, 1 Ton, 2 Ton,3 Ton, 4 Ton,5 Ton

Adjustable gantry crane for sale - adjustable height & adjustable span gantry crane with portable / fixed gantry design, 1 ton, 2 ton,3 ton, 4 ton,5 ton.

Adjustable Gantry Cranes: An In-Depth Handbook for Gantry Crane Buyers and Users

Adjustable gantry crane for sale. Among the array of versatile options available, adjustable gantry cranes stand out as paramount tools. These cranes, renowned for their adaptability and multifunctionality, redefine efficiency in the handling of heavy loads.

Adjustable gantry cranes, at their core, are designed to seamlessly adapt to various lifting requirements and environments. Unlike traditional fixed cranes, these adaptive giants offer a wide range of adjustments, accommodating diverse load sizes and working spaces. This innate flexibility ensures that no matter the task at hand, an adjustable gantry crane can rise to the occasion with ease.

Flexibility is not just a feature; it's a catalyst for operational excellence. The ability to modify the crane's height and width settings swiftly translates into enhanced productivity. Whether it's navigating through tight spaces or reaching greater heights, these cranes serve as indispensable assets across multiple industries.

Portable gantry cranes bring forth a blend of adaptability and mobility, presenting a solution for users requiring efficient, transportable lifting systems. This article will delve deeper into the realm of adjustable portable gantry cranes, uncovering their functionalities, benefits, and ideal applications.

Overveiw of Adjustable Gantry Cranes

Adjustable gantry cranes stand tall as a beacon of innovation and adaptability in the realm of material handling equipment. To truly grasp their significance, it's pivotal to delve into their essential features, diverse types, advantages over fixed cranes, and the extensive array of industries they serve.

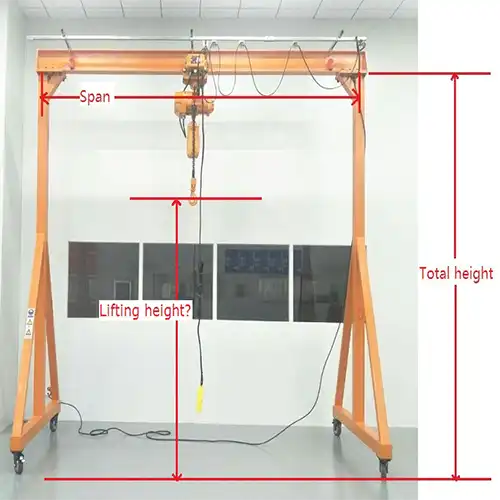

At the heart of adjustable gantry cranes lies a set of core attributes that define their functionality. These cranes boast adjustable heights and widths, providing unparalleled flexibility to cater to diverse lifting needs. Equipped with sturdy frames and efficient lifting mechanisms, they ensure reliability and precision in handling heavy loads.

Types of Adjustable Gantry Cranes

Adjustable gantry cranes aren't a one-size-fits-all solution; instead, they encompass a spectrum of variations tailored to meet specific requirements. Among these variations are the adjustable height, portable, and aluminum gantry cranes.

Adjustable Height Gantry Cranes - These cranes are revered for their ability to modify the lifting height swiftly. Their hydraulic or manual height adjustment mechanisms empower operators to seamlessly adapt to varying lifting demands, making them indispensable in industries requiring versatile height adjustments.

Portable Adjustable Gantry Cranes - Mobility and adaptability converge in portable gantry cranes. Their ease of assembly and disassembly, coupled with their ability to be moved to different locations, make them ideal for dynamic work environments. Whether it's in workshops, warehouses, or construction sites, their mobility caters to ever-changing operational needs.

Aluminum Gantry Cranes - Crafted from lightweight yet robust aluminum, these cranes excel in environments where corrosion resistance and durability are paramount. Their innate ability to withstand harsh conditions, especially in marine or outdoor applications, makes them a reliable choice for industries operating in challenging settings.

The adaptability of adjustable gantry cranes offers distinct advantages over their fixed counterparts. The ability to adjust height and width settings ensures optimal utilization of space and resources. Additionally, their versatility allows for the handling of various loads and weights, contributing to increased operational efficiency. The utility of adjustable gantry cranes transcends across a wide spectrum of industries. From construction and manufacturing to warehousing and shipbuilding, these cranes play a pivotal role in streamlining material handling processes. Their adaptability and functionality make them indispensable assets in environments requiring flexible lifting solutions.

Height Adjustable Portable Gantry Crane:

Features:

- Adjustable Height: Offers versatility in lifting by allowing height adjustments to accommodate various load sizes and workspace requirements.

- Portability: Designed for easy transportation and assembly, enabling users to move the crane to different work areas or job sites.

- Sturdy Construction: Despite its portability, built with durable materials to ensure stability and reliability during lifting operations.

Benefits:

- Flexibility: Ability to adjust the crane's height ensures adaptability to different lifting tasks within diverse work environments.

- Ease of Mobility: Facilitates quick setup and disassembly, allowing for efficient relocation to address changing operational needs.

- Space Optimization: Provides a solution for locations with limited space, enabling efficient lifting without compromising stability.

Typical Applications:

- Construction Sites: Ideal for lifting and positioning materials at varying heights during building or renovation projects.

- Warehouses and Workshops: Efficiently handles inventory or machinery movement within confined spaces.

- Outdoor Events: Used for stage assembly, lighting rig setups, or equipment handling due to their mobility and adjustable height capabilities.

Portable Adjustable Aluminum Gantry Crane:

Features:

- Mobility: Easy transportation and assembly, facilitating movement across different work areas or job sites.

- Corrosion Resistance: Lightweight yet robust aluminum construction, ensuring durability and resistance to harsh elements.

- Adjustable Span: Configurable span width for handling various load sizes.

Benefits:

- Versatility: Enables flexible lifting operations across different locations and applications.

- Durability & Corrosion Resistance: Suitable for outdoor use and marine applications due to its resistance to corrosion.

- Ease of Assembly/Disassembly: Facilitates quick setup and dismantling, reducing downtime during transitions.

Typical Applications:

- Construction Sites: Offers mobility and adaptability for lifting tasks in dynamic construction environments.

- Warehouse Operations: Efficiently moves goods or heavy equipment within warehouses or distribution centers.

- Outdoor Applications: Used in outdoor settings such as event setups, construction projects, or temporary workstations due to its portability and versatility.

Stationary Height Adjustable Aluminum Gantry Crane:

Features:

- Sturdy Aluminum Construction: Resistant to corrosion, making it suitable for outdoor or harsh environments.

- Height Adjustability: Provides versatility in lifting operations with adjustable height configurations.

- Fixed Placement: Designed for stability and permanence in a specific work area.

Benefits:

- Durability: Aluminum construction ensures longevity, especially in environments prone to rust or corrosion.

- Stability: Offers a stable lifting solution for consistent tasks within a fixed workspace.

- Adaptability: Adjustable height settings cater to varying load sizes, enhancing operational flexibility.

Typical Applications:

- Manufacturing Facilities: Used for consistent lifting operations in production lines or assembly stations.

- Marine Environments: Ideal for shipyards or dockyards due to corrosion-resistant properties, handling marine-related materials.

- Industrial Workshops: Provides a stable lifting solution for repetitive tasks within a specific workspace.

Adjustable Span Aluminum Gantry Crane for Indoor and Outdoor Use

Features:

- Adjustable Span Width: Ability to modify the span width based on specific lifting requirements.

- Lightweight Construction: Maintains the advantages of aluminum while providing adjustable span capabilities.

- Versatile Configurations: Available in stationary, portable, or configurations with adjustable span widths.

Benefits:

- Customization: Provides adaptability to accommodate various load sizes and workspace constraints.

- Efficient Space Utilization: Adjusts span width to optimize space and streamline lifting operations.

- Configurable Mobility: Available in portable configurations for versatile use in different work areas.

Typical Applications:

- Workshops with Varied Tasks: Handles diverse lifting tasks, catering to different load sizes and operational requirements.

- Job Sites Requiring Flexibility: Offers adaptability to varying work environments with changing lifting needs.

- Industrial Facilities with Space Constraints: Optimizes space utilization for lifting operations within confined areas.

Each type of adjustable gantry crane offers unique advantages suited to specific operational demands, ensuring flexibility, efficiency, and safety across various industries and applications.

Features and Benefits of Each Type

As we unravel the intricacies of adjustable gantry cranes, let's delve deeper into the distinct features and inherent advantages offered by each type.

Adjustable Height Gantry Crane: Versatile Height Adjustment

This crane type is a master of adaptability when it comes to elevation settings. Its paramount feature lies in its ability to swiftly adjust lifting heights. This characteristic opens doors to a myriad of advantages:

- Precision and Control: The capability to precisely set the crane's height ensures meticulous control over lifting operations, enhancing overall efficiency.

- Flexibility in Applications: From handling loads of various sizes to accommodating different working environments, its height adaptability makes it a versatile solution for diverse industries.

- Streamlined Operations: The efficiency gained by promptly adjusting to specific height requirements translates into optimized workflow and minimized downtime.

Portable Adjustable Gantry Crane: Maneuverability and Multifaceted Applications

Mobility and flexibility define the portable adjustable gantry crane. Its distinctive features offer an array of benefits:

- Ease of Mobility: This crane's design facilitates quick assembly and disassembly, allowing for easy relocation to different work areas within a facility or across job sites.

- Adaptability in Various Environments: Its maneuverability makes it a prime choice for industries requiring frequent repositioning of lifting equipment, ensuring efficient use across diverse applications.

- Enhanced Operational Agility: The ability to swiftly set up the crane at different locations streamlines operations and saves valuable time.

Adjustable Aluminum Gantry Crane: Lightweight, Durable, and Corrosion-Resistant

The adjustable aluminum gantry crane is a testament to durability and resilience in challenging environments. Its standout features bring forth substantial benefits:

- Lightweight Construction: Despite its robust build, the crane remains lightweight, facilitating easy transportation and setup without compromising strength.

- Corrosion Resistance: Its resistance to corrosion makes it an ideal choice for applications exposed to harsh environmental elements, ensuring longevity and reliability in various industries.

- Versatile Configurations: Whether in stationary, portable, or adjustable span configurations, this crane type offers flexibility to cater to diverse lifting needs.

Stationary Adjustable Aluminum Gantry Crane,

In addition to the features highlighted above, each specialized configuration of the adjustable aluminum gantry crane further refines its functionality:

- Stationary Configuration: Ideal for consistent and fixed lifting operations, offering stability and reliability in a specific work area.

- Portable Configuration: Emphasizes mobility, catering to shifting operational needs and facilitating efficient relocation as required.

- Adjustable Span Configuration: Provides versatility in adjusting the span width, accommodating varying load sizes and workspace constraints.

Portable Adjustable Aluminum Gantry Crane: Mobility Redefined

The Portable Adjustable Aluminum Gantry Crane combines the inherent advantages of portability, adaptability, and corrosion resistance found in aluminum gantry cranes. Its features and benefits cater to dynamic work environments requiring swift adjustments and mobility:

- Enhanced Maneuverability: Engineered for ease of transportation, this crane offers swift assembly and disassembly, enabling users to relocate it effortlessly across different work zones or job sites.

- Adaptability in Varied Settings: Its portable nature ensures adaptability to diverse working environments, allowing for efficient use in settings where lifting requirements change frequently.

- Corrosion-Resistant Structure: Crafted from durable aluminum, this crane boasts corrosion resistance, making it an optimal choice for outdoor applications or areas exposed to moisture and harsh elements.

Adjustable Span Aluminum Gantry Crane: Versatility in Span Width

The Adjustable Span Aluminum Gantry Crane's defining feature lies in its ability to modify the span width according to specific operational needs. This type of crane offers distinct advantages owing to its flexible span adjustments:

- Customizable Width: The crane's capability to adjust the span width ensures adaptability to various load sizes and workspace limitations, maximizing operational efficiency.

- Space Optimization: By allowing alterations in span width, this crane optimizes the utilization of available space, providing a tailored solution for varying lifting requirements.

- Multi-Purpose Utility: Its ability to cater to a range of span widths makes it an asset in industries where lifting needs fluctuate or where multiple operations with different load sizes occur concurrently.

Each variation of the adjustable aluminum gantry crane—be it portable or boasting adjustable span capabilities—brings unique strengths to the table. Whether emphasizing mobility for agile operations or offering adjustable spans for versatile load handling, these aluminum gantry crane models epitomize adaptability and efficiency across diverse industrial settings.

Key Benefits of Adjustable Gantry Cranes

Adjustable gantry cranes stand out as veritable assets in the realm of material handling, offering a multitude of advantages that set them apart from their fixed counterparts. Let's delve into the primary benefits that make these cranes a top choice for diverse industries:

Dynamic Adjustments for Diverse Lifting Requirements

- Height and Width Flexibility: The crane's ability to adjust both height and width settings swiftly ensures adaptability to various load sizes and workspace constraints, enhancing operational flexibility.

- Precision in Adjustments: The crane's mechanism allows for precise alterations, enabling operators to meet specific lifting demands accurately, resulting in increased efficiency and productivity.

Portability & Swift Assembly

- Mobility and Ease of Relocation: Designed for easy transportation and setup, these cranes enable users to swiftly move and install them in different locations, catering to changing operational needs.

- Efficient Assembly/Disassembly: Quick setup and disassembly minimize downtime, allowing for seamless transitions between different work areas or job sites, promoting operational agility.

Versatile Load Handling Capabilities

- Adaptability to Various Loads: Whether handling heavy or irregularly shaped items, adjustable gantry cranes are equipped to efficiently lift and maneuver diverse loads, ensuring versatile applications across industries.

Cost-Effectiveness & Return on Investment (ROI)

- Optimized Resource Utilization: Their adaptability results in efficient space utilization, reducing the need for multiple fixed cranes and potentially lowering operational costs.

- Long-Term Savings: Despite initial investment, their versatility and durability often result in higher long-term cost savings and better returns on investment compared to fixed cranes.

Emphasis on Safety Features and Considerations

- Safety Protocols: Implementing stringent safety measures ensures secure operations, with features such as overload protection and comprehensive operator training, minimizing risks and accidents.

- Compliance Standards: Meeting industry safety standards and regulations ensures safe and reliable crane operations, prioritizing the well-being of personnel and assets.

Adjustable portable gantry cranes are versatile equipment known for their mobility, adaptability, and ease of use. Here are more detailed and practical applications where these cranes find extensive use:

Practical Applications of Adjustable Portable Gantry Cranes:

Construction Sites:

- Building Construction: Lifting heavy materials such as steel beams, concrete blocks, and building components to various heights during construction phases.

- Roofing Projects: Facilitating the installation of roofing materials or machinery at elevated levels efficiently and safely.

Manufacturing and Assembly:

- Factory Assembly Lines: Assisting in moving heavy machinery or components along production lines, aiding in assembly or disassembly processes.

- Manufacturing Processes: Lifting and positioning large or heavy products within manufacturing plants for assembly or packaging.

Warehousing and Logistics:

- Material Handling: Transferring heavy items or pallets within warehouses, facilitating efficient loading and unloading operations.

- Inventory Management: Assisting in rearranging and organizing inventory, optimizing storage space.

Maintenance and Repair:

- Mechanical Workshops: Supporting maintenance activities by lifting heavy engines, machinery, or equipment for inspection or repairs.

- Vehicle Repair Garages: Aiding in hoisting vehicle parts or engines for maintenance or replacement purposes.

Event Setup and Entertainment:

- Outdoor Events: Assisting in setting up stages, lighting rigs, or audio-visual equipment at outdoor events or concerts due to their portability and adjustable height capabilities.

- Theater and Film Production: Supporting set construction or rigging for props, offering flexibility in stage setup.

Dockyards and Marine Environments:

- Shipbuilding and Repair: Lifting and moving heavy marine components or vessels during construction or repair operations in shipyards or docks.

- Loading and Unloading at Ports: Handling cargo and containers efficiently at ports or dockyards due to their mobility and adaptability.

Emergency Response and Rescue:

- Emergency Situations: In disaster relief operations, these cranes can assist in lifting and moving heavy objects or debris during rescue or cleanup operations.

Agriculture and Farming:

- Farm Operations: Assisting in lifting and moving heavy equipment or materials on farms or agricultural facilities.

Adjustable portable gantry cranes' versatility makes them invaluable across numerous industries, enabling safe and efficient lifting in various work environments. Their ability to adapt to different tasks and locations, combined with their ease of transport and setup, renders them indispensable in addressing diverse lifting needs.

Loads Handled by Portable Adjustable Gantry Crane across Industrial Sectors

Portable adjustable gantry cranes are designed to handle a wide range of loads across various industrial sectors. The specific loads these cranes can handle depend on their load capacity and configuration. Here are typical loads managed by portable adjustable gantry cranes in industrial settings:

- Heavy Machinery and Equipment: Portable gantry cranes are often used to lift and move heavy machinery, such as motors, engines, compressors, and industrial equipment within manufacturing facilities or workshops.

- Construction Materials: These cranes are utilized to handle construction materials like steel beams, concrete blocks, bricks, lumber, and scaffolding, assisting in construction projects by lifting and positioning materials at different heights.

- Palletized Goods and Containers: In warehouse settings, portable gantry cranes are employed to lift and transport palletized goods, boxes, crates, and containers, aiding in logistics and distribution operations.

- Vehicles and Automotive Parts: They can lift vehicle parts, engines, transmissions, or even entire vehicles in automotive repair garages or workshops, simplifying maintenance and repair tasks.

- Agricultural Machinery: Portable gantry cranes are useful in the agricultural sector for lifting and moving farming machinery, irrigation equipment, or heavy farm materials.

- Industrial Components: They handle various industrial components, including large valves, pipes, motors, and machine parts, assisting in assembly or production processes within manufacturing plants.

- Event and Entertainment Equipment: Used in event management or entertainment industries for hoisting audio-visual equipment, stage props, lighting rigs, or other stage-related components during setup and tear-down of events.

- Marine and Dockyard Operations: In marine environments, these cranes can lift heavy marine components, boat engines, small vessels, and assist in loading/unloading cargo in dockyard or port operations.

- Emergency and Disaster Relief: In emergency situations, portable gantry cranes can lift heavy debris, assist in rescue operations, or aid in cleanup efforts during disaster relief operations.

Portable adjustable gantry cranes come in various load capacities, typically ranging from a few hundred kilograms to several tons, catering to a wide spectrum of industrial lifting needs. Their adaptability, mobility, and capacity to handle diverse loads make them invaluable equipment across multiple industrial sectors.

Typical Industrial Applications

Adjustable gantry cranes serve as indispensable assets across various industries, each crane type finding its niche based on specific operational requirements. Let's delve into their applications across different sectors, highlighting their unique functionalities:

Adaptable Heights in Action

- Construction Industry: Height-adjustable gantry cranes play a pivotal role in construction sites, facilitating the lifting of heavy materials to varying heights. From erecting structural elements to facilitating rooftop installations, these cranes ensure seamless maneuverability and precision in lifting operations.

- Shipbuilding & Maritime Applications: Height-adjustable cranes are fundamental in shipyards, where the ability to lift materials and components to different levels of a vessel is crucial. They aid in constructing ships with intricate designs, catering to varying height requirements within the marine industry.

Portable Crane Utility

- Workshops & Manufacturing Facilities: The portable nature of these cranes finds extensive use in workshops and manufacturing plants. Whether relocating heavy machinery or aiding in assembly operations, their mobility ensures swift and efficient material handling within these environments.

- Warehousing & Distribution Centers: Portable gantry cranes are invaluable in warehouse settings, where the need for versatile and mobile lifting solutions is paramount. They facilitate the movement of goods, loading and unloading of cargo, and swift reconfiguration of storage layouts.

Aluminum Crane Excellence

- Marine & Outdoor Applications: The corrosion-resistant properties of aluminum gantry cranes make them a staple in marine environments. These cranes endure exposure to moisture and salt in docks, harbors, and shipyards, where conventional cranes might be susceptible to corrosion, ensuring longevity and reliability.

- Outdoor Construction & Utility Operations: Environments subject to outdoor elements benefit greatly from the durability of aluminum cranes. Whether in construction sites or utility operations, these cranes maintain structural integrity in adverse weather conditions, ensuring continuous functionality.

Practical Applications and Use Cases

The real testament to the efficacy of adjustable gantry cranes lies in their practical applications across diverse industries. Let's explore real-life scenarios and user experiences that underscore the versatility and advantages these cranes offer:

Practicle Scenarios & Case Studies

- Streamlining Construction Processes: Case studies in the construction sector will showcase how adjustable gantry cranes expedite operations by efficiently lifting and positioning heavy materials at various heights, reducing manual labor and project timelines.

- Optimizing Manufacturing Operations: Case scenarios within manufacturing plants will highlight the pivotal role of these cranes in optimizing workflows, aiding in the assembly, movement, and positioning of machinery and parts with precision and ease.

Versatility in Industries

- Construction Sector: Exploring how adjustable gantry cranes streamline the erection of structural components, assist in roofing installations, and aid in material movement within construction sites, enhancing overall productivity.

- Manufacturing Facilities: Demonstrating how these cranes bolster manufacturing processes by facilitating efficient handling of raw materials, heavy components, and machinery assembly, ensuring seamless operations.

- Warehousing and Logistics: Showcasing how these cranes contribute to warehousing efficiencies, from loading and unloading operations to inventory management, where their adaptability and mobility play a crucial role.

User Testimonials & Insights

- First-Hand Experiences: Sharing insights and testimonials from crane operators, managers, and industry professionals, shedding light on the tangible benefits and advantages experienced in their daily operations.

- Operational Efficiency and Safety: Users' perspectives on how these cranes have improved operational efficiency, minimized downtime, and ensured safety compliance in their work environments.

Addressing User Concerns and Queries

Understanding and addressing user concerns and queries regarding adjustable gantry cranes are pivotal aspects in ensuring their effective utilization. Let's delve into critical aspects including safety measures, maintenance guidelines, and financial considerations:

Safety Measures for Crane Operation

- Certifications and Training: Highlighting the importance of certified operators trained in crane operations to ensure adherence to safety protocols and minimize risks associated with lifting heavy loads.

- Safety Features and Inspections: Outlining the critical safety features of adjustable gantry cranes, emphasizing the necessity of regular inspections and maintenance checks to uphold optimal safety standards.

Maintenance Guidelines for Longevity

- Routine Inspections: Detailing best practices for routine inspections and maintenance to ensure the crane's longevity and sustained performance, covering aspects such as lubrication, structural integrity checks, and electrical systems.

- Comprehensive Service Schedules: Exploring the importance of following manufacturer-recommended service schedules, including preventive maintenance, and timely repairs to prevent breakdowns and ensure operational efficiency.

Financial Considerations and Investment

- ROI Analysis: Discussing factors influencing the initial investment and long-term returns, such as the crane's lifespan, operational efficiency, reduced downtime, and potential cost savings compared to fixed cranes.

- Total Cost of Ownership: Delving into the total cost of ownership, including initial purchase, installation, maintenance, and operational costs, to provide potential buyers with a comprehensive financial perspective.

Factors to Consider When Buying an Adjustable Gantry Cranes

Investing in an adjustable gantry crane requires careful consideration of various factors to ensure it aligns with specific operational needs and offers long-term value. Let's delve into essential factors that potential buyers should contemplate before making a purchase:

Performance Metrics: Load Capacity and Lifting Height

- Load Handling Capacity: Assessing the maximum weight the crane will need to lift and ensuring the selected crane's load capacity exceeds operational requirements to avoid strain and ensure safety.

- Lifting Height Requirements: Evaluating the range of lifting heights needed within the operational environment and selecting a crane that meets these specific height demands for seamless operations.

Quality Standards: Material, Build, and Durability

- Material Quality: Examining the construction materials, emphasizing robustness and durability, especially for harsh environments or frequent use scenarios.

- Build Integrity: Ensuring structural integrity and adherence to quality standards to guarantee reliable and safe operations throughout the crane's lifecycle.

Mobility and Assembly: Portability Features and Setup Ease

- Portability Features: Assessing the crane's mobility aspects, including ease of transportation, assembly, and disassembly, to cater to dynamic operational requirements.

- Ease of Setup/Disassembly: Considering the simplicity and efficiency of setting up and dismantling the crane, ensuring minimal downtime during transitions.

Post-Purchase Support: Warranty and After-Sales Service

- Warranty Coverage: Reviewing warranty details offered by manufacturers to safeguard against potential faults or malfunctions, ensuring peace of mind post-purchase.

- After-Sales Service Assurance: Considering the availability and reliability of after-sales support, including maintenance services, spare parts availability, and technical assistance, ensuring continued operational efficiency.

Maintenance and Safety Tips

Maintenance and safety protocols are paramount in ensuring the longevity, optimal performance, and secure operations of adjustable gantry cranes. Let's delve into comprehensive maintenance protocols and safety guidelines:

Maintenance Protocols: Preserving Longevity and Performance

- Routine Inspection Schedule: Establishing a regular inspection routine for critical components such as structural elements, electrical systems, and lifting mechanisms to detect and address any potential issues promptly.

- Lubrication and Cleaning: Implementing proper lubrication schedules and cleaning procedures to prevent corrosion, maintain smooth operation, and extend the crane's service life.

- Component Replacement: Ensuring timely replacement of worn-out or damaged parts, following manufacturer recommendations and industry standards to uphold crane performance.

Safety Guidelines: Ensuring Safe Operations

- Operator Training and Certification: Mandating thorough operator training programs and certifications to ensure that individuals operating the crane are well-versed in safety protocols, crane functionalities, and emergency procedures.

- Safety Features Adherence: Emphasizing adherence to safety features such as limit switches, overload protection, emergency stop buttons, and ensuring they are functional and in compliance with safety standards.

- Compliance with Regulations: Staying updated with industry regulations, standards, and certifications to ensure adherence to safety protocols and legal requirements.

By diligently following maintenance protocols and strictly adhering to safety guidelines, operators and organizations can ensure the safe and efficient operation of adjustable gantry cranes, mitigating risks and promoting a secure working environment.

Get Your Custom Adjustable Crane, Our Commitment to Excellence

As we draw the curtains on our comprehensive guide to adjustable gantry cranes, we reiterate our commitment to delivering excellence in material handling solutions. Our dedication extends to empowering users with knowledge and support to make informed decisions aligned with their unique operational needs.

Encouragement & Guidance: Empowering Informed Decisions

- Tailored Solutions: Encouraging users to evaluate their lifting requirements and operational environments to make well-informed decisions when selecting adjustable gantry cranes that perfectly suit their specific needs.

- Empowering Decision-Making: Providing comprehensive insights and guidance offered in this guide, empowering users to navigate through various options and factors to ensure optimal crane selection and utilization.

Manufacturer's Pledge: Assurance of Quality and Support

- Quality Commitment: Reaffirming our commitment to producing high-quality adjustable gantry cranes, engineered for durability, reliability, and efficiency in diverse industrial applications.

- Continuous Support: Assuring unwavering support, including comprehensive after-sales service, maintenance assistance, and a commitment to delivering unmatched material handling solutions.

As a manufacturer and supplier deeply invested in delivering exceptional material handling equipment, we stand by our promise to provide reliable, innovative, and top-notch adjustable gantry cranes. We believe that through our commitment to excellence, we not only contribute to enhancing operational efficiency but also ensure a safe and secure working environment for all users.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch